Hilti HIT-HY 150 MAX anchor system

Diunggah oleh

Mihnea-Bogdan NicolaescuDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hilti HIT-HY 150 MAX anchor system

Diunggah oleh

Mihnea-Bogdan NicolaescuHak Cipta:

Format Tersedia

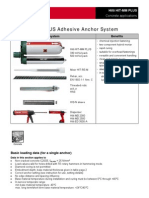

Hilti HIT-HY 150 MAX with HIT-TZ

Hilti HIT-HY 150 MAX with HIT-TZ

Injection mortar system

Hilti HITHY 150 MAX 330 ml foil pack (also available as 500 ml and 1400 ml foil pack)

Benefits

- suitable for cracked and noncracked concrete C 20/25 to C 50/60 - hammer drilled and diamond cored bore holes - high loading capacity - suitable for dry and water saturated concrete - under water application - No cleaning required

Statik mixer HIT-TZ HIT-RTZ rod

Concrete

Tensile zone

Corrosion resistance

European Technical Approval

CE conformity

Hilti anchor design software

Approvals / certificates

Description European technical approval

a)

Authority / Laboratory DIBt, Berlin

No. / date of issue ETA-04/0084 / 2009-12-09

a) All data given in this section according ETA-04/0084, issue 2009-12-09.

Basic loading data (for a single anchor)

All data in this section applies to For details see Simplified design method - Correct setting (See setting instruction) - No edge distance and spacing influence - Steel failure - Base material thickness, as specified in the table - Embedment depth, as specified in the table - One anchor material, as specified in the tables - Concrete C 20/25, fck,cube = 25 N/mm - Temperate range I (min. base material temperature -40C, max. long term/short term base material temperature: +50C/80C) - Installation temperature range +5C to +40C

488

6 / 2010

Hilti HIT-HY 150 MAX with HIT-TZ

Embedment depth and base material thickness for the basic loading data.

Mean ultimate resistance, characteristic resistance, design resistance, recommended loads. Anchor size M8 M10 M12 M16 55 65 75 90 Embedment depth [mm] Base material thickness [mm] 110 130 150 180 M20 120 240

Mean ultimate resistance a): concrete C 20/25 fck,cube = 25 N/mm, anchor HIT-TZ

Anchor size Non-cracked concrete Tensile NRu,m HIT-TZ Shear VRu,m HIT-TZ Cracked concrete Tensile NRu,m HIT-TZ Shear VRu,m HIT-TZ M8 [kN] [kN] [kN] [kN] 21,3 11,6 12,0 12,0 M10 26,7 17,9 21,3 17,9 M12 33,3 26,3 26,7 26,3 M16 57,5 49,4 40,0 49,4 M20 88,5 77,7 53,3 77,7

Characteristic resistance: concrete C 20/25 fck,cube = 25 N/mm, anchor HIT-TZ

Anchor size Non-cracked concrete Tensile NRk HIT-TZ Shear VRk HIT-TZ Cracked concrete Tensile NRk HIT-TZ Shear VRk HIT-TZ M8 [kN] [kN] [kN] [kN] 16,0 11,0 9,0 9,0 M10 20,0 17,0 16,0 17,0 M12 25,0 25,0 20,0 25,0 M16 43,1 47,0 30,0 47,0 M20 66,4 74,0 40,0 74,0

Design resistance: concrete C 20/25 fck,cube = 25 N/mm, anchor HIT-TZ

Anchor size Non-cracked concrete Tensile NRd HIT-TZ Shear VRd HIT-TZ Cracked concrete Tensile NRd HIT-TZ Shear VRd HIT-TZ M8 [kN] [kN] [kN] [kN] 10,7 8,8 6,0 6,0 M10 13,3 13,6 10,7 13,6 M12 16,7 20,0 13,3 20,0 M16 28,7 37,6 20,0 37,6 M20 44,3 59,2 26,7 53,3

Recommended loads a): concrete C 20/25 fck,cube = 25 N/mm, anchor HIT-TZ

Anchor size Non-cracked concrete Tensile Nrec HIT-TZ Shear Vrec HIT-TZ Cracked concrete Tensile Nrec HIT-TZ Shear Vrec HIT-TZ M8 [kN] [kN] [kN] [kN] 7,6 6,3 4,3 4,3 M10 9,5 9,7 7,6 9,7 M12 11,9 14,3 9,5 14,3 M16 20,5 26,9 14,3 26,9 M20 31,6 42,3 19,0 38,1

a) With overall partial safety factor for action = 1,4. The partial safety factors for action depend on the type of loading and shall be taken from national regulations. According ETAG 001, annex C, the partial safety factor is G = 1,35 for permanent actions and Q = 1,5 for variable actions.

6 / 2010

489

Hilti HIT-HY 150 MAX with HIT-TZ

Service temperature range

Hilti HIT-HY 150 MAX injection mortar with anchor rod HIT-TZ may be applied in the temperature ranges given below. An elevated base material temperature may lead to a reduction of the design bond resistance. Base material temperature -40 C to +80 C Maximum long term base material temperature +50 C Maximum short term base material temperature +80 C

Temperature range Temperature range I

Max short term base material temperature Short-term elevated base material temperatures are those that occur over brief intervals, e.g. as a result of diurnal cycling. Max long term base material temperature Long-term elevated base material temperatures are roughly constant over significant periods of time.

