Butterfly Valve Principle

Diunggah oleh

Devendra BangarHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Butterfly Valve Principle

Diunggah oleh

Devendra BangarHak Cipta:

Format Tersedia

High-performance butterfly valves

1. Disc and Shaft Design High-performance butterfly valves have a double-eccentric design. First, the sealing plane of the disc is offset from the axis of rotation. This provides an uninterrupted circular sealing surface on the disc that makes it possible for a circular sealing element to be placed in the valve. It can be easily removed from the valve without disassembly of the shaft/disc closure elements. Second, the axis of rotation of the disc is laterally displaced from the true centre of the disc so that it will "cam" away from the seat to eliminate jamming or squeezing as the valve is opened and closed. This design eliminates wear points around the disc at the top and bottom of the seat. When closing, the disc cams tightly into its seat to create a bubble-tight seal with consistent torque. This eccentric rotation has a tremendous impact of extending the duration of the valve's leak-free performance. 2. Seat Design There are many seat designs. Metal seats provide consistent, long-lasting shutoff, but they are not considered bubble-tight. Services which require 100% tight shutoff must rely on soft seats, which are made for instance of PTFE and Filled PTFE. The principle of double eccentricity:

Triple eccentric butterfly valves

With the triple eccentric construction the metal seated butterfly valve ensures an ideal conical sealing principle. Even at extreme temperature fluctuations and pressure tops by the optimal interpretation of three times eccentric geometry and your special features reliable function and tightness is guaranteed for a long time. Lowest torques and the non-appearance of lot breaking moments become obtained by conical literature geometry. Gas tightness, sticking free function and pressure customization are broader advantages of this construction. The three offsets are: 1E - the centre of rotation is offset from the tightness surface to allow a total contact around the complete seal 2E - the centre of rotation of the disc is offset from the pipe centreline to allow a cleaning opening valve 3E - the third offset due to the seal cone tilting cancels jamming and friction and allows complete tightness without seal

deformation (solid seats).

To summarize this kind of butterfly valves we can enumerate the following advantages: 1. 2. 3. 4. 5. 6. Excellent durability of seat part and low operating torque by non-rubbing characteristics with triple offset construction. Bi-directional zero leakage service by resilient metal sealing and torque seating. Unrestricted selection of face-to-face dimensions for API, ASME (ANSI), BS, DIN and another standards. The design and the choice of materials allows a large working temperature range (from -196C up to +700C). The profiled disc reduces the pressure drop and allows a high Cv value for regulation applications. Also to get in fire safe design which allows the use of these valves on every combustible medium application.

The principle of triple eccentricity:

Anda mungkin juga menyukai

- Funcionamiento Hidraulico Cat 416D OrtogonalDokumen23 halamanFuncionamiento Hidraulico Cat 416D OrtogonalMauriciow85% (20)

- Materials EquivalantsDokumen10 halamanMaterials EquivalantsFareed EngineeringBelum ada peringkat

- ME Lab 2 Module No. 2Dokumen17 halamanME Lab 2 Module No. 2Ismaeli Kiel86% (7)

- Erection Manual-Pc PipingDokumen219 halamanErection Manual-Pc Pipingalinor_tn100% (2)

- Shaffer ShpericalDokumen11 halamanShaffer Shpericaljeinerdt100% (1)

- Heat TreatmentDokumen14 halamanHeat TreatmentAkhilesh KumarBelum ada peringkat

- Valves AssignmentDokumen16 halamanValves AssignmentAdil Jutt GBelum ada peringkat

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Dokumen26 halamanCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduBelum ada peringkat

- Pump Troubleshooting GuideDokumen3 halamanPump Troubleshooting GuidebbmokshBelum ada peringkat

- 1.4462 PropertiesDokumen1 halaman1.4462 PropertiesutreshwarmiskinBelum ada peringkat

- Engineering Design Calculation Orifice FlowDokumen1 halamanEngineering Design Calculation Orifice FlowCarlos SopasBelum ada peringkat

- ME080 Section 8 - Other Hydraulic ComponentsDokumen101 halamanME080 Section 8 - Other Hydraulic ComponentsAhmed FaragBelum ada peringkat

- Split Air ConditionerDokumen13 halamanSplit Air ConditionerInzi Gardezi100% (1)

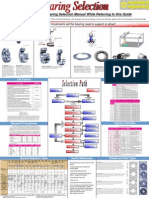

- Basic Rolling Bearing TechnologyDokumen75 halamanBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- Friction torque of rotary shaft lip sealDokumen5 halamanFriction torque of rotary shaft lip sealmans2014Belum ada peringkat

- Performance Slurry PumpDokumen154 halamanPerformance Slurry PumpJhonny AlvarezBelum ada peringkat

