Vib - Use of Maximum

Diunggah oleh

Hatem AbdelrahmanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Vib - Use of Maximum

Diunggah oleh

Hatem AbdelrahmanHak Cipta:

Format Tersedia

835 Innovation Drive Knoxville, TN 37932 Phone: (865) 675-2110 Fax: (865) 675-3100 Customer Support: (865) 671-4274

DoctorKnow Application Paper

Title: Use of Maximum Peak Time Waveform Trend Parameter Source/Author: Nelson Baxter Product: Data Collector/Analyzer Technology: Vibration

Use of Maximum Peak Time Waveform Trend Parameter

Written By Nelson Baxter ABM Technical Services Plainfield, IN Edited By Todd Reeves Computational Systems, Incorporated Knoxville,TN

Introduction:

This paper presents some examples of the use of the Maximum Peak Time Waveform Parameter. This feature, patented by CSI, is used exclusively in the route based mode of CSI's 2120 Machinery Analyzer. ABM Technical Services has found this parameter to be very useful in identifying bearing problems. In many cases, this parameter will flag a problem that every other parameter misses.

Background:

Depending upon overall velocity readings or velocity spectra alone to detect bearing problems can result in errors. The following are two reasons that can explain why velocity readings need to be backed up with other analysis parameters. Most advanced analysts understand that the FFT is a batch process. For instance to generate a 400 line spectrum, 1024 time samples are taken. All of these samples are used in the calculation of the spectral components. Depending upon the type of weighting window, some values may be attenuated and others amplified, but they are nonetheless all used in the calculations. If the signal is continuous as in the case of unbalance, vane-pass or electrical problems, the FFT does a good job of calculating an accurate magnitude of each spectral component. If, however, the signal is transient relative to the time period of the analysis window, the amplitudes calculated by the FFT will be in error. In the case of bearings with defects, that is exactly the situation that exists. For instance, if a maximum frequency range of 2000 Hz is selected at a setting of 400 lines, the time period to collect the data would be 400/2000 which equals 0.2 seconds. If a machine is running 20 Hz and has a bearing defect frequency of 4.8 times its speed, the impact rate would be 96 times per second. In the 0.2 second window, nineteen impacts could be expected. This means

that if the pulses are one sample wide that of the 1024 time samples only nineteen would have energy associated with the bearing defect. When the FFT is calculated, the bearing defect frequency will have a very low value. If there is any noise present, it is likely that the bearing defect will be totally lost below the noise floor. To make matters worse, when the maximum frequency is increased, there are even fewer impacts in the time sample. For instance in the above sample, if the maximum frequency is set to 5000 HZ, the time period would then be 0.08 seconds and the number of defect impacts would be reduced to less than eight. If a couple of those are attenuated by the Hanning window on each end of the time block, there is nothing left to create a bearing defect spectral component. The second reason that velocity and velocity spectra can miss a bearing problem is that velocity spectra by the very nature of the physics involved are produced by integrating the acceleration signal. Defects are impactive pulse events. The sharper and narrower the impact, the more the integration process will attenuate round-off and smear their characteristics. As a result of these problems, other techniques have been developed that reinforce the velocity readings. Envelope detection and CSI's PeakVueTTM (PeakVue is a registered trademark of Computational Systems, Incorporated.) technology are valuable techniques that help in the early detection of bearing problems. However, not everyone takes enveloped or PeakVue data, because extra data has to be taken and then interpreted.

The Value Of The Maximum Peak Time Waveform Parameter

ABM Technical Services has found that for the vast majority of bearings an extremely valuable aid in calling out bearings is monitoring a trend of the maximum peak value detected in the raw RMS acceleration time display. The analyzer is set up for digital integration with the spectra then being displayed in velocity. A time plot is obtained in acceleration. A Maximum Peak Time parameter is then setup. By monitoring the peak value seen in the time display, impacts due to bearing defects can easily be detected. They are neither FFT'd nor integrated away. Every month we detect problems with this technique that do not show up in velocity or even RMS Acceleration measurements. The following are some plots of data showing a comparison between the Maximum Peak Time parameter and velocity or RMS Acceleration trends. VELOCITY TREND OF BAD BEARING MAX PEAK IN TIME TREND

VELOCITY SPECTRA TIME WAVEFORM NOT MUCH IS SEEN THE CHANGE IS OBVIOUS

The above plots show what is occurring. In terms of the velocity level, there was not much of an increase. This is also reflected in the velocity spectra. There is an increase in the broad base band energy. However, as can be seen from the Maximum Peak trend, which records the highest acceleration level in the time block, there was a very significant increase. As would be expected, the time based plot has much higher levels. It after all is where the maximum peak in measured.

