Close Approach Cooling System

Diunggah oleh

happale2002Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Close Approach Cooling System

Diunggah oleh

happale2002Hak Cipta:

Format Tersedia

SELECTIONS CLOSE APPROACH

FlatPlate heat exchangers can be used in applications whereby the Approach Temperatures can be 10F or less, and as

low as 2F. This means that the Heating (or Cooling) Source will Heat (or Cool) the Secondary load side to within a 2F to

10F of the Source temperature. This allows for a wide range of applications and versatility for utilizing FlatPlate heat

exchangers. FlatPlate heat exchangers can be used for many Fluid to Fluid applications where a Heating (or Cooling) Source

is used to transfer heat to a Load. Many applications include:

Boiler Water to Process

Chilled Water to Process

Glycol to Process Water

Process water to Process water

Hot Water Heater to Radiant Floor

Cooling tower/Free Cooling to Chilled

Water loop

Engine Water to Process

High Pressure (300psi) Isolation to

Low Pressure (150psi) Equipment

Sea Water to Process (MP Series)

Diagram 1-Standard Piping Arrangement 10F and Higher Approach

Strainer

SOURCE

(Boiler, Heat Pump,

Chiller, etc.)

Approach Temperature = Side A (Source) Entering

Temperature (F) - Side B (Load) Leaving Temperature (F)

For Example:

Side A: 95F in , 85F out

Side B 77F in , 87F out = 8F Approach

Temperature Difference (TD) of (Side A or Side B) are

defined as:

Entering Temperature - minus Leaving Temperature

For Example:

Side A: 95F in , 85F out = 10F TD for Side A

Side B 77F in , 87F out = 10F TD for Side B

Optimum Approach temperature for a Brazed Plate Heat

Exchanger is typically 10F for cost effective selections, yet

3F and 4F Approach temperatures are possible for special

applications.

Ideal Temperature Difference (TD) is typically 10F and is

widely prefered in many applications.

To select a Close Approach Heat Exchanger, use the

Selection Tables.

Side A

In

Side B

Out

Bypass/Balancing

Adjustment

LOAD

Bypass

Adjustment

Strainer

Diagram 2-Heat Exchanger to Cooling Tower

Side A

In

Side B

Out

Bypass/

Balancing

Valve

Chilled

Water / or Process

Loop

Strainer

Heat Exchanger

to Cooling Tower

Diagram 3-High Pressure Isolation

Side A

In

Side B

Out

High Pressure

Loop

< 450psi

Low Pressure

Loop

< 150psi

High Pressure

Isolation

Step 1 Determine the BTUH Heat transfer required

(Interceptor)

Step 2 Select the Approach Temperature desired for your

application, then use the appropriate Table.

For example: For 100,000 BTUH Boiler water at 180F, to be used to heat water

to 172F, an 8F approach, Model FP5x12-50 can be selected from the 8F

Approach table. Note, the tables assume 10F temperature split on both the

boiler (180F in/170F out) and 10F temperature split on the load side (162F

in/172F out)

Step 3 For fluid temperatures below 80F, use the Temperature Correction Factor Table.

Multiply the Correction Factor times the last two digits of the model number to

obtain the appropriate model:

For example: If a FP5x12-50 is selected and one of the fluids is entering at 55F,

multiply the last two digits of the model number by 1.21 (FP5x12-50) to obtain a

FP5x12-60 as the appropriate selection.

17

SELECTIONS CLOSE APPROACH

Note: ALL the Tables shown assume a 10F Split in the IN/OUT temperatures of both Side A and Side B fluids. Identical

GPM, both sides. For temperature splits other than a 10F TD Split or if Glycols are being used, call your local FlatPlate

representative for a computer selection.

