Duct Calculator Programme

Diunggah oleh

Mohammed Hassan Mohiuddin KhanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Duct Calculator Programme

Diunggah oleh

Mohammed Hassan Mohiuddin KhanHak Cipta:

Format Tersedia

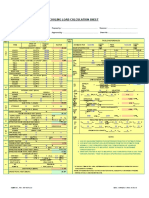

DUCT CALCULATOR PROGRAM INTRODUCTION The DUCT CALC program (hereafter called DUCT) is a program for IBM-PC's and

compatibles that calculates the required size of ducts given the maximum velocity and pressure drop allowed. It performs mathematical operations using reverse polish notation (RPN) similar to a Hewlett-Packard calculator. This program was written in BASIC by Randall C. Wilkinson and compiled into an .EXE file using Microsoft QuickBASIC. If you have a Microsoft mouse it will be automatically recognized and used. You can use the mouse to perform all DUCT functions. If the mouse is available, a number pad will appear to allow you to point to digits on the screen when entering numbers. Many default operating parameters for DUCT can be changed to suit your needs (or desires). Some of the parameters that can be changed are: max. duct velocity, max. duct pressure drop, default rectangular duct height, screen colors, menu locations on screen and numeric accuracy displayed. RPN OPERATION As mentioned above, the program operates like an HP calculator. When you enter a number, it is assumed to be an air quantity flowing in CFM. It is put into the bottom of the stack and the size of a duct is calculated according to the current sizing parameters. When you enter another number, the first number is pushed up to the second position the stack. The second CFM is sized and now occupies the bottom position in the stack. If the two ducts combine together to form a single duct, you can add the two air quantities together by pressing the '+' key. The air quantities are added together and now the new total CFM occupies the bottom spot in the stack. The new duct size is calculated and displayed. The program can perform addition, subtraction, multiplication and division. As you can see, this is a powerful tool for quickly sizing entire ductwork systems. Simply enter the air flowing from each branch in a system, the program sizes the branch duct, then that air can be added to the running total in the trunk duct, and the trunk duct will be automatically re-sized. The RPN stack can contain up to 13 items and can be saved to, or recalled from a disk file. DUCT SIZING When calculating the required size of a duct, the program will iterate until it finds the smallest standard diameter duct that does not exceed the maximum velocity or maximum pressure drop allowed. Once the diameter is calculated, the program then calculates the rectangular duct width so that the rectangular duct has the same pressure losses. The method for calculating the pressure drop in a duct was taken from the Carrier System Design Manual, Part 2, page 31. The formula for converting rectangular to round duct was taken from the same manual, page 34. Duct roughness factors used by DUCT are for new, clean, galvanized steel. Pressure drops displayed are per 100' of duct.

When started, the program assumes you are sizing low pressure/velocity ductwork. The pressure drop limit is initially set to 0.10 inches H2O/100', and velocity limit is set to 1200 FPM. STARTING DUCT Starting the program can be done by typing DUCT. After an initial title screen, a blank screen will be displayed. The block near the center of the screen is the mouse pointer. At the top of the screen is a list of all valid operators or commands and the keys that invoke them. At the right is a number pad that lets you point with the mouse to enter numbers. At the bottom of the screen is the DUCT CFM or OPERATOR prompt. This is where new numbers are entered before going into the stack. The open area in the center is where the stack will be. EXAMPLES Enter 500 then press ENTER. A duct is sized for 500 CFM. Enter 5000 then press ENTER. Another duct is sized, this time for 5000 CFM. Enter 50000 then press ENTER. Press [UP ARROW] to increase rectangular duct height, until the HT field says 60. Notice that the duct width decreases as height increases. The screen now displays three sized ducts. A 110x60 duct carrying 50,000 CFM is limited by velocity. This is confirmed by looking at the VEL field, it is near its limit of 1200 FPM. But the PDROP field says 0.016 in./100', this is well below the limit of 0.1. A more realistic maximum velocity for such a large duct might be 2500 FPM. Press 'D' for Duct data, The stack momentarily disappears, and the program prompts for a new velocity limit. Enter 2500 then press ENTER. Then it prompts for a new pressure drop limit, press ENTER to keep the same 0.1. The program now prompts for a new default duct height, press enter to keep the previous entry. The stack should re-appear. Changing the pressure drop and velocity limits will not effect ducts that have already been sized, pressing 'S' will force the duct at the bottom of the stack to be re-sized. The new diameter, velocity, and duct width will be displayed. OPERATORS An operator is an action that is performed by the program. Some operators act on numbers in the stack, some perform program control functions. All operators are invoked by pressing the keystroke corresponding to that operator as indicated at the top of the screen. The following is a description of each operator, and how it is used: ADD (`+' key) Adds the CFM in position 1 of the stack to the CFM in position 2, then erases both CFMs from the stack, and inserts the sum into position 1, pushing the remaining items up in the stack. The new CFM is sized as a duct. SUBT (`-' key)

