Soil Paper PDF

Diunggah oleh

Ala ThajilJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Soil Paper PDF

Diunggah oleh

Ala ThajilHak Cipta:

Format Tersedia

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp.

428 - 440,2005

PAVEMENT PERFORMANCE MODEL FOR

FEDERAL ROADS

Lt Col Abdul Hamid Mohd Isa, Dadang Mohamed Ma'soem

Research Associate Lecturer

34, Jalan Intan Baiduri 4D Department of Civil Engineering

Taman Intan Baiduri Faculty of Engineering

52100 Kuala Lumpur University Putra Malaysia

Malaysia 43400 Serdang, Selangor

Fax: 603-2071 3465 Malaysia

E-mail: abdhamidisa@hotmail.com Fax: 603-8943 2509

E-mail: dadang@eng.upm.edu.my

Law Tiek Hwa

Lecturer

Department of Civil Engineering

Faculty of Engineering

University Putra Malaysia

43400 Serdang, Selangor

Malaysia

Fax: 603-8943 2509

E-mail: lawtiek@putra.edu.my

Abstract: Malaysia has a matured flexible pavement road network owned by the

public sector called the Federal Road. The 14,757 .KIn road networks are providing

excellent service to road users for interstate movement. The industrialisation process

of the country demands for more movements at higher load to transport products to

their destination within the country sites. Over the years, The Malaysian Government

through J.K.R (The Public Works Department) has spent huge amount of money to

ensure the roads are in good operating condition. In year 1998 about RM 139 mil

(USD 36.5 mil) is being allocated for the maintenance of the Federal Roads, the

allocated fund is very much below than what is required (RM 369mi1) to maintain the

Federal Roads (www.piarc./cpcjr) thus prioritisation become crucial. Future

performance of the pavement is required to anticipate maintenance strategy to prevent

further deterioration, as it would cost more if it were not repaired at the right time.

Pavement performance modelling is an important tool used by pavement managers in

decision making in prioritisation and budgeting for maintenance work. The aim of

this study is to develop pavement performance models for Federal Roads using

available data provided by J.K.R.

Keywords: Flexible Pavement Performance Models, Rutting

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440,2005

1. INTRODUCTION

Pavement deterioration process is complex and involves not only structural fatigue

but also involves many functional distresses of pavement. It result from the

interaction between traffic, climate, material and time. Deterioration is used to

represent the change in pavement performance overtime. The ability of the road to

satisfy the demands of traffic and environment over its design life is referred to as

performance. Due to the great complexity of the road deterioration process,

performance models are the best approximate predictors of expected conditions.

There are many parameters that need to be acquired to successfully predict the rate of

pavement deterioration. Among others is annual average daily traffic (AADT),

percent of trucks, drainage, pavement thickness, pavement strength in term of

structural number (SN) or CBR value and mix design parameters.

The objective of this study is to establish simple practicable pavement performance

model for network level of the Malaysian Federal Road where rutting is the focus of

the measurement. The model shall incorporate relevant variables such as pavement

condition, pavement strength, traffic loading and pavement age. Statistical analysis by

mean of multiple linear regressions were conducted to test and examine the data as

well as to develop the model.

1.1 Rutting and Possible Influencing Factors

Mix Design

Parameters

Pavement

Layers

Thickness

Pavement

Roughness

Traffic

Loading

Pavement

Strength

:>

Rutting

Figure 1: Among Factors Influencing Pavement Rutting in Relation to Modelling

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

1.1.1 Rutting

One of the most common distresses on flexible pavement is surface rutting. Rutting is

defined as longitudinal deformation or depression in the wheel paths, which occur

after repeated application of axle loading. It may occur in one or both wheel path of a

lane. It can be categorised as either traffic load associated deformation, wear related

or the combination of both. The causes include traffic load, age of pavement and

deformation of the entire pavement structure or instability in the form of one or more

pavement layers as explained by Figure 1. In engineering term the deformation occur

due to the critical strain experience by the top layer of subgrade as shown in Figure 2.

Rutting make the road surface uneven, patchy and bumpy and subsequently affects

the handling of vehicles which can lead to safety problems. The unit use to measure

rut depth is millimetre (mm) .

Wheel load

Bituminous layer

Compressive strain at the top

of subgrade formation level,

related to permanent

deformation !_f_

z

Granular layer

_

Subgrade

Figure 2: Vertical Critical Strain (E

z

) in Pavement Layers

1.1.2 Mix Design Properties

Mix design properties are important in resisting permanent deformation under traffic

load. In particular, flow and consolidation on hot mix asphalt (HMA) design will

affect the deformation of the pavement surface. Asphalt content that provides stiffer

asphalt cement at higher temperature would be able to improve rutting resistance.

Aggregate type, gradation and shape also affect pavement deformation; for example

cubical and angular with rough surface texture aggregate will contribute to strong

aggregate interlock.

Tensile strain at the

bottom of asphalt,

related to cracking

f

r

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

1.1.3 Pavement Thickness

Pavement layers and its thickness plays very important role in distributing wheel load

to underlying subgrade. More layer or thicker pavement structure would mean least

load being distributed to the subgrade and subsequently reduce vertical critical strain.