Approach Temperature = Hot Side Supply Temp In (Side A In) minus Cold Side Temp Out (Side B Out)

10F Approach

8F Approach

6F Approach

Model

BTUH

GPM PD (Hot) PD (Cold)

BTUH

GPM PD (Hot) PD (Cold)

BTUH

GPM PD (Hot) PD (Cold)

FP5x12-4 (3/4" MPT)

4,930

1.0

3.2

0.9

2,960

0.6

1.3

0.3

1,520

0.3

0.3

0.2

FP5x12-6 (3/4" MPT)

8,870

1.8

2.6

1.3

4,440

0.9

0.7

0.4

2,470

0.5

0.3

0.2

FP5x12-8 (3/4" MPT)

13,300

2.7

2.6

1.6

8,400

1.7

1.2

0.7

4,930

1.0

0.4

0.3

FP5x12-10 (3/4" MPT)

17,750

3.6

2.6

1.7

12,300

2.5

1.3

0.9

7,400

1.5

0.6

0.4

FP5x12-12 (3/4" MPT)

26,600

5.4

3.8

2.8

22,200

4.5

2.6

1.9

12,300

2.5

0.9

0.7

FP5x12-14 (3/4" MPT)

35,000

7.1

4.5

3.3

26,600

5.4

2.8

2.0

14,800

3.0

0.9

0.7

FP5x12-16 (3/4" MPT)

43,900

8.9

5.1

4.1

29,600

6.0

2.5

1.9

17,300

3.5

0.9

0.7

FP5x12-20 (1" MPT)

59,200 12.0

5.5

4.6

41,400

8.4

2.9

2.5

23,700

4.8

1.0

0.9

FP5x12-24 (1" MPT)

74,000 15.0

5.9

5.1

49,300

10.0

2.8

2.5

27,100

5.5

0.9

0.9

FP5x12-30 (1" MPT)

93,600 19.0

5.9

5.4

64,100

13.0

3.0

2.6

37,000

7.5

1.2

1.0

FP5x12-36 (1" MPT)

113,400 23.0

6.1

5.7

78,900

16.0

3.2

2.9

44,400

9.0

1.2

1.0

FP5x12-40 (1-1/4" MPT)

133,100 27.0

6.8

6.4

88,700

18.0

3.2

3.0

51,800

10.5

1.2

1.2

FP5x12-50 (1-1/4" MPT)

162,700 33.0

6.8

6.5

113,400

23.0

3.5

3.3

64,100

13.0

1.2

1.2

FP5x12-60 (1-1/4" MPT)

187,300 38.0

6.7

6.4

138,000

28.0

3.8

3.6

78,900

16.0

1.3

1.3

FP5x12-70 (1-1/4" MPT)

221,800 45.0

7.4

7.1

157,800

32.0

3.9

3.8

88,700

18.0

1.3

1.3

FP5x12-80 (1-1/4" MPT)

246,000 50.0

7.5

7.4

172,600

35.0

3.9

3.8

98,600

20.0

1.3

1.3

Note: For applications with sea water, brackish water, pool or spa water, Low PH water, steam, substitute MP Marine 5x12 Models. See page 16 for other

fluids compatibility.

6F Approach

4F Approach

3F Approach

Model

BTUH

GPM PD (Hot) PD (Cold)

BTUH

GPM PD (Hot) PD (Cold)

BTUH

GPM PD (Hot) PD (Cold)

FP10x20-20 (1-1/2" MPT)

111,600

22

7.3

7.1

49,300

10

1.7

1.3

25,370

5

0.4

0.3

FP10x20-24 (1-1/2" MPT)

133,100

27

7.4

6.2

73,900

15

2.5

2.0

FP10x20-30 (1-1/2" MPT)

202,100

41

10.2

9.0

88,700

18

2.2

1.9

49,300

10

0.7

0.6

FP10x20-36 (1-1/2" MPT)

246,000

50

10.3

9.4

108,500

22

2.3

2.0

FP10x20-40 (1-1/2" MPT)

271,000

55

10.2

9.3

123,200

25

2.3

2.2

69,100

14

0.7

0.7

FP10x20-50 (2" MPT)

296,000

60

7.8

7.4

147,800

30

2.2

2.0

FP10x20-50 (2" MPT)

345,000

70

10.4

9.7

167,600

34

2.8

2.6

87,400

18

0.9

0.7

FP10x20-60 (2" MPT)