Subtracts the CFM in position 1 of the stack from the CFM in position 2, then erases both CFMs from the stack, and inserts the difference into position 1, pushing the remaining items up in the stack. The new CFM is sized as a duct. MULT (`*' key) Multiplies the number in the CFM field in position 1 of the stack by the CFM in position 2, then erases both items from the stack, and inserts the new CFM into position 1, pushing the remaining items up in the stack. The new CFM is sized as a duct. DIVIDE (`/' key) Divides the CFM in position 2 of the stack by the number in the CFM field in CFM in position 1, then erases both items from the stack, and inserts the new CFM into position 1, pushing the remaining items up in the stack. The new CFM is sized as a duct. DROP (`X' key) Drops (discards) the item in position 1 of the stack (the bottom), and shifts the remaining items down 1 position. SWAP (`W' key) Exchanges the items in positions 1 and 2 with each other. DUP (`U' key) Moves all items in the stack up 1 position and duplicates the item now in position 2 to position 1. SIZE (`S' key) Forces the program to re-size the duct in position 1 of the stack. The redisplays the new size MODES (`M' key) Not yet implemented. Eventually will allow summing pressures rather than airflows, with the intention of being able to calculate total system pressure drop. Currently does nothing. DUCT DATA (`D' key) Prompts for velocity and pressure drop limits as well as default rectangular duct height to be used for subsequent duct sizing. MORE HT (`up arrow' key)

Increases the rectangular duct height for the duct in position 1 of the stack. The duct width is re-calculated and adjusted on screen to be equivalent to the duct diameter already calculated. LESS HT (`dn arrow' key) Decreases the rectangular duct height for the duct in position 1 of the stack. The duct width is re-calculated and adjusted on screen to be equivalent to the duct diameter already calculated. LOAD (`L' key) Reads items into the stack from a file called RPN.STK as saved by the SAVE operator. SAVE (`A' key) Writes all data in the stack to a file called RPN.STK in the current subdirectory. The file is stored as ASCII characters in a comma delimited format, with each line in the file corresponding to a stack position. The numbers are stored with full numeric accuracy, regardless of the display accuracy. This file could easily be read by LOTUS, dBASE, etc. CLEAR (`C' key) Destroys forever, all information in all positions of the stack. QUIT (`Q' key) Quits the program and returns to DOS. CUSTOMIZING When the DUCT program is started it looks in the current subdirectory for a file called DEFAULT.RPN. If that file exists, the program will read CUSTOMIZING parameters from it and use those parameters for the current DUCT session. A DEFAULT.RPN file can be loaded from another subdirectory by specifying the full path and file name as a command line parameter to the DUCT command from the DOS prompt. For example: C:\DOS>DUCT C:\MYDIR\MYSETUP.RPN

An example DEFAULT.RPN file looks like this: FORMAT HEADER : cfmdiavelpdrophtwdthlenfrict CFM FORMAT :########_ DIAM FORMAT :###_

VELOCITY FORMAT PDROP FORMAT HEIGHT FORMAT WIDTH FORMAT LENGTH FORMAT FRICTION FORMAT STACK LINE PROMPT LINE OPERATORS LINE DEFAULT PDROP DEFAULT VELOCITY DEFAULT HEIGHT DEFAULT FRICTION DEFAULT ROUNDING PAD LINE MAX LINES STACK FG STACK BG OPERATORS FG OPERATORS BG PAD FG PAD BG PROMPT FG PROMPT BG

:#####_ :##.###_ :###_ :####_ :#####_ : #.##_ :23 :25 :5 :.1 :1200 :18 :.9 :2 :20 :23 :1 :3 :3 :1 :1 :2 :15 :0