1.1.4 Pavement Condition (Roughness)

Present pavement condition state will influence it future performance. As pavement

surface deteriorate over time, one distress condition would add up to another distress

condition if no appropriate action taken to correct the initial condition. This would

lead to more costly maintenance. This paper use pavement roughness as pavement

condition measure in mm/m.

1.1.5 Tramc loading

The magnitude and number of wheel load passes is the main agent to deteriorate the

pavement surface. Heavy and medium trucks normally fitted with large axles would

significantly damage the surface as well as deform the underlying pavement layers

permanently. Normally medium truck loading is used to predict pavement

deterioration and referred as annual average daily traffic (AADT), it is measured in

vehicles per day (vpd).

1.1.6 Pavement Strength

Another significant element that resists permanent pavement deformation is pavement

strength. The pavement can be measured in term of CBR (California Bearing Ratio)

or SN (Structural Number).

2. Data Collection and Sampling

Data are being source from Institut Kerja Raya Malaysia (lKRAM) and JKR, these

data are categories as historical and pavement survey data. Historical data includes

the pavement thickness and pavement strength index while the survey data are traffic

load and pavement condition such as rutting and roughness measurement. Initially it

was the intent to use age of pavement as one of the independent variable; however

data on pavement age was not available.

The data population of this study is sections of the Federal Road in Peninsular

Malaysia. The division of the road sections is entirely depending on J.K.R. Total

sample size gathered from J.K.R was 137 cases out of which 102 for Federal Road

Route I (74.4%),20 for Federal Road Route 8 (14.6%),10 for Federal Road Route 9

(7.3%) and 5 for Federal Road Route 26 (3.7%). Out of these samples, only 42

samples were selected for the further analyses.

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

Table 1: Samples of Data

Ser Section Name Length Rut Depth Roughness MT AADT SN

(Km) (mm) (mm/m) (vpd)

1 001035000-001035999-1 1 9.20 4.37 39846 3.79

- __ - __._ - .0 _ P' __ _ .. _ _ .. .. _ .. __ __ ..

2 001036000-001036999-2 1 5.13 3.02 19923 3.41

-_. _. -_ _'- _ _ _ - P"p - p_ p _ __ A .. _ __

3 001036000-001036999-3 1 6.37 3.52 19923 3.41

..---- -_.- --- --- - --_ .. _.". -- _ -_ ..-- ----_ -_ --_ - -- -_ --- -_ ..

...4.._.9.Q! _. _ ? _.. L .. .._. __ !

5 001122000-001136999-1 15 3.09 1.98 10626 5.69

-_ .. -_ _." - p - p- - _. _ --- ----_ -- -_ .. -_ _ -_ -_ -.

6 001137000-001138999-1 2 4.03 2.73 10626 4.16

................................. _ ---. - -. - . -----. -.. ---. ----_. - ------- -. --------_ --------. -.. ---- '

7 001155000-001156999-1 2 4.83 3.36 10626 3.98

_.. _ _ -_ - _. _ _._ -- --.. -_ -- -_ --_ .. ---_.. -_. _.. - -_ .

8 001157000-001160999-1 4 3.39 2.19 10317 4.97

.- .. _ _ _ - _- _.- _.- --- -_.. __ .- . __ --- _ -- _A. _ _. _ _. __ -._.

9 001197000-001208999-1 12 3.11 1.92 10804 5.32

_ '_. _ .. ' - -_ _ - _ _. _ _ - - _. __ A __ __ __ - _ _ - - _ _. __ _ _. _

10 001270000-001270999-1 1 6.75 2.04 13480 2.95

----- --_ --_.- ---"' .. -- --_.- _ - .. ------- ._-- .-- --- --_._. ------ _ _ -----_ _-----_.. -----_..

11 001318000-001319999-1 2 6.05 2.53 39718 4.20

-_ .. - _ -. -- _- .-_.- _ -.-_._ _. ----_._. -_ -_.- --.. _. ---_._ -. _..

12 001416000-001416999-1 1 5.35 2.29 45631 4.51

_ -. -. -. --_. ---. -.. --------- _.. -- --. --.. ---------. --. -------.. ----------- ------_ -----.. -.

13 001417000-001437999-1 21 3.17 1.84 8729 5.08

.. -_.. _ _ -_ _.. _ _ ..'--_. _.. _. _ -_.. _.. -.. _. -_.. ---- -_._. -- .. _. _ _. -- -_. _.. _.- _..

14 001438000-001441999-1 4 1.96 1.98 8729 5.06

._- -- .-. __ . __ . _. --- .. -_ .. _. _._- --,--- ---_.- ._- _.. _... __ .-..-._-- -- ---------- -_.. _... _- --_.. _.. -. --- ._- ._.

15 001444000-001446999-1 3 2.13 1.87 8729 5.67

.-. --_.. - _.. -.- --_.- - -. -_.- --.. _ ----- ------ -_. ------ --_._. ----------_ .. ------ _.-_. ------- -_ _.