394,000

80

9.7

9.1

197,200

40

2.6

2.5

FP10x20-70 (2" MPT)

444,000

90

9.1

8.8

221,800

45

2.5

2.5

123,200

25

0.9

0.7

FP10x20-70 (2" MPT)

493,000

100

11.2

10.7

231,700

47

2.8

2.6

FP10x20-80 (2" MPT)

542,000

110

10.6

10.3

246,500

50

2.5

2.3

147,900

30

0.9

0.9

FP10x20-90 (2-1/2" MPT)

591,000

120

10.3

10.0

281,000

57

2.6

2.5

FP10x20-100 (2-1/2" MPT)

641,000

130

10.2

9.9

320,400

65

2.8

2.8

187,300

38

1.0

1.0

FP10x20-110 (2-1/2" MPT)

690,000

140

10.2

9.9

369,700

75

3.2

3.0

FP10x20-120 (2-1/2" MPT)

788,000

160

11.5

11.2

419,000

85

3.5

3.3

221,800

45

1.0

1.0

FP10x20-130 (2-1/2" MPT)

838,000

170

11.5

11.3

453,600

92

3.6

3.5

FP10x20-140 (2-1/2" MPT)

887,000

180

11.6

11.5

483,100

98

3.6

3.6

271,100

55

1.2

1.2

FP10x20-150 (2-1/2" MPT)

887,000

180

10.6

10.4

517,600

105

3.8

3.8

FP10x20-160 (2-1/2" MPT)

936,000

190

10.9

10.7

542,300

110

3.8

3.8

305,700

62

1.3

1.3

FP10x20-170 (2-1/2" MPT)

986,000

200

11.2

11.0

566,900

115

3.9

3.8

FP10x20-180 (2-1/2" MPT)

1,109,000

225

13.1

12.9

616,200

125

4.2

4.2

345,100

70

1.3

1.3

FP10x20-190 (2-1/2" MPT)

1,109,000

225

12.3

12.2

665,500

135

4.6

4.6

Note: For applications with sea water, brackish water, pool or spa water, Low PH water, steam, use multiple MP Marine 5x12 Models, piped in parallel to

obtain the BTUH and GPM flow rate needed. See page 16 for other fluids compatibility.

For 2F approach temperatures, use the 4F table for BTUH and GPM selection to select TWO (2) identical models to be piped in Series. Fluid PD will be

2x shown.

For 10F approach temperatures or greater, contact your local FlatPlate representative for exact selection.

Temperature Correction Table

Fluid Entering Temperature

Model Correction Factor

> 80F

1.00

> 60F and < 80F

1.21

> 32F and < 60F

1.42

18

1. Multiply the last 2 digits of the model number to obtain the correct model.

2. For Glycol applications, contact your local FlatPlate representative.

Anda mungkin juga menyukai

- Samsung RS275-RS277 - Refrigerator TrainingDokumen93 halamanSamsung RS275-RS277 - Refrigerator Trainingblackwellbert92% (13)

- Evaporators CondensersDokumen13 halamanEvaporators CondensersKumlachew Mengistu0% (1)

- Heat KingDokumen28 halamanHeat KingWayne Grey100% (3)

- Chapter 5Dokumen4 halamanChapter 5Marco Luigi100% (1)

- TraneDokumen33 halamanTranejake1000100% (1)

- SS-AEPF Goodman Air ConditionerDokumen8 halamanSS-AEPF Goodman Air ConditionerArmando EnriquezBelum ada peringkat

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDokumen30 halamanEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiBelum ada peringkat

- Deron Heat Pump CatalogueDokumen39 halamanDeron Heat Pump CatalogueCarlos Lehman100% (4)

- GU-379 Pipeline Emergency Repair ManualDokumen76 halamanGU-379 Pipeline Emergency Repair Manualhappale2002Belum ada peringkat

- SP-1208 - Sep 2005 PIPELINE - CONSTRUCTION - SPECIFICATION - (PCS-01) - SP-1208Dokumen125 halamanSP-1208 - Sep 2005 PIPELINE - CONSTRUCTION - SPECIFICATION - (PCS-01) - SP-1208Vignesh Naidu69% (13)

