389 - R10 - Moni 200H e

Diunggah oleh

John Arllan DiestroJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

389 - R10 - Moni 200H e

Diunggah oleh

John Arllan DiestroHak Cipta:

Format Tersedia

MONI-200N-E

Multi-circuit trace-heating control and monitoring unit

The MoniTrace 200N-E unit is the central element of a multi-circuit electronic control and monitoring system for trace-heating used in process temperature maintenance and frost protection applications. The unit controls up to 130 trace-heating circuits in either surface sensing, ambient sensing, or PASC. PASC The proportional ambient sensing control (PASC) mode uses a proprietary algorithm that measures ambient temperature and calculates the cycle time during which the trace-heating will be energised. On cold days, the heating cables are energised frequently. On warm days, they are energised less frequently, or not at all. Using PASC, the MoniTrace 200N-E unit can be used to control groups of trace-heating circuits based solely on ambient temperature. Therefore, flow path design considerations can be eliminated, greatly reducing the number of circuits required, thus saving circuit breakers, panel space, wiring, and controllers. The result is a simpler, more reliable system.

Control Heating cable circuits are switched ON and OFF using up to 10 remote modules for control (RMCs) typically located in trace-heating power distribution panels. Each RMC unit can be configured for 2 to 32 relay outputs, which are wired directly to heating cable power contactors. RMCs are connected via a single, twisted pair RS-485 cable to the MoniTrace 200N-E. Monitoring The MoniTrace 200N-E monitors up to 16 remote monitoring modules (RMMs) that each have inputs for eight three wire Pt 100 temperature sensors. The RMMs are typically located as close as possible to the application in order to minimize the amount of RTD wires required. RMM2 units are connected to the MoniTrace 200N-E control unit using the same RS-485 network as being used by the RMCs and are connected by the same RS-485 cable to the MoniTrace 200NE. Additional monitoring of the status of RCDs and contactors is provided through inputs in the MoniTrace 200N-E unit and in RMCs.

Based on temperature inputs from RMMs, the MoniTrace 200N-E determines which heating cable circuits are to be energised and sends this information to RMCs that then turn the heating cable power contactors ON or OFF. Because RMMs are local to temperature sensors and RMCs are local to contactors in distribution panels, wiring costs and complexity are reduced significantly. User interface Set-up parameters, system status, and alarm conditions are available locally at the MoniTrace 200N-E panel or remotely via an RS-232/RS-485 link to a host system supporting the Modbus protocol, such as a PC running Raychems MoniTrace Supervisor software. For local use, the MoniTrace 200N-E features a function keypad and 4-line LCD display that make controller set-up and system status review simple.

Mo

rac niT

e2

00

MoniTrace 200N-E

DOC-389 Rev.10 03/06

126

MONI-200N-E

Dimensions (in mm)

300 mm 20 mm 261 mm

25 mm

77 mm

20 mm

MoniTrace 200N

POWER

GRP 1

GRP 2

ALARM

200 mm

Test Ack Reset

240 mm

Menu

Esc

Enter

Removable gland plate on bottom of enclosure for entries.

8 mm dia. typical

General Area of use Approvals Supply voltage (nominal) Internal power consumption Enclosure Protection Base and lid Lid fixing Entries Power cable gland Control cable gland Sensor/network cable glands Ambient operating temperature range Ambient storage temperature range Relative humidity Climate class IP54 Material: steel, coating: powder painted, lid seal: neoprene 1 flathead screw None provided, space for 6 x M20 entries on removable gland plate 1 x M20, 6-12 mm cable, IP54 min. 1 x M20, 5-9 mm cable, IP54 min. 3 x M16, 2-6 mm cable, IP54 min. 0C to +50C 20C to +60C Max. 95%, noncondensing 3K3, per EN 60 721 Ordinary area, indoors

FM

APPROVED

100 / 120 V, 208 / 240 V +10% -10%, 50/60 Hz switch selectable 5W

Also available as panel mount version suitable for custom panel applications (MONI-200N-PM) Monitoring inputs Ambient or pipe temperatures One or two Pt 100 sensors directly connected to MoniTrace 200N-E The sensor cable may be extended with a 3 (+PE)-wire signal cable adding 20 Ohms lead resistance maximum. When using 1.5 mm2 cable this equals to 150 m of cable. When the sensor cable is laid in cable ducts or in the vicinity of high voltage carrying cables the sensor extension cable should be shielded. The shield of the extension cable should be grounded at the controller end only. Up to 128 Pt 100 sensors connected via Remote Monitoring Modules (RMMs) 2 digital inputs per MoniTrace 200N-E or optional one per circuit via MONI-RMC and MONI-RMC-2DI 2 digital inputs per MoniTrace 200N-E or optional one per circuit via MONI-RMC and MONI-RMC-2DI

