A Tracer Study of Headspace Ventilation in A Collector Sewer

Diunggah oleh

samadonyDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Tracer Study of Headspace Ventilation in A Collector Sewer

Diunggah oleh

samadonyHak Cipta:

Format Tersedia

Parker and Ryan TECHNICAL PAPER

ISSN 1047-3289 J. Air & Waste Manage. Assoc. 51:582-592

Copyright 2001 Air & Waste Management Association

A Tracer Study of Headspace Ventilation in a Collector Sewer

Wayne J. Parker Department of Civil and Environmental Engineering, Carleton University, Ottawa, Ontario, Canada Helen Ryan Industrial Wastes Section, Regional Municipality of OttawaCarleton, Ottawa, Ontario, Canada

ABSTRACT A field-scale tracer test was conducted to evaluate in-situ ventilation rates in a major collector sewer. The sewer under study was ~11 km long and ranged from 0.61 to 2.1 m in diameter. For the purposes of the tracer testing, the collector was divided into four reaches, each of which was tested individually. The tracer test involved injecting a measured volume of CO gas into a manhole over a short time period. CO concentrations were then measured in the collector headspace at selected manholes along the length of the reach. The technique employed successfully measured average headspace velocities over extended lengths of the collector. In a section that had a relatively stagnant headspace, ~1.1 km of sewer could be evaluated, with substantial tracer loss attributed to losses to manholes. In a section of the sewer with elevated headspace velocities, a section ~7.0 km long was successfully tested with one injection of tracer gas. The velocities observed in the collector varied substantially with time and location in the collector. The lowest velocities measured were in the upstream sections, with a minimum observed value of 3.8 m/min. The highest velocities were observed in the downstream sections, with a maximum value of 31.5 m/min. The presence of a substantial drop structure appeared to reduce the headspace velocity in the upstream reach. In general, there was an increasing trend in gas-phase flows with distance along the length of the collector. Flows at

the discharge end of the collector were almost 2 orders of magnitude greater than those at the beginning. INTRODUCTION The Regional Municipality of OttawaCarleton is conducting an ongoing study of the ventilation patterns within its collector sewer systems. The information collected in this study will subsequently be employed to assess the fate of volatile organic compounds and odor-bearing compounds within the collector system. A number of studies describing the behavior of these substances in sewer environments have been reported.1-5 In these studies, the parameter consistently recognized as an unknown is the degree of headspace ventilation that occurs under natural conditions. Five factors that have been identified as contributing to sewer ventilation include wind across ventilation stacks, wastewater drag, the rise and fall of wastewater levels, temperature differentials, and barometric pressure fluctuations.6 Pilot and field-scale tests were performed to assess the impact of wind and wastewater drag on sewer ventilation.6 In the pilot study, it was found that the water velocity and the relative depth of water in the sewer impacted upon air movement. The average air velocity was found to increase with the product of the water surface width and the liquid velocity divided by the hydraulic radius of the headspace. In experiments with a 300-mm diameter pipe, the average velocity approached a limiting value of 0.2 m/sec. The field studies focused primarily upon exchange of headspace gas with the atmosphere through educt stacks and did not focus directly on movement of the headspace gas. Field testing of headspace ventilation in two sewer reaches with lengths ranging from 464 to 803 m has been reported.7 In this study, the use of continuous injection of sulfur hexafluoride (SF6) and slug injection of CO was evaluated, with the latter determined to be superior when losses of tracer to manholes occurred. In a sewer with a diameter of 0.9 m and a slope of 0.2%, the headspace velocities were found to vary from 0.09 to 0.17 m/sec.

Volume 51 April 2001

IMPLICATIONS Ventilation in sewer systems impacts on gas-phase concentrations of volatile substances as well as on emissions of these substances from sewer systems. The study described here consisted of tracer analysis of headspace ventilation in a full-scale collector sewer and is the first study of its kind. The results of this study provide a range of ventilation rates that can be used as guidance when modeling the fate of volatile substances in sewer systems.

582 Journal of the Air & Waste Management Association

Parker and Ryan

The studies of Pescod and Price6 and Monteith et al.7 do not include all of the sewer structures and conditions that may be present in large collector sewer systems. For example, the presence of drop structures and hot-water discharges in a sewer system may impact upon the migration of sewer gases. An approach for estimating ventilation in full-scale systems based on pressure measurements and the use of empirical correlations that relate velocity to pressure drop has been reported.8 However, limited measured data are available that describe ventilation patterns in full-scale sewer systems; hence, in this project, the ventilation patterns in a major collector sewer were evaluated. A volume of tracer gas was injected into selected manholes along the length of the collector and was continuously monitored at downstream manholes. All manholes were maintained in place to ensure that the sewer was functioning in a natural state. Two rounds of testing were completed to investigate ventilation under warm-weather conditions. DESCRIPTION OF COLLECTOR SEWER The sewer evaluated in this study collected sewage from a mixture of residential and small industrial sources and drained into a second collector through a drop structure with a drop height of ~5.8 m. The collector had a length of ~11 km and varied in diameter from 0.61 to 2.4 m. The slope of the collector varied considerably over the length of the sewer, with minimum and maximum slopes of 0.001 and 0.9%, respectively. The physical dimensions of the collector are summarized in Table 1. An inverted siphon was located 1717 m from the upstream end of the collector. The siphon was constantly submerged and, hence, acted as a permanent block for headspace movement past this point. Two drop structures were located 3496 and 3755 m from the upstream end of the collector. Both structures were located in the 1.4-m diameter portion of the collector and had drop heights of 7.1 and 1.3 m, respectively. The collector had a number of small connections entering into it along its length. For the purposes of this report, only the major city connections will be documented. The characteristics and locations of the major connections are presented in Table 2. SEWER VENTILATION TESTING A tracer technique was employed to characterize the ventilation patterns in the sewer. In this technique, a volume of CO gas was introduced into the sewer at a manhole and was monitored at selected manholes downstream of the injection point. Selective monitoring was performed to determine whether the sewer gas moved countercurrent to the wastewater movement. Under none of the circumstances evaluated in this study was the tracer gas found to move countercurrent to the wastewater flow.

