Waste Heat Recovery Power Plant

Diunggah oleh

srimant1984Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Waste Heat Recovery Power Plant

Diunggah oleh

srimant1984Hak Cipta:

Format Tersedia

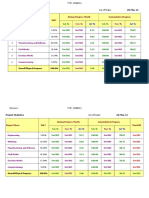

F-46

Keywords X3 factory Y3 equipment or facility Z4 electricity F26 general machinery

Kawasaki Heavy Industries, Ltd.

Waste Heat Recovery Power Plant

Features

◆ The waste heat recovery boiler recovers electric

energy from the heat energy in the high-temperature

waste gas discharged from various plants.

◆ Many cement plants have installed the system

because of its excellent energy-saving effect.

◆ The system is being used to recover waste heat not

only at cement plants but also at steel-making and

non-nonferrous smelting plants.

Waste heat recovery power plant for coke oven

(SOL CST in Brazil)

PH boiler

AQC boiler

Waste heat recovery power plant for cement plant Waste heat recovery power plant for sintering cooler

(Conch Cement in China) (Wuhan Steel in China)

Basic Concept or Summary

PH waste gas

◆ The principle is explained based on a waste heat

recovery power plant for cement plants where many AQC waste gas

systems have been installed.

◆ The waste heat recovery power plant for cement plants

consists of two waste recovery boilers - a PH boiler

and an AQC boiler - both of which are installed in the

waste gas line.

◆ The PH boiler recovers waste heat from the pre-heater

used for pre-heating raw materials (Boiler inlet gas Waste heat recovery power

plant for cement plant Steam turbine Generator

temperature: 320ºC).

◆ The AQC boiler recovers waste heat from the air Con-

denser

quenching cooler that quenches baked clinker (Boiler Cooler

inlet gas temperature: 320ºC). The heat exchangers PH boiler

using the heat from the two boilers are sequenced to

ensure high efficiency.

AQC boiler

System diagram of waste heat recovery

power plant for cement plant

F-46

Effects or Remarks

◆ Self-developed technology

◆ Cement plants have reduced electric energy used at the entire plant by 30%.

◆ At a standard plant where daily production of clinker is 5,000 tons, 95,000 kW can be saved at the

generating end, worth ¥550,000,000 annually (assuming the unit price of electric energy is ¥7.9/kWh).

◆ In terms of CO2 emission, this reduction is equivalent to 540,000 tons, which is significant for the clean

development mechanism.

Installation in Practice or Schedule

Domestic ◆ Since the first waste heat recovery power plant was delivered to a cement plant (Sumitomo

Osaka Cement, Gifu Plant) in 1980, we have supplied about 10 of the 21 plants installed in

Japan.

◆ Three waste heat recovery power plants for sintering coolers were delivered to JFE Steel

and other companies.

Overseas ◆ Waste heat recovery power plants for cement plants have been delivered to Taiwan, China,

India, Vietnam, and Korea since 1990. Especially in China, our plant with a high heat

recovery rate has been highly evaluated, and we received a bulk order for 11 plants for the

eight cement companies affiliated to Anhui Conch Cement Company Limited, the largest

cement maker in China, in March 2005.

And our company established a joint venture in January 2007, which is primarily engaged

in the design, procurement, and manufacture of waste heat recovery power plants for

cement plants.

◆ We delivered a waste heat recovery

power plant for a coke plant of American

Suncoke, which was constructed in the

Arcelor-Mittal-Turbarao Ironworks in

Brazil. This is the third largest waste heat

recovery power plant in the world, and is

designed to recover electric energy from

dusty high-temperature waste gas at

1,000ºC or more. It was the largest plant

and the first plant to be installed outside

of the U.S. The generating capacity is 98

MW x 2 systems. Waste heat recovery power plant for coke oven

(SOL CST in Brazil)