RCD trip alarm Contactor actuation monitor Control outputs Number of output relays

Two independently switching control relays (internal) Up to 128 control relays connected via RMCs and MONI-RMC-2RO One alarm relay (internal) Double pole change over, NC. Rating: 5 A, 120 / 240 VAC, 24 VDC Closes to energise trace-heating Double pole change over. Rating: 5 A, 120 / 240 VAC, 24 VDC Normally energised; closes in alarm mode 5 x 104 at rated current

Control relay Alarm relay Number of relay operations

DOC-389 Rev.10 03/06

127

MONI-200N-E

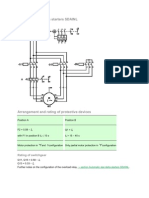

Connection details

max. 16A

*

17 CB C PWR 15 21 23

L1

L2

RS-485

60 61 27 29 28 -4

24 VDC

L N

*

RMC-BASE RMC-2RO RMC-2RO

K5 K4 K3

RMM2

+3 2 6 5

MONITRACE 200N

1 14 13 12 11 40 41 42

RS-485

......

PE

RMC

Pt 100

Pt 100

Pt 100

heating cable heating cable heating cable

trace-heating system group control (or individual control, not shown)

K1 K2 K3 K4 K5

= = = = =

Control contactort for Group 1 Power monitor contactor for Group 1 heating cable heating cable heating cable Control contactor for individual control heating circuit 1 trace-heating system individual Control contactor for individual control heating circuit 2 control or group control Control contactor for individual control heating circuit 13

* Two- or four-pole electrical protection by circuit-breaker may be needed for local circumstances, standards and regulations. ** Depending on the application, one- or three-pole circuit-breakers or contactors may be used. Network connections Connection to RMMs and RMCs Number of RMM2s Number of RMCs Host communication connection Host communication protocol Programming and setting Method Language Stored parameters Memory Set points Control modes 10 touch keys on front panel (Test, Reset, Ack, Menu, Esc, Enter, , , , ) Four-line, 20-character back-lit LCD display English, French, German Control settings, system settings, time- and date-stamped event log Nonvolatile, restored after power loss Pipe maintain temperature range: 7C to +315C Minimum ambient temperature range: 73C to +52C User-selectable for each circuit: Line (surface) sensing PASC (proportional ambient sensing) Ambient sensing ON/OFF Fixed duty cycle (0-100%) High/low pipe or ambient temperature Sensor failure Communications failure RCD trip Contactor failure Daily power test (user-defined time of day) Contactor on/off cycle counter and alarm Heating cable hourly usage counter With the timed start-up function the MONI-200N-E controller can be programmed such that the control circuits are switched ON one after another with in between a programmable delay. The function is integrated as 2 user definable timers LoadShed Start and LoadShed Int. Using the LoadShed functions can avoid peak demands in electrical power when the system is started-up at low ambient temperature. RS-485 shielded twisted pair network cable, maximum length 1200 m (MONI-RS485-WIRE) Up to 16, individually addressable, each with up to 8, 3 wire Pt 100 inputs Up to 10, individually addressable, each with 2 to 32 relay outputs. Serial port, RS-232 (default) or RS-485, max. 19200 baud rate Modbus, RTU or ASCII