Materials

Mechanical properties of HIT-(R)TZ

Anchor size Nominal tensile strength f uk Yield strength fyk M8 HIT-TZ HIT-RTZ HIT-TZ HIT-RTZ [N/mm] [N/mm] [N/mm] [N/mm] [mm] [mm] 600 600 480 480 36,6 31,9 M10 600 600 480 480 58,0 62,5 M12 600 600 480 480 84,3 109,7 M16 600 600 480 480 157 278 M20 600 600 480 480 245 542

Stressed crossHIT-TZ section As Moment of HIT-TZ resistance W

Material quality

Part HIT-TZ HIT-RTZ Material C-steel cold formed steel galvanized 5m EN ISO 4042 stainless steel cold formed 1.4404 and 1.4401 EN 10088

Anchor dimensions

Anchor size HIT-(R)TZ Anchor embedment depth M8 M8x55 55 M10 M10x65 65 M12 M12x75 75 M16 M16x90 90 M20 M20x120 120

[mm]

Setting

installation equipment

Anchor size Rotary hammer M8 M10 M12 TE 2 TE 16 M16 M20 TE 40 - TE 70

490

6 / 2010

Hilti HIT-HY 150 MAX with HIT-TZ

Setting instruction Dry, water-saturated concrete, under water, hammer drilling and diamond coring

1. Diamond coring is permissible only when the Hilti DD EC-1 diamond core drilling machine and the corresponding DD-C core bit are used. 2. Check the setting depth and compress the drilling dust. It is not necessary to clean the hole. 3. For use with Hilti HIT-HY 150 / Hilti HIT-HY 150 MAX. Read the instructions before use. For detailed information on installation see instruction for use given with the package of the product.

Curing time for general conditions

Temperature of the base material 30 C to 40 C 20 C to <30 C 5 C to <20 C Curing time before anchor can be fully loaded tcure 30 min 30 min 60 min

6 / 2010

491

Hilti HIT-HY 150 MAX with HIT-TZ

Setting details

Anchor size Nominal diameter of drill bit Diameter of element Effective anchorage depth Drill hole depth Minimum base material thickness Diameter of clearance hole in the fixture Non cracked concrete Minimum spacing for Minimum edge distance for Cracked concrete Minimum spacing for Minimum edge distance for Critical spacing for splitting failure Critical edge distance for splitting failure Critical spacing for concrete cone failure Critical edge distance for concrete cone failure Torque moment M8 d0 d hef h0 hmin a) df smin c cmin s smin c cmin s scr,sp ccr,sp scr,N ccr,N Tinst [Nm] 12 23 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] 10 8 55 60 110 9 40 50 40 70 40 65 50 80 M10 12 10 65 70 130 12 50 70 50 80 60 85 60 120 M12 14 12 75 80 150 14 55 75 55 85 70 100 70 130 2 ccr,sp 2 hef 2 ccr,N 1,5 hef 40 70 130 M16 18 16 90 95 180 18 70 80 70 85 80 100 80 140 M20 22 20 120 125 240 22 80 90 80 90 100 120 100 150

For spacing (edge distance) smaller than critical spacing (critical edge distance) the design loads have to be reduced. a) h: base material thickness (h hmin)

492

6 / 2010

Hilti HIT-HY 150 MAX with HIT-TZ

Simplified design method

Simplified version of the design method according ETAG 001, Annex C. Design resistance according data given in ETA-04/0084, issue 2009-12-09. Influence of concrete strength Influence of edge distance Influence of spacing Valid for a group of two anchors. (The method may also be applied for anchor groups with more than two anchors or more than one edge distance. The influencing factors must then be considered for each edge distance and spacing. The calculated design loads are then on the save side: They will be lower than the exact values according ETAG 001, Annex C. To avoid this, it is recommended to use the anchor design software PROFIS anchor) The design method is based on the following simplification: No different loads are acting on individual anchors (no eccentricity) The values are valid for one anchor.

For more complex fastening applications please use the anchor design software PROFIS Anchor.

Tension loading

The design tensile resistance is the lower value of

- Steel resistance: NRd,s - Combined pull-out and concrete cone resistance: NRd,p = N0Rd,p fB,p fh,p - Concrete cone resistance:

-

NRd,c = N0Rd,c fB f1,N f2,N f3,N fh,N fre,N

Concrete splitting resistance (only non-cracked concrete): NRd,sp = N0Rd,c fB f1,sp f2,sp f3,sp f h,sp fre,N

Basic design tensile resistance Design steel resistance NRd,s

Anchor size NRd,s HIT-TZ [kN] M8 14,7 M10 23,3 M12 34,0 M16 62,7 M20 98,0

Design combined pull-out and concrete cone resistance NRd,p = N0Rd,p fB,p fh,p

Anchor size Embedment depth hef [mm] Non-cracked concrete 0 N Rd,p Temperature range I Cracked concrete 0 N Rd,p Temperature range I M8 55 [kN] [kN] 10,7 6,0 M10 65 13,3 10,7 M12 75 16,7 13,3 M16 90 28,7 20,0 M20 120 44,3 26,7

