Category Overview

Diunggah oleh

shru6sanviDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Category Overview

Diunggah oleh

shru6sanviHak Cipta:

Format Tersedia

11:21:53AM

Category Overview

March 10, 2010

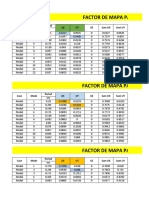

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Key Performance Indicators

System

Number Out

Average

100

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

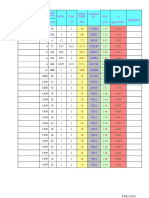

Entity Time

VA Time part NVA Time part Wait Time part Transfer Time part Other Time part Total Time part

Average Half Width Minimum Value Maximum Value

1.9149

Average

(Insufficient)

Half Width

0.00

Minimum Value

56.4540

Maximum Value

1.8780

Average

(Insufficient)

Half Width

0.1300

Minimum Value

22.3500

Maximum Value

22.9331

Average

(Insufficient)

Half Width

0.00

Minimum Value

228.06

Maximum Value

0.00

Average

(Insufficient)

Half Width

0.00

Minimum Value

0.00

Maximum Value

0.00

Average

(Insufficient)

Half Width

0.00

Minimum Value

0.00

Maximum Value

26.7260

(Insufficient)

0.1300

269.36

Other

Number In part Number Out part WIP part

Value

301.00

Value

100.00

Average Half Width Minimum Value Maximum Value

101.48

(Correlated)

0.00

201.00

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Queue Time

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Queue Time

Waiting Time aerofoil inspection 1 process.Queue aerofoil inspection 2 process.Queue Bench marking.Queue bench work 1.Queue bench work 2.Queue blade inspection 1 process.Queue blade inspection 2 process.Queue blade inspection 3 process.Queue blade inspection 4 process.Queue blade inspection process.Queue blohm surface grinding.Queue Bristol root grinding.Queue correct twist and droop.Queue Deburring 1.Queue Deburring 2.Queue Deburring 3.Queue defect inspection process.Queue engraving.Queue final inspection process.Queue finish inspection process.Queue Flash removal.Queue Forging inspection process.Queue Fritz werner milling.Queue Fw 2 milling.Queue glass beed peening.Queue Horizontal milling 1.Queue Horizontal milling 2.Queue Horizontal milling 3.Queue Horizontal milling 4.Queue metallurgical inspection procass.Queue milling inspection process.Queue morris flex polishing.Queue

Average Half Width Minimum Value Maximum Value

0.4806 0.00 11.0180 1.8164 0.2600 0.7970 8.4900 2.5000 0.3900 0.4900 0.5700 0.03664286 0.5344 1.5311 0.00 1.9140 1.0600 0.00 0.00 0.00 11.5445 2.2987 83.5467 56.3460 0.00 68.4696 68.0692 67.4314 87.5600 2.6000 0.2600 2.3500

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 0.00 0.00 0.2600 0.00 8.4900 2.5000 0.3900 0.4900 0.5700 0.00 0.00 0.00 0.00 1.9140 1.0600 0.00 0.00 0.00 0.00 0.00 42.3400 21.9400 0.00 0.00 0.00 2.6800 87.5600 2.6000 0.2600 2.3500

3.3500 0.00 23.4000 25.0800 0.2600 4.7300 8.4900 2.5000 0.3900 0.4900 0.5700 0.8200 4.1500 20.4500 0.00 1.9140 1.0600 0.00 0.00 0.00 23.4100 25.6000 107.78 80.8000 0.00 136.69 136.96 135.06 87.5600 2.6000 0.2600 2.3500

Page

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Queue Time

Waiting Time osmond cut off.Queue painting.Queue parawash.Queue peening inspection process.Queue plating.Queue Polishing 2.Queue preperation of cd test.Queue stripping inspection process.Queue stripping.Queue vibroetch cd test.Queue

Average Half Width Minimum Value Maximum Value

0.00 0.00 1.1900 1.2400 0.02000000 0.1300 2.2100 0.1300 0.1300 0.00

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 1.1900 1.2400 0.02000000 0.1300 2.2100 0.1300 0.1300 0.00

