Nps - NPSM - NPSC Taps

Diunggah oleh

Carlos Murguia PerezDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Nps - NPSM - NPSC Taps

Diunggah oleh

Carlos Murguia PerezHak Cipta:

Format Tersedia

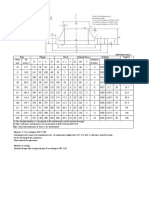

Taps: Straight Pipe Taps

TABLE 335-STRAIGHT PIPE TAPS

Ground Threads

American National Standard Straight Pipe Thread Form

(NPS) (NPSC) (NPSM)

THREAD LIMITS

Major Diameter

Nominal Threads

Plug

at Min.

Per

Sizes

Max.

Inch Gaging

Inches

H

G

Notch

1/8

1/4

3/8

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

3

3 1/2

4

27

18

18

14

14

11-1/2

11-1/2

11-1/2

11-1/2

8

8

8

8

0.3983

0.5286

0.6640

0.8260

1.0364

1.2966

1.6413

1.8803

2.3542

2.8454

3.4718

3.9721

4.4704

0.4022

0.5347

0.6701

0.8347

1.0447

1.3062

1.6507

1.8897

2.3639

2.8604

3.4868

3.9872

4.4855

0.4032

0.5357

0.6711

0.8357

1.0457

1.3077

1.6522

1.8912

2.3654

2.8619

3.4883

3.9887

4.4870

Pitch Diameter

Plug at

Gaging Min. Max.

K

L

Notch

E

0.3736 0.3746 0.3751

0.4916 0.4933 0.4938

0.6270 0.6287 0.6292

0.7784 0.7806 0.7811

0.9889 0.9906 0.9916

1.2386 1.2402 1.2412

1.5834 1.5847 1.5862

1.8223 1.8237 1.8252

2.2963 2.2979 2.2994

2.7622 2.7640 2.7660

3.3885 3.3904 3.3924

3.8888 3.8908 3.8928

4.3871 4.3891 4.3911

ANGLE TOLERANCE

Threads Per Inch

Deviation In Half Angle

8

11 1/2 to 27 Inclusive

25' plus or minus

30' plus or minus

FORMULA FOR AMERICAN NATIONAL

STANDARD PIPE FORM (NPS)

The maximum Pitch Diameter of tap is based upon an allowance

deducted from the maximum product pitch diameter of NPSC or

NPSM, whichever is smaller. The minimum Pitch Diameter of tap

is derived by subtracting the ground thread pitch diameter tolerance for actual equivalent size as shown in Table 331, A 107,

Col. D.

Minor Diameter

Major Diameter

Nominal

Sizes

Inches

1/8

1/4 to 3/4 incl.

1 to 4 incl.

Max.

H

K + A -- 0.0010

K + A -- 0.0020

K + A -- 0.0021

Min.

G

H -- 0.0010

H -- 0.0010

H -- 0.0015

Max.

M -- B

M -- B

M -- B

Note: Taps made to these specifications are marked NPS and used

for NPS, NPSC and NPSM.

TABLE 335-A-STRAIGHT PIPE TAPS

Ground Thread

American National Standard Straight Dryseal

Pipe Thread Form (NPSF)

1/16

1/8

1/4

3/8

1/2

3/4

1

27

27

18

18

14

14

11-1/2

Major Diameter

Plug at

Min.

Max. Gaging

Notch

G

H

E

0.3008 0.3018 0.2812

0.3932 0.3942 0.3736

0.5239 0.5249 0.4916

0.6593 0.6603 0.6270

0.8230 0.8240 0.7784

1.0335 1.0345 0.9889

1.2933 1.2943 1.2386

27

18

14

11 1/2

8

0.0296

0.0444

0.0571

0.0696

0.1000

0.0257

0.0401

0.0525

0.0647

0.0946

Actual

measured

pitch

diameter

FORMULA FOR AMERICAN NATIONAL

STANDARD DRYSEAL PIPE FORM (NPSF)

Major Diameter

THREAD LIMITS

Nominal Threads

Per

Sizes

Inch

Inches

NPSF

Threads

Per Inch

Pitch Diameter

Minor*

Min.