16 001463000-001468999-1 6 3.23 1.44 9284 5.35

_. __ . -_ ... -,_. _.. _.. _... _.... -_. _.'. -.. _ .. ---_.- _.- -. -_ .. -_ ... __ .------- -_._ .. __ ... --- -- _.... ---- _._. -_.- ----

17 001517000-001518999-3 2 3.13 2.16 5621 5.30

---- ---- ----- _...... -- -----_ .... --. ----._- .. _._- -----_ ... -------_._._._. -- ---_.... _.. -.- .. _.- --.-

18 001539000-001539999-2 1 3.18 2.93 6123 7.72

.-.. -_ _ . _ _.- . _. - ---- --_. _.. _. --- .. -.. --- --_ .. --_. _ _.. --. _.. _

19 001539000-001539999-3 1 3.55 3.35 6123 7.72

- _. -_ -.. _.. ---_ _ --. - _ _. - _. _ _. -- _. _.. _-_ --- _. --- ----. _.. -_.. ----..-_ - _..

20 001580000-001581999-1 2 6.26 3.08 24135 4.87

._ .... _.. ..-- ... ---_. -_... _.. --.. _. _... _.. _. _.. --_ ... _. --_. -- _. _.. _. --_. _... _... -..._.. -_._ .....------- _...

21 001610000-001611999-2 2 10.13 2.65 21618 3.51

, .----... -.. -. -------........ -_. --- .. _.. .. --.. ----. -. - .-------- ...-----------.. ---. -- -... ---. ----. -.. -

22 001620300-001621999-2 2 4.18 2.20 10001 6.49

-_. -- .. - _ - -_ _ . _- ._ _ - -_ _.---._-_ _----- -_._-- -- - _._._- ._. - - -- --_oo ..

23 001623000-001633999-1 11 5.14 2.75 17681 4.74

----_ oo - . _._ _. - - _ .. __ .. _._ - __ A

24 001626000-001628999-2 3 4.23 2.27 8841 3.73

._ -._ .. _ _ - -'. -- - - -- - _.- - _oo _. _. - - - __ - _ . .. - - - - _ - - - __ - - - - - - __ -

25 001674000-001677999-1 4 4.46 2.74 12166 5.73

.. --- --_.._...-_._- -...... _. _.... -. ---_. -_ ..... ---... _. --_ .... _. -.. --- --- -. _. -----_.... ------_ .. ---- -----_. _.

26 001853000-001855999-2 3 4.89 4.37 15308 5.46

- - - .. - oo. - _. - _. - _.. - _ - - - _ _ - - - - - - - - _ _. - - - - - - - __ .. - - - - - - - - - - - - - - - - - - - ... - - - - - - - - .. - - _

27 001856000-001857999-3 2 5.85 3.02 15308 4.39

.-_._ .. _... _..--- _A. _.... _.- __ --_. - - ..... -._.. _- ..... - -- __ " - ... _

28 008000000-008004999-1 5 3.76 3.12 9637 5.99

-_ ..... -- .. ---- --- -_ ... _. -- -- _ ... _.-. ----- ----_... _. ----- _._. --- --- ----- ---- ---- _... -.. -------_.- ---- -_..

29 008015000-008040999-1 26 5.00 3.16 9291 4.51

- - _. _ - ..... _. _ -. - -_ oo __ _ _ - __ _ __ .. __ - __ .. __ _ - _ _. __ - _. _ _ - _ .. _ - _

30 008043000-008045999-1 3 3.59 3.03 5817 6.25

.. _.... ---_.'._ ..._. -- --_ .. --- -. --- _..._-_ ..... --- _.... -_. -.- ----_. _._-- ---- .. --_ .... ---_. _.. _.- ------. -_ ....

31 008115000-008118999-1 4 2.56 2.03 5485 6.85

._. -- - -_. -_. _ -'._-- - --,- _ .. _. _ __ - --- -- --------- --- - _.- - -- _. - -_. -. - A _. __ - ._. __ ..

32 008119000-008158999-1 40 3.35 1.85 5485 5.63

_. - - -'- _ _ _. - - _ _ -_.- - - -_.- -_._ ... -- - - - - -_ .. - _ _. - - - --_ - _. - -- - - - _ _. - - - -- --- - -_. - - -- - -- _oo

_._-

33

_ _

008305144-008306999-1

--_. _. --_. __ .. - -_...... _oo- __ _

2

_ - _ .. _ _

2.08

_ .... A. _A. -- _._- _.__ . - __

6508

- __

2.06

--- .... __ .

7.56

..

34 008307877-008311999-1 5 3.13 1.98 6508 7.56

-- - -- - - - --,- - -- - -_.- - -- - _ _oo. ._. _. oo __ - - __ - _ _ - _._ - _. __ - - - - - - _ __ - - - __

35 008312000-008331999-1 20 3.01 1.97 6508 7.56

-- --- ._ --. --- .. _.. -- _.. --_.. _.'.. _.. -.. _.. ---_ .. -_ .. _- --- -_ .. --_ -- -.-- ---.. --. __ . -_ -- .. -. -_ ..

36 008332000-008339999-1 8 3.69 1.82 13606 7.56

.- _ _. --- -- - .... ---_. _ - .. - .. _.'- -_ - _. -- _. -_ .. _. _A .... _ _ - _ - __ _ - - - __ _. __ __ ._.

37 009045000-009046999-1 2 4.98 2.36 13995 3.40

-- - --_ _. _.oo. __ - _ oo _ - _. __ .. - _. oo ._. __ _

38 009047000-009052999-1 6 6.42 3.01 13027 1.93

- - - - -- - - -. _oooo. _ _ _ - - __ _. __ - __ - __ - __ ._ - __ - - - - _ _. __ - __ _. __ - - - _. _

- .