Alarm conditions

Maintenance assistance

Timed start up

DOC-389 Rev.10 03/06

128

MONI-200N-E

Connection terminals Supply Internal earth Pt 100 connections Control relay connection RCD alarm relay connection Contactor relay connection Alarm relay connection RS-485 connection to RMM and RMC RS-485 connection to host computer Electromagnetic compatibility Immunity Emissions Mounting method Complies with EN 50 082-2 (heavy industrial) Complies with EN 50 081-1 (light industrial) Surface mounting with 4 fixing holes on 261 mm x 200 mm centres Hole diameter: 8 mm Part description PN 266429-000 746245-000 967094-000 140910-000 549097-000 Weight 3.9 kg 3.2 kg 0.6 kg 0.2 kg 75 kg (300 m reel) 2 terminals for 0.2 mm2 to 4 mm2 1 clamp for 0.2 mm2 to 10 mm2 2 x 3 terminals for 0.2 mm2 to 2.5 mm2 2 x 2 terminals for 0.2 mm2 to 2.5 mm2 2 x 2 terminals for 0.2 mm2 to 2.5 mm2 2 x 2 terminals for 0.2 mm2 to 2.5 mm2 3 terminals for 0.2 mm2 to 2.5 mm2 3 terminals for 0.2 mm2 to 2.5 mm2 RS-485: 3 terminals for 0.2 mm2 to 2.5 mm2 RS-232: 6 terminals for 0.2 mm2 to 2.5 mm2

Ordering details (Weight)

MoniTrace 200N-E controller including MONI-200N-E supervisory software on CD Panel mount version without enclosure Pt 100 temperature sensor for Zone 1 Pt 100 temperature sensor for non-hazardous areas RS485 Communication cable MONI-200N-PM MONI-PT100-EXE MONI-PT100-NH MONI-RS485-WIRE

note: Easy to use windows based configuration software (MoniTrace Supervisor) included for confortable configuration and supervision.

DOC-389 Rev.10 03/06

129

Anda mungkin juga menyukai

- Suportes e RTD EuropaDokumen26 halamanSuportes e RTD EuropaPaulo CostaBelum ada peringkat

- Acme PIUDokumen4 halamanAcme PIUJay TrivediBelum ada peringkat

- DKG-307 Automatic Mains Failure Unit: Canbus and Mpu VersionsDokumen2 halamanDKG-307 Automatic Mains Failure Unit: Canbus and Mpu VersionsYuri Da Gama SantosBelum ada peringkat

- 111-300 Trans Temp MonDokumen4 halaman111-300 Trans Temp MonLucian2001Belum ada peringkat

- Power Interface UnitDokumen2 halamanPower Interface UnitPushkar MishraBelum ada peringkat

- Eurotherm 818Dokumen8 halamanEurotherm 818Luis Carlos GutierrezBelum ada peringkat

- DKG-509 Automatic Mains Failure Unit: Canbus and Mpu VersionsDokumen2 halamanDKG-509 Automatic Mains Failure Unit: Canbus and Mpu VersionsAnonymous V9fdC6Belum ada peringkat

- Instruction TEC TF7650Dokumen24 halamanInstruction TEC TF7650turboedBelum ada peringkat

- Smart Temperature Transmitter: Application AreasDokumen8 halamanSmart Temperature Transmitter: Application AreasautrolBelum ada peringkat

- Altec: Instruction ManualDokumen33 halamanAltec: Instruction Manualfrankie35Belum ada peringkat

- 317 DatakomDokumen2 halaman317 DatakomAbdul KhaliqBelum ada peringkat

- Mini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273Dokumen7 halamanMini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273vijicsaBelum ada peringkat

- Motan 960Dokumen11 halamanMotan 960DgfdghfghFfdhgfhjgBelum ada peringkat

- 118L Digital BulletinDokumen4 halaman118L Digital Bulletinmbk.2k3Belum ada peringkat

- Ea2 TX 100 HDDokumen2 halamanEa2 TX 100 HDAdam Mazurek0% (1)

- MPR2000Dokumen40 halamanMPR2000JoselopezperezBelum ada peringkat

- DKG-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsDokumen2 halamanDKG-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsThao Nguyen XuanBelum ada peringkat

- Emcp 2Dokumen4 halamanEmcp 2Muhammad Ahsen100% (2)

- DK PC3000 ModulesDokumen11 halamanDK PC3000 ModulessickosatBelum ada peringkat

- Gefran 600 DatasheetDokumen4 halamanGefran 600 DatasheetAnderson OliveiraBelum ada peringkat

- Instruction Manual: Dossena S.N.CDokumen12 halamanInstruction Manual: Dossena S.N.CRazvan SasuBelum ada peringkat

- Manual 1 PDFDokumen31 halamanManual 1 PDFdarrel_julioBelum ada peringkat

- NT935 Standard ING R4Dokumen12 halamanNT935 Standard ING R4JorgeAlvesBelum ada peringkat

- Am100 Flyer eDokumen2 halamanAm100 Flyer eRazvan PredaBelum ada peringkat

- Ate 310Dokumen4 halamanAte 310Edder Moises Simon LozanoBelum ada peringkat

- 0144 MNEC CommunicationsDokumen4 halaman0144 MNEC CommunicationsVagelis AntoniouBelum ada peringkat