- GU-379 Pipeline Emergency Repair ManualDokumen76 halamanGU-379 Pipeline Emergency Repair Manualhappale2002Belum ada peringkat

- Thermodynamics 2Dokumen6 halamanThermodynamics 2markalvinbon0% (1)

- Duct Velocity AshraeDokumen1 halamanDuct Velocity Ashraekdpmansi100% (5)

- Capacity Regulator CpceDokumen8 halamanCapacity Regulator CpceNovan AndriantoBelum ada peringkat

- Fujitsu RLS2HDokumen2 halamanFujitsu RLS2HEric HalsteadBelum ada peringkat

- Thermostatically Operated Cooling Water Valves Types AVTA and FJVADokumen12 halamanThermostatically Operated Cooling Water Valves Types AVTA and FJVAMasroor RasoolBelum ada peringkat

- Catalogo ChillerDokumen8 halamanCatalogo ChillerJoan Sebastian DazaBelum ada peringkat

- HR E577rDokumen6 halamanHR E577rAnton RenaldoBelum ada peringkat

- Broad X Non-Electric Chiller: Model Selection & Design ManualDokumen27 halamanBroad X Non-Electric Chiller: Model Selection & Design ManualdokundotBelum ada peringkat

- Optyma CU Leaflet - 46CDokumen8 halamanOptyma CU Leaflet - 46CRahul PatilBelum ada peringkat

- Performance Data: Curve 14.00 1BB065, 2BB065Dokumen2 halamanPerformance Data: Curve 14.00 1BB065, 2BB065texwan_Belum ada peringkat

- Boiler Protections, Emergencies and EfficiencyDokumen40 halamanBoiler Protections, Emergencies and EfficiencyAnirudh MeshramBelum ada peringkat

- Acson Service Guide Book 2010Dokumen90 halamanAcson Service Guide Book 2010afnc777100% (1)

- Daewoo ForestDokumen59 halamanDaewoo ForestMahdiBelum ada peringkat

- r557 Mixing ManifoldDokumen12 halamanr557 Mixing Manifolddejanoski_aBelum ada peringkat

- Compressor Selection: 2-Stage Semi-Hermetic Reciprocating CompressorsDokumen3 halamanCompressor Selection: 2-Stage Semi-Hermetic Reciprocating CompressorsSalah El Dine ZantoutBelum ada peringkat

- LS2 - Variation in Refrigeration Coefficient of Performance at Various Operating ConditionsDokumen7 halamanLS2 - Variation in Refrigeration Coefficient of Performance at Various Operating ConditionsAlif Zharfan Azizul RahimBelum ada peringkat

- FCU Celling Daikin CatalogueDokumen20 halamanFCU Celling Daikin CatalogueTuyen NguyenBelum ada peringkat

- Exp. 5 Heat Transfer Study On Plate Heat ExchangerDokumen6 halamanExp. 5 Heat Transfer Study On Plate Heat ExchangerElaine PuiBelum ada peringkat

- Salon Tipi 3 Faz ServisDokumen79 halamanSalon Tipi 3 Faz ServisaydintarakBelum ada peringkat

- Series N170-M3 and LFN170-M3 Installation InstructionsDokumen12 halamanSeries N170-M3 and LFN170-M3 Installation InstructionsWattsBelum ada peringkat

- Coldspell Manual Rev2Dokumen25 halamanColdspell Manual Rev2ipl200910Belum ada peringkat

- Aqua Top Planning DocumentDokumen100 halamanAqua Top Planning DocumentAnghel DumitriuBelum ada peringkat

- Program: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554Dokumen7 halamanProgram: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554NHBelum ada peringkat

- BROAD X Absorption Chiller Model Selection Design ManualDokumen46 halamanBROAD X Absorption Chiller Model Selection Design Manualpseudosil0% (1)

- Complressor R134aDokumen2 halamanComplressor R134aHikmat KtkBelum ada peringkat

- Avery 112Dokumen5 halamanAvery 112Leed ENBelum ada peringkat

- Operation Installation Manual Heat PumpDokumen97 halamanOperation Installation Manual Heat Pumpvillszer2014Belum ada peringkat