Volume 51 April 2001

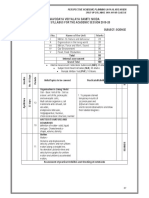

Table 1. Summary of collector physical characteristics. Segment Diameter (m) Incremental Length (m) 1189 643 532 518 1765 2788 1294 1511 808 Cumulative Distance (m) 1189 1832 2364 2882 4647 7435 8729 10,240 11,048 Range of Slopes (%) 0.0070.67 0.090.94 0.0010.77 0.040.48 0.0010.83 0.0010.65 0.0060.32 0.0010.44 0.0010.70

1 2 3 4 5 6 7 8 9

0.61 0.69 0.76 1.4 1.2 1.4 1.5 2.0 2.1

The CO gas was injected into the sewer at a controlled flow rate from a cylinder of pure gas via a pressure regulator, a rotameter, and a length of 3-mm inside diameter flexible copper tubing. Sampling was conducted by continuously pulling gas from the headspace of the sewer via this copper tubing and then continuously analyzing the gas for CO with an Industrial Scientific Model 410 gas detector. The gas was drawn with the detectors Industrial Scientific SPF400 on-board pump at a pumping rate of ~23 cm3/sec. All injection and sampling tubing was installed several days before the tests, and the lines were cleaned with compressed air just prior to the test. In all cases, the copper tubing was passed through the pick holes in the manholes so that the ventilation testing could be performed with all manholes in place. The CO gas was introduced and withdrawn at an elevation approximately in the middle of the sewer headspace. The injection piping was bent to direct the CO gas downstream, while the sampling tubing was bent to collect gas from upstream. Because it was anticipated that CO gas would be lost from the tracer due to entrapment in manholes and outgassing from some manholes, the sewer was divided into four reaches for testing. The first reach extended from the beginning of the collector to the siphon. A summary of

Table 2. Summary of major connections to collector. Cumulative Distance (m) 0 361 749 1111 1313 1491 1533 1575 Diameter (cm) Cumulative Distance (m) 1798 3291 3496 3755 3760 3969 6417 Diameter (cm)

30, 45 25, 25 25 30 20 22.5 22.5 37.5

75 37.5 30 37.5 30 22.5 61

Journal of the Air & Waste Management Association 583

Parker and Ryan

the reaches and sampling locations is presented in Table 3. Differing quantities of CO gas were injected into the reaches depending upon the diameter of the reach tested. Table 4 presents a summary of the quantities injected into these reaches. In addition to monitoring CO concentrations, the headspace temperature was monitored at the sampling locations over the duration of the test. Wastewater flow data were collected from the in-sewer monitoring station located at the discharge of the collector. Information on atmospheric conditions including temperature, wind speed, and barometric pressure was obtained from the local weather office for the testing period. RESULTS The results of the tracer testing consisted of CO concentrations measured at each monitoring location as a function of time. Figure 1 presents typical response curves obtained from the three sampling locations in the third reach for the first round of testing. The shapes

Table 3. Summary of reaches tested. Reach Start/End Distances (m) 38 1651 Sample Location Distances (m) 118 573 1189 1651 2329 3722 4765 6379 7563 8620 9882 11,048 Distance from Injection (m) 80 535 1151 1613 535 1928 1043 2657 3841 1057 2319 3485

2 3

1794 3722 3722 7563 7563 11,048

Table 4. Summary of CO gas injection. Run Reach Vol. Flow (L/min) 1 1 2 3 4 2 1 3, 4 10 10 30 30 10 10 30 CO Injection Mass Flow Duration (g/min) (min) 9.6 9.6 28.8 28.8 9.6 9.6 28.8 5 5 5 10 5 5 5

Volume (L)