6 / 2010

493

Hilti HIT-HY 150 MAX with HIT-TZ

Design concrete cone resistance a) NRd,c = N0Rd,c fB f1,N f2,N f3,N fh,N fre,N Design splitting resistance NRd,sp = N0Rd,c fB f h,N f1,sp f2,sp f3,sp fre,N

Anchor size N0Rd,c Non cracked concrete [kN] N0Rd,c Cracked concrete [kN] M8 13,7 9,8 M10 17,6 12,6 M12 21,9 15,6 M16 28,7 20,5 M20 44,3 31,5

Influencing factors Influence of concrete strength on combined pull-out and concrete cone resistance

Concrete strength designation (ENV 206)

0.1 a)

C 20/25

C 25/30

C 30/37

C 35/45

C 40/50

C 45/55 1,08

C 50/60 1,09

f B,p = (f ck,cube/25N/mm) 1 1,02 1,04 1,06 1,07 a) fck,cube = concrete compressive strength, measured on cubes with 150 mm side length

Influence of embedment depth on combined pull-out and concrete cone resistance fh,p = hef/hef,typ Influence of concrete strength on concrete cone resistance

Concrete strength designation (ENV 206) C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 1,48 C 50/60 1,55

fB = (f ck,cube/25N/mm)1/2 a) 1 1,1 1,22 1,34 1,41 a) fck,cube = concrete compressive strength, measured on cubes with 150 mm side length

Influence of edge distance a)

c/ccr,N c/ccr,sp f 1,N = 0,7 + 0,3c/ccr,N f 1,sp = 0,7 + 0,3c/ccr,sp f 2,N = 0,5(1 + c/ccr,N) 0,1 0,73 0,2 0,76 0,3 0,79 0,4 0,82 0,5 0,85 0,6 0,88 0,7 0,91 0,8 0,94 0,9 0,97 1 1

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1 f 2,sp = 0,5(1 + c/ccr,sp) a) The the edge distance shall not be smaller than the minimum edge distance cmin given in the table with the setting details. These influencing factors must be considered for every edge distance smaller than the critical edge distance.

Influence of anchor spacing a)

s/scr,N s/scr,sp f 3,N = 0,5(1 + s/scr,N) 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1 f 3,sp = 0,5(1 + s/scr,sp) a) The anchor spacing shall not be smaller than the minimum anchor spacing smin given in the table with the setting details. This influencing factor must be considered for every anchor spacing.

Influence of embedment depth on concrete cone resistance fh,N = (hef/hef,typ)1,5

494

6 / 2010

Hilti HIT-HY 150 MAX with HIT-TZ

Influence of reinforcement

80 90 100 a) a) 0,9 0,95 1 f re,N = 0,5 + hef/200mm 1 a) This factor applies only for dense reinforcement. If in the area of anchorage there is reinforcement with a spacing 150 mm (any diameter) or with a diameter 10 mm and a spacing 100 mm, then a factor f re = 1 may be applied. hef [mm]

Shear loading

The design shear resistance is the lower value of

- Steel resistance:

-

VRd,s VRd,cp = k lower value of NRd,p and NRd,c VRd,c = V

0 Rd,c

Concrete pryout resistance:

- Concrete edge resistance:

fB f f h f4

Basic design shear resistance Design steel resistance VRd,s

Anchor size VRd,s HIT-(R)TZ [kN] M8 8,8 M10 13,6 M12 20,0 M16 37,6 M20 59,2

Design concrete pryout resistance VRd,cp = lower valuea) of k NRd,p and k NRd,c k = 1 for hef < 60 mm k = 2 for hef 60 mm

a) NRd,p: Design combined pull-out and concrete cone resistance NRd,c: Design concrete cone resistance

Design concrete edge resistance a) VRd,c = V0Rd,c fB f f h f4 Non-cracked concrete

Anchor size

0 V Rd,c

Cracked concrete

M8 M10 2,4 M12 3,1 M16 5,0 M20 6,9

M8

M10

M12

M16

M20

3,1 4,5 6,1 8,5 13,4 1,6 [kN] a) For anchor groups only the anchors close to the edge must be considered.

Influencing factors Influence of concrete strength

Concrete strength designation (ENV 206)

1/2 a)

C 20/25

C 25/30

C 30/37

C 35/45

C 40/50

C 45/55 1,48

C 50/60 1,55

fB = (f ck,cube/25N/mm) 1 1,1 1,22 1,34 1,41 a) fck,cube = concrete compressive strength, measured on cubes with 150 mm side length

6 / 2010

495

Hilti HIT-HY 150 MAX with HIT-TZ

Influence of angle between load applied and the direction perpendicular to the free edge

Angle 0 - 55 60 65 70 75 80 85 90 - 180

1,07

1,14

1,23

1,35

1,50

1,71

Influence of base material thickness

h/c fh = {h/(1,5 c)}

2/3

0,15 1 0,22

0,3 0,34

0,45 0,45

0,6 0,54

0,75 0,63

0,9 0,71

1,05 0,79

1,2 0,86

1,35 0,93

1,5 1,00

Influence of anchor spacing and edge distance a) for concrete edge resistance: f4 f4 = (c/hef)1,5 (1 + s / [3 c]) 0,5