0.00 0.00 1.1900 1.2400 0.02000000 0.1300 2.2100 0.1300 0.1300 0.00

Other

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Queue Other

Number Waiting aerofoil inspection 1 process.Queue aerofoil inspection 2 process.Queue Bench marking.Queue bench work 1.Queue bench work 2.Queue blade inspection 1 process.Queue blade inspection 2 process.Queue blade inspection 3 process.Queue blade inspection 4 process.Queue blade inspection process.Queue blohm surface grinding.Queue Bristol root grinding.Queue correct twist and droop.Queue Deburring 1.Queue Deburring 2.Queue Deburring 3.Queue defect inspection process.Queue engraving.Queue fatigue test process.Queue final inspection process.Queue finish inspection process.Queue Flash removal.Queue Forging inspection process.Queue Fritz werner milling.Queue Fw 2 milling.Queue glass beed peening.Queue Horizontal milling 1.Queue Horizontal milling 2.Queue Horizontal milling 3.Queue Horizontal milling 4.Queue metallurgical inspection procass.Queue milling inspection process.Queue

Average Half Width Minimum Value Maximum Value

0.02723333 0.00 7.9576 0.1635 0.00086667 0.07173333 0.02830000 0.00833333 0.00130000 0.00163333 0.00190000 0.00342000 0.04810000 0.1429 0.00 0.00638000 0.00353333 0.00 0.00 0.00 0.00 7.6894 2.2944 1.6861 1.7532 0.00 42.0366 21.7976 11.5937 0.7749 0.00866667 0.00086667

(Insufficient) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

1.0000 0.00 19.0000 2.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 2.0000 0.00 1.0000 1.0000 0.00 0.00 0.00 0.00 19.0000 26.0000 4.0000 5.0000 0.00 86.0000 44.0000 24.0000 2.0000 1.0000 1.0000

Page

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Queue Other

Number Waiting morris flex polishing.Queue osmond cut off.Queue packing.Queue painting.Queue parawash.Queue peening inspection process.Queue plating 2.Queue plating.Queue Polishing 2.Queue preperation of cd test.Queue stamp number.Queue stripping inspection process.Queue stripping.Queue vibroetch cd test.Queue

Average Half Width Minimum Value Maximum Value

0.00783333 0.00 0.00 0.00 0.00396667 0.00413333 0.00 0.00006667 0.00043333 0.00736667 0.00 0.00043333 0.00043333 0.00

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

1.0000 0.00 0.00 0.00 1.0000 1.0000 0.00 1.0000 1.0000 1.0000 0.00 1.0000 1.0000 0.00

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

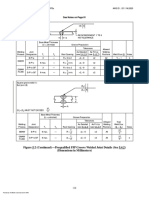

Resource Usage

Instantaneous Utilization cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays Number Busy cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays Number Scheduled cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

Average Half Width Minimum Value Maximum Value

0.00243333 0.01050000 0.01066667 0.9881 0.3086 0.6292 0.9944 0.3996 0.01000000 0.00166667

Average

(Insufficient) (Insufficient) (Insufficient) (Correlated) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

Half Width

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Minimum Value

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

Maximum Value

0.00243333 0.01050000 0.01066667 0.9881 0.3086 0.6292 0.9944 0.3996 0.01000000 0.00166667

Average

(Insufficient) (Insufficient) (Insufficient) (Correlated) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

Half Width

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Minimum Value

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

Maximum Value

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Resource Usage

Scheduled Utilization cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

1.000 0.800 0.600 0.400 0.200 0.000

cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

Value

0.00243333 0.01050000 0.01066667 0.9881 0.3086 0.6292 0.9944 0.3996 0.01000000 0.00166667

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

of

20

11:21:53AM

Category Overview

March 10, 2010

Reduction in lead time of rotor blades of Orpheus engine using VSM

Replications:

Time Units:

Days

Resource Usage

Total Number Seized cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

450.000 400.000 350.000 300.000 250.000 200.000 150.000 100.000 50.000 0.000

cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

Value

1.0000 1.0000 1.0000 383.00 29.0000 419.00 186.00 27.0000 1.0000 1.0000

Unnamed Project

Replications:

Time Units:

Days

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

10

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Key Performance Indicators

System

Number Out

Average

100

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

11

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Entity Time

VA Time part NVA Time part Wait Time part Transfer Time part Other Time part Total Time part