- DKG-307 Automatic Mains Failure Unit: Canbus and Mpu VersionsDokumen2 halamanDKG-307 Automatic Mains Failure Unit: Canbus and Mpu VersionsThao Nguyen XuanBelum ada peringkat

- DKG-329 Ats Controller: 2 Gensets + MainsDokumen2 halamanDKG-329 Ats Controller: 2 Gensets + MainsmxnoxnBelum ada peringkat

- Elec Floor Heating HandbookDokumen60 halamanElec Floor Heating HandbookNavanee KrishnanBelum ada peringkat

- DATAKOM DKG519 DatasheetDokumen2 halamanDATAKOM DKG519 DatasheetDanh TrầnBelum ada peringkat

- E7000 - Instruction Manual - v10Dokumen38 halamanE7000 - Instruction Manual - v10edcooBelum ada peringkat

- Flatpack 2Dokumen18 halamanFlatpack 2NamVTNBelum ada peringkat

- Termostat Honeywell DT92A1004Dokumen17 halamanTermostat Honeywell DT92A1004FlorinBelum ada peringkat

- Signal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsDokumen11 halamanSignal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsFeela NazBelum ada peringkat

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDokumen5 halamanSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicBelum ada peringkat

- Ad00879m Nuflo Scanner 2200 Efm Data SheetDokumen4 halamanAd00879m Nuflo Scanner 2200 Efm Data SheetCarlos Alberto MoviBelum ada peringkat

- Temperature Controller T2612 Instruction ManualDokumen16 halamanTemperature Controller T2612 Instruction ManualtduskoBelum ada peringkat

- 2416 CatalougeDokumen8 halaman2416 CatalougeSuresh N ReddyBelum ada peringkat

- Fludex EOC SystemDokumen11 halamanFludex EOC SystemSholhan Aziz100% (2)

- Flatpack2 Rectifier 242000Dokumen2 halamanFlatpack2 Rectifier 242000nhlongdnBelum ada peringkat

- Feeder ProtectiondetDokumen22 halamanFeeder ProtectiondetNitish SinghBelum ada peringkat

- Mnb-300 Bacnet Unitary Controller: Tac I/A SeriesDokumen4 halamanMnb-300 Bacnet Unitary Controller: Tac I/A SeriesCED1100Belum ada peringkat

- Dkg-329 Automatic Transfer Switch Controller: With Uninterrupted Transfer and Multiple Genset SupportDokumen2 halamanDkg-329 Automatic Transfer Switch Controller: With Uninterrupted Transfer and Multiple Genset SupportJermaine PeñaBelum ada peringkat

- T2612-AD - 20 +200 OFFSET 25 ENG r.1.2Dokumen16 halamanT2612-AD - 20 +200 OFFSET 25 ENG r.1.2tduskoBelum ada peringkat

- Automatic Weather StationDokumen8 halamanAutomatic Weather StationMyat Tun OoBelum ada peringkat

- Mmy 170Dokumen4 halamanMmy 170thotalnBelum ada peringkat

- (Lehe0124-00) RTD Module - Emcp 4Dokumen4 halaman(Lehe0124-00) RTD Module - Emcp 4victor.ciprianiBelum ada peringkat

- K 76 800 - ARIES - NetLink - 10 8 14Dokumen14 halamanK 76 800 - ARIES - NetLink - 10 8 14DioBelum ada peringkat

- WWW - Johnsoncontrols.in Content Dam WWW Jci Be Eu Library Product Information Bms Products Electronic Control Tech Info Facility Explorer Product Bulletin TUC0311 Europe 12 2011Dokumen11 halamanWWW - Johnsoncontrols.in Content Dam WWW Jci Be Eu Library Product Information Bms Products Electronic Control Tech Info Facility Explorer Product Bulletin TUC0311 Europe 12 2011Leo Prasanth Xavier MartinBelum ada peringkat

- Dkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionDokumen2 halamanDkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionThao Nguyen XuanBelum ada peringkat

- Vision™ OPLC™: Technical SpecificationsDokumen7 halamanVision™ OPLC™: Technical SpecificationsPaulo RobertoBelum ada peringkat

- Delta Es48 200 Uqa02Dokumen2 halamanDelta Es48 200 Uqa02Aey PalakornBelum ada peringkat