50 50 150 300 50 50 150

of these curves are indicative of a dispersed plug flow regime in the sewer headspace. At all three sampling locations, the CO concentration increased rapidly to a peak value and then decreased at a slower rate with some tailing of the curve. In all of the runs, the CO peak height consistently decreased in magnitude as it progressed through a reach. For example, in the first run conducted on the third reach, the peak concentrations were 759, 171, and 111 ppm at the three sampling locations. There was less of a trend in peak widths, with corresponding values of 63, 32, and 35 min, respectively, for this run. Peak widths were determined as the time from which detectable concentrations were measured at the monitoring location until the time that the gas could no longer be detected. In other runs, the peak width increased in some cases and decreased in others. The shape of the response curve observed in the sewer headspace would be determined by longitudinal dispersion in the sewer reaches, exchange of sewer headspace with manholes, and gas-liquid mass transfer of the tracer. This assumes that migration of the tracer is dominated by advective processes and that diffusion can be neglected. Given the relatively high velocities measured in this study, this assumption is valid. If dispersion were the only mechanism affecting the shape of the tracer response curve, then the mass of CO would be conserved; that is, there would not be any loss of CO from the sewer. Exchange with manholes would likely result in the loss of some of the CO from the sewer, thereby tending to reduce the total area under the concentration versus time curve. In addition, CO gas that migrated into a manhole as the bulk of the CO passed by could then reenter the sewer headspace and thereby tend to extend the duration of the CO peak. Entry of air into the sewer along a reach would also change the tracer response curve by diluting the tracer concentration. When tracer gas transferred into the liquid phase, it would then migrate with the liquid phase. If there were a velocity differential between the two phases, the tracer could reenter the gas phase from the liquid. To assess the potential for this latter mechanism, a dynamic model considering the gas-liquid mass transfer of CO for a sewer reach flowing half-full with a diameter of 1 m and a length of 0.5 km was assembled. A dispersed plug flow regime was employed to represent the mixing of the headspace in the sewer. A mass transfer coefficient for CO was calculated using the correlation of Parkhurst and Pomeroy,9 which was corrected for the diffusivity of CO, and a Henrys Law coefficient of 5 104 atm/mol fraction10 was employed. In this test reach, it was found that less than 2% of the tracer gas transferred from the gas to the liquid phase, and there was negligible reentry of CO into the gas phase. Hence, for the purposes of this study, it was

Volume 51 April 2001

584 Journal of the Air & Waste Management Association

Parker and Ryan

Figure 1. CO concentrations in reach 3, run 1.

assumed that migration of tracer in the liquid phase had a minimal effect on the shape of the gas-phase tracer curve. Traditionally, tracer mass recovery is employed as a measure of quality control for a tracer study. However, these tracers are commonly employed in closed systems with constant volumetric flow rates. In the system under study, velocities and flow rates varied with distance along the sewer. The values subsequently reported were averaged over the length of each of the subreaches (length of collector between an injection and sampling point or between two sampling points) studied and do not reflect values at any specific location. Therefore, it was not possible to accurately calculate a mass flow rate of tracer at any of the monitoring locations. And because an independent measure of flow rate at each monitoring point was not available, there was insufficient information to perform a formal tracer mass recovery analysis. Subsequent discussions of tracer losses refer to changes in the area under the concentrationtime diagram and do not represent a true tracer recovery analysis. The tracer technique employed here was effective in quantifying the travel times for headspace gas over relatively long lengths of collector. In the second run, a single injection was effectively employed to characterize the travel times in both reaches 3 and 4, constituting a combined length of ~7 km of sewer. This effectiveness was primarily due to the relatively high rate of movement of sewer gas in these reaches, which appeared to result in small tracer losses during the test. More difficulty was encountered in reach 1, where the headspace velocities were low and substantial tracer loss was observed. In this reach, only the first 1100 m of the reach could be

Volume 51 April 2001

evaluated with one injection. The average time required for the CO to move through a subreach was estimated as the first moment of the peak area around the origin, as follows: (1) where tavg is the average travel time for CO tracer (min); ti is the time of individual CO concentration measurements (min); Ci is the CO concentration (ppm); and n is the total number of concentration measurements. The average velocity of the gas in each subreach was then calculated as the subreach length divided by the average travel time in the subreach. It should be noted that these velocities were averaged over a considerable length of sewer and in several of the subreaches encompassing more than one size of pipe. The entrance of tributary connections between sampling locations also impacted upon the localized velocities in that additional liquid flow entered the sewer at these points. The additional liquid flow increased the velocity in the collector sewer and, hence, increased the liquid drag on the gas phase. In addition, it is likely that collector sewers introduce additional gas flows pulled from the tributary sewer along with the liquid flow. Thus, local velocities at a point would likely have deviated from the average values measured in this study. The estimated values of the average velocities calculated from the data collected in this study are summarized in Table 5. Examining Table 5 reveals that the velocities observed in the collector varied substantially with time and location in the collector. Reach 1 demonstrated the lowest velocities

Journal of the Air & Waste Management Association 585

Parker and Ryan

Table 5. Summary of average velocities. Reach Subreach Average Velocity (m/min) Run 1 Run 2 4.0 4.0 4.0 NA 16.9 11.3 8.7 30.1 24.8 28.8 31.5 22.7 5.8 3.6 12.9 NA 28.8 8.2 23.4 22.8 25.9 17.7 16.8 24.2

2 3

1 2 3 4 1 2 1 2 3 1 2 3

Note: NA = gas velocities too slow to measure.