Average Half Width Minimum Value Maximum Value

1.9149

Average

(Insufficient)

Half Width

0.00

Minimum Value

56.4540

Maximum Value

1.8780

Average

(Insufficient)

Half Width

0.1300

Minimum Value

22.3500

Maximum Value

22.9331

Average

(Insufficient)

Half Width

0.00

Minimum Value

228.06

Maximum Value

0.00

Average

(Insufficient)

Half Width

0.00

Minimum Value

0.00

Maximum Value

0.00

Average

(Insufficient)

Half Width

0.00

Minimum Value

0.00

Maximum Value

26.7260

(Insufficient)

0.1300

269.36

Other

Number In part Number Out part WIP part

Value

301.00

Value

100.00

Average Half Width Minimum Value Maximum Value

101.48

(Correlated)

0.00

201.00

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

12

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Queue Time

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

13

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Queue Time

Waiting Time aerofoil inspection 1 process.Queue aerofoil inspection 2 process.Queue Bench marking.Queue bench work 1.Queue bench work 2.Queue blade inspection 1 process.Queue blade inspection 2 process.Queue blade inspection 3 process.Queue blade inspection 4 process.Queue blade inspection process.Queue blohm surface grinding.Queue Bristol root grinding.Queue correct twist and droop.Queue Deburring 1.Queue Deburring 2.Queue Deburring 3.Queue defect inspection process.Queue engraving.Queue final inspection process.Queue finish inspection process.Queue Flash removal.Queue Forging inspection process.Queue Fritz werner milling.Queue Fw 2 milling.Queue glass beed peening.Queue Horizontal milling 1.Queue Horizontal milling 2.Queue Horizontal milling 3.Queue Horizontal milling 4.Queue metallurgical inspection procass.Queue milling inspection process.Queue morris flex polishing.Queue

Average Half Width Minimum Value Maximum Value

0.4806 0.00 11.0180 1.8164 0.2600 0.7970 8.4900 2.5000 0.3900 0.4900 0.5700 0.03664286 0.5344 1.5311 0.00 1.9140 1.0600 0.00 0.00 0.00 11.5445 2.2987 83.5467 56.3460 0.00 68.4696 68.0692 67.4314 87.5600 2.6000 0.2600 2.3500

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 0.00 0.00 0.2600 0.00 8.4900 2.5000 0.3900 0.4900 0.5700 0.00 0.00 0.00 0.00 1.9140 1.0600 0.00 0.00 0.00 0.00 0.00 42.3400 21.9400 0.00 0.00 0.00 2.6800 87.5600 2.6000 0.2600 2.3500

3.3500 0.00 23.4000 25.0800 0.2600 4.7300 8.4900 2.5000 0.3900 0.4900 0.5700 0.8200 4.1500 20.4500 0.00 1.9140 1.0600 0.00 0.00 0.00 23.4100 25.6000 107.78 80.8000 0.00 136.69 136.96 135.06 87.5600 2.6000 0.2600 2.3500

Page

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

14

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Queue Time

Waiting Time osmond cut off.Queue painting.Queue parawash.Queue peening inspection process.Queue plating.Queue Polishing 2.Queue preperation of cd test.Queue stripping inspection process.Queue stripping.Queue vibroetch cd test.Queue

Average Half Width Minimum Value Maximum Value

0.00 0.00 1.1900 1.2400 0.02000000 0.1300 2.2100 0.1300 0.1300 0.00

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 1.1900 1.2400 0.02000000 0.1300 2.2100 0.1300 0.1300 0.00

0.00 0.00 1.1900 1.2400 0.02000000 0.1300 2.2100 0.1300 0.1300 0.00

Other

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

15

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Queue Other

Number Waiting aerofoil inspection 1 process.Queue aerofoil inspection 2 process.Queue Bench marking.Queue bench work 1.Queue bench work 2.Queue blade inspection 1 process.Queue blade inspection 2 process.Queue blade inspection 3 process.Queue blade inspection 4 process.Queue blade inspection process.Queue blohm surface grinding.Queue Bristol root grinding.Queue correct twist and droop.Queue Deburring 1.Queue Deburring 2.Queue Deburring 3.Queue defect inspection process.Queue engraving.Queue fatigue test process.Queue final inspection process.Queue finish inspection process.Queue Flash removal.Queue Forging inspection process.Queue Fritz werner milling.Queue Fw 2 milling.Queue glass beed peening.Queue Horizontal milling 1.Queue Horizontal milling 2.Queue Horizontal milling 3.Queue Horizontal milling 4.Queue metallurgical inspection procass.Queue milling inspection process.Queue