Single anchor 0,75 1,50 2,25 0,50 0,35 0,27 0,35 0,35 0,75 0,65 0,43 0,54 0,65 1,00 1,00 0,63 0,75 0,88 1,25 1,40 0,84 0,98 1,12 1,50 1,84 1,07 1,22 1,38 1,75 2,32 1,32 1,49 1,65 2,00 2,83 1,59 1,77 1,94 2,25 3,38 1,88 2,06 2,25 2,50 3,95 2,17 2,37 2,57 2,75 4,56 2,49 2,69 2,90 3,00 5,20 2,81 3,03 3,25 3,25 5,86 3,15 3,38 3,61 3,50 6,55 3,51 3,74 3,98 3,75 7,26 3,87 4,12 4,36 4,00 8,00 4,25 4,50 4,75 4,25 8,76 4,64 4,90 5,15 4,50 9,55 5,04 5,30 5,57 4,75 10,35 5,45 5,72 5,99 5,00 11,18 5,87 6,15 6,43 5,25 12,03 6,30 6,59 6,87 5,50 12,90 6,74 7,04 7,33 a) The anchor spacing and the edge minimum edge distance cmin. c/hef Group of two anchors s/hef 3,00 3,75 4,50 5,25 6,00 6,75 7,50 8,25 9,00 9,75 10,50 11,25 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,26 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,53 1,68 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,82 1,98 2,15 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,12 2,30 2,47 2,65 2,83 2,83 2,83 2,83 2,83 2,83 2,83 2,83 2,44 2,63 2,81 3,00 3,19 3,38 3,38 3,38 3,38 3,38 3,38 3,38 2,77 2,96 3,16 3,36 3,56 3,76 3,95 3,95 3,95 3,95 3,95 3,95 3,11 3,32 3,52 3,73 3,94 4,15 4,35 4,56 4,56 4,56 4,56 4,56 3,46 3,68 3,90 4,11 4,33 4,55 4,76 4,98 5,20 5,20 5,20 5,20 3,83 4,06 4,28 4,51 4,73 4,96 5,18 5,41 5,63 5,86 5,86 5,86 4,21 4,44 4,68 4,91 5,14 5,38 5,61 5,85 6,08 6,31 6,55 6,55 4,60 4,84 5,08 5,33 5,57 5,81 6,05 6,29 6,54 6,78 7,02 7,26 5,00 5,25 5,50 5,75 6,00 6,25 6,50 6,75 7,00 7,25 7,50 7,75 5,41 5,67 5,93 6,18 6,44 6,70 6,96 7,22 7,47 7,73 7,99 8,25 5,83 6,10 6,36 6,63 6,89 7,16 7,42 7,69 7,95 8,22 8,49 8,75 6,27 6,54 6,81 7,08 7,36 7,63 7,90 8,17 8,45 8,72 8,99 9,26 6,71 6,99 7,27 7,55 7,83 8,11 8,39 8,66 8,94 9,22 9,50 9,78 7,16 7,45 7,73 8,02 8,31 8,59 8,88 9,17 9,45 9,74 10,02 10,31 7,62 7,92 8,21 8,50 8,79 9,09 9,38 9,67 9,97 10,26 10,55 10,85 distance shall not be smaller than the minimum anchor spacing smin and the

Combined tension and shear loading

For combined tension and shear loading see section Anchor Design.

496

6 / 2010

Hilti HIT-HY 150 MAX with HIT-TZ

Precalculated values

Design resistance: concrete C 20/25 fck,cube = 25 N/mm

Anchor size M8 Embedment depth hef = [mm] 55 Base material thickness hmin= [mm] 110 Tensile NRd: single anchor, no edge effects Non-cracked concrete HIT-(R)TZ [kN] 10,7 Cracked concrete HIT-(R)TZ [kN] 6,0 M10 65 130 M12 75 150 M16 90 180 M20 120 240

13,3 10,7

16,7 13,3

28,7 20,0

44,3 26,7

Shear VRd: single anchor, no edge effects, without lever arm Non-cracked concrete HIT-(R)TZ [kN] 8,8 13,6 20,0 Cracked concrete HIT-(R)TZ [kN] 6,0 13,6 20,0

37,6 37,6

59,2 53,3

Design resistance: concrete C 20/25 fck,cube = 25 N/mm

Anchor size M8 M10 Embedment depth hef = [mm] 55 65 Base material thickness hmin= [mm] 110 130 Tensile NRd: single anchor, min. edge distance (c = cmin) Non-cracked concrete cmin [mm] 50 60 HIT-(R)TZ Cracked concrete cmin HIT-(R)TZ [kN] [mm] [kN] 6,5 40 3,3 8,2 50 6,0 M12 75 150 M16 90 180 M20 120 240

70 10,3 55 7,4

80 17,3 70 11,3

100 25,9 80 14,2

Shear VRd: single anchor, min. edge distance (c = cmin) , without lever arm Non-cracked concrete cmin 50 60 70 80 [mm] HIT-(R)TZ Cracked concrete cmin HIT-(R)TZ [kN] [mm] [kN] 3,1 40 1,6 4,5 50 2,4 6,1 55 3,1 8,5 70 5,0

100 13,4 80 6,9

6 / 2010

497

Hilti HIT-HY 150 MAX with HIT-TZ

Design resistance: concrete C 20/25 fck,cube = 25 N/mm (load values are valid for single anchor)