The program will read each line and look for the key words listed above. It will then skip up to and including the colon. All characters after the colon are significant. The FORMAT HEADER item is printed as a string at the top of the stack. The FORMAT items specify the way numbers will look on screen, refer to the BASIC manual, under the PRINT USING statement, for the meaning of the symbols used. The LINE items specify which screen line on the particular item will be located. Mouse sensitivity will move with the location of the item. The number used will be the screen location of the lowest line of multi-line items. The DEFAULT items specify the numbers assumed when calculating duct sizes. The FG and BG items specify the foreground and background colors as used by BASIC's COLOR command. The program will use built-in defaults for any items that do not appear in your custom DEFAULT.RPN file. Thus, you may leave out any items that do not concern you.

Anda mungkin juga menyukai

- MAXNC Operation ManualDokumen12 halamanMAXNC Operation ManualDede NurjaeniBelum ada peringkat

- FX SeriesDokumen376 halamanFX SeriesRicardoBelum ada peringkat

- Laminar Pipe Flow SimulationDokumen21 halamanLaminar Pipe Flow SimulationirqoviBelum ada peringkat

- Microprocessor, Type Mctt-7: Manual For The User and Installer Version MCTT-7 COMBIDokumen30 halamanMicroprocessor, Type Mctt-7: Manual For The User and Installer Version MCTT-7 COMBIthiago_canelaBelum ada peringkat

- Sensor de Temp. LabviewDokumen9 halamanSensor de Temp. Labviewhumber1187Belum ada peringkat

- PX 777 Programming Software InstructionsDokumen7 halamanPX 777 Programming Software InstructionsNei LobãoBelum ada peringkat

- TRA1 MessageDokumen5 halamanTRA1 MessageguestBelum ada peringkat

- Hysys Process SimulationDokumen45 halamanHysys Process SimulationseguntaiwoBelum ada peringkat

- User'S Manual Synop - Synchronous Generator Optimization Synan - Synchronous Generator AnalysisDokumen20 halamanUser'S Manual Synop - Synchronous Generator Optimization Synan - Synchronous Generator AnalysisguestBelum ada peringkat

- HASS Manual Chapter 4Dokumen28 halamanHASS Manual Chapter 4Victor KimBelum ada peringkat

- Create Base Demand Maps in EpaNETDokumen3 halamanCreate Base Demand Maps in EpaNETAnonymous iTzCnMBelum ada peringkat

- Tutorial Urbano 7 CanalisDokumen75 halamanTutorial Urbano 7 CanalisStroe GeorgeBelum ada peringkat

- High Frequency Amplifier Introduction to ADSDokumen26 halamanHigh Frequency Amplifier Introduction to ADSJulio AltamiranoBelum ada peringkat

- A. Visual Basic and DOS SoftwareDokumen3 halamanA. Visual Basic and DOS SoftwareClaudia CastañoBelum ada peringkat

- Assembly Language Lecture From Engr GatdulaDokumen16 halamanAssembly Language Lecture From Engr GatdulaMary Rose SantiagoBelum ada peringkat

- Smart Duct Sizer V 3.0Dokumen10 halamanSmart Duct Sizer V 3.0ashishBelum ada peringkat

- Tuning Applications Using The Profile User CommandDokumen22 halamanTuning Applications Using The Profile User CommandHRCBelum ada peringkat

- Algorithms and FlowchartsDokumen12 halamanAlgorithms and FlowchartsGeovanni Collantes DumpasanBelum ada peringkat

- Calculator NetafimDokumen26 halamanCalculator Netafimradiofonistu100% (1)

- Showcase Article - Report Layout Utility (RLU)Dokumen2 halamanShowcase Article - Report Layout Utility (RLU)Ino Gomez LarrozaBelum ada peringkat

- xlTRANSFER QuickStartDokumen2 halamanxlTRANSFER QuickStartNecrophagusBelum ada peringkat

- Techno Main Salt Lake: Group Number-A.7Dokumen28 halamanTechno Main Salt Lake: Group Number-A.7SHAMINDRA SENBelum ada peringkat

- User Manual Handheld Inkjet Printer QM-750: Please Read The User Manual Carefully To Use The Printer in Better WayDokumen14 halamanUser Manual Handheld Inkjet Printer QM-750: Please Read The User Manual Carefully To Use The Printer in Better Wayx94p4s46rmBelum ada peringkat