in this portion of the study. The low velocities observed in this section resulted in considerable loss of tracer gas as it progressed through the system. The tracer loss was apparent from the substantially diminished size of the CO peak observed at the monitoring sites. When the CO tracer moved slowly through the collector, there would be an increased opportunity for a fraction of the gas to migrate into each manhole it passed. In both runs, the concentrations measured after the first three subreaches had diminished to such an extent that it was not possible to measure concentrations in the last subreach, so it was not possible to estimate a velocity there. Reach 1 was bounded by connections to city sewers on the upstream end and the siphon on the downstream end. In addition, this reach had the smallest diameter, with predominantly 0.61- and 0.69-m diameter pipe. The combination of the obstruction posed by the siphon and the increased friction exerted by the small-diameter pipe was likely responsible for the low velocities. In general, it would appear that the headspace in this section was relatively stagnant as compared with the other reaches examined in this study. The velocities observed in reach 2 were generally higher than those in reach 1, likely partially due to the absence of a confining structure at the downstream end of reach 2. In both tests of this reach, the velocity in subreach 1 was noticeably higher than the velocity in subreach 2, despite the fact that the upstream end of subreach 1 was effectively sealed by the presence of the siphon. The decrease in velocity in subreach 2 may have been a result of the presence of a very substantial drop structure (drop height = 7.1 m) located in this subreach. Drop structures such as these can cause substantial in-gassing at that location and pressurize the bottom of the drop.8 This pressurization may have reduced the air

586 Journal of the Air & Waste Management Association

flow through the drop structure; however, because the tracer passed through the drop structure, apparently this pressurization did not completely stop it. In the second test, the velocity in subreach 1 was almost twice that observed in the first test, indicating a substantial day-to-day variability in ventilation within this subreach. The velocities observed in reaches 3 and 4 were generally higher than those observed in reach 2. The velocities increased and decreased somewhat randomly and appeared to have reached a plateau at a velocity of ~25 m/min. Considerable variability was observed between the two test runs in some of the subreaches. The largest difference was for subreach 1 of reach 3, where the velocities differed by a factor of almost 3. Considerable differences between tests were also observed for subreaches 1 and 2 of reach 4, with a factor of almost 2 for the latter. The temperature of the sewer headspace was measured at each sampling location as an indicator of the discharge of warm streams into the sewer that might impact on gas movement. Table 6 summarizes the minimum, mean, and maximum temperatures measured at each sampling location. Several observations can be made with respect to the sewer headspace temperatures. In general, at each sampling location the headspace temperatures did not substantially change over the duration of a test. This is apparent from the relatively narrow ranges about the mean values (typically 1 C). In addition, similar trends in temperature were observed along the length of the reaches for the two test runs. In fact, there were relatively small differences between the average temperatures at each sampling location for the two test runs, despite an interval of ~10 days between the test runs. This would suggest that the phenomena impacting the headspace temperatures were consistent over the period of the testing. In general, the headspace temperature increased along the length of the collector from the upstream to the downstream end. There was one notable exception to this pattern around the second sampling location of reach 2. In this case, the temperature increased dramatically from the upstream sampling location (5.7 and 3.3 C on the first and second test runs, respectively). The temperature then decreased over the next section, with decreases of 6.7 and 4.4 C, respectively. The increased temperature at the second sampling location of reach 2 was also indicated by a substantial amount of vapor emitted from this manhole when the cover was removed for equipment installation. The increased temperature there may have been due to discharges of sewage with elevated temperatures into either this manhole or manholes located immediately upstream. The decrease in temperature between this manhole and the downstream sections is presumably due to dilution of the

Volume 51 April 2001

Parker and Ryan

Table 6. Summary of sewer headspace temperatures. Reach Subreach Minimum Run 1 1 1 2 3 4 1 2 1 2 3 1 2 3 NA NA 10.0 NA 13.3 18.9 12.1 12.5 12.9 14.6 15.8 15.4 Run 2 14.9 NA 13.7 NA 14.4 16.9 13.1 14.4 17.7 17.0 NA NA Temperature (C) Mean Run 1 Run 2 NA NA 11.0 NA 13.4 19.1 12.4 12.7 14.3 14.7 16.0 15.4 15.0 NA 13.8 NA 14.4 17.7 13.3 15.0 16.2 17.1 NA NA

Maximum Run 1 NA NA 13.6 NA 13.6 19.6 12.6 13.0 15.4 14.7 16.1 15.4 Run 2 15.1 NA 14.3 NA 14.5 19.0 13.4 15.8 17.6 17.2 NA NA

2 3

Note: NA = not available.

air stream with cooler air from other tributary sewers as well as heat transfer from the gas to the cooler liquid phase in the collector. Data on the ambient temperature, atmospheric pressure, and wind speed were obtained from the Ottawa weather station for the days that the testing was conducted. The minimum, mean, and maximum values for the parameters over the test period are summarized in Table 7. The atmospheric conditions tended to vary somewhat from day to day as the testing progressed. The greatest contrast in conditions was between day 2 and day 3day 2 was warm and calm, while day 3 was cool and windy. Unfortunately, the reaches tested on these two days were different, and therefore a comparison of the impact of these contrasting conditions on ventilation rates

Table 7. Summary of atmospheric conditions. Parameter Value Day 1 Run 1 Reach 1 Reach 2 Day 2 Run 1 Reach 3

could not be performed. In addition to the variation between test days, the ambient temperature and wind speed changed throughout each day. Temperature followed an increasing trend with time each day, while the wind speed tended to vary randomly with time. By contrast, the atmospheric pressure tended to remain relatively constant during each test day. Hence, it is not expected that fluctuations in atmospheric pressure would have had any significant impact on the movement of gas in the sewer headspace. The headspace velocities observed in this study appeared to plateau at ~25 m/min. In a pilot study,6 a plateau of ~12 m/min was observed. The results of this study clearly indicate that headspace velocities in fullscale systems can exceed those observed in the previous