Max. Diam.

Flat

K

L

Max.

0.2772 0.2777 0.004

0.3696 0.3701 0.004

0.4859 0.4864 0.005

0.6213 0.6218 0.005

0.7712 0.7717 0.005

0.9817 0.9822 0.005

1.2295 1.2305 0.006

*As specified or sharper.

NOTE:The major diameter of standard taper pipe plug gages and the minor diameter

of standard taper pipe ring gages used for gaging dryseal threads will be truncated

.20p minimum to .25p maximum for all pitches.

Tap Technical

FORMULA VALUES

LEAD TOLERANCE

A maximum lead deviation of plus or minus .0005" within any two

threads not farther apart than one inch is permitted.

Pitch Diameter

Nominal

Sizes

Inches

Min.

G

Max.

H

Min.

K

Max.

L

Max.

Minor

Diam.

1/6

1/8

1/4

3/8

1/2

3/4

1

H -- 0.0010

H -- 0.0010

H -- 0.0010

H -- 0.0010

H -- 0.0010

H -- 0.0010

H -- 0.0010

K + Q -- 0.0005

K + Q -- 0.0005

K + Q -- 0.0005

K + Q -- 0.0005

K + Q -- 0.0005

K + Q -- 0.0005

K + Q -- 0.0001

L -- 0.0005

L -- 0.0005

L -- 0.0005

L -- 0.0005

L -- 0.0005

L -- 0.0005

L -- 0.0010

E -- F

E -- F

E -- F

E -- F

E -- F

E -- F

E -- F

M -- Q

M -- Q

M -- Q

M -- Q

M -- Q

M -- Q

M -- Q

FORMULA VALUES

Threads

Per Inch

27

18

14

11 1/2

Pitch diameter

of plug

at gaging

notch

0.0035

0.0052

0.0067

0.0081

Actual

measured

pitch

diameter

0.0251

0.0395

0.0533

0.0649

ANGLE TOLERANCE

Threads Per Inch

11 1/2 to 27 inclusive

Deviation in Half Angles

30' plus or minus

WWW.OSGTOOL.COM

LEAD TOLERANCE

A maximum lead deviation of plus or minus .0005" within any

two threads not farther apart than one inch is permitted.

800.837.2223

303

Anda mungkin juga menyukai

- Inch Series Dowel Pins: Mechanical PropertiesDokumen2 halamanInch Series Dowel Pins: Mechanical PropertieswilliaqBelum ada peringkat

- NPT 2Dokumen3 halamanNPT 2Mario Barbarić100% (1)

- Quick Knurling CatalogueDokumen28 halamanQuick Knurling CatalogueMilos Lazovic100% (1)

- SKF Lock Nuts PDFDokumen22 halamanSKF Lock Nuts PDFgrupa2904Belum ada peringkat

- JIS B.0203.e.1982Dokumen14 halamanJIS B.0203.e.1982Angel Alvarez CarrilloBelum ada peringkat

- DinDokumen1 halamanDinMelissa SmithBelum ada peringkat

- Trapezoidal ISO ThreadsDokumen4 halamanTrapezoidal ISO Threadsnicholas_j_vaughanBelum ada peringkat

- Dowel Pin Tolerances PDFDokumen4 halamanDowel Pin Tolerances PDFHenrique Marques100% (1)

- DIN 936 DIV 5655: Hexagon Thin Nuts Hexagon Nuts, (H D)Dokumen3 halamanDIN 936 DIV 5655: Hexagon Thin Nuts Hexagon Nuts, (H D)linijatzBelum ada peringkat

- Precision Dowel Pins - 303, 416, Alloy SteelDokumen5 halamanPrecision Dowel Pins - 303, 416, Alloy Steelnikhilpathak16674Belum ada peringkat

- Tesi Poligono P3GDokumen172 halamanTesi Poligono P3Ger_sor_magaraBelum ada peringkat

- DIN&ISO GB标准紧固件号对照表Dokumen32 halamanDIN&ISO GB标准紧固件号对照表Wei YaoBelum ada peringkat