- Area, Volume Calculator - C++ Input/Output PracticeDokumen3 halamanArea, Volume Calculator - C++ Input/Output PracticeAditya ElayavalliBelum ada peringkat

- Tutorial For Urbano Hydra 7 Version 1Dokumen92 halamanTutorial For Urbano Hydra 7 Version 1dobridorinBelum ada peringkat

- EDSIMDokumen44 halamanEDSIMsania20110% (1)

- MPMC 1Dokumen84 halamanMPMC 1Kiran TejaBelum ada peringkat

- Creating an Inverter in S-EditDokumen18 halamanCreating an Inverter in S-EditmanirnaiduBelum ada peringkat

- Spice For Ece 3041/ece3042: Pspice Ad - LNKDokumen7 halamanSpice For Ece 3041/ece3042: Pspice Ad - LNKRyan Alexander BahrBelum ada peringkat

- NASCOM NAS-SYS 1 ManualDokumen12 halamanNASCOM NAS-SYS 1 Manualpsc098100% (1)

- PSSE Intro Stabilty InstructionsDokumen4 halamanPSSE Intro Stabilty InstructionsAsanka RodrigoBelum ada peringkat

- Decimal BasicDokumen62 halamanDecimal Basicsharkman2020Belum ada peringkat

- Workflow to expose circle on a curved lens surfaceDokumen14 halamanWorkflow to expose circle on a curved lens surfaceAmbar ShuklaBelum ada peringkat

- Quick Start for TMS320VC33 DSP Starter KitDokumen6 halamanQuick Start for TMS320VC33 DSP Starter Kitvalivali30Belum ada peringkat

- Tutorial Urbano 7 HydraDokumen79 halamanTutorial Urbano 7 HydraStroe George0% (1)

- MAXNC Operation ManualDokumen29 halamanMAXNC Operation ManualBreno LizardoBelum ada peringkat

- Program calculator solutions feet-inch conversionsDokumen12 halamanProgram calculator solutions feet-inch conversionsAlquimimo OrnelasBelum ada peringkat

- Calculating Huge NumbersDokumen8 halamanCalculating Huge NumbersSoumyajit PradhanBelum ada peringkat

- CHEMCAD TutorialDokumen33 halamanCHEMCAD TutorialKF Estrella ZBelum ada peringkat

- Ics 232 Lab 1Dokumen9 halamanIcs 232 Lab 1psl36533Belum ada peringkat

- APAME tutorial for aircraft panel methodDokumen24 halamanAPAME tutorial for aircraft panel methodmartig87Belum ada peringkat

- Introduction of 8086Dokumen12 halamanIntroduction of 8086k. akhilaBelum ada peringkat

- CARE, IIT Delhi CRP718 - 2015-16/1 Semester Experiment On PC Based Multi-Channel Data Acquisition. 1. ObjectivesDokumen9 halamanCARE, IIT Delhi CRP718 - 2015-16/1 Semester Experiment On PC Based Multi-Channel Data Acquisition. 1. ObjectivesPunitBelum ada peringkat

- Console ApplicationDokumen13 halamanConsole ApplicationTrynosBelum ada peringkat

- Console ApplicationDokumen13 halamanConsole Applicationkomi_dot100% (2)

- Learn QBasic programming with this tutorialDokumen47 halamanLearn QBasic programming with this tutorialproodoot100% (1)

- Programming User RPLIn PCDokumen26 halamanProgramming User RPLIn PCselm27Belum ada peringkat

- PropCalc Manual - Performance Data of PropellersDokumen5 halamanPropCalc Manual - Performance Data of PropellersDemetrio Hinojosa EBelum ada peringkat

- Ustaad Cali Xasa: Software Design Using C+ +Dokumen23 halamanUstaad Cali Xasa: Software Design Using C+ +calimaaxBelum ada peringkat

- Abs Construct Users Manual Vacanti Yacht DesignDokumen24 halamanAbs Construct Users Manual Vacanti Yacht Designyann1982Belum ada peringkat

- Manual EngDokumen5 halamanManual EngAlexander PrimoBelum ada peringkat

- Introduction To ORCADDokumen15 halamanIntroduction To ORCADCruise_IceBelum ada peringkat

- Guide to realigning railway curves using a computer programDokumen15 halamanGuide to realigning railway curves using a computer programvpmohammedBelum ada peringkat