39

..... _

009053000-009054999-1

.. -- - _ _OO'. __ . - _. _..- _... __ - _._. _. - - - . __

2

- - - _..

5.75

.... __ _

13027

__ .. . ... - -

2.47

..... _.... _- _. ._. _. -

2.56

_A._..

40 009058000-009059999-1 2 5.60 2.74 13027 2.62

._ _. _oo _ _ - - _ _oo _ _ oo _ - - - __ __ __ __ - - - oo - _ - _ .. - _ _oo

__ _.. _? __ ._. _..1. E49.._.._.?:Q!.

42 026000100-026004999-3 5 2.57 1.49 5740 7.35

of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

3. Developing The Pavement Performance Models

3.1 Regression Analyses and Statistical Tests

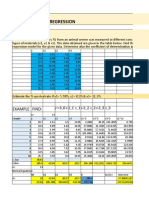

Several regression analyses were conducted on to the data set. The initial analyses are

meant to see the response of among variables and statistical tests were performed on

the developed models namely the coefficient of determinant and level of significant.

The main tests conducted to validate the models are:

a. Coefficient of determinant (R

2

) .

b. Level of significant at 0.05

c. The standard error ofthe estimate.

d. The heteroscedasticity of variance.

e. Normality tests.

The coefficient of determinant (R

2

) and level of significant at 0.05 are the main

criteria to be achieved for the selection of good model. Coefficient of determinant

(R

2

) describes the strength of an association between variables. An association

between variables means that the value of one variable can be predicted, to some

extent, by the value of the other. A correlation is a special kind of association: there is

a linear relation between the values ofthe variables.

The standard error of the estimate is a measure of the accuracy of predictions made

with a regression line. The regression line seeks to minimise the sum of the squared

errors of prediction. A model with lowest value of standard error of estimate is

preferred.

One of the main assumptions for the ordinary least squares regression is the

homogeneity of variance of the residuals. If the model is well fitted, there should be

no pattern to the residuals plotted against the fitted values. If the variance of the

residuals is non-constant, then the residual variance is said to be "heteroscedastic."

There are graphical and non-graphical methods for detecting heteroscedasticity. In

this paper, non-graphical method is use i.e. Durbin Watson Statistic (D value), D

value range from 0 to 4 where best value in 2 (or close to 2) to show that the constant

variance is homoscedatisity.

Final test on the models is normality test; a normality test is a statistical process used

to determine if a sample or any group of data fits a standard normal distribution. A

normality test can be performed mathematically or graphically. Normal distribution is

the spread of information where the most frequently occurring value is in the middle

of the range and other probabilities tail off symmetrically in both directions. Normal

distribution is graphically categorized by a bell-shaped curve, also known as a

Gaussian distribution or the data plot along the straight line in the Probability Plot

(P-P). For normally distributed data, the mean and median are very close and may be

identical. This paper use P-P to test the normality.

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440,2005

3.2 Results

Regression # 1 with Constant

After tabulating the data, first regression analysis was run using SPSS by stepwise

method. Rut depth was assigned as dependent variables where as roughness, AADT

and SN were assigned as independent variables. Significant level (a) of 0.05 was set.

It is appear that the following models were suggested:

Table 2: Initial Regression Models With Constant

Dependent Variable: Rut Depth

Model Constant SN Roughness AADT Std

Err

I 8.620 -0.796 1.477 0.426

................ {Q:Q9.QL JQ.Q9.QL "'" __ .

2 4.473 -0.608 1.243 1.217 0.620

___ ... __ .... .(Q:Q9.Q2. .... -( Q . Q 9 ~ 2 __ .. _... (9:9.Q9L. _.. __ . .... ,' _...... __ . __ . .__ .. __ ... __ ....

3 3.439 -0.473 1.046 6.373 x 10' 1.112 0.691

(0.003) (0.001) (0.000) (0.005)

Value of Durbin Watson statistic (mean constant variance) = 1.71\

Value in bracket is the significant level value (a)

The main purpose for this initial analysis is to observe the response of the variables

while identifying the potential model. Constant was included in this model. From the

analysis Model # 3 appear to be the best among them; it can be written in the

following form:

Rut Depth =3.439 - 0.473(SN) + 1.046 (Roughness) + 6.373 x 10.

5

(AADT) (1)

Regression # 2 without Constant

Using the same data and regression technique, another regression was run. However

this analysis does not include constant. The following results were obtained:

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

Table 3: Second Regression Models With Constant

Dependent Variable: Rut Depth

Model Roughness AADT Std

Err

1 1.762 1.494 0.909

(0.000)

.- . -- .. -- -- . -- .. -. - ... """ .. - .. -- . "'" ' " . '- --5 - ._. .. -"""""" -'-' _. -.- - - .. _

2 1.281 9.359 x 10' 1.272 0.936

(0.000) (0.000)

Value of Durbin Watson statistic (mean constant variance) = ] .877

Value in bracket is the significant level value (a)

In this analysis the R

2

and Durbin Watson value seem to be good; however this

model dropped the SN variable. Since SN value is an important indicator for

pavement strength, it is essential that SN value to be included in the model, however