- Shaktiman Tech. Tools (India) - Patiala Data SheetDokumen1 halamanShaktiman Tech. Tools (India) - Patiala Data Sheetਗਗਨ ਜੋਤBelum ada peringkat

- Section Q: Splined Hubs, Drive KitsDokumen8 halamanSection Q: Splined Hubs, Drive KitshaggBelum ada peringkat

- Code Wizard Workshop NotesDokumen29 halamanCode Wizard Workshop NotesRenato SimõesBelum ada peringkat

- DIN 915 EN-1980 Hexagon Socket Set Screws With Dog PointDokumen4 halamanDIN 915 EN-1980 Hexagon Socket Set Screws With Dog Pointthachpn100% (1)

- NPTF / PTF Threads: Total Solution For Thread GaugingDokumen3 halamanNPTF / PTF Threads: Total Solution For Thread GaugingFatih YükselBelum ada peringkat

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesDokumen5 halamanNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliBelum ada peringkat

- Federal Screw Thread Standards for Pipes, Gas Cylinders and HosesDokumen126 halamanFederal Screw Thread Standards for Pipes, Gas Cylinders and HosesMisaelBelum ada peringkat

- ISO 228 - Pipe Threads Where Pressure-Tight Joints Are Not Made On The ThreadsDokumen4 halamanISO 228 - Pipe Threads Where Pressure-Tight Joints Are Not Made On The ThreadsjesusBelum ada peringkat

- 05 Dial GaugesDokumen103 halaman05 Dial GaugesZélia OrnelasBelum ada peringkat

- UNC, UNF, & UNEF Thread ANSI B1,1 PDFDokumen4 halamanUNC, UNF, & UNEF Thread ANSI B1,1 PDFGILBERTO YOSHIDA100% (1)

- HeliCoil Insert Specs ImperialDokumen1 halamanHeliCoil Insert Specs ImperialAce Industrial SuppliesBelum ada peringkat

- ISO 262 1998 Diameter and PitchDokumen1 halamanISO 262 1998 Diameter and PitchturboprofanBelum ada peringkat

- BZ 8002953Dokumen15 halamanBZ 8002953uuur35Belum ada peringkat

- National Pipe Thread Chart PDFDokumen1 halamanNational Pipe Thread Chart PDFLiu YangtzeBelum ada peringkat

- Gage Calibration IDokumen2 halamanGage Calibration Imanha3Belum ada peringkat

- 15.2 Thread StandardsDokumen3 halaman15.2 Thread Standardssathish69Belum ada peringkat

- Tolerance of Position (TOP) - 1Dokumen34 halamanTolerance of Position (TOP) - 1maddy_scribdBelum ada peringkat

- Thread Standard BSPDokumen7 halamanThread Standard BSPĐạt TrầnBelum ada peringkat

- Parallel Pin Din 6325-2.5X12 PDFDokumen1 halamanParallel Pin Din 6325-2.5X12 PDFFer VFBelum ada peringkat

- Metric Insert Catalog SectionDokumen4 halamanMetric Insert Catalog SectionvaseaBelum ada peringkat

- Fittings Din11852 Din11850Dokumen14 halamanFittings Din11852 Din11850dingobk1Belum ada peringkat

- Parallel Key Calculation According To DIN 6892Dokumen21 halamanParallel Key Calculation According To DIN 6892zahirshah1436923Belum ada peringkat

- Din Flange Din 2627: (Dimensions in MM.)Dokumen12 halamanDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönBelum ada peringkat

- List of DIN Standards - 2006-04-20 PDFDokumen4 halamanList of DIN Standards - 2006-04-20 PDFSerggie TabanaoBelum ada peringkat

- Reference Standards PDFDokumen3 halamanReference Standards PDFAsghar AliBelum ada peringkat

- 20 INV SPL. 2.50 MOD 20 PA 22F01113 HB IND. 55x50x MM (PART - ModelDokumen1 halaman20 INV SPL. 2.50 MOD 20 PA 22F01113 HB IND. 55x50x MM (PART - Modelhb IndustriesBelum ada peringkat