- NUMAQ v1.1: NUMAQ - Number of Machines To Use On WorkstationsDokumen14 halamanNUMAQ v1.1: NUMAQ - Number of Machines To Use On WorkstationsSteward FloresBelum ada peringkat

- Getting Started with Numerical Methods SoftwareDokumen142 halamanGetting Started with Numerical Methods SoftwareIan 'Waffy Gambo' MartinBelum ada peringkat

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesDari EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesPenilaian: 5 dari 5 bintang5/5 (1)

- Tasawwuf BurudzhDokumen20 halamanTasawwuf BurudzhMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Tasawwuf Burudzh PDFDokumen457 halamanTasawwuf Burudzh PDFMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Islamic Quiz PDFDokumen8 halamanIslamic Quiz PDFMohammed Hassan Mohiuddin KhanBelum ada peringkat

- HVAC Commisioning ChecklistDokumen65 halamanHVAC Commisioning ChecklistBalakumar100% (13)

- IEDokumen2 halamanIEMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Blk415 Naco CDDokumen2 halamanBlk415 Naco CDMohammed Hassan Mohiuddin KhanBelum ada peringkat

- WATER SUPPLY CALCULATIONSDokumen23 halamanWATER SUPPLY CALCULATIONSSabu Joseph100% (2)

- Fatiha Khalf ImamDokumen16 halamanFatiha Khalf ImamMohammed Hassan Mohiuddin KhanBelum ada peringkat

- SMACNA Successful Building Project CoordinationDokumen27 halamanSMACNA Successful Building Project CoordinationMohammed Hassan Mohiuddin Khan50% (2)

- PsychDokumen2 halamanPsychMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Agricultural Bank Chilled Water Pumps Head Loss CalculationDokumen6 halamanAgricultural Bank Chilled Water Pumps Head Loss CalculationMohammed Hassan Mohiuddin Khan67% (3)

- Cooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/DoorDokumen6 halamanCooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/Doorashfaq-matte-799375% (4)

- Network PrimerDokumen11 halamanNetwork PrimerMohammed Hassan Mohiuddin KhanBelum ada peringkat

- WATER SUPPLY CALCULATIONSDokumen23 halamanWATER SUPPLY CALCULATIONSSabu Joseph100% (2)

- Custom AHUDokumen16 halamanCustom AHUMohammed Hassan Mohiuddin Khan100% (1)

- Stair Case Pressurization Unit Software: The Amount of CFMDokumen17 halamanStair Case Pressurization Unit Software: The Amount of CFMMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Bill of Quantities General SummaryDokumen2 halamanBill of Quantities General SummaryMohammed Hassan Mohiuddin KhanBelum ada peringkat

- HVAC Heat Load Calculation for Electrical BuildingDokumen7 halamanHVAC Heat Load Calculation for Electrical BuildingMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Stair Case PressurizationDokumen2 halamanStair Case PressurizationMohammed Hassan Mohiuddin Khan100% (2)

- 92 & 93 - AirconditioningDokumen4 halaman92 & 93 - AirconditioningMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Warehouse-81 - AirconditioningDokumen1 halamanWarehouse-81 - AirconditioningMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Chishti Nizami Habibi Soofie: The International Sufi OrderDokumen2 halamanChishti Nizami Habibi Soofie: The International Sufi OrderMohammed Hassan Mohiuddin KhanBelum ada peringkat

- 90 & 91 - AirconditioningDokumen4 halaman90 & 91 - AirconditioningMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Pump Head & HP Calculations SampleDokumen10 halamanPump Head & HP Calculations SampleMohammed Hassan Mohiuddin KhanBelum ada peringkat

- CarvingDokumen1 halamanCarvingMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Fresh Air AirconditioningDokumen1 halamanFresh Air AirconditioningMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Heat OnlyDokumen1 halamanHeat OnlyMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Heat OnlyDokumen1 halamanHeat OnlyMohammed Hassan Mohiuddin KhanBelum ada peringkat

- CoolingDokumen4 halamanCoolingMohammed Hassan Mohiuddin KhanBelum ada peringkat

- 92 & 93 - AirconditioningDokumen4 halaman92 & 93 - AirconditioningMohammed Hassan Mohiuddin KhanBelum ada peringkat