Table 4 suggest model # 2 as the best model and written as follows:

Rut Depth = 1.281 (Roughness) +9.359 x 10'5 (AADT) (2)

Regression # 3 Using Transformed Variables Without Constant

Since SN is expected to be included in the model to represent the strength of the

pavement in question, transformation of variables is a possible solution. Once

transformation of variables is done, another regression analysis was conducted at

significant level (a) of 0.05 and without constant. The following results obtained:

Table 4: Third Regression Models of Transformed

Variables without Constant

Dependent Variable: Rut Depth

Model Roughness AADT Std

Err

1 1.762 1.495 0.909

- _

2

-_ iQ:Q9.Qt --.. -.---'- '" -'-'5 -.. - - -

1.281 9.359 x 10' -

-.- .. - . - - - -

1.272

- . - - -

0.936

-

..... _. __

3

_. ,(Q. Q 9 ~ 2 ._

1.565

_(9: 9_QQ)

8.002 x 10.

5

_._.' __ . __ .. _. __

-0.022

_ _

1.212

_.. __

0.943

.

(0.000) (0.001) (0.030)

Value of Durbin Watson statistic (mean constant variance) = 1.77]

Value in bracket is the significant level value (a)

The third model is the best among them and it includes all the expected variables; it

can be written in the following form:

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440,2005

Rut Depth = 1.565 (Roughness) + 8.002 x 10.

5

(AADT) - 0.022 (SN)2 (3)

Regression # 4 Using Transformed Variables With Constant

Another trial was made to obtain a model with a constant in the equation. For this

analysis the dependent variable was transformed to logarithmic. The following

models were suggested:

Table 5: Fourth Regression Models of Transformed

Variables with Constant

Dependent Variable: Log Rut Depth

Model Constant SN :z Roughness AADT Std

Err

1 0.825 -0.007 0.130 0.454

_. __ .. _ _. C Q . Q 9 ~ L -CQ.Q9.QL _ _ _ _ _ _ _ _ __ . __ ..

2 0.479 -0.005 0.116 0.104 0.660

... --.. - -CQ:Q9.QL._. --(Q:Q9.QL (Q:Q.QQl - --.. - --T -- ' .

3 0.415 -0.004 0.100 5.473 x 10" 0.095 0.723

(0.000) (0.000) (0.000) (0.030)

Value of Durbin Watson statistic (mean constant variance) = 1.470

Value in bracket is the significant level value (a)

The equation of the third model can from the above table suggest low standard error

with reasonable value of coefficient of determinant (R

2

) . The equation can be written

as:

Log Rut Depth =0.415 + 0.1 (Roughness) + 5.473 x 10-

6

(AADT) - 0.004 (SN)2 (4)

3.3 Summary of Developed Models

From the above analyses, the following models were developed with their own

characteristics.

a. Model # 1

Rut Depth = 3.439 - 0.473(SN) + 1.046 (Roughness) + 6.373 x 10.

5

(AADT) (1)

R

2

= 0.691

Durbin Watson Value = 1.711

Standard Error = 1.112

Proceedings ofthe Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428440,2005

b. Model # 2

Rut Depth = 1.281 (Roughness) + 9.359 x 10-

5

(AADT) (2)

R

2

= 0.936

Durbin Watson Value = 1.877

Standard Error = 1.272

c. Model # 3

Rut Depth = 1.565 (Roughness) + 8.002 x 10.

5

(AADT) - 0.022 (SNi (3)

R

2

= 0.943

Durbin Watson Value = 1.771

Standard Error = 1.212

d. Model # 4

Log Rut Depth = 0.415 + 0.1 (Roughness) + 5.473 x 10-6 (AADT)

- 0.004 (SN)2 (4)

R

2

= 0.723

Durbin Watson Value = 1.470

Standard Error = 0.954

The above models have their own strength and weaknesses based on the validity in

explaining the variables and homogeneity of variance of the residual. Model # 3 has

the highest value of R

2

, however the model did not represented by a constant. Model

# 4 is regarded as better model for this paper, for its representation of expected

variables and constant. Therefore Model # 4 is selected.

3.4 Validation of the Selected Model

The selected model validation is generated during the regression process. These

values are prominent indicators to show that the model is practical or useable as

pavement performance prediction.

a. Coefficient of Determination ( R ~ 1 The selected model has R

2

value

of 0.723. This illustrates that 72.3% of the variation in the Rut Depth vis-a-vis

roughness, AADT and SN has been explained in the regression line.

b. Standard Error of Estimate. Standard error of estimate needs to be

relatively small, it mean that less error in estimating the relationship in the

equation. The. value of 0.954 for this model is considered small and

acceptable.

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

Rutting Vs Number of ~ ~ ; - - - - ---I

17.5

16.5

15.5

E 14.5

.. 13.5

C)

.5 12.5

==

11.5

10.5

9.5

8.5

...

/'

/'

/'

/

--

JI# ./"

~

./

/

:

--------- I - - - - - ~ - _ . - .---- - - - - - ~ - ~ - - - - - - - - - - - - - -

....

