Mcs 2013 Feore

Diunggah oleh

Gaston CasapiaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mcs 2013 Feore

Diunggah oleh

Gaston CasapiaHak Cipta:

Format Tersedia

84

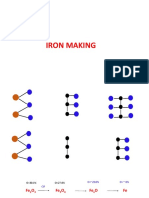

IRON ORE1

(Data in million metric tons of usable ore unless otherwise noted) Domestic Production and Use: In 2012, mines in Michigan and Minnesota shipped 97% of the usable ore produced in the United States, with an estimated value of $6.0 billion. Thirteen iron ore mines (11 open pits, 1 reclamation operation, and 1 dredging operation), 9 concentration plants, and 9 pelletizing plants operated during the year. Almost all ore was concentrated before shipment. Eight of the mines operated by three companies accounted for virtually all of the production. The United States was estimated to have produced and consumed 2% of the worlds iron ore output. Salient StatisticsUnited States: Production, usable Shipments Imports for consumption Exports Consumption: 3 Reported (ore and total agglomerate) e Apparent 4 Price, U.S. dollars per metric ton Stocks, mine, dock, and consuming plant, yearend, excluding byproduct ore Employment, mine, concentrating and pelletizing plant, quarterly average, number 5 Net import reliance as a percentage of apparent consumption (iron in ore) Recycling: None (see Iron and Steel Scrap section). Import Sources (200811): Canada, 76%; Brazil, 7%; Russia, 5%; Chile, 4%; and other, 8%. Tariff: Item Concentrates Coarse ores Fine ores Pellets Briquettes Sinter Roasted Iron Pyrites Number 2601.11.0030 2601.11.0060 2601.11.0090 2601.12.0030 2601.12.0060 2601.12.0090 2601.20.0000 Normal Trade Relations 123112 Free. Free. Free. Free. Free. Free. Free. 2008 53.6 53.6 9.2 11.1 51.9 49.7 70.43 4.07 4,770 E 2009 26.7 27.6 3.9 3.9 31.0 25.7 92.76 5.06 3,530 E 2010 49.9 50.6 6.4 10.0 42.3 48.0 98.79 3.47 4,780 E 2011 54.7 55.6 5.3 11.1 46.3 49.1 99.45 3.26 5,270 E 2012 53.2 54.1 5.2 11.8 45.0 49.6 101.00 3.50 5,290 E

e 2

Depletion Allowance: 15% (Domestic), 14% (Foreign). Government Stockpile: None. Events, Trends, and Issues: U.S. iron ore production was slightly less in 2012 owing to reduced steel consumption and destocking. In Cedar City, UT, the former Mountain Lion Mine returned to production and was renamed the Iron Mountain Project, selling crushed iron ore to China under contract. Construction of an iron nugget plant, planned for production in Michigans Upper Peninsula, was determined to be not commercially viable. However, after closing down in June $60 million was invested in the Empire Mine, bringing it back into production in August. It was expected to remain in operation until at least 2015. Following a 30% decrease in the worldwide price for iron ore fines sold in European and Asian markets in the first three quarters of 2012, owing to an increase in global iron ore production and project development, the price stabilized in the fourth quarter of 2012. Major iron-ore-mining companies continued to reinvest profits in mine development, but increases in production capacity outstripped expected consumption throughout early 2012, as economic growth that had been dominated by China slowed. Declining demand in China led to drops in spot prices for iron ore, and the delay, cancellation, or reorganization of major production improvement projects worldwide. Global prices declined steadily since 2011, and in September 2012, they reached the lowest benchmark prices since 2009.