Day 3 Run 1 Reach 4 Run 2 Reach 2 10.0 11.5 12.4 998.2 999.5 1000.9 17.8 36.5 55.5

Day 4 Run 2 Reach 1

Day 5 Run 2 Reach 3 Reach 4

Temp. (C)

Atm. press. (mbar)

Wind speed (km/hr)

Min Mean Max Min Mean Max Min Mean Max

5.0 10.8 16.8 1017.5 1018.3 1019.2 16.7 19.3 24.1

7.9 16.6 22.0 1023.5 1024.7 1025.6 7.4 9.8 16.7

8.5 12.0 15.2 1001.0 1004.2 1005.8 11.1 21.9 27.8

8.8 14.6 19.2 1008.4 1010.4 1011.2 13.0 19.3 31.5

Volume 51 April 2001

Journal of the Air & Waste Management Association 587

Parker and Ryan

pilot study.6 Correlations between the headspace velocity and the following lumped parameters have been proposed6 (2) computed parameters. These poor correlations may have had several causes, including (1) errors in estimation of the wastewater flows in the subreaches required to estimate the parameters in eqs 2 and 3; (2) the averaging of sewer properties and flows over the lengths of the subreaches; and (3) the presence of structures in the sewer, such as drops and manholes, that influence gas movement that were not present in the sewer tested by Pescod and Price.6 In conclusion, it is not likely that the correlations of Pescod and Price6 can be employed with distance-averaged inputs to estimate gas velocities in large systems as employed in this study. Drag exerted by wastewater on the headspace gas will likely influence the movement of the gas. In this study, wastewater flow rates were monitored at a station located near the discharge of the collector. In all cases, a diurnal flow pattern was observed, with little change in the pattern of wastewater flows observed during the testing period. The minimum flow tended to vary between test days; however, these flows occurred very early in the morning prior to the testing and were therefore expected to have little impact upon the gas movement measured by the tracer tests. The average flow observed at the collector discharge over the five test days was 0.71 m3/sec. Quantification of the volumetric gas flow rate required that the cross-sectional area of the sewer occupied by wastewater be determined so that the gas-phase cross-sectional area could be calculated. In addition, the wastewater flow conditions, such as velocity and interfacial surface area, would impact upon the drag exerted

(3) where W is the width of the water surface; V is the mean water surface velocity; L is the perimeter length of the headspace; and R is the hydraulic radius of the headspace. In both of these parameters, the driving force for gas movement is the product of the water surface velocity and the width of the surface. The resistance to gas-phase movement is primarily due to frictional forces exerted by the sewer walls. In these parameters, the unwetted perimeter (eq 2) and the hydraulic radius (eq 3) are representative of this resistance. Hence, the velocity of gas movement should increase with the liquid drag force and decrease with the frictional drag. The correlations of Pescod and Price6 were determined for a single pilot-scale sewer reach and have not been evaluated with full-scale data. Therefore, the observed gasphase velocities were plotted against the above parameters, which were computed for each subreach. The values of W, L, and R were computed as the average values for each subreach in a fashion similar to that employed to estimate the headspace cross-sectional areas, which is subsequently described. The resulting plots are presented in Figures 2 and 3 for eqs 2 and 3, respectively. From these plots, it is apparent that there was a poor correlation between the observed velocities and the

Figure 2. Headspace velocity vs. W V/L.

588 Journal of the Air & Waste Management Association Volume 51 April 2001

Parker and Ryan

Figure 3. Headspace velocity vs. W V/R.

by the wastewater on the headspace gas. To investigate the impact of these parameters on the gas-phase flow, it was necessary to estimate the liquid flow conditions. Ideally, measured values for the flow of wastewater in each of the subreaches examined would be employed for this purpose. However, this parameter could not be measured at all of the monitoring locations while the sewer was closed for the gas-phase testing, so these data were not obtained. As previously indicated, wastewater flow data were available at the discharge of the collector, and it was decided to use these data to partition the flow to each of the major tributaries into the sewer. The wastewater flow in each subreach was calculated by accumulating the tributary flows along the length of the collector. For the purposes of this study, the flows from the tributary sewers were assumed to be proportional to the areas of the contributing sewers. Hence, the total flow measured at the collector discharge was partitioned to each tributary sewer by multiplying it by the ratio of the cross-sectional area of the tributary sewer to the sum of all of the tributary cross-sectional areas. Because the flow characteristics did not change substantially between the testing days and the tests were conducted over an extended period of time each day, the average total flow of 0.71 m3/sec was employed to estimate the wastewater flows. The estimated wastewater flows in each of the subreaches are summarized in Table 8. The headspace volumetric flow rates in the collector were calculated as the product of the gas velocity and the cross-sectional area of the headspace in the sewer. The headspace cross-sectional area available for gas flow depends on the liquid flow in the sewer. With a change in the liquid flow in a reach, the elevation of the liquid will vary, thereby changing the headspace cross-sectional area.