Average Half Width Minimum Value Maximum Value

0.02723333 0.00 7.9576 0.1635 0.00086667 0.07173333 0.02830000 0.00833333 0.00130000 0.00163333 0.00190000 0.00342000 0.04810000 0.1429 0.00 0.00638000 0.00353333 0.00 0.00 0.00 0.00 7.6894 2.2944 1.6861 1.7532 0.00 42.0366 21.7976 11.5937 0.7749 0.00866667 0.00086667

(Insufficient) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

1.0000 0.00 19.0000 2.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 2.0000 0.00 1.0000 1.0000 0.00 0.00 0.00 0.00 19.0000 26.0000 4.0000 5.0000 0.00 86.0000 44.0000 24.0000 2.0000 1.0000 1.0000

Page

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

16

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Queue Other

Number Waiting morris flex polishing.Queue osmond cut off.Queue packing.Queue painting.Queue parawash.Queue peening inspection process.Queue plating 2.Queue plating.Queue Polishing 2.Queue preperation of cd test.Queue stamp number.Queue stripping inspection process.Queue stripping.Queue vibroetch cd test.Queue

Average Half Width Minimum Value Maximum Value

0.00783333 0.00 0.00 0.00 0.00396667 0.00413333 0.00 0.00006667 0.00043333 0.00736667 0.00 0.00043333 0.00043333 0.00

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

1.0000 0.00 0.00 0.00 1.0000 1.0000 0.00 1.0000 1.0000 1.0000 0.00 1.0000 1.0000 0.00

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

17

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Resource Usage

Instantaneous Utilization cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays Number Busy cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays Number Scheduled cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

Average Half Width Minimum Value Maximum Value

0.00243333 0.01050000 0.01066667 0.9881 0.3086 0.6292 0.9944 0.3996 0.01000000 0.00166667

Average

(Insufficient) (Insufficient) (Insufficient) (Correlated) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

Half Width

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Minimum Value

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

Maximum Value

0.00243333 0.01050000 0.01066667 0.9881 0.3086 0.6292 0.9944 0.3996 0.01000000 0.00166667

Average

(Insufficient) (Insufficient) (Insufficient) (Correlated) (Insufficient) (Correlated) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

Half Width

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Minimum Value

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

Maximum Value

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

(Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient) (Insufficient)

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000 1.0000

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

18

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Resource Usage

Scheduled Utilization cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

1.000 0.800 0.600 0.400 0.200 0.000

cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

Value

0.00243333 0.01050000 0.01066667 0.9881 0.3086 0.6292 0.9944 0.3996 0.01000000 0.00166667

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

19

of

20

11:21:53AM

Category Overview

March 10, 2010

Unnamed Project

Replications:

Time Units:

Days

Resource Usage

Total Number Seized cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

450.000 400.000 350.000 300.000 250.000 200.000 150.000 100.000 50.000 0.000

cutting machine engraving machine equipments gauging machine grinding machine man milling machine OMT projector peening machine sprays

Value

1.0000 1.0000 1.0000 383.00 29.0000 419.00 186.00 27.0000 1.0000 1.0000

Model Filename: F:\project\PPT\SIMULATION\SELECTED\MODEL R3

Page

20

of

20

Anda mungkin juga menyukai

- 2021-12-01 Australian Wood Review - Sanet.st - 1-84Dokumen227 halaman2021-12-01 Australian Wood Review - Sanet.st - 1-84Muwehid Tewhid50% (2)

- Base Plate & Anchor Bolt - BP1Dokumen20 halamanBase Plate & Anchor Bolt - BP1munishant1Belum ada peringkat

- Optimum Pipe Size - Liquid Flow: CROSS-SECTIONAL AREA (SF)Dokumen1 halamanOptimum Pipe Size - Liquid Flow: CROSS-SECTIONAL AREA (SF)genergiaBelum ada peringkat

