FS Manual

Diunggah oleh

Fred Johonatan Lopez CoaquiraDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

FS Manual

Diunggah oleh

Fred Johonatan Lopez CoaquiraHak Cipta:

Format Tersedia

CONVEYOR COMPONENTS COMPANY

130 Seltzer Road, PO Box 167 Croswell, MI 48422 USA PHONE: (810) 679-4211 TOLL FREE (800) 233-3233 FAX: (810) 679-4510 Email: info@conveyorcomponents.com http:\\www.conveyorcomponents.com

MODEL FS FLOW CONTROL FOR BULK MATERIALS A. HOW IT WORKS The Model FS Flow Control is designed to produce a signal if the flow of material at any critical point is interrupted. This signal can then be used to correct the difficulty and/or warn the operator. Several controls can be used, each one placed at critical points along the conveying system. A continuous flow of material past the control holds the paddle-shaftcounterweight assembly out of the actuated position. If the flow stops, then the paddle is allowed to pivot and then actuate the micro-switch. When this occurs, a signal is generated to start or stop supporting machinery, or to activate visual or audible alarm systems. The Model FS control is also fully adjustable. The paddle and counterweight assemblies can be positioned at various points along the shaft and rotated to any angular position. The shaft itself can be adjusted laterally. Inside, the actuating cams can be rotated so that the micro-switch actuation will occur at pre-determined points. This versatile control can be mounted on all types of conveyors and feeders; in discharge openings of bins, bunkers, or hoppers; in angled and vertical chutes; or in discharge chutes of any configuration. It is available with either a cast-iron or aluminum housing, and in standard or explosion proof models. The paddle and shaft are both made of stainless steel. B. INSTALLATION INSTRUCTIONS 1. A cam (or two cams on the two micro-switch unit) on the shaft actuates the micro-switch. Loosening the cam(s) and the shaft locking collars permits the shaft to be moved laterally in the casting. The paddle sensor and counterweight can be positioned anywhere on the shaft. Use the 3/32 allen wrench supplied with the control. Refer to figure 3. 2. The housing can be mounted in any position. The counterweight permits paddle operation in any position from vertical to horizontal. Refer to figure 4 for dimensions. 3. After mounting the unit, the cover should be removed to adjust the cam on the shaft to give micro-switch actuation at the desired point. Both the paddle and the counterweight may have to be loosened, rotated and re-tightened on the shaft to achieve proper actuation. Refer to figure 3.

I0210001revB.DOC

Copyright Conveyor Components, Co. 2003

1 OF 4

4. The paddle or counterweight may be easily field altered to suit the application. 5. Field wiring must meet or exceed the requirements of the National Electrical Code and any other agency or authority having jurisdiction over the installation. Refer to figures 1 through 3 for wiring information. C. TECHNICAL INFORMATON 1. Individual Switch Contact Ratings: SPDT switches: 20 Amps, 125/250/480 VAC 10 Amps, 125 VAC Inductive 1 hp, 125 VAC 2 hp, 250 VAC Amp, 125 VDC Amp, 250 VDC DPDT switches: 15 Amps, 125/250 VAC 3/4 hp, 125 VAC 1 1/2 hp, 250 VAC N/A N/A

2. Conduit opening: One NPT standard opening is built-in. 3. Actuating System: Paddle sensor is stainless steel with stainless steel shaft with zinc plated steel counterweight. 4. External Hardware: stainless steel 5. Operating Temperature Range: -40F to 150F

I0210001revB.DOC

Copyright Conveyor Components, Co. 2003

2 OF 4

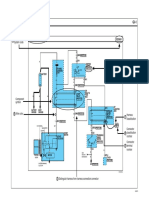

D. WIRING

Figure 1: SPDT 2-Switch Schematic

Figure 2: DPDT 2-Switch Schematic

Figure 3: Terminal Identification (SPDT)

Figure 4: Terminal Identification (DPDT)

To properly wire to the micro-switches on the model FS, route incoming wires under the shaft and micro-switches to the rear right side of the switches. Avoid contact with the micro-switch levers and other moving parts inside enclosure. Figure 5: Wire Routing, Model FS-2 shown

I0210001revB.DOC

Copyright Conveyor Components, Co. 2003

3 OF 4

E. DIMENSIONS Figure 6: Dimensions and Mounting, Model FS-2 shown

I0210001revB.DOC

Copyright Conveyor Components, Co. 2003

4 OF 4

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- 2006 Hyundai Santa FE Electrical Wiring Diagram PDFDokumen233 halaman2006 Hyundai Santa FE Electrical Wiring Diagram PDFEnil Perez Rivera78% (27)

- TDI - Full Cave Diver Course: TDI Instructor Manual Part 2 - Diver Standards Date: 12/31/2009 Revision: 10.0Dokumen5 halamanTDI - Full Cave Diver Course: TDI Instructor Manual Part 2 - Diver Standards Date: 12/31/2009 Revision: 10.0BraulioBelum ada peringkat

- Manual BCM44 Version 26Dokumen13 halamanManual BCM44 Version 26juanmalegre100% (2)

- Simplex 4007ES Basic Programming WorkbookDokumen51 halamanSimplex 4007ES Basic Programming WorkbookFred Johonatan Lopez CoaquiraBelum ada peringkat