Volume 51 April 2001

In addition, a change in slope will also change the liquid depth in the sewer, thereby influencing the headspace cross-sectional area. In this study, average velocities of the headspace gas were determined for a number of subreaches of the sewer. These velocities were averaged over the range of pipe diameters and headspace cross-sectional areas present in the subreaches. Therefore, to determine the average volumetric flow rate in each subreach, an average headspace crosssectional area was calculated, as follows: (1) The subreach was divided into segments with respect to consistent pipe diameter. (2) The liquid flow in each segment was estimated as the sum of the flow entering the segment in the collector sewer and any tributary connections. (3) The average slope of each segment was calculated as the weighted average of the individual lengths

Table 8. Wastewater flows estimated in subreaches. Reach 1 Subreach 1 2 3 4 1 2 1 2 3 1 2 3 Estimated Flow (m3/sec) 0.09 0.13 0.18 0.26 0.44 0.58 0.60 0.71 0.71 0.71 0.71 0.71

2 3

Journal of the Air & Waste Management Association 589

Parker and Ryan

within the segment as follows: errors associated with partitioning the total wastewater flow to each of the tributaries. There was a greater potential for error in estimation of the upstream flows than of the downstream values because all of the significant tributaries were located ahead of the second subreach of reach 3. In general, there was an increasing trend in gas-phase flows with distance along the length of the collector. Flows at the discharge end of the collector were almost 2 orders of magnitude greater than those at the beginning. Figures 4 and 5 present a comparison of the measured velocities and the calculated flows with distance along the reach. These figures suggest that while the headspace velocities tended to vary somewhat erratically and plateau at the downstream end of the reach, the flow tended to increase more steadily along the reach. The difference between the two parameters results from the varying headspace cross-sectional area along the length of the collector. For example, the diameter of the collector in subreach 2 of reach 2 (1.4 and 1.2 m) increased substantially from that of the prior reach (0.76 m), and the headspace areas therefore increased from 0.16 to 0.96 m2. Over this subreach, the velocity of the headspace decreased on both days, while the flow increased. Hence, as the gas moved along the collector from a small cross-section to a large cross-section, the velocity was reduced but the total flow continued on and actually increased. In the first test run, the volumetric flow decreased in subreach 1 of reach 3 (Case 1) and along subreach 3 of reach 4 (Case 2), while in the second run, the flow decreased in subreach 1 of reach 4 (Case 3). The flow may have decreased in Case 1 because testing of this subreach was conducted on a different day than that of the upstream subreach. However, in Cases 2 and 3, the reaches of interest were tested in conjunction with the upstream and downstream reaches. These reaches were both downstream of all major tributary sewers, and therefore the estimation of wastewater depth and, thus, the gas-phase cross-sectional area should have been relatively accurate. The decrease in flow along these subreaches would suggest that there was significant out-gassing from the collector at these locations. The cause of this apparent out-gassing is unclear because it was not replicated on both days for any of the subreaches in which it was observed. The lack of repeatability would suggest that it was not caused by a physical structure but rather by some other time-varying mechanism, such as wind-induced draft out of a manhole. The exact cause of the reduced flow with distance in the sewer could not be identified conclusively with the results obtained from the tracer testing. CONCLUSIONS AND RECOMMENDATIONS The CO technique appeared to function well for quantifying the movement of headspace gas in a large collector

Volume 51 April 2001

(4)

where Li is the distance between manholes; Si is the slope of the collector between manholes; and n is the number of pipe length in the segment. (4) The depth of liquid in the segment was calculated using Mannings equation and was then employed to calculate the cross-sectional area occupied by wastewater. (5) The cross-sectional area of the headspace was calculated by reducing the cross-sectional area of the collector by the area of the cross-sectional segment occupied by wastewater. (6) The average cross-sectional area of the subreach was calculated as

(5)

where xi is the length of the segment with a constant diameter; Ai is the cross-sectional area of the segment; and n is the number of segments of constant diameter. Table 9 summarizes the average volumetric flow rates estimated for each of the subreaches. In interpreting Table 9, it must recognized that there was considerable uncertainty in the wastewater flows employed to estimate the headspace cross-sectional areas and, hence, the volumetric flow rates in the subreaches. This uncertainty was due to the potential

Table 9. Summary of estimated volumetric flow rates. Reach Subreach Run 1 1 1 2 3 4 1 2 1 2 3 1 2 3 0.6 0.6 0.6 NA 2.7 10.8 4.4 25.6 25.8 28.8 81.9 68.1 Flows (m3/min) Run 2 1.1 0.5 1.8 NA 4.6 7.9 11.9 19.4 26.9 17.7 43.7 72.6

2 3

Note: NA = not able to estimate gas velocity.

590 Journal of the Air & Waste Management Association

Parker and Ryan

Figure 4. Headspace velocity and volumetric flow vs. distancerun 1.

Figure 5. Headspace velocity and volumetric flow vs. distancerun 2.