- OPEN LOOP TRAVERSE COMPUTATION BY TOTAL STATIONDokumen59 halamanOPEN LOOP TRAVERSE COMPUTATION BY TOTAL STATIONMostafa Al ArabiBelum ada peringkat

- Baker SPDDokumen49 halamanBaker SPDWilliamBelum ada peringkat

- Week 8 Sheet Metal FormingDokumen69 halamanWeek 8 Sheet Metal FormingashkansoheylBelum ada peringkat

- Gasoline Storage TankDokumen10 halamanGasoline Storage Tankumair saeed100% (3)

- Victorian (Sterling)Dokumen13 halamanVictorian (Sterling)NickiedeposieBelum ada peringkat

- Mill Foundation Sample DesignDokumen8 halamanMill Foundation Sample Designsandeep sharmaBelum ada peringkat

- Calibration Compare Report Parameters and ValuesDokumen36 halamanCalibration Compare Report Parameters and ValuesWillianPachecoBelum ada peringkat

- 487B Slope 2 Calculations and Test Values - r02Dokumen24 halaman487B Slope 2 Calculations and Test Values - r02Betto MtBelum ada peringkat

- Troubleshooting Optical Fiber Networks: Understanding and Using Optical Time-Domain ReflectometersDari EverandTroubleshooting Optical Fiber Networks: Understanding and Using Optical Time-Domain ReflectometersPenilaian: 5 dari 5 bintang5/5 (2)

- The Benefits of Forged Steel Gears - HofmannEng - MarkupDokumen11 halamanThe Benefits of Forged Steel Gears - HofmannEng - MarkupJorge VillalobosBelum ada peringkat

- Shear stress vs deformation experimentDokumen9 halamanShear stress vs deformation experimentArfan HaiderBelum ada peringkat

- Single Channel Queue Model with Poisson Arrivals and Exponential ServiceDokumen59 halamanSingle Channel Queue Model with Poisson Arrivals and Exponential ServiceDivyanshu Shekhar100% (1)

- Oracle OS WatcherDokumen14 halamanOracle OS WatcherIan HughesBelum ada peringkat

- Modal Participating Mass Ratios and Diaphragm Displacements TableDokumen13 halamanModal Participating Mass Ratios and Diaphragm Displacements TableJose AmayaBelum ada peringkat

- Key Performance Indicators: Unnamed ProjectDokumen6 halamanKey Performance Indicators: Unnamed ProjectdridlyBelum ada peringkat

- Tabla A.3 Áreas de La Curva Normal Estándar: WWW - Freelibros.MeDokumen2 halamanTabla A.3 Áreas de La Curva Normal Estándar: WWW - Freelibros.MeAvalos DavidBelum ada peringkat

- DATA SCIENCE IDC 302 end sem projectDokumen1 halamanDATA SCIENCE IDC 302 end sem projectsoniakar3000Belum ada peringkat

- Design of Long Columns v.3Dokumen8 halamanDesign of Long Columns v.3Mohammed A. Al-HaddadBelum ada peringkat

- MachineReport 20231110 173216Dokumen14 halamanMachineReport 20231110 173216v.strik1986Belum ada peringkat

- Suzuki DF100/115 Parts Catalogue GuideDokumen245 halamanSuzuki DF100/115 Parts Catalogue Guideernesto tejedaBelum ada peringkat

- Force Analysis of Grinding Wheel On DifferentDokumen13 halamanForce Analysis of Grinding Wheel On DifferentMahesh PatilBelum ada peringkat

- ISOLATED FOOTING DETAILSDokumen7 halamanISOLATED FOOTING DETAILSSakar ShresthaBelum ada peringkat

- Isolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F PDokumen7 halamanIsolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F Prockey shresthaBelum ada peringkat

- Category by Replication ActualDokumen1.311 halamanCategory by Replication ActualGustavo MartinezBelum ada peringkat

- Practice Exercises # 3 Fall 2023Dokumen6 halamanPractice Exercises # 3 Fall 2023Nidhi ShettyBelum ada peringkat

- MachineReport 20230926 162144Dokumen14 halamanMachineReport 20230926 162144v.strik1986Belum ada peringkat

- 8mm Stopsol Supersilver + 12ar90 + 6mm Iplus Energy 72Dokumen1 halaman8mm Stopsol Supersilver + 12ar90 + 6mm Iplus Energy 72Wynel SadsadBelum ada peringkat