- FT8 - Cold Air Buffer - P&W FT8 - Solar Turbines Technical BLOGDokumen7 halamanFT8 - Cold Air Buffer - P&W FT8 - Solar Turbines Technical BLOGLibyanManBelum ada peringkat

- GN Boiler RangeDokumen16 halamanGN Boiler Range9810482818Belum ada peringkat

- Refrigerantion Complete 2Dokumen27 halamanRefrigerantion Complete 2Ricardo Wan Aguero50% (2)

- Export Pricelist 2013Dokumen80 halamanExport Pricelist 2013Ion VasileBelum ada peringkat

- Water To Water Heat Pump Catalog - R134a - R410aDokumen24 halamanWater To Water Heat Pump Catalog - R134a - R410aKCFUNGBelum ada peringkat

- Guia de Servicio TXV S R404 (SER04-33)Dokumen3 halamanGuia de Servicio TXV S R404 (SER04-33)gladiador2613Belum ada peringkat

- Service Bulletin: WarningDokumen11 halamanService Bulletin: Warningninzau100% (1)

- V. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFDokumen7 halamanV. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFgonzalezpcjBelum ada peringkat

- Carrier Air Con 38QRR ManualDokumen30 halamanCarrier Air Con 38QRR ManualYorkistBelum ada peringkat

- Service Manual: Advanced Air Conditioning SystemsDokumen42 halamanService Manual: Advanced Air Conditioning SystemsSuciu MariusBelum ada peringkat

- Fujitsu Seria LC PDFDokumen50 halamanFujitsu Seria LC PDFDimo GrigorovBelum ada peringkat

- Discus Launch PackageDokumen69 halamanDiscus Launch Packageourstocks2002Belum ada peringkat

- AE1327Dokumen13 halamanAE1327Maria DazaBelum ada peringkat

- FJ Ary90 TM FujitsuDokumen15 halamanFJ Ary90 TM FujitsuSopon CristiBelum ada peringkat

- Chiller Series Operators Manual PDFDokumen29 halamanChiller Series Operators Manual PDFmarceloestimuloBelum ada peringkat

- RCD Ebara Absorption ChillerDokumen24 halamanRCD Ebara Absorption Chillera_salehi83% (6)

- Document Code: Issuing Date: StatusDokumen12 halamanDocument Code: Issuing Date: StatusPru Manurung BinsarBelum ada peringkat

- Performance Data: 345 1 BB, BCDokumen2 halamanPerformance Data: 345 1 BB, BCtexwan_Belum ada peringkat

- Pompa Caldura WZH HidrosDokumen6 halamanPompa Caldura WZH HidrosAdrian RuxandaBelum ada peringkat

- Rheem 310 Series Heat Pump Hot WaterDokumen68 halamanRheem 310 Series Heat Pump Hot WaterDavid HarpleyBelum ada peringkat

- Water Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35Dokumen28 halamanWater Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35jeromeduytscheBelum ada peringkat

- Distributed Power: Cooling Systems Application of VGF Engines at Elevated Jacket Water TemperaturesDokumen5 halamanDistributed Power: Cooling Systems Application of VGF Engines at Elevated Jacket Water TemperaturesGustavo BerbergiBelum ada peringkat

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryDari EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryBelum ada peringkat

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualDari EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualBelum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Spec 457 Rev 3 1126784921-Horizontal Centrifugal PumpDokumen11 halamanSpec 457 Rev 3 1126784921-Horizontal Centrifugal Pumphappale2002Belum ada peringkat

- Spec - 452 - Rev - 3 - 1126784860-Positive Displacment Pump - Controlled VolumeDokumen11 halamanSpec - 452 - Rev - 3 - 1126784860-Positive Displacment Pump - Controlled Volumehappale2002Belum ada peringkat

- NIOEC Vendor List Based On ManufacturersDokumen234 halamanNIOEC Vendor List Based On Manufacturershappale2002Belum ada peringkat