- COUPLINGDokumen11 halamanCOUPLINGabduallah rabahBelum ada peringkat

- Double Disc Gate Valve: Pressure Seal BonnetDokumen12 halamanDouble Disc Gate Valve: Pressure Seal BonnetMuhammadImaduddienSalamBelum ada peringkat

- Shaft Alignment MathDokumen8 halamanShaft Alignment MathJose RattiaBelum ada peringkat

- Shaft Components and Design FactorsDokumen25 halamanShaft Components and Design FactorsHüseyinYılmazBelum ada peringkat

- Lubrication & Journal Bearings (Compatibility Mode)Dokumen44 halamanLubrication & Journal Bearings (Compatibility Mode)Abhinav TiwariBelum ada peringkat

- O RingsDokumen6 halamanO RingsCuepattBelum ada peringkat

- Manual Compresor GA-315-150 ATLAS COPCO PDFDokumen179 halamanManual Compresor GA-315-150 ATLAS COPCO PDFAlcides Zárate EstelaBelum ada peringkat

- Quincy Compressor QSI SeriesDokumen100 halamanQuincy Compressor QSI SeriesWendy CassidyBelum ada peringkat

- Sump Pump Selection Final ReportDokumen19 halamanSump Pump Selection Final ReportEngr Saad Bin SarfrazBelum ada peringkat

- Hydraulic Circuits and ApplicationsDokumen20 halamanHydraulic Circuits and ApplicationsLalola HahohaBelum ada peringkat

- Welding Electrode ClassificationsDokumen2 halamanWelding Electrode ClassificationsKarthi KeyanBelum ada peringkat

- Valves: Types, Functions, Uses, Maintenance & TroubleshootingDokumen68 halamanValves: Types, Functions, Uses, Maintenance & TroubleshootingToniBelum ada peringkat

- Velan Forged Steel CatalogueDokumen26 halamanVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezBelum ada peringkat

- Limits Fits Engineering TolerancesDokumen29 halamanLimits Fits Engineering TolerancesEmmanuel Nicholas100% (2)

- Rolling Contact BEARINGS - Part1: ME 308 Machine Elements IiDokumen58 halamanRolling Contact BEARINGS - Part1: ME 308 Machine Elements Iixxx100% (1)

- Isolation Valves - Linear MovementDokumen9 halamanIsolation Valves - Linear MovementEmad A.AhmadBelum ada peringkat

- Certificado de Valvulas K18H010 Mill Test Certificate PDFDokumen3 halamanCertificado de Valvulas K18H010 Mill Test Certificate PDFdsoto_108536Belum ada peringkat

- What Loads or Movements Will The Bearing Need To Support or Allow?Dokumen1 halamanWhat Loads or Movements Will The Bearing Need To Support or Allow?subhampce085Belum ada peringkat

- Partial Stoke TestingDokumen13 halamanPartial Stoke TestingDevendra BangarBelum ada peringkat

- Partial Stoke TestingDokumen13 halamanPartial Stoke TestingDevendra BangarBelum ada peringkat

- CAT DewranceDokumen93 halamanCAT DewranceHorvatAladar100% (1)

- Shaft Alignment White PaperDokumen14 halamanShaft Alignment White PaperHamed HamedBelum ada peringkat

- Shaft Locking DeviceDokumen24 halamanShaft Locking DevicechienhamthepBelum ada peringkat

- Basics of Wear IiwDokumen7 halamanBasics of Wear IiwSomnath ChakravartyBelum ada peringkat

- Gatevalve (Wedge Vs Parallel Slide - Flowserve)Dokumen5 halamanGatevalve (Wedge Vs Parallel Slide - Flowserve)Shameer MajeedBelum ada peringkat

- 5 Poppet ValvesDokumen14 halaman5 Poppet ValvesVIJAYIOCLBelum ada peringkat

- Birkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Dokumen52 halamanBirkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Mark RomeroBelum ada peringkat

- Gate Valve Wedge PDFDokumen5 halamanGate Valve Wedge PDFpvsreddy2002Belum ada peringkat

- Hydraulic MachineryDokumen60 halamanHydraulic MachinerySushil Kumar Singh100% (1)

- Facts About ForgingDokumen7 halamanFacts About ForgingRikhil YalamanchiBelum ada peringkat

- Forgings PDFDokumen23 halamanForgings PDFrrameshsmitBelum ada peringkat

- Butterfly ValveDokumen25 halamanButterfly ValveRahul JadhavBelum ada peringkat

- Install, operate and maintain Hopkinsons swing check valveDokumen7 halamanInstall, operate and maintain Hopkinsons swing check valveGiorgiana RosuBelum ada peringkat