Contact: Kawasaki Plant Systems, Ltd., Overseas Sales Department, Power Group

Tel: 03-3615-6974 Fax: 03-3615-9667

URL: http://www.khi.co.jp/kplant/products/PowerPlant/02.html

Anda mungkin juga menyukai

- Waste Water ReportDokumen27 halamanWaste Water ReportkomalBelum ada peringkat

- Plant Tender EZ OffDokumen16 halamanPlant Tender EZ OffGowri GaneshBelum ada peringkat

- LCC Executive SummaryDokumen23 halamanLCC Executive SummarySuhartomtBelum ada peringkat

- Err:511 Err:511 Err:511 Err:511 Err:511Dokumen2 halamanErr:511 Err:511 Err:511 Err:511 Err:511Anonymous 3ESYcrKPBelum ada peringkat

- L12-13 Material BalancesDokumen9 halamanL12-13 Material Balancesjivie300998Belum ada peringkat

- Solid Waste Engineering: Pattaraporn Kim Department of Chemical Engineering, Chulalongkorn UniversityDokumen59 halamanSolid Waste Engineering: Pattaraporn Kim Department of Chemical Engineering, Chulalongkorn UniversityMalikBelum ada peringkat

- CHE501 Heat Transfer ExperimentDokumen7 halamanCHE501 Heat Transfer ExperimentEd Ryan RualesBelum ada peringkat

- Waste Heat Recovery System (WHRS)Dokumen32 halamanWaste Heat Recovery System (WHRS)Дмитрий ЗинченкоBelum ada peringkat

- VFD For Compresor Motor 75 HP Bhimavrm IMCDokumen35 halamanVFD For Compresor Motor 75 HP Bhimavrm IMCVivek SinghBelum ada peringkat

- 1.761 - Process Operation Manual WWTP - PitestiDokumen68 halaman1.761 - Process Operation Manual WWTP - PitestiDany DogeBelum ada peringkat

- Solid Waste Incinerator ManufacturersDokumen2 halamanSolid Waste Incinerator Manufacturersbl engineeringBelum ada peringkat

- Dewatering sludge through filtration and drying bedsDokumen46 halamanDewatering sludge through filtration and drying bedsClaudia AvramBelum ada peringkat

- Rules Of Thumb For Air CompressorsDokumen2 halamanRules Of Thumb For Air CompressorsHoney Tiwari100% (1)

- Plate and Frame FiltrationDokumen11 halamanPlate and Frame FiltrationQuenneBelocuraBelum ada peringkat

- Heat Transfer ConductionDokumen29 halamanHeat Transfer ConductionDilaFirizqinaBelum ada peringkat

- 1 Sludge Treatment and Disposal-1Dokumen27 halaman1 Sludge Treatment and Disposal-1Liyana RaisBelum ada peringkat

- S Curves - DM PlantDokumen6 halamanS Curves - DM PlantnikunjBelum ada peringkat

- PR Minent: Plan View Piping SchematicDokumen1 halamanPR Minent: Plan View Piping SchematicrameshBelum ada peringkat

- Cerlic - Sludge Handling BrochureDokumen6 halamanCerlic - Sludge Handling BrochureShiva Shakthi0% (1)

- Wastewater ManagementDokumen347 halamanWastewater ManagementAravind Kumar100% (4)

- Gomez - Payongayong-Filtration-ESE144 - AutosavedDokumen56 halamanGomez - Payongayong-Filtration-ESE144 - AutosavedMaha GomezBelum ada peringkat

- Process DryersDokumen12 halamanProcess DryersSantosh JaiswalBelum ada peringkat

- Seawater Electrochlorination SystemDokumen8 halamanSeawater Electrochlorination Systemshitrio100% (1)

- Grundfos Category Heading Grundfos Boiler Feed ManualDokumen32 halamanGrundfos Category Heading Grundfos Boiler Feed ManualTasawwur TahirBelum ada peringkat

- Slurry Piping Systems, Its Design and Instrumentation - PIPING GUIDEDokumen8 halamanSlurry Piping Systems, Its Design and Instrumentation - PIPING GUIDESriramShraffBelum ada peringkat

- Pump Selection - Teluk Kabung (07.10.2015) - With CommentDokumen15 halamanPump Selection - Teluk Kabung (07.10.2015) - With CommentPriyo Jati WahyonoBelum ada peringkat