Anchor size M8 M10 M12 Embedment depth hef = [mm] 55 65 75 Base material thickness hmin= [mm] 110 130 150 Tensile NRd: double anchor, no edge effects, min. spacing (s = smin) Non-cracked concrete smin [mm] 40 60 70 HIT-(R)TZ Cracked concrete smin HIT-(R)TZ [kN] [mm] [kN] 6,3 40 3,5 8,2 50 6,4 10,3 55 7,9 M16 90 180 M20 120 240

80 17,6 70 11,9

100 26,7 80 15,6

Shear VRd: double anchor, no edge effects, min. spacing (s = smin) , without lever arm Non-cracked concrete smin [mm] 40 60 70 80 HIT-(R)TZ Cracked concrete smin HIT-(R)TZ [kN] [mm] [kN] 6,6 40 3,7 13,6 50 13,4 20,0 55 16,6 37,3 70 25,2

100 56,5 80 32,6

Precalculated values

Recommended loads: concrete C 20/25 fck,cube = 25 N/mm

Anchor size M8 M10 Embedment depth hef = [mm] 55 65 Base material thickness hmin= [mm] 110 130 Tensile Nrec: single anchor, no edge effects Non-cracked concrete HIT-(R)TZ Cracked concrete HIT-(R)TZ [kN] [kN] 7,6 4,3 9,5 7,6 M12 75 150 M16 90 180 M20 120 240

11,9 9,5

20,5 14,3

31,6 19,0

Shear Vrec: single anchor, no edge effects, without lever arm Non-cracked concrete HIT-(R)TZ [kN] 6,3 9,7 14,3 Cracked concrete HIT-(R)TZ [kN] 4,3 9,7 14,3

26,9 26,9

42,3 38,1

For the recommended loads an overall partial safety factor for action = 1,4 is considered. The partial safety factors for action depend on the type of loading and shall be taken from national regulations. According ETAG 001, annex C, the partial safety factor is G = 1,35 for permanent actions and Q = 1,5 for variable actions.

498

6 / 2010

Hilti HIT-HY 150 MAX with HIT-TZ

Recommended loads: concrete C 20/25 fck,cube = 25 N/mm

Anchor size M8 M10 Embedment depth hef = [mm] 55 65 Base material thickness hmin= [mm] 110 130 Tensile Nrec: single anchor, min. edge distance (c = cmin) Non-cracked concrete cmin [mm] 50 60 HIT-(R)TZ Cracked concrete cmin HIT-(R)TZ [kN] [mm] [kN] 4,6 40 2,4 5,8 50 4,3 M12 75 150 M16 90 180 M20 120 240

70 7,3 55 5,3

80 12,4 70 8,1

100 18,5 80 10,2

Shear Vrec: single anchor, min. edge distance (c = cmin) , without lever arm Non-cracked concrete cmin [mm] 50 60 70 80 HIT-(R)TZ Cracked concrete cmin HIT-(R)TZ [kN] [mm] [kN] 2,2 40 1,1 3,2 50 1,7 4,4 55 2,2 6,1 70 3,5

100 9,6 80 4,9

Recommended loads: concrete C 20/25 fck,cube = 25 N/mm (load values are valid for single anchor)

Anchor size M8 M10 M12 Embedment depth hef = [mm] 55 65 75 Base material thickness hmin= [mm] 110 130 150 Tensile Nrec: double anchor, no edge effects, min. spacing (s = smin) Non-cracked concrete smin [mm] 40 60 70 HIT-(R)TZ Cracked concrete smin HIT-(R)TZ [kN] [mm] [kN] 4,5 40 2,5 5,9 50 4,5 7,3 55 5,6 M16 90 180 M20 120 240

80 12,5 70 8,5

100 19,1 80 11,1

Shear Vrec: double anchor, no edge effects, min. spacing (s = smin) , without lever arm Non-cracked concrete smin [mm] 40 60 70 80 HIT-(R)TZ Cracked concrete smin HIT-(R)TZ [kN] [mm] [kN] 4,7 40 2,7 9,7 50 9,6 14,3 55 11,9 26,6 70 18,0

100 40,4 80 23,3

For the recommended loads an overall partial safety factor for action = 1,4 is considered. The partial safety factors for action depend on the type of loading and shall be taken from national regulations. According ETAG 001, annex C, the partial safety factor is G = 1,35 for permanent actions and Q = 1,5 for variable actions.