\11

1 2 3 4 5 6 7 8 9

Number of Year

Figure 3: Rutting Prediction Graph Based on the Developed

Model

Using this prediction, appropriate steps can be taken to schedule maintenance

activities subsequently assist the pavement managers in budgeting and disseminating

limited fund.

4. CONCLUSION

The proposed model could provide reasonable prediction of pavement performance,

this it could facilitate the decision making of maintenance and rehabilitation in

pavement management system. It is concluding that the regression equation to be use

for particular road network take the following form:

Log Rut Depth = 0.415 + 0.1 (Roughness) + 5.473 x 10-

6

(AADT)

- 0.004 (SN)2 (4)

Using the equation, rut depth can be estimated by computing value of roughness,

medium trucks AADT and structural number. The factor of time can be added into

this model indirectly, it can be done through forecasting AADT by method of

predicting growth and compounding.

oceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

c. Durbin Watson Statistic CD Value). The D value for the selected

model is 1.470 which is close to 2. It mean the variance of the residual is

almost constant; i.e. homoscedastic.

d. Normality Test. Normality test was conducted on the data set using

probability plot and its emerged to be short tail, which means that the

probability plot have non-linear pattern. This reveals that the data set does not

fit normal distribution.

3.5 Using The Model

Say, the average value of roughness and structural number (SN) for the pavement

surface in question are 4mm/m and 7 respectively, it is also forecasted for the next ten

years of the AADT for medium truck is shown in the following table. Computing

values of rutting and structural number into the final equation (Model # 4), rut depth

is predicted for the next ten years.

Table 6: Predicted Rutting using the Developed Model

Years Medium Truck AADT (vpd) Rutting (mm)

_____ ._L " __ .. ._ . .. ._. __

...... _._ _ _.._ _. __ _.._ _ _. _ .

__ _} _.__ """ ._ _. _ .. __ ..__ .

..... __ _ __ _?Qt9Q9.. . .. _. _.

_____ ..?__ . _. .__ . . ._. _. ._ . ._.

...... .?__ ."" .._. _ _ __ __ _ _..

.......? __ _"'" _ ??t9Q9_ _._ _ _. _. __ __ __ .

._"'_ .."' __ ._ _.._. ._ ...?Qt9Q9 .._ __ .._ ),4:?_..__ .

_.._ ? ._ _.._ _._ ._.. _ _. _ .._ _ .

10 80,000 16.5

Plotting rutting and number of year will give us the following graph which will assist

the pavement managers to decide as to when to start rehabilitation or maintenance

work on the pavement. If the agency only accepts rutting below than 12.0 mm; the

agency will need to maintain the surface at year five.

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

I

Rutting Vs Number of Year

I 17.5

16.5 + - - - - - - - - - - - - - - - - - - - ~

15.5 +-----------

E 14.5 +-----

.. 13.5

en

.5 12.5

:::

~ 11.5

.. _-------_.... _.._._..--

10.5

9.5 +--.::7""---

-----11-------.. --....-.---

8.5 +-+---r-+-,--f-.,.....-I--,--"'-.--+-r-+-.--+-..,..-+---,--t----1

1 2 3 4 5 6 7 8

9 10 I

Number of Year

---.-7""-+---------....- ------.-.--.

Figure 3: Rutting Prediction Graph Based on the Developed

Model

Using this prediction, appropriate steps can be taken to schedule maintenance

activities subsequently assist the pavement managers in budgeting and disseminating

limited fund.

4. CONCLUSION

The proposed model could provide reasonable prediction of pavement performance,

this it could facilitate the decision making of maintenance and rehabilitation in

pavement management system. It is concluding that the regression equation to be use

for particular road network take the following form:

Log Rut Depth = 0.415 + 0.1 (Roughness) + 5.473 x 10-6 (AADT)

- 0.004 (SN)2 (4)

Using the equation, rut depth can be estimated by computing value of roughness,

medium trucks AADT and structural number. The factor of time can be added into

this model indirectly, it can be done through forecasting AADT by method of

predicting growth and compounding.

Proceedings of the Eastern Asia Society for Transportation Studies, Vol. 5, pp. 428 - 440, 2005

REFERENCES

a) Books

Peterson D.E. (1977) Good Road Cost Less. Utah Department of Transport, Utah

Ralph Haas. (1997) Pavement Design and Management Guide. Transportation

Association of Canada

b) Journalpapen

Dr. Charles Nunoo. (2002) Pavement Management System, Florida International

University, Florida

Kuo et al. (2003) Development of Pavement Performance Model', Transport

Research Board

Prozzi and Madanat. (2002) A Non Linear Model for Predicting Pavement

Serviceability, Transport Research Board

Samer Madanat. (1997) Predicting Pavement Deterioration, Institute of

Transportation Studies

Sedat Gulen et al. (2001) Development of Improved Pavement Performance Model,

Indiana Department of Transport

Stephen F. Shober et aI, (1998) A Pavement Preservation Strategy, Wisconsin

Department of Transport

c) Other Documents

AASTHO. (1993) Guide for Design of Pavement Structures

A Guide to Visual Assessment of Flexible Pavement Surface Condition. (1992)

Jabatan Kerja Raya (J.K.R)

Carey et al. (1960) Highway Research Board, Washington.