A Case Of Another Motor Bearing:

VELOCITY TREND RMS ACCELERATION TREND

VELOCITY SPECTRA MAXIMUM PEAK IN WAVEFORM TREND Not much here

TIME PLOTS IN G'S SHOWS CHANGE

In this case, there was virtually no increase in the overall velocity. There is some broad band energy in the velocity spectra that if recognized could have been analyzed. The RMS Acceleration went up some and the Maximum Peak in Time went up the most.

Use of Maximum Peak in Time with PeakVue

The above case shows how the Maximum Peak in Time Parameter can be used in conjunction with PeakVue data to make it an even more effective tool in recognizing short duration transients that may signal a problem. This was a very low speed piece of equipment. The time based data was taken over an 8 second time period. The PeakVue time plot clearly shows the presence of impacts as high as 3.6 G's (Lower right display). This was easily picked up in the Maximum Peak in time plot(Lower left plot). However, as can be seen, the trend in the overall PeakVue value only shows a maximum of 0.316 G's (Upper left display) and the maximum spectral component was only 0.06 G (Upper right display). This is a good example of the problem discussed at the beginning of this paper. As stated in the beginning, the FFT is a batch process and as such it does not produce a good representation of the severity of transient events such as impacts from bearings or chipped gear teeth. The method ABM Technical Services has found most effective is to monitor, trend and then alarm on the following parameters: 1. Velocity: Works best on unbalance, looseness, misalignment, vane-pass, electrical and other continuous signals. 2. RMS Acceleration: Works well when broad band signals such as cavitation or bearings with multiple defects are present. 3. Maximum Peak In Acceleration Time Plot: Works very well when there are transient impacts that the integrated FFT and/or RMS do not pickup. 4. PeakVue: Is vital in low speed applications 5. Maximum Time in PeakVue: Is helpful in very low speed applications where the impacts don't occur very often. Note the above parameters are only flags. AN analysis then has to be performed to determine if there is actually a problem and how severe it is. However, it is very important to have as good a radar system as possible. If you collect, for instance 3000 points, it is imperative that there be a reliable method of screening the data to determine which points to analyze. The above combination of parameters catches a very high percentage of all problems that occur. Due to the reasons stated in the first part of this paper, the Maximum Peak in Time parameter is a vital part of that detection system because it catches what other parameters sometimes miss. All contents copyright 1998, Computational Systems, Inc. All Rights Reserved.

Anda mungkin juga menyukai

- Understandingamp - Phaseinrotatingmachineryvibinst 07 20pgsDokumen20 halamanUnderstandingamp - Phaseinrotatingmachineryvibinst 07 20pgsHatem Abdelrahman100% (1)

- Field Balancing Large Rotating MachineryDokumen26 halamanField Balancing Large Rotating MachineryShantanu SamajdarBelum ada peringkat

- Huang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDDokumen130 halamanHuang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDHatem AbdelrahmanBelum ada peringkat

- Fault Zone - : Air GapDokumen0 halamanFault Zone - : Air GapHatem AbdelrahmanBelum ada peringkat

- The Magnetic Center Finding Using Vibrating Wire TechniqueDokumen6 halamanThe Magnetic Center Finding Using Vibrating Wire TechniqueHatem AbdelrahmanBelum ada peringkat

- Icmtech435435 345435 43543Dokumen63 halamanIcmtech435435 345435 43543Hatem Abdelrahman100% (1)

- WEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishDokumen40 halamanWEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishHatem AbdelrahmanBelum ada peringkat

- Practical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetDokumen2 halamanPractical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetHatem AbdelrahmanBelum ada peringkat

- Dynamic Stresses Hydro Power Plant RKAggarwalDokumen22 halamanDynamic Stresses Hydro Power Plant RKAggarwalDheeraj DhimanBelum ada peringkat