- H28 2aDokumen49 halamanH28 2ajwsiglerBelum ada peringkat

- DOZNA - 6000 KN - DIN-6319 PDFDokumen4 halamanDOZNA - 6000 KN - DIN-6319 PDFzoranmiskovicBelum ada peringkat

- AMADA Katalog 2011 PDFDokumen93 halamanAMADA Katalog 2011 PDFdejavu_45Belum ada peringkat

- Lapmaster Catalogue1Dokumen20 halamanLapmaster Catalogue1Hicham HrslBelum ada peringkat

- BS ISO 1832-2017 - (Indexable Inserts For Cutting Tools)Dokumen34 halamanBS ISO 1832-2017 - (Indexable Inserts For Cutting Tools)HuiFrankyBelum ada peringkat

- Pressure Tight Thread Joints ISO 7Dokumen3 halamanPressure Tight Thread Joints ISO 7Adrian BurlacuBelum ada peringkat

- M4 Carbine SpecificationDokumen56 halamanM4 Carbine SpecificationGary WilliamsBelum ada peringkat

- Unf ThreadDokumen1 halamanUnf Threadhisaj4uBelum ada peringkat

- Profi Le Rings WR-15 Acc. DIN 3869Dokumen4 halamanProfi Le Rings WR-15 Acc. DIN 3869Jose Luis Ortiz PerdomoBelum ada peringkat

- HeliCoil NPT Inserts 8UN 2Dokumen2 halamanHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesBelum ada peringkat

- HeliCoil NPT Inserts 8UNDokumen4 halamanHeliCoil NPT Inserts 8UNAce Industrial SuppliesBelum ada peringkat

- SmtdataDokumen8 halamanSmtdataDaftDeveloperBelum ada peringkat

- ROSCASDokumen3 halamanROSCASDilucom EspeciasBelum ada peringkat

- Copper Tube For HVACR ApplicationsDokumen4 halamanCopper Tube For HVACR ApplicationskabeerdossBelum ada peringkat

- NPT Thread Specifications for PipesDokumen1 halamanNPT Thread Specifications for PipesAan Sarkasi Amd100% (1)

- Pipe Chart Excel WorksheetDokumen33 halamanPipe Chart Excel WorksheetValiaveetil Thomas JoselineBelum ada peringkat

- BS 1387/1985 Standard for Black and Galvanized Steel TubesDokumen2 halamanBS 1387/1985 Standard for Black and Galvanized Steel TubesmullanjiBelum ada peringkat

- SRTDokumen3 halamanSRTDaniel SamokovliaBelum ada peringkat

- NPT (Asme B1.20.1)Dokumen5 halamanNPT (Asme B1.20.1)Afronie Cepoz D'nextBelum ada peringkat

- Bolting Information Pertaining To ASTM A193Dokumen25 halamanBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- PIPE THREAD DimensionDokumen2 halamanPIPE THREAD DimensionAriel AnascoBelum ada peringkat

- Pipe PDFDokumen6 halamanPipe PDFnguyendan81985Belum ada peringkat

- Broca Helice Alta PDFDokumen2 halamanBroca Helice Alta PDFCarlos Murguia PerezBelum ada peringkat

- VMV 30Dokumen2 halamanVMV 30Carlos Murguia PerezBelum ada peringkat

- Nps - NPSM - NPSC TapsDokumen1 halamanNps - NPSM - NPSC TapsCarlos Murguia PerezBelum ada peringkat

- MachueleadorasDokumen1 halamanMachueleadorasCarlos Murguia PerezBelum ada peringkat

- AdvED Project Introduction WS2023-24Dokumen12 halamanAdvED Project Introduction WS2023-24Tanishk AgarwalBelum ada peringkat

- N.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposesDokumen2 halamanN.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposessunilmoryaBelum ada peringkat

- Repair Procedure For Damaged Harness Wiring (1408) : Special InstructionDokumen19 halamanRepair Procedure For Damaged Harness Wiring (1408) : Special InstructionOscar Rafael Melendez AbantoBelum ada peringkat

- UNIT 4 Power ScrewsDokumen4 halamanUNIT 4 Power Screwsrahul dBelum ada peringkat