- Pipe Network Details and SpecificationsDokumen11 halamanPipe Network Details and SpecificationsOscar vega guevaraBelum ada peringkat

- Thong So Banh RangDokumen7 halamanThong So Banh RangVũ Trường LamBelum ada peringkat

- SPO2 IDAToolDokumen82 halamanSPO2 IDAToolLucho IdaBelum ada peringkat

- Output 1aDokumen5 halamanOutput 1aMOSES KPUMBelum ada peringkat

- Inteligentni P SDokumen1 halamanInteligentni P Sdzenan97100% (1)

- Libro 1Dokumen4 halamanLibro 1Roy AlfaroBelum ada peringkat

- WAVE Kurva Kalibrasi Metformin 3 - 5ppm PDFDokumen4 halamanWAVE Kurva Kalibrasi Metformin 3 - 5ppm PDFSalmanBelum ada peringkat

- HY-8 Culvert Analysis ReportDokumen9 halamanHY-8 Culvert Analysis ReportVYOINGENIERIA SASBelum ada peringkat

- Annexure 3 - Stability - Case IIIDokumen4 halamanAnnexure 3 - Stability - Case IIIMd Ghani HaiderBelum ada peringkat

- 18mm Airolam Acacia 575 BSLDokumen17 halaman18mm Airolam Acacia 575 BSLsangram routBelum ada peringkat

- Ditch Excluding RoadDokumen16 halamanDitch Excluding RoadR. JenaBelum ada peringkat

- Brinell Hardness Test LabDokumen9 halamanBrinell Hardness Test LabAlec ThaemlitzBelum ada peringkat

- TỪ M0.25 ĐẾN M600 Bảng Tra Kích Thước Ren Iso Hệ Mét: Metric Thread - Extended Thread Size Range (Iso)Dokumen19 halamanTỪ M0.25 ĐẾN M600 Bảng Tra Kích Thước Ren Iso Hệ Mét: Metric Thread - Extended Thread Size Range (Iso)Anh Sơn LêBelum ada peringkat

- Annexure 2 - Stability - Case IIDokumen4 halamanAnnexure 2 - Stability - Case IIMd Ghani HaiderBelum ada peringkat

- API-650 Tank Analysis Wind and Material DetailsDokumen3 halamanAPI-650 Tank Analysis Wind and Material DetailsImran Ahmed ShaikhBelum ada peringkat

- Title of Document Project Client Contractor Manufacturer Design Document NumberDokumen33 halamanTitle of Document Project Client Contractor Manufacturer Design Document NumberArjunBelum ada peringkat

- Portal FrameDokumen2 halamanPortal FrameThaiNguyenBelum ada peringkat

- 02° Modos de VibraciónDokumen4 halaman02° Modos de VibraciónCarolinaClaudiaBelum ada peringkat

- Flow Rate and Pressure Drop DataDokumen3 halamanFlow Rate and Pressure Drop DatamuzikkuBelum ada peringkat

- Air PropertyDokumen1 halamanAir PropertyDawit WaleBelum ada peringkat

- 3.2 ULS CyclicDokumen5 halaman3.2 ULS CyclicLaura RossBelum ada peringkat

- 3519-Out ExcelDokumen19 halaman3519-Out ExcelAdam RejczykBelum ada peringkat

- Duct Size Selector ProgramDokumen2 halamanDuct Size Selector ProgramNiaYuniantiAndiniBelum ada peringkat

- UntitledDokumen12 halamanUntitledBrix GleciaBelum ada peringkat

- FDokumen103 halamanFBEN BENBelum ada peringkat

- RSI Booklet (R1) 14042020Dokumen20 halamanRSI Booklet (R1) 14042020Jecc EngBelum ada peringkat

- UntitledDokumen11 halamanUntitledBrix GleciaBelum ada peringkat

- Week10 - Explicit Dynamic ContactDokumen9 halamanWeek10 - Explicit Dynamic ContactjshanakaBelum ada peringkat

- U1 Seccion CircularDokumen31 halamanU1 Seccion CircularserviciosmbalderasBelum ada peringkat

- TP C FLEX V41.outDokumen4 halamanTP C FLEX V41.outgaima.luisilloBelum ada peringkat