- 19 KKKKKKKKKKKKKKKKKKDokumen4 halaman19 KKKKKKKKKKKKKKKKKKHatem Abdelrahman100% (1)

- Article 6hy JytjuytDokumen7 halamanArticle 6hy JytjuytHatem AbdelrahmanBelum ada peringkat

- Gei 100351Dokumen32 halamanGei 100351Hatem Abdelrahman100% (1)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYDokumen46 halamanEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- Prec Maint March 2007Dokumen9 halamanPrec Maint March 2007Hatem AbdelrahmanBelum ada peringkat

- Don't Get Soft: Cover Series: Installation Best PracticesDokumen6 halamanDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Article 6hy JytjuytDokumen7 halamanArticle 6hy JytjuytHatem AbdelrahmanBelum ada peringkat

- Vibrations NotesDokumen43 halamanVibrations NotesNicolas LuchmunBelum ada peringkat

- V106 Relative Motion Record FormDokumen0 halamanV106 Relative Motion Record FormHatem Abdelrahman100% (1)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYDokumen46 halamanEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- Customer Application Centers: Global Accessibility To Our TechnologyDokumen1 halamanCustomer Application Centers: Global Accessibility To Our TechnologyHatem AbdelrahmanBelum ada peringkat

- Best Practices: Asset Condition ManagementDokumen2 halamanBest Practices: Asset Condition ManagementHatem AbdelrahmanBelum ada peringkat

- 1q07 Beat Freq Back To BasicsDokumen3 halaman1q07 Beat Freq Back To BasicsHatem AbdelrahmanBelum ada peringkat

- 1q03 3500 22mDokumen4 halaman1q03 3500 22mscribdkhatnBelum ada peringkat

- Kingsbury Leg ComponentsDokumen3 halamanKingsbury Leg ComponentsHatem Abdelrahman100% (1)

- IBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsDokumen4 halamanIBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsHatem AbdelrahmanBelum ada peringkat

- 2 Q 01 HanifanDokumen2 halaman2 Q 01 HanifanHatem AbdelrahmanBelum ada peringkat

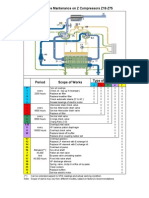

- Preventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsDokumen1 halamanPreventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsHatem AbdelrahmanBelum ada peringkat

- Why Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsDokumen2 halamanWhy Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsHatem AbdelrahmanBelum ada peringkat

- Ontario Power Generation's Nanticoke Power PlantDokumen3 halamanOntario Power Generation's Nanticoke Power PlantHatem AbdelrahmanBelum ada peringkat

- Helping You ... : Fourth Quarter 1999 Vol. 20 No. 4Dokumen1 halamanHelping You ... : Fourth Quarter 1999 Vol. 20 No. 4Hatem AbdelrahmanBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- DFS PDFDokumen149 halamanDFS PDFRabia SaeedBelum ada peringkat

- 087 GC2014 Deterministic Marine Deghosting Tutorial and AdvancesDokumen6 halaman087 GC2014 Deterministic Marine Deghosting Tutorial and AdvancesSudip RayBelum ada peringkat

- AN3716 Folded-Frequency CalculatorDokumen5 halamanAN3716 Folded-Frequency Calculator郑登宇Belum ada peringkat

- Envelope Analusis-The Key To Rolling-Element Bearing DiagnosisDokumen4 halamanEnvelope Analusis-The Key To Rolling-Element Bearing DiagnosisNuM NaBelum ada peringkat

- 42-Comparing MCSA With Vibration Analysis in Order To Detect Bearing Faults - A Case Study PDFDokumen7 halaman42-Comparing MCSA With Vibration Analysis in Order To Detect Bearing Faults - A Case Study PDFPoonthalirBelum ada peringkat

- Arai Et Al. - 2019 - Proceedings of The Future Technologies Conference PDFDokumen1.188 halamanArai Et Al. - 2019 - Proceedings of The Future Technologies Conference PDFjpcoteBelum ada peringkat

- (Course Booklet For PG Section) Handbook of Informationv6Dokumen70 halaman(Course Booklet For PG Section) Handbook of Informationv6Pitambar KunduBelum ada peringkat