- Hydraulic CylindersDokumen7 halamanHydraulic Cylinderspacopil34Belum ada peringkat

- Persta Industrie eDokumen140 halamanPersta Industrie ezoraze32Belum ada peringkat

- Flat Fan Nozzles Lechler enDokumen40 halamanFlat Fan Nozzles Lechler enWANKEL25Belum ada peringkat

- Shaft Design GuideDokumen3 halamanShaft Design GuideDr_M_Soliman100% (1)

- Bettis CBA 725Dokumen16 halamanBettis CBA 725kutts76100% (1)

- Tyco Parallel Side Gate ValveDokumen7 halamanTyco Parallel Side Gate ValveanaattiaBelum ada peringkat

- Maximum Shear Stress Theory-DerivationDokumen21 halamanMaximum Shear Stress Theory-DerivationMaria Elisa Lara50% (2)

- 2,4 Pipes&PumpsDokumen226 halaman2,4 Pipes&PumpsShankar Angappan100% (1)

- 1) Unfilled Section:: ForgingDokumen1 halaman1) Unfilled Section:: ForgingdillipBelum ada peringkat

- Knife Gate Valve Testing ProceduresDokumen2 halamanKnife Gate Valve Testing ProceduresmehtahemalBelum ada peringkat

- Wps GT 9b Cvn90 Rev 1 PDFDokumen6 halamanWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniBelum ada peringkat

- Bearing Fits PDFDokumen9 halamanBearing Fits PDFMujahidin AhmadBelum ada peringkat

- Quality Control in Welding Repair of Pelton RunnerDokumen8 halamanQuality Control in Welding Repair of Pelton RunnerDheeraj ThakurBelum ada peringkat

- Lloyd S Register Sec. III 2015 Edition OverviewDokumen23 halamanLloyd S Register Sec. III 2015 Edition OverviewYoshua PortugalBelum ada peringkat

- Cut Steel With Flying ShearsDokumen4 halamanCut Steel With Flying Shearsrazen_in0% (1)

- SCC Screw Lift 289B LDokumen12 halamanSCC Screw Lift 289B LJuan Carlos RBelum ada peringkat

- Texsteam-Ñ Bomba QuímicaDokumen8 halamanTexsteam-Ñ Bomba QuímicarivomarBelum ada peringkat

- PTFE Design HandbookDokumen16 halamanPTFE Design HandbookOscar CruzBelum ada peringkat

- Ball Screw CalculatorDokumen60 halamanBall Screw Calculatorمنير بوزيدBelum ada peringkat

- Triple OffsetyButerfly ValveDokumen2 halamanTriple OffsetyButerfly ValveMuhammad RidwanBelum ada peringkat

- Why Triple Offset The Benefits of Triple Offset Butterfly ValvesDokumen2 halamanWhy Triple Offset The Benefits of Triple Offset Butterfly Valvesmtrj59Belum ada peringkat

- Matrix Material SelectionDokumen3 halamanMatrix Material SelectionDevendra BangarBelum ada peringkat

- Packing 111Dokumen45 halamanPacking 111Devendra BangarBelum ada peringkat

- Introduction to Mechatronics and Measurement SystemsDokumen1 halamanIntroduction to Mechatronics and Measurement SystemsDevendra BangarBelum ada peringkat

- packing length formula and installation guideDokumen2 halamanpacking length formula and installation guideDevendra BangarBelum ada peringkat

- Waste ZZXZDokumen1.719 halamanWaste ZZXZDevendra BangarBelum ada peringkat

- SdadgDokumen13 halamanSdadgDevendra BangarBelum ada peringkat

- Chapter4 Allowable StresseDokumen26 halamanChapter4 Allowable StresseDevendra BangarBelum ada peringkat

- Valve AttributesDokumen4 halamanValve AttributesDevendra BangarBelum ada peringkat

- TiN Coating Best for Valves in Severe ApplicationsDokumen1.635 halamanTiN Coating Best for Valves in Severe ApplicationsDevendra BangarBelum ada peringkat

- Worthless 1 ADokumen154 halamanWorthless 1 ADevendra BangarBelum ada peringkat

- Waste ZZXASDokumen1.854 halamanWaste ZZXASDevendra BangarBelum ada peringkat

- Waste 1 ASCQ2Dokumen1.584 halamanWaste 1 ASCQ2Devendra BangarBelum ada peringkat

- Waste 1 AXAXDokumen880 halamanWaste 1 AXAXDevendra BangarBelum ada peringkat

- Fire Safe Nickel Aluminium Bronze ValvesDokumen51 halamanFire Safe Nickel Aluminium Bronze ValvesDevendra BangarBelum ada peringkat