Prepared by Christopher A. Tuck [(703) 6484912, ctuck@usgs.gov]

85

IRON ORE

Slight price rebounds in the fourth quarter were expected to be maintained through yearend of 2012 because of supply constraints from decreased exports; 1.6 million tons of output losses from worker strikes at Sishen Mine, South Africa; 1 million tons of shipment losses resulting from protests at Carajas Mine, Brazil: and 5 million tons per month of export losses owing to mining bans in Goa, India. This decline in supply led to prices increasing by approximately 30% in October 2012. It was estimated that in 2012, China imported more than 60% of the worlds total iron ore trade, the Republic of Korea reported increases in imports of 15%, and Japans imports fell by 4.4%. International iron ore imports are indicators of iron ore consumption, demonstrating that iron ore consumption in Asia is currently a key factor for the expansion of the international iron ore industry. Chinese companies are investing in all phases of mining and production, to include the takeover of a major iron ore producer in South Africa, for increased production of higher grade ore by Chinese mining groups. Despite overall weak iron ore prices, several major Australian producers planned to continue expansions of mines and shipping ports. World Mine Production and Reserves: The mine production estimate for China is based on crude ore, rather than usable ore, which is reported for the other countries. Iron ore reserve estimates for Kazakhstan and Ukraine have been revised based on new information from those countries. Mine production e 2011 2012 55 53 488 525 373 375 34 40 1,330 1,300 240 245 28 28 25 25 12 12 15 13 100 100 60 61 25 25 81 81 17 20 59 61 2,940 3,000 Crude ore 6,900 35,000 29,000 6,300 23,000 7,000 2,500 2,500 1,100 700 25,000 1,000 3,500 7 6,500 4,000 12,000 170,000 Reserves Iron content 2,100 17,000 16,000 2,300 7,200 4,500 1,400 900 700 400 14,000 650 2,200 7 2,300 2,400 6,000 80,000

6

United States Australia Brazil Canada China India Iran Kazakhstan Mauritania Mexico Russia South Africa Sweden Ukraine Venezuela Other countries World total (rounded)

World Resources: U.S. resources are estimated to be about 27 billion tons of iron contained within 110 billion tons of ore. U.S. resources are mainly low-grade taconite-type ores from the Lake Superior district that require beneficiation and agglomeration prior to commercial use. World resources are estimated to exceed 230 billion tons of iron contained within greater than 800 billion tons of crude ore. Substitutes: The only source of primary iron is iron ore, used directly as lump ore or converted to briquettes, concentrates, pellets, or sinter. At some blast furnace operations, ferrous scrap may constitute as much as 7% of the blast furnace feedstock. Scrap is extensively used in steelmaking in electric arc furnaces and in iron and steel foundries, but scrap availability can be an issue. Technological advancements were made, which allow hematite to be recovered from tailings basins and pelletized.

e 1

Estimated. E Net exporter. See also Iron and Steel and Iron and Steel Scrap. 2 Agglomerates, concentrates, direct-shipping ore, and byproduct ore for consumption. 3 Includes weight of lime, flue dust, and other additives in sinter and pellets for blast furnaces. 4 Estimated from reported value of ore at mines. 5 Defined as imports exports + adjustments for Government and industry stock changes. 6 See Appendix C for resource/reserve definitions and information concerning data sources. 7 For Ukraine, reserves consist of the A+B categories of the former Soviet Unions reserves classification system.

U.S. Geological Survey, Mineral Commodity Summaries, January 2013

Anda mungkin juga menyukai

- Precios Gps y LaptopDokumen2 halamanPrecios Gps y LaptopGaston CasapiaBelum ada peringkat

- Tributos Sunat EmpresaDokumen14 halamanTributos Sunat EmpresaGaston CasapiaBelum ada peringkat

- Competitividad Perú 2014-2015Dokumen2 halamanCompetitividad Perú 2014-2015Gaston CasapiaBelum ada peringkat

- Competitividad Perú 2014-2015Dokumen2 halamanCompetitividad Perú 2014-2015Gaston CasapiaBelum ada peringkat

- WEF Global Risks Report 2012Dokumen64 halamanWEF Global Risks Report 2012leithvanonselenBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Historical Structural Steelwork HandbookDokumen76 halamanHistorical Structural Steelwork Handbookjimmyoftheworld100% (1)

- Session-1-Introduction and Coke MakingDokumen51 halamanSession-1-Introduction and Coke MakingHeroBelum ada peringkat

- Comparison of Sinter and Pellet Usage in An Integrated Steel PlantDokumen11 halamanComparison of Sinter and Pellet Usage in An Integrated Steel PlantRam Babu RamzzBelum ada peringkat