- Constant Pressure FiltrationDokumen2 halamanConstant Pressure FiltrationHarjasa AdhiBelum ada peringkat

- Data NormalisationDokumen31 halamanData NormalisationAshish GulabaniBelum ada peringkat

- Removing fat from meat plant wastewater with hydrocyclonesDokumen63 halamanRemoving fat from meat plant wastewater with hydrocyclonesNopparutBelum ada peringkat

- Centrifugal PumpDokumen7 halamanCentrifugal PumpTife BakreBelum ada peringkat

- Compressed Air: Open University' Project Slide 1Dokumen62 halamanCompressed Air: Open University' Project Slide 1kISHOREBelum ada peringkat

- Improve Railcar Unloading with Semidense ConveyingDokumen5 halamanImprove Railcar Unloading with Semidense Conveying설동하Belum ada peringkat

- Air Filter For TurbineDokumen8 halamanAir Filter For TurbineAnonymous Q9i062VBelum ada peringkat

- VOL IV - Mechanical PDFDokumen144 halamanVOL IV - Mechanical PDFVaijayanti JoshiBelum ada peringkat

- Cyclone PDFDokumen34 halamanCyclone PDFAndrew FloresBelum ada peringkat

- Horizontal KO PotDokumen4 halamanHorizontal KO Pothk168Belum ada peringkat

- Equipment Specification Project - RFQ - #: Page 1 of 12Dokumen12 halamanEquipment Specification Project - RFQ - #: Page 1 of 12Calin SeraphimBelum ada peringkat

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDokumen4 halamanPB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoBelum ada peringkat

- Technical Specification for Effluent Treatment PlantDokumen190 halamanTechnical Specification for Effluent Treatment PlantkumarBelum ada peringkat

- Sub-Sectoral Environmental and Social Guideline: Pulp and PaperDokumen17 halamanSub-Sectoral Environmental and Social Guideline: Pulp and PaperJuan Pablo Palma PizarroBelum ada peringkat

- Water Treatment 4-Stage ProcessDokumen145 halamanWater Treatment 4-Stage ProcessSelvitien Eka PutriBelum ada peringkat

- Performance Evaluation of A Central WastewaterDokumen155 halamanPerformance Evaluation of A Central WastewaterWayne HamiltonBelum ada peringkat

- Operating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryDokumen12 halamanOperating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryJoshua OmolewaBelum ada peringkat

- Cooling Water and Cooling TowerDokumen37 halamanCooling Water and Cooling Towersandip singhBelum ada peringkat

- Process CalculationsDokumen11 halamanProcess CalculationsGeevarghese Mammen KoyippallyBelum ada peringkat

- O&M Manual: BALLOKI 1223MW Combined Cycle Power PlantDokumen28 halamanO&M Manual: BALLOKI 1223MW Combined Cycle Power PlantMehtab AhmedBelum ada peringkat

- Heat Load Calculation For Pumping Station - 13Dokumen6 halamanHeat Load Calculation For Pumping Station - 13Deepak JoyBelum ada peringkat

- Proposal Work Flow GuidelineDokumen2 halamanProposal Work Flow Guidelineirshad sondeBelum ada peringkat

- Storage PDFDokumen12 halamanStorage PDFanasabdullahBelum ada peringkat

- Cata en 7Dokumen16 halamanCata en 7Ram Ranjan100% (1)

- Appendix P - Sizing of Water Piping SystemDokumen20 halamanAppendix P - Sizing of Water Piping SystemDeese MarieBelum ada peringkat

- Blower Power CalculDokumen4 halamanBlower Power Calculm_stasys9939Belum ada peringkat

- Tech Specification VSDDokumen9 halamanTech Specification VSDDony SaputraBelum ada peringkat

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Dokumen8 halamanAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraBelum ada peringkat

- Waste Heat To Power ApplicationsDokumen10 halamanWaste Heat To Power ApplicationsArul PrakashBelum ada peringkat