- Giesse - Motoare Electrice - Tabel UtilizariDokumen1 halamanGiesse - Motoare Electrice - Tabel UtilizariDima MarianaBelum ada peringkat

- NGM 251-301 - 01-07Dokumen49 halamanNGM 251-301 - 01-07Jaroslav IvanBelum ada peringkat

- Steel Tubes Bs 1387 en 10255pdfDokumen6 halamanSteel Tubes Bs 1387 en 10255pdfMuhammad Mahbub HussainBelum ada peringkat

- H13 Vortex Datasheet 0822Dokumen4 halamanH13 Vortex Datasheet 0822Harshit RajBelum ada peringkat

- AWWA Manual M11, Steel Pipe-A Guide For Design and InstallationDokumen3 halamanAWWA Manual M11, Steel Pipe-A Guide For Design and InstallationFrancis DhanarajBelum ada peringkat

- Electric Screw Driver M 54-2823 English Rev 1.5Dokumen17 halamanElectric Screw Driver M 54-2823 English Rev 1.5Dina NadeemBelum ada peringkat

- Mechanical Engineering Minor Project Report On Staircase Climber MAE IPUDokumen26 halamanMechanical Engineering Minor Project Report On Staircase Climber MAE IPUAakash SachdevaBelum ada peringkat

- Cable Track Sizing Final Sheet 15.07.23Dokumen6 halamanCable Track Sizing Final Sheet 15.07.23iqbal husseinBelum ada peringkat

- Eco/Regul options for shredders and hydraulic feeder controlsDokumen2 halamanEco/Regul options for shredders and hydraulic feeder controlsMINH Phạm Mai NhậtBelum ada peringkat

- AngleSettingJig 2Dokumen5 halamanAngleSettingJig 2mikkelBelum ada peringkat

- HAZOP WorksheetDokumen5 halamanHAZOP WorksheetchristyleneBelum ada peringkat

- Data Consolidation Patimban SDDokumen24 halamanData Consolidation Patimban SDUtari Tri NoviatiBelum ada peringkat

- Horizontal Honing Tools, होनिंग उपकरण in Vasai East, Vasai, Manisha Machinery Private Limited - ID - 2035935873Dokumen8 halamanHorizontal Honing Tools, होनिंग उपकरण in Vasai East, Vasai, Manisha Machinery Private Limited - ID - 2035935873TuntunBelum ada peringkat

- Disclosure To Promote The Right To InformationDokumen11 halamanDisclosure To Promote The Right To InformationSriram SubramanianBelum ada peringkat

- Construction brickwork notes for column reinforcementDokumen1 halamanConstruction brickwork notes for column reinforcementswapnil bokadeBelum ada peringkat

- Rewinder STD Extra5 GB01Dokumen126 halamanRewinder STD Extra5 GB01ruboBelum ada peringkat

- Machining Time and Power EstimationDokumen50 halamanMachining Time and Power EstimationGnanakumar GanesanBelum ada peringkat

- Building Drawing Sangita SahuDokumen15 halamanBuilding Drawing Sangita SahuKavya Engineering ConsultancyBelum ada peringkat

- TBM vs D&B MethodsDokumen30 halamanTBM vs D&B MethodsAbhinav Singh ChauhanBelum ada peringkat

- OneSystem Price List 2022Dokumen52 halamanOneSystem Price List 2022caipaBelum ada peringkat

- Balfour Beatty CLDokumen1 halamanBalfour Beatty CLAidan BrittonBelum ada peringkat

- Electrical Bus System Layout GuideDokumen8 halamanElectrical Bus System Layout GuideRajeshRaman100% (1)

- MS 300 Belt Selection FactorsDokumen22 halamanMS 300 Belt Selection FactorsaldoarthoBelum ada peringkat

- AFPADokumen8 halamanAFPAFrancisco Javier Villegas AndersonBelum ada peringkat

- Lecture 47 - Laterally Supported BeamsDokumen11 halamanLecture 47 - Laterally Supported BeamsSudarshan BaroleBelum ada peringkat

- BOP - Type A and T PDFDokumen13 halamanBOP - Type A and T PDFjulioramcaBelum ada peringkat