- Cautions, Warnings, and Regulatory Information: NAC Card Installation GuideDokumen14 halamanCautions, Warnings, and Regulatory Information: NAC Card Installation GuideFred Johonatan Lopez CoaquiraBelum ada peringkat

- 4007ES CPU and Display Board 4007ES IDNAC PSU (Addressable) : Jumper Purpose Connector PurposeDokumen2 halaman4007ES CPU and Display Board 4007ES IDNAC PSU (Addressable) : Jumper Purpose Connector PurposeFred Johonatan Lopez CoaquiraBelum ada peringkat

- Turck - Bi5-G18-Y1xDokumen4 halamanTurck - Bi5-G18-Y1xFred Johonatan Lopez CoaquiraBelum ada peringkat

- NG5021Dokumen2 halamanNG5021Fred Johonatan Lopez CoaquiraBelum ada peringkat

- NLLK FLURESCENTE Ex Linear EmergencyDokumen4 halamanNLLK FLURESCENTE Ex Linear EmergencyJOSEBelum ada peringkat

- Nikon Micro-Macro LensDokumen71 halamanNikon Micro-Macro LensEditor: Bora ERESICI100% (6)

- Types of Coaxial CableDokumen12 halamanTypes of Coaxial CableJanryLibrandoBelum ada peringkat

- Din 2441-78 Steel Tubes Heaby Weight For Suitable For ScrewingDokumen3 halamanDin 2441-78 Steel Tubes Heaby Weight For Suitable For ScrewingVadimBelum ada peringkat

- With ASME ' U ' StampDokumen4 halamanWith ASME ' U ' StampOSWALINFRA HEDBelum ada peringkat

- Car Mechatronics Business Unit: Shinano Kenshi Co., LTDDokumen86 halamanCar Mechatronics Business Unit: Shinano Kenshi Co., LTDcristino_djBelum ada peringkat

- Arduino KitDokumen9 halamanArduino KitGhulam UddinBelum ada peringkat

- kbk-900 Eng PDFDokumen2 halamankbk-900 Eng PDFVandana Aggarwal100% (1)

- Datasheet of DS 2CE10KF0T PFS - 20210510Dokumen4 halamanDatasheet of DS 2CE10KF0T PFS - 20210510amalkrishnan.achuBelum ada peringkat

- Extra High Voltage System Standard PDFDokumen41 halamanExtra High Voltage System Standard PDFyoussef essamBelum ada peringkat

- Al-Ain Mall - Mos 17-01-2023Dokumen3 halamanAl-Ain Mall - Mos 17-01-2023Abdul RaheemBelum ada peringkat

- Physics Practical Class 12 Full Wave Rectifier With GraphicsDokumen13 halamanPhysics Practical Class 12 Full Wave Rectifier With GraphicsSuraj Official100% (4)

- تقرير ثرمو داينمكDokumen7 halamanتقرير ثرمو داينمكHe DoBelum ada peringkat

- Boonton Manual 260A Q MeterDokumen36 halamanBoonton Manual 260A Q MeterrmansBelum ada peringkat

- Parts For Triple Duty Valves - Reduced Port: Separately On 3" Through 12" Valves. You Must Order The Disc AssemblyDokumen1 halamanParts For Triple Duty Valves - Reduced Port: Separately On 3" Through 12" Valves. You Must Order The Disc AssemblyManolo PonceBelum ada peringkat

- AC Dimmer: Components RequiredDokumen8 halamanAC Dimmer: Components Requiredovais123Belum ada peringkat

- Maual Solar Swimming Pool HEatingDokumen14 halamanMaual Solar Swimming Pool HEatingMubasherBelum ada peringkat

- SC RF - Safety Edge ReceiverDokumen8 halamanSC RF - Safety Edge ReceiverDmitriiȘtirbuBelum ada peringkat

- RT22-677 Cooking 592 E-84 E-85 ErrorDokumen2 halamanRT22-677 Cooking 592 E-84 E-85 ErrorpasantitoBelum ada peringkat

- LEVALIGN Expert - 2 Page Flyer - DOC 06.300 - 17 03 11 - enDokumen2 halamanLEVALIGN Expert - 2 Page Flyer - DOC 06.300 - 17 03 11 - enplueluvBelum ada peringkat

- US ARMY RoboticDokumen12 halamanUS ARMY RoboticGabriel OnofreiBelum ada peringkat

- Ebara 3m DatasheetDokumen2 halamanEbara 3m DatasheetIkechukwu UzoBelum ada peringkat

- Section09CameraSupports PDFDokumen65 halamanSection09CameraSupports PDFLucas DelgadoBelum ada peringkat

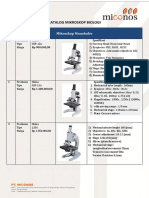

- Katalog MikroskopDokumen14 halamanKatalog MikroskopDewi Endar YatunBelum ada peringkat

- Eclipse ManualDokumen10 halamanEclipse ManualgiancarlohoneyBelum ada peringkat

- Sri Balaji Enterprises - Just Another Wordpress SiteDokumen3 halamanSri Balaji Enterprises - Just Another Wordpress Sitesaurabhjerps231221Belum ada peringkat

- Underhive ArmoryDokumen22 halamanUnderhive ArmoryCody SkrineBelum ada peringkat