- Plat Coil Heat Exchanger PDFDokumen20 halamanPlat Coil Heat Exchanger PDFhappale2002Belum ada peringkat

- Plat Coil Heat Exchanger PDFDokumen20 halamanPlat Coil Heat Exchanger PDFhappale2002Belum ada peringkat

- Spec 458 Rev 3 1126785077-Vertical In-Line Centrifugal PumpDokumen11 halamanSpec 458 Rev 3 1126785077-Vertical In-Line Centrifugal Pumphappale2002Belum ada peringkat

- Spec524rev4coating Threaded Fasterners 1124440653Dokumen4 halamanSpec524rev4coating Threaded Fasterners 1124440653happale2002Belum ada peringkat

- Tech Sheet 110 - HEI StandardDokumen15 halamanTech Sheet 110 - HEI StandardzulryBelum ada peringkat

- TIS-113-Prime Surface Heat ExchangerDokumen0 halamanTIS-113-Prime Surface Heat Exchangerhappale2002Belum ada peringkat

- Nash Priming ValveDokumen4 halamanNash Priming Valvehappale2002Belum ada peringkat

- Vacuum Pumps and Compressors For The Electric Power IndustryDokumen6 halamanVacuum Pumps and Compressors For The Electric Power IndustryPinky BasuBelum ada peringkat

- Vacuum Pumps and Compressors For The Electric Power IndustryDokumen6 halamanVacuum Pumps and Compressors For The Electric Power IndustryPinky BasuBelum ada peringkat

- Mist EliminatorDokumen4 halamanMist Eliminatorhappale2002Belum ada peringkat

- SP-1136 Cathodic Protection DrawingsDokumen4 halamanSP-1136 Cathodic Protection Drawingshappale2002Belum ada peringkat

- SP-1200 Procurement Specification For Pipeline Check ValvesDokumen25 halamanSP-1200 Procurement Specification For Pipeline Check Valveshappale2002Belum ada peringkat

- SP 1190 Desing - For - Sour - Service - SpecificationDokumen15 halamanSP 1190 Desing - For - Sour - Service - Specificationhappale2002100% (1)

- Specification For Cathodic Protection DesignDokumen39 halamanSpecification For Cathodic Protection Designhezron7771% (7)

- PR-1272 Standard Welding PQRs For On-Plot PipingDokumen10 halamanPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002Belum ada peringkat

- SP 1032 Specification - For - The - Design - of - Pipeline - Block - ValvDokumen17 halamanSP 1032 Specification - For - The - Design - of - Pipeline - Block - Valvhappale2002100% (1)

- PR-1522 Procedure For Analysis of Pipeline Road Crossings RevDokumen35 halamanPR-1522 Procedure For Analysis of Pipeline Road Crossings Revhappale2002Belum ada peringkat

- GU-504 Gas Flotation Tank Systems Rev2 Old PDFDokumen37 halamanGU-504 Gas Flotation Tank Systems Rev2 Old PDFhappale2002Belum ada peringkat

- PERD Predicting Relief Valve ReliabilityDokumen6 halamanPERD Predicting Relief Valve ReliabilityMOhamad YarmohamadiBelum ada peringkat

- Valve Selection Guide: 2/2 Way SolenoidsDokumen4 halamanValve Selection Guide: 2/2 Way Solenoidshappale2002Belum ada peringkat

- Free Energy - Steam Jet Water-Air Pump PDFDokumen1 halamanFree Energy - Steam Jet Water-Air Pump PDFhappale2002Belum ada peringkat

- Handbook of Polyethylene Pipe Hvac Applications PDFDokumen27 halamanHandbook of Polyethylene Pipe Hvac Applications PDFhappale2002Belum ada peringkat

- Checklst Per Hazop PDFDokumen19 halamanChecklst Per Hazop PDFhappale2002Belum ada peringkat

- Thermodynamics McqsDokumen31 halamanThermodynamics McqsRohitBelum ada peringkat

- Calculation of Enthalpy Changes: Basic Principles and Calculations in Chemical EngineeringDokumen7 halamanCalculation of Enthalpy Changes: Basic Principles and Calculations in Chemical EngineeringSafa AlniamiBelum ada peringkat