Interim Guide to Evaluation and Rehabilitation of Flexible Road Pavement. (1994)

Institut Kerja Raya Malaysia (IKRAM)

PAVEMENT CONDITION RATING SHEET

LOCATION DATE & DAY

ROAD NO TYPES OF PAVEMENT

CLIMATE WIDTH

Types of Distress Rating Rating Given Remarks

A. Surface Defects

1. Fatty Surface 0-5

2. Smooth Surface 0-5

3. Streaking 0-5

4. Hungry Surface 0-5

B. Cracks

1. Hairline Cracks 0-5

2. Alligator Cracks 0-5

3. longitudinal Cracks 0-5

4. Edge Cracks 0-5

5. Shrinkage Cracks 0-5

6. Reflection Cracks 0-5

C. Deformation

1. Slippage 0-5

2. Rutting 0-5

3. Corrugation 0-5

4. Shoving 0-5

5. Shallow Dipression 0-5

6. Settlement & Upheavel 0-5

D. Disintegration

1. Stripping 0-5

2. Loss of Aggragate 0-5

3. Ravelling 0-5

4. Potholes 0-5

5. Edge Breaking 0-5

5

VERY SEVERE

4

SEVERE

3

2

t'-IGHT

1

VERYtLlGHT

0

Anda mungkin juga menyukai

- Standard Proctor TestDokumen28 halamanStandard Proctor TestShuja MalikBelum ada peringkat

- 21file Info223Dokumen1 halaman21file Info223Ala ThajilBelum ada peringkat

- CBR CalculationDokumen2 halamanCBR CalculationAla ThajilBelum ada peringkat

- Topcon ManualDokumen174 halamanTopcon ManualsiddiqueBelum ada peringkat

- Soil EngineeringDokumen181 halamanSoil EngineeringAla ThajilBelum ada peringkat

- Buringh Soil and Soil Conditions in IraqDokumen338 halamanBuringh Soil and Soil Conditions in IraqAhqeterBelum ada peringkat

- Iau Ca UsaDokumen34 halamanIau Ca Usajohnlew975509Belum ada peringkat

- T NW PDFDokumen6 halamanT NW PDFAla ThajilBelum ada peringkat

- Rep05 06Dokumen32 halamanRep05 06Ala ThajilBelum ada peringkat

- 21file Info223Dokumen1 halaman21file Info223Ala ThajilBelum ada peringkat

- Asphalt Mix Design - Superpave FundamentalsDokumen27 halamanAsphalt Mix Design - Superpave FundamentalsJohn Tejada IIIBelum ada peringkat

- Rep05 06Dokumen32 halamanRep05 06Ala ThajilBelum ada peringkat

- Chapter 02Dokumen51 halamanChapter 02Ala ThajilBelum ada peringkat

- Chapter 03Dokumen81 halamanChapter 03Ala ThajilBelum ada peringkat

- Marshall Teoria y Ejercicios PDFDokumen30 halamanMarshall Teoria y Ejercicios PDFYuliana Meriño TBelum ada peringkat

- 3 - IntroDesignDokumen48 halaman3 - IntroDesignAla ThajilBelum ada peringkat

- Arcgis: ExtensionsDokumen16 halamanArcgis: ExtensionsAla ThajilBelum ada peringkat

- Laboratory Hydro MechanicalDokumen2 halamanLaboratory Hydro MechanicalAla ThajilBelum ada peringkat

- FP 03uscDokumen718 halamanFP 03uscAla ThajilBelum ada peringkat

- 3 - IntroDesignDokumen48 halaman3 - IntroDesignAla ThajilBelum ada peringkat

- Soil Spatial SssajDokumen14 halamanSoil Spatial SssajAla ThajilBelum ada peringkat

- Experiment Specific GravityDokumen7 halamanExperiment Specific Gravitypj_bankBelum ada peringkat

- Chapter 02Dokumen51 halamanChapter 02Ala ThajilBelum ada peringkat

- Asphalt Mix Design - Superpave FundamentalsDokumen27 halamanAsphalt Mix Design - Superpave FundamentalsJohn Tejada IIIBelum ada peringkat

- An Introduction To Asphalt PavingDokumen2 halamanAn Introduction To Asphalt PavingAla ThajilBelum ada peringkat

- Arcgis: ExtensionsDokumen16 halamanArcgis: ExtensionsAla ThajilBelum ada peringkat

- An Introduction To Asphalt PavingDokumen2 halamanAn Introduction To Asphalt PavingAla ThajilBelum ada peringkat

- Tim BlinDokumen5 halamanTim BlinAla ThajilBelum ada peringkat

- Stock PHD ThesisDokumen330 halamanStock PHD ThesisAla ThajilBelum ada peringkat

- Asphalt Mix Design - Superpave FundamentalsDokumen27 halamanAsphalt Mix Design - Superpave FundamentalsJohn Tejada IIIBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Endterm QAM II 2019 BCFDokumen3 halamanEndterm QAM II 2019 BCFABHISHEK KUMAR SINGHBelum ada peringkat

- 3060 PROBLEM SET 9-1Dokumen1 halaman3060 PROBLEM SET 9-1Person DuhBelum ada peringkat