Volume 51 April 2001 Journal of the Air & Waste Management Association 591

Parker and Ryan

sewer. In reaches where headspace movement was relatively fast (2030 m/min), longer reaches (7 km) could be assessed with one injection. Where movement was slow (313 m/min), a shorter distance (~1 km) could be assessed with one injection. The velocities observed in the collector varied substantially with time and location in the collector. Reach 1, bounded by the upstream end of the collector and the siphon, demonstrated the lowest velocities in this portion of the study. The velocities observed in reaches 2, 3, and 4 (8.231.5 m/min) were generally higher than those observed in reach 1 (3.612.9 m/min). The presence of a substantial drop structure appeared to reduce the headspace velocity in the upstream reach. Downstream of this structure, the velocities increased and decreased somewhat randomly and appeared to have reached a plateau at a velocity of ~25 m/min. Employing the correlations of Pescod and Price6 with distance-averaged inputs did not accurately predict the gas velocities observed in this collector. While the headspace velocities tended to vary somewhat erratically and plateau at the downstream end of the reach, the headspace volumetric flow tended to increase more steadily along the reach. In isolated cases, the volumetric flow rate appeared to decrease in certain subreaches, suggesting that out-gassing occurred in these instances. However, these occurrences were not repeated in both runs at any location, suggesting that they were not caused by a physical structure but rather by some timevarying mechanism, such as wind-induced out-gassing. REFERENCES

1. 2. Jensen, N.A.; Hvitved-Jacobsen, T. Method for Measurements of Reaeration in Gravity Sewers Using Radio-Tracers; J.Water Pollut. Control Fed. 1991, 63, 758-767. Zytner, R.G.; Madani-Isfahani, M.; Corsi; R.L. Oxygen Uptake and VOC Emissions at Enclosed Drop Structures; Water Environ. Res. 1997, 69, 286-294. 3. Corsi, R.L.; Quigley, C.J.; Melcer, H.; Bell, J. Aromatic VOC Emissions from a Municipal Sewer Interceptor; Water Sci. Technol. 1995, 31, 137146. 4. Corsi, R.L.; Birkett, S.; Melcer, H.; Bell, J. Control of VOC Emissions from Sewers: A Multi-Parameter Assessment; Water Sci. Technol. 1995, 31, 147-158. 5. Quigley, C.J.; Corsi, R.L. Emissions of VOCs from a Municipal Sewer; J. Air & Waste Manage. Assoc. 1995, 45, 395-403. 6. Pescod, M.B.; Price, A.C. Major Factors in Sewer Ventilation; J.Water Pollut. Control Fed. 1982, 54, 385-397. 7. Monteith, H.; Bell, J.; Harvey, T. Assessment of Factors Controlling Sewer Ventilation Rates. In Control of Odors and VOC Emissions, Proceedings of the Water Environment Federation Specialty Conference, Houston, TX, April 2023, 1997. 8. Sorenson, H.; Joyce, J.; Day, D.; Fallara, T.C. Odor Control for Large Diameter Deep Sewer TunnelsThe City of Columbus, Ohio. In Odors and VOC Emissions 2000, Proceedings of the Water Environment Federations Specialty Conference, Cincinnati, OH, April 1619, 2000. 9. Parkhurst, J.D.; Pomeroy, R.D. Oxygen Absorption in Streams; J. Environ. Eng. 1972, 98, 101. 10. Metcalf; Eddy. Wastewater Engineering: Treatment, Disposal and Reuse, 3rd ed.; McGraw-Hill: New York, 1991.

About the Authors Wayne Parker is an associate professor in the Department of Civil and Environmental Engineering at Carleton University in Ottawa, Ontario. Helen Ryan is supervisor of the Industrial Wastes Section of the Regional Municipality of OttawaCarleton in Ottawa, Ontario. Correspondence should be directed to Dr. Wayne Parker, Department of Civil and Environmental Engineering, Carleton University, 1125 Colonel By Drive, Ottawa, Ontario, K1S 5B6; or e-mail: wparker@ccs.carleton.ca.

592 Journal of the Air & Waste Management Association

Volume 51 April 2001

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Refrig Lec6Dokumen14 halamanRefrig Lec6samadonyBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Centrifugal Pump ExperimentsDokumen18 halamanCentrifugal Pump ExperimentssamadonyBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Static C/cs of MeasurementsDokumen3 halamanStatic C/cs of MeasurementssamadonyBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Part B - System of Equations For Pipe NetworkDokumen137 halamanPart B - System of Equations For Pipe Networksamadony100% (2)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- AC-Training II.2 Cooling DistributionDokumen94 halamanAC-Training II.2 Cooling DistributionsamadonyBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Solar DryerDokumen5 halamanSolar DryersamadonyBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Ventricle Assist Devices - ReviewDokumen39 halamanVentricle Assist Devices - ReviewsamadonyBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Pipe Flow ReviewDokumen12 halamanPipe Flow ReviewsamadonyBelum ada peringkat

- Trusses and FramesDokumen12 halamanTrusses and FramessamadonyBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Lecture Notes On StaticsDokumen121 halamanLecture Notes On StaticsМарко Шилобод75% (4)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Selected Topics in Heat and Mass TransferDokumen196 halamanSelected Topics in Heat and Mass TransfersamadonyBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- University of Colorado Denver Department of Civil Engineering CVEN-3414 Design of Water and Wastewater Systems)Dokumen2 halamanUniversity of Colorado Denver Department of Civil Engineering CVEN-3414 Design of Water and Wastewater Systems)samadonyBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- EGR231 Lecture24Trusses Method of SectionsDokumen7 halamanEGR231 Lecture24Trusses Method of Sectionssamadony0% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Hazen-Williams Pipe Flow DiagramDokumen2 halamanHazen-Williams Pipe Flow DiagramsamadonyBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Effect of EMF On Human BeingDokumen37 halamanEffect of EMF On Human BeingsamadonyBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Ventricular Assist DeviceDokumen12 halamanVentricular Assist DevicesamadonyBelum ada peringkat