- Late medieval iron making and the quality of armourDokumen45 halamanLate medieval iron making and the quality of armourEdvards Puciriuss100% (1)

- Unit 9-Industrial Inorganic Chemistry (Notes)Dokumen13 halamanUnit 9-Industrial Inorganic Chemistry (Notes)Maryam RehanBelum ada peringkat

- BUKU Kinetika Reduksi OreDokumen213 halamanBUKU Kinetika Reduksi OreGalih SenopatiBelum ada peringkat

- Digital Manufacturing in India: Towards Greener SteelDokumen24 halamanDigital Manufacturing in India: Towards Greener SteelRavi BabuBelum ada peringkat

- Project Reoprt On JSW SteelsDokumen30 halamanProject Reoprt On JSW SteelsSakthi Krishnan100% (1)

- Extracting IronDokumen5 halamanExtracting IronThunderBelum ada peringkat

- Trial Number ZeroDokumen12 halamanTrial Number ZeroLeandro DijonBelum ada peringkat

- TATA Annual Report 2011 12Dokumen252 halamanTATA Annual Report 2011 12Uhrin ImreBelum ada peringkat

- Ironmaking Process AlternativeDokumen153 halamanIronmaking Process AlternativesintaBelum ada peringkat

- 16.1.1 Furnaces For Roasting and Calcining: 16.1.1.1 Rotary KilnsDokumen66 halaman16.1.1 Furnaces For Roasting and Calcining: 16.1.1.1 Rotary Kilnshisem100% (1)

- Siri Project On Working-Capital FinalDokumen57 halamanSiri Project On Working-Capital FinalBillu GurunadhamBelum ada peringkat

- CNC Gear Project ReportDokumen64 halamanCNC Gear Project ReportManikanta Naidu100% (1)

- TREATMENT OF SLAG TO PRODUCE A LIGHT FOAM-LIKE STRUCTUREDokumen6 halamanTREATMENT OF SLAG TO PRODUCE A LIGHT FOAM-LIKE STRUCTUREandresBelum ada peringkat

- Maintaining Water Cooling in Finishing MillDokumen52 halamanMaintaining Water Cooling in Finishing MillRoshan Joe MathewBelum ada peringkat

- History of The Steel Industry in The Port Talbot Area 1900-1988 (S Parry 2011)Dokumen359 halamanHistory of The Steel Industry in The Port Talbot Area 1900-1988 (S Parry 2011)rees1098Belum ada peringkat

- Blockflow Diagram Smelter Nikel LateritDokumen2 halamanBlockflow Diagram Smelter Nikel LateritNur PertiwiBelum ada peringkat

- Gpoe 2022 PDFDokumen341 halamanGpoe 2022 PDFApper kumariBelum ada peringkat

- M6 Materials and Hardware PDFDokumen495 halamanM6 Materials and Hardware PDFRichard StanleyBelum ada peringkat

- Energy Conservation Measures in Pusher-Type Reheating Furnace Through Modifications and ModernizationDokumen7 halamanEnergy Conservation Measures in Pusher-Type Reheating Furnace Through Modifications and ModernizationNoman AliBelum ada peringkat

- IMZ - Institute For Ferrous MetallurgyDokumen1 halamanIMZ - Institute For Ferrous Metallurgyecosta_32Belum ada peringkat

- Pig IronDokumen42 halamanPig IronWajih HaiderBelum ada peringkat

- Hos Pet Steels LimitedDokumen116 halamanHos Pet Steels LimitedArvind GargBelum ada peringkat

- H3PO4Dokumen14 halamanH3PO4Muhammad UsmanBelum ada peringkat

- Sintering Plant at A GlanceDokumen72 halamanSintering Plant at A GlanceShailesh Kumar100% (1)

- Iron Ore Pellets Reduction by Pet CokeDokumen9 halamanIron Ore Pellets Reduction by Pet CokesrinijaganBelum ada peringkat

- Iron Making PPT Notes 2Dokumen49 halamanIron Making PPT Notes 2SHUBHAM VERMABelum ada peringkat

- Blast Furnace Ironmaking Volume OneDokumen511 halamanBlast Furnace Ironmaking Volume OneNoah Ryder82% (11)