- أثر التسويق الداخلي على الرضا الوظيفي دراسة تطبيقية على مستوى الصندوق الوطني للتقاعد - وكالة بشار- ARticle 2 PDFDokumen22 halamanأثر التسويق الداخلي على الرضا الوظيفي دراسة تطبيقية على مستوى الصندوق الوطني للتقاعد - وكالة بشار- ARticle 2 PDFÄlễMḑärBelum ada peringkat

- David Forsyth - Applied Machine Learning (2019)Dokumen496 halamanDavid Forsyth - Applied Machine Learning (2019)ernestoBelum ada peringkat

- Lecture 6 Example ProblemDokumen5 halamanLecture 6 Example ProblemReinold NdreuBelum ada peringkat

- Curvas ROC (Receiver Operating Characteristic, o Característica Operativa Del Receptor)Dokumen7 halamanCurvas ROC (Receiver Operating Characteristic, o Característica Operativa Del Receptor)datalifeBelum ada peringkat

- Nguyen Duc Anh. CA7-010Dokumen5 halamanNguyen Duc Anh. CA7-010Đức Anh LeoBelum ada peringkat

- ML Quiz-1Dokumen4 halamanML Quiz-1Saikat BhattacharyyaBelum ada peringkat

- Pengaruh Manajemen K3 Dan Budaya K3 Terhadap Kinerja Pekerja Proyek (Studi Kasus Proyek Pembangunan Cengkareng Business City Lot 5)Dokumen8 halamanPengaruh Manajemen K3 Dan Budaya K3 Terhadap Kinerja Pekerja Proyek (Studi Kasus Proyek Pembangunan Cengkareng Business City Lot 5)fauzi ihsanBelum ada peringkat

- Linear Regression-2: Prof. Asim Tewari IIT BombayDokumen19 halamanLinear Regression-2: Prof. Asim Tewari IIT BombayScion Of VirikvasBelum ada peringkat

- Probit Analysis MiniTab - Waktu (LT50)Dokumen3 halamanProbit Analysis MiniTab - Waktu (LT50)Hendra A. Herlambang100% (1)

- Chapter 4Dokumen37 halamanChapter 4110me0313Belum ada peringkat

- Regression StatisticsDokumen8 halamanRegression StatisticsAbdul ArifBelum ada peringkat

- Applied Predictive Modeling - Max KuhnDokumen57 halamanApplied Predictive Modeling - Max KuhnDavid75% (4)

- Bnad 277 Final ProjectDokumen11 halamanBnad 277 Final Projectapi-638728331Belum ada peringkat

- Unit 7 Regration and CorrelationDokumen11 halamanUnit 7 Regration and CorrelationhayelomBelum ada peringkat

- Project Delhi Metro 20 April 2016Dokumen41 halamanProject Delhi Metro 20 April 2016Avneet AhujaBelum ada peringkat

- Referensi Jurnal Tata Letak Material Terhadap ProduktivitasDokumen14 halamanReferensi Jurnal Tata Letak Material Terhadap ProduktivitasArdiBelum ada peringkat

- Etf3600 Lecture3 Mle LPM 2013Dokumen36 halamanEtf3600 Lecture3 Mle LPM 2013Vince LauBelum ada peringkat

- Question No 1: Month Rainfall (MM) X Umbrellas Sold YDokumen6 halamanQuestion No 1: Month Rainfall (MM) X Umbrellas Sold YAli AhmadBelum ada peringkat

- Tutorial in Biostatistics Using The General Linear Mixed Model To Analyse Unbalanced Repeated Measures and Longitudinal DataDokumen32 halamanTutorial in Biostatistics Using The General Linear Mixed Model To Analyse Unbalanced Repeated Measures and Longitudinal Datapedro veigaBelum ada peringkat

- Cc-Lec Individual Assignment Week 8 Quality ControlDokumen4 halamanCc-Lec Individual Assignment Week 8 Quality ControlJ Pao Bayro LacanilaoBelum ada peringkat

- Exploratory Factor Analysis On Road Accidents in Cagayan de Oro CityDokumen23 halamanExploratory Factor Analysis On Road Accidents in Cagayan de Oro CityEino DuldulaoBelum ada peringkat

- Solutions To Practice Problems For Part VI: Regression StatisticsDokumen40 halamanSolutions To Practice Problems For Part VI: Regression Statisticsshannon caseyBelum ada peringkat

- 07 August 2020 by 23:59: Assignment 2Dokumen6 halaman07 August 2020 by 23:59: Assignment 2Hafeni tulongeni HamukotoBelum ada peringkat

- Cuevas AA3Dokumen8 halamanCuevas AA3KHAkadsbdhsgBelum ada peringkat

- This Study Resource Was: U Poverty Enroll End MathDokumen9 halamanThis Study Resource Was: U Poverty Enroll End MathZoloft Zithromax ProzacBelum ada peringkat

- Linear Correlation / Regression: Gaurang RamiDokumen4 halamanLinear Correlation / Regression: Gaurang RamiDEVAANSH LALWANIBelum ada peringkat

- Dissertation Using Multiple RegressionDokumen8 halamanDissertation Using Multiple RegressionWriteMyPapersDiscountCodeCanada100% (2)

- GED102-1 Multiple and Nonlinear Regression ExcelDokumen20 halamanGED102-1 Multiple and Nonlinear Regression ExcelKarylle AquinoBelum ada peringkat