- Cae331 513 Lecture12 Psychrometric-EquationsDokumen42 halamanCae331 513 Lecture12 Psychrometric-EquationscelsoBelum ada peringkat

- MSI - CS Dan ABFDokumen7 halamanMSI - CS Dan ABFMaz ZildaneBelum ada peringkat

- MaterialDokumen18 halamanMaterialImane ZaidiBelum ada peringkat

- PriceListHirePurchase Normal6thNov2019Dokumen56 halamanPriceListHirePurchase Normal6thNov2019Jamil AhmedBelum ada peringkat

- Body Temperature and Time of DeathDokumen9 halamanBody Temperature and Time of DeathAnanya GSBelum ada peringkat

- EntropyDokumen30 halamanEntropyفضائح لا تصدقBelum ada peringkat

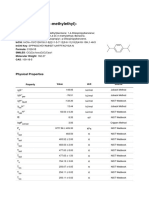

- Benzene, 1,4-Bis (1-Methylethyl) - : Physical PropertiesDokumen3 halamanBenzene, 1,4-Bis (1-Methylethyl) - : Physical PropertiesLAURA LUC�A ATENCIA CASTILLOBelum ada peringkat

- Heat Calculations Practice 2Dokumen2 halamanHeat Calculations Practice 2Rizqi HidayatBelum ada peringkat

- First Law of ThermodynamicsDokumen9 halamanFirst Law of ThermodynamicsSunshine Llamas GuzmanBelum ada peringkat

- Topic 4.1 Psychometry and Air ConditioningDokumen76 halamanTopic 4.1 Psychometry and Air ConditioningCARL IJADE PINOBelum ada peringkat

- Chapter 63 Standard Integration: EXERCISE 256 Page 707Dokumen9 halamanChapter 63 Standard Integration: EXERCISE 256 Page 707Khaerul UmamBelum ada peringkat

- Converting Fahrenheit and CelsiusDokumen2 halamanConverting Fahrenheit and CelsiusKayzeelyn MoritBelum ada peringkat

- Gujarat Technological University: InstructionsDokumen3 halamanGujarat Technological University: InstructionsRenieBelum ada peringkat

- VIP 3 REF ExamDokumen8 halamanVIP 3 REF ExamJaybee LabraBelum ada peringkat

- Chapter 08Dokumen14 halamanChapter 08Gianne Karl AlmarinesBelum ada peringkat

- Refrigeration Cycle Presentation 1 JSarkarDokumen11 halamanRefrigeration Cycle Presentation 1 JSarkarKusmakarBelum ada peringkat

- Lecture 2: Enthalpy: - Reading: Zumdahl 9.2, 9.3 - OutlineDokumen18 halamanLecture 2: Enthalpy: - Reading: Zumdahl 9.2, 9.3 - Outlinesyahrial_chaniago4769Belum ada peringkat

- Instituto Episcopal San Cristóbal Workshop # - Temperature Teacher: Elva de Clarke Level: 9°Dokumen4 halamanInstituto Episcopal San Cristóbal Workshop # - Temperature Teacher: Elva de Clarke Level: 9°IcecreamchuserBelum ada peringkat

- Doctype HTML PublicDokumen5 halamanDoctype HTML PublicMICHAEL VINICIO DE LA CRUZ GUAYASAMINBelum ada peringkat

- Icrmae 2015Dokumen14 halamanIcrmae 2015Mujammil Choudhari100% (1)

- CH 12 Study GuideDokumen8 halamanCH 12 Study GuideyawahabBelum ada peringkat

- Equivalence of KelvinDokumen4 halamanEquivalence of KelvinGianina So-LimjocoBelum ada peringkat

- Week8 LS3 DLL Celsuis - FarenheitDokumen9 halamanWeek8 LS3 DLL Celsuis - FarenheitJenielyn Sado100% (1)

- TermoDokumen14 halamanTermoGagah ArofatBelum ada peringkat

- Tutorial 2Dokumen2 halamanTutorial 2Angelina PutriBelum ada peringkat