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDokumen4 halamanTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnBelum ada peringkat

- Siemens Climatix IO ModuleDokumen10 halamanSiemens Climatix IO Moduleamitdesai1508Belum ada peringkat

- Man Cseries 22862CDokumen31 halamanMan Cseries 22862Cthanna9783Belum ada peringkat

- 3 2 LJ FT 47 1Dokumen3 halaman3 2 LJ FT 47 1CatalinGhineaBelum ada peringkat

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDari EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsPenilaian: 3.5 dari 5 bintang3.5/5 (6)

- Flam DragDokumen1 halamanFlam DragJohn Arllan DiestroBelum ada peringkat

- Doc-606 R1Dokumen13 halamanDoc-606 R1John Arllan DiestroBelum ada peringkat

- PLC Basic Programme BookDokumen45 halamanPLC Basic Programme Bookapi-384889275% (4)

- Why Static ExcitationDokumen15 halamanWhy Static ExcitationJohn Arllan DiestroBelum ada peringkat

- SITRAIN Schedule 2011 1st HalfDokumen3 halamanSITRAIN Schedule 2011 1st HalfJohn Arllan DiestroBelum ada peringkat

- C158 EoDokumen1 halamanC158 EoJohn Arllan DiestroBelum ada peringkat

- CaliperDokumen1 halamanCaliperzgcaboBelum ada peringkat

- Venergy Extending Current Transformer Wire LeadsDokumen4 halamanVenergy Extending Current Transformer Wire LeadsJohn Arllan DiestroBelum ada peringkat

- Halogen Reflector enDokumen20 halamanHalogen Reflector enJohn Arllan DiestroBelum ada peringkat

- RTD Cable LayingDokumen3 halamanRTD Cable LayingNAYEEMBelum ada peringkat

- Symmetrical ComponentsDokumen2 halamanSymmetrical ComponentsHamayoun Murtaza100% (1)

- Seite154 169 HB30englisch SGE1 Console SystemsDokumen16 halamanSeite154 169 HB30englisch SGE1 Console SystemsJohn Arllan DiestroBelum ada peringkat

- Power Semiconductor Device NptelDokumen14 halamanPower Semiconductor Device NptelMohammad Aminul IslamBelum ada peringkat

- ASCO Overview BrochureDokumen16 halamanASCO Overview BrochureJohn Arllan DiestroBelum ada peringkat

- Vigirex CatalogueDokumen29 halamanVigirex CatalogueGansar Kharismawan100% (1)

- E 7 Ear Thing RequirmentsDokumen8 halamanE 7 Ear Thing RequirmentsJohn Arllan DiestroBelum ada peringkat

- NeedsDokumen8 halamanNeedsJohn Arllan DiestroBelum ada peringkat

- Junction Boxes EnclosuresDokumen13 halamanJunction Boxes EnclosuresJohn Arllan DiestroBelum ada peringkat

- Fire RatedDokumen3 halamanFire RatedJohn Arllan DiestroBelum ada peringkat

- Seite878 890 HB30englisch Accessories Bases PlinthsDokumen13 halamanSeite878 890 HB30englisch Accessories Bases PlinthsJohn Arllan DiestroBelum ada peringkat

- Seite1010 1013 HB30englisch Accessories Cable Attachment EarthingDokumen4 halamanSeite1010 1013 HB30englisch Accessories Cable Attachment EarthingJohn Arllan DiestroBelum ada peringkat

- Seite1000 1003 HB30englisch Accessories Signal ConsolesDokumen4 halamanSeite1000 1003 HB30englisch Accessories Signal ConsolesJohn Arllan DiestroBelum ada peringkat

- CatalogueDokumen56 halamanCatalogueJohn Arllan DiestroBelum ada peringkat

- HB31Dokumen1.219 halamanHB31John Arllan DiestroBelum ada peringkat

- Stage 1 Engineering AssociateDokumen6 halamanStage 1 Engineering AssociateJohn Arllan DiestroBelum ada peringkat

- Hi POT Test BasicsDokumen6 halamanHi POT Test BasicsdeepakBelum ada peringkat

- Price TagDokumen4 halamanPrice TagJohn Arllan DiestroBelum ada peringkat

- VB255ENDokumen12 halamanVB255ENJohn Arllan DiestroBelum ada peringkat

- VB255ENDokumen12 halamanVB255ENJohn Arllan DiestroBelum ada peringkat

- Sequencial Trippng of Steam Turbine Generators PDFDokumen10 halamanSequencial Trippng of Steam Turbine Generators PDFAnonymous BBX2E87aH100% (1)