- Vibxpert Catalog EN 04122014 PDFDokumen78 halamanVibxpert Catalog EN 04122014 PDFRizal RivaldiBelum ada peringkat

- Tatarski - Wave Propagation in A Turbulent Medium (1961)Dokumen154 halamanTatarski - Wave Propagation in A Turbulent Medium (1961)Joel Rasch100% (1)

- Comparison of PSD of Normal and Abnormal ECGsDokumen5 halamanComparison of PSD of Normal and Abnormal ECGsEduardoHernandezBelum ada peringkat

- Analisis de Vibraciones SKFDokumen118 halamanAnalisis de Vibraciones SKFJose EsquedaBelum ada peringkat

- Jacobi 2009 - On Measuring and Analyzing Vowels and DiphthongsDokumen12 halamanJacobi 2009 - On Measuring and Analyzing Vowels and DiphthongsfajarfitrianBelum ada peringkat

- MECH826 Week05 MachineVibrationStandardsandAcceptanceLimitsDokumen78 halamanMECH826 Week05 MachineVibrationStandardsandAcceptanceLimitsDefinal ChaniagoBelum ada peringkat

- On The Spectrum Behavior of Vibrated Granular MatterDokumen4 halamanOn The Spectrum Behavior of Vibrated Granular MatterJofi001Belum ada peringkat

- 7.+PDACS7 PhaseNoise Final KNDokumen25 halaman7.+PDACS7 PhaseNoise Final KN張敬昊Belum ada peringkat

- Assignment 22 PDFDokumen5 halamanAssignment 22 PDFsayan mukherjeeBelum ada peringkat

- ISO 4180 INTERNATIONAL STANDARD. Packaging Complete, Filled Transport Packages General Rules For The Compilation of Performance Test SchedulesDokumen24 halamanISO 4180 INTERNATIONAL STANDARD. Packaging Complete, Filled Transport Packages General Rules For The Compilation of Performance Test Schedulesירון אהרון שיטריתBelum ada peringkat

- Smith Julius, Signal Processing Libraries For FaustDokumen9 halamanSmith Julius, Signal Processing Libraries For FaustaffiomaBelum ada peringkat

- FEMCI Book - Random Vibration Specification Magnitude EquationsDokumen2 halamanFEMCI Book - Random Vibration Specification Magnitude EquationsVijet BhandiwadBelum ada peringkat

- Environmental Conditions and Environmental Loads: MARCH 2000Dokumen5 halamanEnvironmental Conditions and Environmental Loads: MARCH 2000Raakze MoviBelum ada peringkat

- CVTT Series: Belt Driven Cabinet FansDokumen7 halamanCVTT Series: Belt Driven Cabinet Fansbasheer9Belum ada peringkat

- Esacrack-Course-2012-18-Additional Examples - ESALOAD-ESAFATIG-v3a-final PDFDokumen7 halamanEsacrack-Course-2012-18-Additional Examples - ESALOAD-ESAFATIG-v3a-final PDFDaniel González JuárezBelum ada peringkat

- Ship PropulsionDokumen86 halamanShip PropulsionYao WeiBelum ada peringkat

- Chatter in Hot Rolling MillDokumen8 halamanChatter in Hot Rolling MillSreekanthMylavarapuBelum ada peringkat

- Lecture11 Line CodingDokumen37 halamanLecture11 Line CodingDebasis Chandra100% (1)

- Jitter-Understanding It, Measuring It, Eliminating It Part 1: Jitter FundamentalsDokumen5 halamanJitter-Understanding It, Measuring It, Eliminating It Part 1: Jitter FundamentalsAbhishek SharmaBelum ada peringkat

- CFD simulations of Laminar Vortex Shedding with openFoamDokumen18 halamanCFD simulations of Laminar Vortex Shedding with openFoamVladimir Valdivia LlancaBelum ada peringkat

- HiltA Centra Course 20160617Dokumen60 halamanHiltA Centra Course 20160617Islam MoinulBelum ada peringkat

- A Vibration Based Condition Monitoring SystemDokumen4 halamanA Vibration Based Condition Monitoring SystemkankokwahBelum ada peringkat

- DSP Lab ManualDokumen20 halamanDSP Lab ManualRavi RavikiranBelum ada peringkat