6 / 2010

499

Anda mungkin juga menyukai

- Weld Like a Pro: Beginning to Advanced TechniquesDari EverandWeld Like a Pro: Beginning to Advanced TechniquesPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Bid ProcessDokumen85 halamanBid ProcessRobiatol Adawiah Mohammad ShamsidiBelum ada peringkat

- FIDIC Silver BookDokumen122 halamanFIDIC Silver BookJavier Contreras75% (4)

- Lorry AirBrakesDokumen3 halamanLorry AirBrakesEnache CristinaBelum ada peringkat

- Manual Rabbit enDokumen29 halamanManual Rabbit enMihnea-Bogdan NicolaescuBelum ada peringkat

- PROFIS Anchor 2.2.0: WWW - Hilti.deDokumen6 halamanPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguBelum ada peringkat

- Law As A Command of SovereignDokumen12 halamanLaw As A Command of SovereignAdv BL Dewasi100% (2)

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDokumen11 halamanHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00Belum ada peringkat

- HVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EDokumen5 halamanHVU Adhesive With HAS Rod: Basic Loading Data (For A Single Anchor) : HVU Capsule With HAS, HAS-EChristopher GarciaBelum ada peringkat

- Hilti Hit Re 500 With Hit V HasDokumen16 halamanHilti Hit Re 500 With Hit V HaslaurentiubnBelum ada peringkat

- Ventilation Plan For Confined Space EntryDokumen9 halamanVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Dokumen85 halamanTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanBelum ada peringkat

- S 45 SX / S 47 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDokumen6 halamanS 45 SX / S 47 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- S 45 SX / S 47 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDokumen6 halamanS 45 SX / S 47 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- Piccolo: Operating and Maintenance Instructions For The Deck OvenDokumen44 halamanPiccolo: Operating and Maintenance Instructions For The Deck OvenAdam B100% (1)

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Dokumen9 halamanTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioBelum ada peringkat

- HVZ adhesive anchor installation and design guideDokumen13 halamanHVZ adhesive anchor installation and design guideMihnea-Bogdan NicolaescuBelum ada peringkat

- 44 - HVZ Adhesive AnchorDokumen14 halaman44 - HVZ Adhesive AnchorHuan VoBelum ada peringkat

- Chumbador HiltDokumen14 halamanChumbador HiltSamanta FigueredoBelum ada peringkat

- Hilti - Calculo Manual de Re500Dokumen41 halamanHilti - Calculo Manual de Re500James ClaytonBelum ada peringkat

- Hilti HIT HY 150 MAX With RebarDokumen14 halamanHilti HIT HY 150 MAX With RebarNelly BuquironBelum ada peringkat

- Hilti Hit Hy 150 Max Con Barra CorrugadaDokumen20 halamanHilti Hit Hy 150 Max Con Barra Corrugadalandsv01Belum ada peringkat

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDokumen10 halamanHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruBelum ada peringkat

- Pipe Rack Hilti Bolt CalculationsDokumen6 halamanPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVBelum ada peringkat

- Hilti HST 1Dokumen11 halamanHilti HST 1Mihnea-Bogdan NicolaescuBelum ada peringkat

- Hilti Hit Hy 200 With Hit VDokumen18 halamanHilti Hit Hy 200 With Hit VRobinReyndersBelum ada peringkat

- Hy-200 FTM 2012-09Dokumen70 halamanHy-200 FTM 2012-09Inhinyero SibilBelum ada peringkat

- Base CHS X 10tDokumen7 halamanBase CHS X 10tCollin NguBelum ada peringkat

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Dokumen9 halaman2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuBelum ada peringkat

- Declaration of Performance for MTH AnchorsDokumen3 halamanDeclaration of Performance for MTH AnchorsFerencz ZsoltBelum ada peringkat

- Hilti HIT MM Plus 1Dokumen14 halamanHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuBelum ada peringkat

- Hilti HIT-HY 150 With Rebar PDFDokumen16 halamanHilti HIT-HY 150 With Rebar PDFMuzammil HawaBelum ada peringkat

- Hilti HIT-HY 150 With HIT-V or HAS PDFDokumen19 halamanHilti HIT-HY 150 With HIT-V or HAS PDFfkh3dBelum ada peringkat

- Anclaje Quimico HILTIDokumen84 halamanAnclaje Quimico HILTIWuceirBelum ada peringkat

- 1 Input Data: Profis Anchor 2.4.6Dokumen6 halaman1 Input Data: Profis Anchor 2.4.6Naresh KumarBelum ada peringkat

- WIT-PE 500 Design Manual RBDokumen24 halamanWIT-PE 500 Design Manual RBMadusha TisseraBelum ada peringkat

- 2011 HSC-I Safety AnchorDokumen3 halaman2011 HSC-I Safety AnchorDifa LiuBelum ada peringkat

- HSL-3 Heavy Duty AnchorDokumen12 halamanHSL-3 Heavy Duty AnchorMihnea-Bogdan NicolaescuBelum ada peringkat

- 2014 HKD Push-In Anchor - Single Anchor ApplicationDokumen3 halaman2014 HKD Push-In Anchor - Single Anchor ApplicationDifa LiuBelum ada peringkat

- 1 Input Data: WWW - Hilti.co - UkDokumen6 halaman1 Input Data: WWW - Hilti.co - UkihpeterBelum ada peringkat

- Hilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodDokumen16 halamanHilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodsandeepsharmafjBelum ada peringkat

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDokumen21 halamanHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisBelum ada peringkat

- 2013 87 - X-EnP Siding and Decking NailDokumen8 halaman2013 87 - X-EnP Siding and Decking NailDifa LiuBelum ada peringkat

- Montavimo Technika Armaturos StrypamsDokumen5 halamanMontavimo Technika Armaturos StrypamsHafidh BaequnieBelum ada peringkat

- Beam End Connection ReportDokumen6 halamanBeam End Connection ReportHibri HalimBelum ada peringkat