- User Journal 002Dokumen7 halamanUser Journal 002Guruvenu KamanuruBelum ada peringkat

- Tesla 511.916 ItaDokumen10 halamanTesla 511.916 ItaMary AndersonBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Meteorology ExamDokumen12 halamanMeteorology ExamNicolle PedragosaBelum ada peringkat

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDokumen11 halamanModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaBelum ada peringkat

- Poultry EggsDokumen41 halamanPoultry EggsNasiru Arisekola Ishola SuleimanBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Cloud Formation ProcessesDokumen7 halamanCloud Formation ProcessesSachin SrivastavaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Earth's SubsystemsDokumen18 halamanThe Earth's Subsystemsthe witcherBelum ada peringkat

- Earth and Life Science 11 - Q1 - MELC 1 - V1Dokumen15 halamanEarth and Life Science 11 - Q1 - MELC 1 - V1Kevin Legaspi VilardeBelum ada peringkat

- Weather Modification PatentsDokumen33 halamanWeather Modification PatentsJohnBelum ada peringkat

- Navodaya Vidyalaya Samiti: Noida: Split-Up Syllabus For The Academic Session 2019-20Dokumen6 halamanNavodaya Vidyalaya Samiti: Noida: Split-Up Syllabus For The Academic Session 2019-20Suraj Kumar PradhanBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Drying Characteristics PDFDokumen6 halamanDrying Characteristics PDFoffayevBelum ada peringkat

- Index Of Refraction Of Air: N = Λ P (1 + P (60 .1 - 0 .972T) × 10Dokumen1 halamanIndex Of Refraction Of Air: N = Λ P (1 + P (60 .1 - 0 .972T) × 10antonioBelum ada peringkat

- 1949 Normal Respiratory and Circulatory PathwaysDokumen8 halaman1949 Normal Respiratory and Circulatory PathwaysvitaarfianaBelum ada peringkat

- Seminar On Air Pollution: Submitted To: Submitted byDokumen33 halamanSeminar On Air Pollution: Submitted To: Submitted bygolucaruBelum ada peringkat

- Ventilation of The Industrial Environment PDFDokumen7 halamanVentilation of The Industrial Environment PDFnelson escuderoBelum ada peringkat

- ACFrOgA3Jfd8opBrwGcc8dXNGVRTX7o9eO3J0cU7F7rQa5CoEWTlyrcxSHxDSq5kYkX5w1IkpyWIhSy68d9Kz J6OGnrBiBQez7ycPdUzK0wUS2DjHXc4uSzpO1H zreWLcK7hE0uG - a25pXTAkH PDFDokumen2 halamanACFrOgA3Jfd8opBrwGcc8dXNGVRTX7o9eO3J0cU7F7rQa5CoEWTlyrcxSHxDSq5kYkX5w1IkpyWIhSy68d9Kz J6OGnrBiBQez7ycPdUzK0wUS2DjHXc4uSzpO1H zreWLcK7hE0uG - a25pXTAkH PDFSarah SanchezBelum ada peringkat

- Case Study On Environmental PollutionDokumen34 halamanCase Study On Environmental PollutionDr Dheeraj Mehrotra63% (8)

- Worksheet - Unit 1 - Lesson 1Dokumen10 halamanWorksheet - Unit 1 - Lesson 1Mai TrangBelum ada peringkat

- Laboratory Report of Collapsing CanDokumen3 halamanLaboratory Report of Collapsing Candubu porkBelum ada peringkat

- Mid Notes EsDokumen8 halamanMid Notes Esmmusa666Belum ada peringkat

- SBT Vol - IDokumen777 halamanSBT Vol - ISujal KumarBelum ada peringkat

- Everyday Science Mcqs 5Dokumen18 halamanEveryday Science Mcqs 5Hina IftikharBelum ada peringkat

- Dictionary of Boiler TerminologyDokumen27 halamanDictionary of Boiler TerminologyAlka Seltzer100% (34)

- Monitoring Hydrogen Cooled Turbogenerators: in Power Plants (Fossil-Fired, Hydro, Nuclear)Dokumen4 halamanMonitoring Hydrogen Cooled Turbogenerators: in Power Plants (Fossil-Fired, Hydro, Nuclear)Rajesh KumarBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- IB ESS IA Example - 2Dokumen16 halamanIB ESS IA Example - 2R. YueBelum ada peringkat

- Circus of Pressure ExperimentsDokumen2 halamanCircus of Pressure ExperimentsDilini WijesinghBelum ada peringkat

- Pollution Under Control Certificate: Form 59Dokumen1 halamanPollution Under Control Certificate: Form 59Subhash PaulBelum ada peringkat

- Climatic Data MeasurementDokumen30 halamanClimatic Data MeasurementchandanaBelum ada peringkat

- Design of Hot Air Drying For Better Foods: ReviewDokumen11 halamanDesign of Hot Air Drying For Better Foods: ReviewRosio SandovalBelum ada peringkat

- Layers of The AtmosphereDokumen2 halamanLayers of The AtmosphereJoseph De Vera DanesBelum ada peringkat

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDari EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsBelum ada peringkat