- Mars Cross Reference Product-X-Ref-New PDFDokumen198 halamanMars Cross Reference Product-X-Ref-New PDFcris melosBelum ada peringkat

- TH360B Plano Sistema ElectricoDokumen4 halamanTH360B Plano Sistema ElectricoCarlos Irabedra100% (1)

- HGM7200 HGM7100A V1.6 enDokumen71 halamanHGM7200 HGM7100A V1.6 enSteven BaynesBelum ada peringkat

- Powermonitor 3000: Installation InstructionDokumen64 halamanPowermonitor 3000: Installation InstructionEmerson Gomes ToledoBelum ada peringkat

- GCP 32 - 37239 PDFDokumen45 halamanGCP 32 - 37239 PDFwagner_guimarães_1Belum ada peringkat

- AGASTAT CB-1029D-30-Tyco-ElectronicsDokumen56 halamanAGASTAT CB-1029D-30-Tyco-ElectronicsArifin SontaniBelum ada peringkat

- Metal Detecting RobotDokumen51 halamanMetal Detecting RobotBariq MohammadBelum ada peringkat

- M GB Level 1 PDFDokumen23 halamanM GB Level 1 PDFZsolt BodóBelum ada peringkat

- Automatic Star DeltaDokumen3 halamanAutomatic Star DeltaJitendra JainBelum ada peringkat

- Manual: Auto Transfer ControllerDokumen32 halamanManual: Auto Transfer ControllerAung Mh100% (1)

- B 1 22 KV 1.2,2.4&3 MVAr Cap Bank Infra Spec 240709Dokumen52 halamanB 1 22 KV 1.2,2.4&3 MVAr Cap Bank Infra Spec 240709balwant singh negiBelum ada peringkat

- ED319912Dokumen697 halamanED319912Ramesh BabuBelum ada peringkat

- Commercial Fireequipment: Silent KnightDokumen2 halamanCommercial Fireequipment: Silent KnightmiturraBelum ada peringkat

- VT400 GPS Tracker User Manual V1.3Dokumen24 halamanVT400 GPS Tracker User Manual V1.3Tony CapuanoBelum ada peringkat

- Automatic Evening LampDokumen4 halamanAutomatic Evening LampsaurabhBelum ada peringkat

- Motor Protection Relay SPAM 150 CDokumen31 halamanMotor Protection Relay SPAM 150 CJBelum ada peringkat

- Datasheet - TR22AxxKNX - ENG - ITADokumen2 halamanDatasheet - TR22AxxKNX - ENG - ITAVishal SuryawaniBelum ada peringkat

- PLC ReportDokumen26 halamanPLC Reportlordofallhearts100% (3)

- Watchdog Sepam 05Dokumen9 halamanWatchdog Sepam 05gede_trinataBelum ada peringkat

- Chapter HDokumen34 halamanChapter HSurangaGBelum ada peringkat

- Dse7200 and Dse7300 Operator ManualDokumen118 halamanDse7200 and Dse7300 Operator ManualGiapy Phuc Tran100% (3)

- BE Cat Penn SSElectronicTempControlsDokumen15 halamanBE Cat Penn SSElectronicTempControlsjose.patinojllBelum ada peringkat

- Cutler-Hammer ATS Parts ManualDokumen70 halamanCutler-Hammer ATS Parts ManualTom LeonardBelum ada peringkat

- Characteristics: Technical Data:: V (V) 300 Resistive LoadDokumen4 halamanCharacteristics: Technical Data:: V (V) 300 Resistive LoadAnoop KrishnanBelum ada peringkat

- JCB 3CX - 4CX - 214 - 214e - 215 - 217-1Dokumen25 halamanJCB 3CX - 4CX - 214 - 214e - 215 - 217-1lahcen boudaoud100% (6)

- SIemens TimerDokumen4 halamanSIemens Timervaithy1990Belum ada peringkat

- Myr HPC Manual 061014Dokumen24 halamanMyr HPC Manual 061014Neal JohnsonBelum ada peringkat

- Motor Controller CenterDokumen17 halamanMotor Controller CenterSimbu ArasanBelum ada peringkat