- Hilti CatalogueDokumen194 halamanHilti CatalogueFeleki AttilaBelum ada peringkat

- Hilti HDA 1Dokumen16 halamanHilti HDA 1Mihnea-Bogdan NicolaescuBelum ada peringkat

- Fischer FIS V Load TAblesDokumen1 halamanFischer FIS V Load TAblesikirby77Belum ada peringkat

- Dynabolt Zinc Coated Steel Design GuideDokumen4 halamanDynabolt Zinc Coated Steel Design GuideMuhammad SarajevoBelum ada peringkat

- Hilti Hit-Hy 200 With Hit-V RodDokumen20 halamanHilti Hit-Hy 200 With Hit-V RodFodor ZoltanBelum ada peringkat

- Hilti Hit Re 500 Cu Has Hit-V His-N 1Dokumen36 halamanHilti Hit Re 500 Cu Has Hit-V His-N 1Sorin RaduBelum ada peringkat

- Hilti HIT-HY 70 injection mortar systemDokumen26 halamanHilti HIT-HY 70 injection mortar systemfkh3dBelum ada peringkat

- Tecfispa Vs Dop enDokumen16 halamanTecfispa Vs Dop enThe DarkBelum ada peringkat

- Hilti Hvu HasDokumen12 halamanHilti Hvu HasAMCRUZ77Belum ada peringkat

- Torque controlled expansion anchor guideDokumen4 halamanTorque controlled expansion anchor guideAnonymous BAzcBzWuBelum ada peringkat

- Heavy-Duty Anchor TA M: TAM Approved ForDokumen3 halamanHeavy-Duty Anchor TA M: TAM Approved ForGökhan GülhanBelum ada peringkat

- Fischer FIS VT 380C Chemical Anchorage JointDokumen3 halamanFischer FIS VT 380C Chemical Anchorage JointKelsey AndersonBelum ada peringkat

- Re 500 SD - FTM - 2012 09 PDFDokumen41 halamanRe 500 SD - FTM - 2012 09 PDFmilivojBelum ada peringkat

- PES Hilti M10 HSA ReportDokumen4 halamanPES Hilti M10 HSA ReportCollin NguBelum ada peringkat

- RE100 With HAS RodsDokumen8 halamanRE100 With HAS RodssahanBelum ada peringkat

- Technical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Dokumen16 halamanTechnical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Biprojit HoreBelum ada peringkat

- PROFIS Anchor 2.4.6: WWW - Hilti.luDokumen6 halamanPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliBelum ada peringkat

- Maxima Stainless Steel Chemical AnchorsDokumen4 halamanMaxima Stainless Steel Chemical AnchorsNestramiBelum ada peringkat

- PROFIS Anchor 2.0.7Dokumen4 halamanPROFIS Anchor 2.0.7Miky CastenBelum ada peringkat

- FS All-Steel Lock-Nut: Reliable Under Extreme PressureDokumen4 halamanFS All-Steel Lock-Nut: Reliable Under Extreme PressureDenis AugustoBelum ada peringkat

- Anchor Fastening Technology ManualDokumen152 halamanAnchor Fastening Technology ManualfdsafsadfBelum ada peringkat

- Hilti Hit Re 500 SD Hit VDokumen26 halamanHilti Hit Re 500 SD Hit Vhector saavedraBelum ada peringkat

- S 52 SX PDFDokumen6 halamanS 52 SX PDFsmishra22220% (1)

- S 52 SX PDFDokumen6 halamanS 52 SX PDFsmishra22220% (1)

- TB 4381 enDokumen2 halamanTB 4381 enMihnea-Bogdan NicolaescuBelum ada peringkat

- Technical Data: Truck-Mounted Concrete Pump Technical Data: Truck-Mounted Concrete PumpDokumen4 halamanTechnical Data: Truck-Mounted Concrete Pump Technical Data: Truck-Mounted Concrete PumpMihnea-Bogdan NicolaescuBelum ada peringkat

- Schwing SetterDokumen6 halamanSchwing Settergsm.nkl60490% (2)

- Truck-Mounted Concrete Pump With 4-Section Placing BoomDokumen6 halamanTruck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- Schwing S 41 SX pump praised for fuel efficiency, reliability by concrete contractorDokumen4 halamanSchwing S 41 SX pump praised for fuel efficiency, reliability by concrete contractorMihnea-Bogdan Nicolaescu0% (1)

- Schwing SetterDokumen6 halamanSchwing Settergsm.nkl60490% (2)

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDokumen6 halamanS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDokumen6 halamanS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- Truck-Mounted Concrete Pump With RZ4 Placing BoomDokumen6 halamanTruck-Mounted Concrete Pump With RZ4 Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- Manual Veaf Excel enDokumen31 halamanManual Veaf Excel enMihnea-Bogdan NicolaescuBelum ada peringkat

- Truck-Mounted Concrete Pump With 3-Section Placing BoomDokumen2 halamanTruck-Mounted Concrete Pump With 3-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- Manual Veaf Micro enDokumen19 halamanManual Veaf Micro enMihnea-Bogdan NicolaescuBelum ada peringkat

- Truck-Mounted Concrete Pump With 4-Section Placing BoomDokumen6 halamanTruck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuBelum ada peringkat

- KVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsDokumen2 halamanKVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsMihnea-Bogdan Nicolaescu100% (1)

- Manual Vaf enDokumen17 halamanManual Vaf enMihnea-Bogdan NicolaescuBelum ada peringkat

- Technoflex Vibrator ManualDokumen21 halamanTechnoflex Vibrator ManualMihnea-Bogdan NicolaescuBelum ada peringkat

- Technical Data: Truck-Mounted Concrete Pump Technical Data: Truck-Mounted Concrete PumpDokumen4 halamanTechnical Data: Truck-Mounted Concrete Pump Technical Data: Truck-Mounted Concrete PumpMihnea-Bogdan NicolaescuBelum ada peringkat

- Manual Veaf Micro enDokumen19 halamanManual Veaf Micro enMihnea-Bogdan NicolaescuBelum ada peringkat

- Manual Sangla enDokumen28 halamanManual Sangla enMihnea-Bogdan NicolaescuBelum ada peringkat

- S 52 SX PDFDokumen6 halamanS 52 SX PDFsmishra22220% (1)

- S 52 SX PDFDokumen6 halamanS 52 SX PDFsmishra22220% (1)

- Manual Veaf Excel enDokumen31 halamanManual Veaf Excel enMihnea-Bogdan NicolaescuBelum ada peringkat

- Manual Sangla enDokumen28 halamanManual Sangla enMihnea-Bogdan NicolaescuBelum ada peringkat

- Technoflex Vibrator ManualDokumen21 halamanTechnoflex Vibrator ManualMihnea-Bogdan NicolaescuBelum ada peringkat

- Flaechendicht k435 de 0216 0 Eng ScreenDokumen2 halamanFlaechendicht k435 de 0216 0 Eng ScreenAlexandru IonescuBelum ada peringkat

- QO™ Load Centers - QO124M200PDokumen4 halamanQO™ Load Centers - QO124M200PIsraelBelum ada peringkat

- Causal Inference For The Brave and True - Causal Inference For The Brave and TrueDokumen2 halamanCausal Inference For The Brave and True - Causal Inference For The Brave and TrueVkook ForeverBelum ada peringkat

- Dav Public School, Berhampur, Odisha Summer Holiday HomeworkDokumen3 halamanDav Public School, Berhampur, Odisha Summer Holiday HomeworkOmBelum ada peringkat

- 5 & 6 Risk AssessmentDokumen23 halaman5 & 6 Risk AssessmentAzam HasanBelum ada peringkat

- Research 3Dokumen30 halamanResearch 3Lorenzo Maxwell GarciaBelum ada peringkat

- Adjustment: - Electronic Modulated Air SuspensionDokumen2 halamanAdjustment: - Electronic Modulated Air SuspensionThar KyiBelum ada peringkat

- General Chemistry 2 - LAS 2 LEARNING CAPSULEDokumen5 halamanGeneral Chemistry 2 - LAS 2 LEARNING CAPSULEMark RazBelum ada peringkat

- E-Governance in KeralaDokumen10 halamanE-Governance in KeralaRahmath SafeenaBelum ada peringkat

- PowerFlex 4M LabDokumen22 halamanPowerFlex 4M Labmaria laura delgado morenoBelum ada peringkat

- Machine Guarding PrinciplesDokumen5 halamanMachine Guarding Principlesliveconnectionz282Belum ada peringkat

- Determination of The Molecular Weight of Polymers From Viscosity MeasurementsDokumen10 halamanDetermination of The Molecular Weight of Polymers From Viscosity MeasurementsAbdullah MunawarBelum ada peringkat

- 3D Printing Seminar REPORT-srijanDokumen26 halaman3D Printing Seminar REPORT-srijanSrijan UpadhyayBelum ada peringkat

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDokumen12 halamanTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasBelum ada peringkat

- CSC309 Extra Credit 1Dokumen5 halamanCSC309 Extra Credit 1Fluffy BagelzBelum ada peringkat

- Reflection 4Dokumen7 halamanReflection 4danilo miguelBelum ada peringkat

- Components of GlobalizationDokumen26 halamanComponents of GlobalizationGiyan KhasandraBelum ada peringkat

- Annexure - Subject Wise IBDP Grade BoundariesDokumen4 halamanAnnexure - Subject Wise IBDP Grade BoundariesazeemBelum ada peringkat

- List of British StandardsDokumen6 halamanList of British StandardsPankajBelum ada peringkat

- Line BalancingDokumen21 halamanLine Balancingarno6antonio6spinaBelum ada peringkat

- Book 3 - Revised 2017-2Dokumen41 halamanBook 3 - Revised 2017-2sales zfBelum ada peringkat

- Matlab 8Dokumen6 halamanMatlab 8Robert RoigBelum ada peringkat

- Middle Range TheoriesDokumen134 halamanMiddle Range TheoriesMary Joyce MejiaBelum ada peringkat

- 3D Technical Data Package Configuration Management, Modeling and Drawing ProcedureDokumen175 halaman3D Technical Data Package Configuration Management, Modeling and Drawing Procedurejesse_w_petersBelum ada peringkat

- Jda Connects The Dots at Its 209821Dokumen5 halamanJda Connects The Dots at Its 209821Gerardo LujanBelum ada peringkat