- Tips&Tricks Sim DragDropDokumen12 halamanTips&Tricks Sim DragDropAmphibious ManBelum ada peringkat

- V Controller GeneralDokumen212 halamanV Controller Generalattila_tamas4283100% (1)

- BSC6910 GSM Hardware Description (V100R015C00 - 08) (PDF) - enDokumen124 halamanBSC6910 GSM Hardware Description (V100R015C00 - 08) (PDF) - enMuhammad Qasim Nazir100% (5)

- IQSET Manual V7.60Dokumen747 halamanIQSET Manual V7.60yolanda83% (6)

- Bo TranDokumen62 halamanBo TrangogodddBelum ada peringkat

- Manual - First Time Startup - MikroTik WikiDokumen4 halamanManual - First Time Startup - MikroTik WikiPablo AntonieBelum ada peringkat

- InstallGuideONESOURCEIDTIntegrationOracle12 5500Dokumen214 halamanInstallGuideONESOURCEIDTIntegrationOracle12 5500Johnson B100% (2)

- Version 4.3 release notes with fixes and improvementsDokumen3 halamanVersion 4.3 release notes with fixes and improvementsRenan GeminoBelum ada peringkat

- EDU-210-90b-Lab GuideDokumen265 halamanEDU-210-90b-Lab GuideEmiliano Medina100% (6)

- Nortel DMS-10 PM3Dokumen38 halamanNortel DMS-10 PM3Mourad MhamdiBelum ada peringkat

- Readme PDFDokumen22 halamanReadme PDFGaneshBelum ada peringkat

- Silo - Tips - NDMP Configuration Guide For Ibm Tivoli Storage ManagerDokumen23 halamanSilo - Tips - NDMP Configuration Guide For Ibm Tivoli Storage ManagerRaul RamirezBelum ada peringkat

- Learning To Program - Python (2006)Dokumen299 halamanLearning To Program - Python (2006)Diego Javier ZeaBelum ada peringkat

- Instant Netcat StarterDokumen65 halamanInstant Netcat Startertaha deghiesBelum ada peringkat

- Using Matlab From A C#Dokumen10 halamanUsing Matlab From A C#Saurav KeshriBelum ada peringkat

- Software Release Note 4.4.3-A1Dokumen102 halamanSoftware Release Note 4.4.3-A1Alexander VasquezBelum ada peringkat

- 10.1.4 Packet Tracer - Configure Initial Router SettingsDokumen4 halaman10.1.4 Packet Tracer - Configure Initial Router SettingsJosetjBelum ada peringkat

- Bibliographic Meta-Data Extraction Using Probabilistic Finite State TransducersDokumen5 halamanBibliographic Meta-Data Extraction Using Probabilistic Finite State TransducersFani KhokharBelum ada peringkat

- Unix Linux IntroductionDokumen157 halamanUnix Linux IntroductionUdea En CristoBelum ada peringkat

- Hardware Installation Guide For Cisco 4000 Series Integrated Services RoutersDokumen46 halamanHardware Installation Guide For Cisco 4000 Series Integrated Services RoutersMarlene EscobarBelum ada peringkat

- SQL Nav Silent IinstallDokumen10 halamanSQL Nav Silent IinstallYumildo GomesBelum ada peringkat

- SAS2Flash Utility: Quick Reference GuideDokumen26 halamanSAS2Flash Utility: Quick Reference GuideArne BergmanBelum ada peringkat

- Unit Test Question BankDokumen15 halamanUnit Test Question BankOmkar TodkarBelum ada peringkat

- Minitab 15Dokumen2 halamanMinitab 15percyBelum ada peringkat

- Mincom LinkOne WinView Technical ReferenceDokumen105 halamanMincom LinkOne WinView Technical ReferenceEric HenriqueBelum ada peringkat

- 3700 - SIM GuideDokumen150 halaman3700 - SIM GuiderussvzBelum ada peringkat

- Gpon Ma5800Dokumen75 halamanGpon Ma5800rommel salvador100% (3)

- Ofw8 Combest Advshm FinalDokumen110 halamanOfw8 Combest Advshm FinalAntonio Martín AlcántaraBelum ada peringkat

- Examen Password SafeDokumen17 halamanExamen Password SafeheisembergBelum ada peringkat

- Configure Ericsson CLIDokumen11 halamanConfigure Ericsson CLIandres1988maturin67% (9)