- Waste 10Dokumen479 halamanWaste 10Devendra BangarBelum ada peringkat

- Waste 4Dokumen45 halamanWaste 4Devendra BangarBelum ada peringkat

- Waste 10Dokumen424 halamanWaste 10Devendra BangarBelum ada peringkat

- Worthless 99Dokumen43 halamanWorthless 99Devendra BangarBelum ada peringkat

- Worthless 99999Dokumen47 halamanWorthless 99999Devendra BangarBelum ada peringkat

- Worthless 1Dokumen285 halamanWorthless 1Devendra BangarBelum ada peringkat

- Waste 4Dokumen47 halamanWaste 4Devendra BangarBelum ada peringkat

- The Cryogenic Valve: Why Use Triple Offset Technology?Dokumen40 halamanThe Cryogenic Valve: Why Use Triple Offset Technology?Devendra BangarBelum ada peringkat

- Fire-Safe Triple Offset Butterfly ValveDokumen22 halamanFire-Safe Triple Offset Butterfly ValveDevendra BangarBelum ada peringkat

- Nothing 2Dokumen7 halamanNothing 2Devendra BangarBelum ada peringkat

- Hobbs Tobv NewsDokumen9 halamanHobbs Tobv NewsDevendra BangarBelum ada peringkat

- Valve Vala NewsDokumen2 halamanValve Vala NewsDevendra BangarBelum ada peringkat

- HOON TobvDokumen16 halamanHOON TobvDevendra BangarBelum ada peringkat

- Fig. 292 ® Gate Valve: Also Available in PN16Dokumen2 halamanFig. 292 ® Gate Valve: Also Available in PN16TamBelum ada peringkat

- Block Diagram For Normal Stop & Emergency Stop of Level 123Dokumen1 halamanBlock Diagram For Normal Stop & Emergency Stop of Level 123nguyen rinBelum ada peringkat

- Pce Ps0474 Pt6a 67d Spec Sheet 9may2017Dokumen2 halamanPce Ps0474 Pt6a 67d Spec Sheet 9may2017Luz Analía Valdez CandiaBelum ada peringkat

- Data Sheet For Barred Tee 010719 PDFDokumen1 halamanData Sheet For Barred Tee 010719 PDFkandraBelum ada peringkat

- CE6451-Fluid Mechanics and MachineryDokumen13 halamanCE6451-Fluid Mechanics and MachineryGracia StephenBelum ada peringkat

- Flow Control Equipment: Gate ValveDokumen1 halamanFlow Control Equipment: Gate ValvesullamsBelum ada peringkat

- Painting Breakdown Surface AreaDokumen6 halamanPainting Breakdown Surface AreaMohd FadzleBelum ada peringkat

- Chapter-6 Fans and BlowersDokumen62 halamanChapter-6 Fans and Blowersye htutkyawme100% (1)

- FPC Unit 1Dokumen28 halamanFPC Unit 1Ravi MishraBelum ada peringkat

- Pipelines InspectionDokumen4 halamanPipelines InspectionSubasis RayBelum ada peringkat

- Pru ScheduleDokumen7 halamanPru ScheduleimranBelum ada peringkat

- APPLICATIONS OF BERNOULLI'S EQUATIONDokumen23 halamanAPPLICATIONS OF BERNOULLI'S EQUATIONRahul ChandrawarBelum ada peringkat

- Hydraulic Valves GuideDokumen60 halamanHydraulic Valves GuideAyenewe mBelum ada peringkat

- Analytical Prediction of Turbocharger Compressor PerformanceDokumen91 halamanAnalytical Prediction of Turbocharger Compressor PerformanceEric21Belum ada peringkat

- Variflex 200Dokumen1 halamanVariflex 200andri putrantoBelum ada peringkat

- Submittal Data Information Submittal Data Information: Plus Two Multi-Purpose Valve Plus Two Multi-Purpose ValveDokumen1 halamanSubmittal Data Information Submittal Data Information: Plus Two Multi-Purpose Valve Plus Two Multi-Purpose ValveRaul RamirezBelum ada peringkat

- LMI Series AA-B-C-E-J-P Metering Pumps ManualDokumen44 halamanLMI Series AA-B-C-E-J-P Metering Pumps ManualShesharam ChouhanBelum ada peringkat

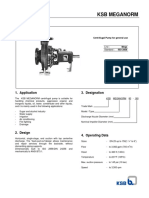

- Ms Meganorm A2742 8e 3 PDFDokumen19 halamanMs Meganorm A2742 8e 3 PDFiamsam869Belum ada peringkat

- Table BrenchDokumen11 halamanTable BrenchLuis GonzalezBelum ada peringkat