- Lecture 2 - ME460 Renewable Energy ResourcesDokumen125 halamanLecture 2 - ME460 Renewable Energy ResourcessaadBelum ada peringkat

- Metallic materials-Tensile Testing Report: Load-Position 曲线Dokumen28 halamanMetallic materials-Tensile Testing Report: Load-Position 曲线Arslan AnjumBelum ada peringkat

- TAPER GRID COUPLING MANUALDokumen16 halamanTAPER GRID COUPLING MANUALEduardoBelum ada peringkat

- Traveled Way Width: 6.6 MetersDokumen10 halamanTraveled Way Width: 6.6 MetersRichard Dean SantosBelum ada peringkat

- CH31007 Mechanical Operations MA 2016Dokumen2 halamanCH31007 Mechanical Operations MA 2016Nitin MauryaBelum ada peringkat

- British Commercial Computer Digest: Pergamon Computer Data SeriesDari EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesBelum ada peringkat

- Melwa (Western Provice) 2018-03-22Dokumen89 halamanMelwa (Western Provice) 2018-03-22Lakshan FonsekaBelum ada peringkat

- Slitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)Dokumen3 halamanSlitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)smartcad60Belum ada peringkat

- Mazzanine floor specification and item listDokumen3 halamanMazzanine floor specification and item listVijay RanaBelum ada peringkat

- Centrifugal Sand Separators Remove InorganicsDokumen4 halamanCentrifugal Sand Separators Remove InorganicsMilena Lemus Fonseca0% (1)

- CINH 01cgDokumen3 halamanCINH 01cgWindy MartdianzahBelum ada peringkat

- Socket Weld ReducerDokumen1 halamanSocket Weld ReducerSteven D BondBelum ada peringkat

- Joint B-P1aDokumen1 halamanJoint B-P1akapsarcBelum ada peringkat

- Aquamarine Water Treatment SW PlantsDokumen5 halamanAquamarine Water Treatment SW PlantsZainalBelum ada peringkat

- Coatings Paints BrochureDokumen2 halamanCoatings Paints BrochureroladinBelum ada peringkat

- Is 4431Dokumen19 halamanIs 4431Nav TalukdarBelum ada peringkat

- Bar and DrawingDokumen54 halamanBar and DrawingJe Siti NazuraBelum ada peringkat

- Chemosil 602Dokumen2 halamanChemosil 602adhityaBelum ada peringkat

- Bondhus CatalogDokumen52 halamanBondhus CatalogCarbide Processors IncBelum ada peringkat

- Duratomic TP Brochure GT15-214 PDFDokumen24 halamanDuratomic TP Brochure GT15-214 PDFDeysi CardenasBelum ada peringkat

- Catálogo 37FSDokumen6 halamanCatálogo 37FSMarcos Marcandali de JesusBelum ada peringkat

- Standard Item Code 19102016Dokumen131 halamanStandard Item Code 19102016hermawan saputroBelum ada peringkat

- List of TESDA Acc Assessment Centers PDFDokumen119 halamanList of TESDA Acc Assessment Centers PDFSollee Montaño FerrerBelum ada peringkat

- Standard Practice For Preparation of Copper and Copper-Base Alloys For Electroplating and Conversion CoatingsDokumen4 halamanStandard Practice For Preparation of Copper and Copper-Base Alloys For Electroplating and Conversion CoatingsJulio EcheverryBelum ada peringkat

- Manufacturing Process AssignmentDokumen9 halamanManufacturing Process AssignmentSaad Ur Rehman0% (1)

- Tugas OPB (Fadiya Salwa Zaizafun 1700020130)Dokumen12 halamanTugas OPB (Fadiya Salwa Zaizafun 1700020130)Fadiya Salwa ZaizafunBelum ada peringkat

- Aerofom - Alu Glass Tape Technical Data SheetDokumen1 halamanAerofom - Alu Glass Tape Technical Data SheetChris SolonBelum ada peringkat

- Lec6 PDFDokumen27 halamanLec6 PDFSANJAY KUMAR YADAV MtechBelum ada peringkat

- Aero HF585BDokumen2 halamanAero HF585BcarmaBelum ada peringkat

- Hardness TestDokumen2 halamanHardness TestjorgekarlosprBelum ada peringkat