- Carbon FilterDokumen6 halamanCarbon FilterFreddy YugchaBelum ada peringkat

- Waste Heat Recovery Power Plant: FeaturesDokumen2 halamanWaste Heat Recovery Power Plant: FeaturesyuvaduraiBelum ada peringkat

- Exergy AnalysisDokumen8 halamanExergy AnalysisNikhil MohiteBelum ada peringkat

- State-Of-The-Art Technologies For The 1,000-Mw 24.5-Mpa/ 600°C/600°C Coal-Fired BoilerDokumen4 halamanState-Of-The-Art Technologies For The 1,000-Mw 24.5-Mpa/ 600°C/600°C Coal-Fired BoilerRezwana SarwarBelum ada peringkat

- Amec Foster Wheeler Industrial BrochureDokumen12 halamanAmec Foster Wheeler Industrial BrochureArual PerezBelum ada peringkat

- Road Design Tutorial For Civil 3dDokumen22 halamanRoad Design Tutorial For Civil 3dPRINCE PAUL CHAKANYUKA60% (5)

- Transmission Tower Thesis A Gupta Good Good GoodDokumen120 halamanTransmission Tower Thesis A Gupta Good Good GoodArogya Raju Pudhota100% (4)

- Resume Mark ReganDokumen3 halamanResume Mark Regansrimant1984Belum ada peringkat

- 4.6 Fans and BlowersDokumen6 halaman4.6 Fans and Blowerssrimant1984Belum ada peringkat

- DM 6-3-B Earthing Practices AdditionalDokumen14 halamanDM 6-3-B Earthing Practices Additionalmajid_20Belum ada peringkat

- Earthing PracticesDokumen16 halamanEarthing PracticesSubu ManiBelum ada peringkat

- 1223, 1225, 1227 - Manual PDFDokumen93 halaman1223, 1225, 1227 - Manual PDFEWERTONBelum ada peringkat

- tp6140 PDFDokumen72 halamantp6140 PDFangel aguilarBelum ada peringkat

- Diesel Generator SpecificationDokumen13 halamanDiesel Generator Specificationmtrj59Belum ada peringkat

- 2416 ManualDokumen104 halaman2416 ManualDAIAPMBelum ada peringkat

- Smoke Alarm - PresentationDokumen17 halamanSmoke Alarm - Presentationrenuka dixaBelum ada peringkat

- Pile Cap DesignDokumen2 halamanPile Cap DesignsivaBelum ada peringkat

- Silikophen P 80xDokumen1 halamanSilikophen P 80xShafiq LatifBelum ada peringkat

- NanomaterialsDokumen260 halamanNanomaterialsTaylor Levi MabeBelum ada peringkat

- Submerged Arc Welding Consumables GuideDokumen19 halamanSubmerged Arc Welding Consumables GuideMarleneLopesBelum ada peringkat

- Celso Foelkel - 46 - SD - Collecting Burning NCGDokumen45 halamanCelso Foelkel - 46 - SD - Collecting Burning NCGLuana BarretoBelum ada peringkat

- Casting AlloysDokumen2 halamanCasting Alloysgalvaosilva100% (1)

- Auto Cruise Control SystemDokumen2 halamanAuto Cruise Control SystemAlex HernandezBelum ada peringkat

- I Unit Os OverviewDokumen14 halamanI Unit Os OverviewChandramouli KolavasiBelum ada peringkat

- Post Tension CablesDokumen1 halamanPost Tension CablesMike FotiouBelum ada peringkat

- Detroid Deisel FluidsDokumen45 halamanDetroid Deisel Fluidsangel017Belum ada peringkat

- Overview of Micro Hydro PowerDokumen51 halamanOverview of Micro Hydro PowerDr. Triratna BajracharyaBelum ada peringkat

- Minicargador 246DDokumen538 halamanMinicargador 246Dmiguelvl2580% (5)

- Oil Free Reciprocating Compressors - IRDokumen2 halamanOil Free Reciprocating Compressors - IRvmohan01Belum ada peringkat

- Makinis Matibay pa na PLAINCRETE BlocksDokumen7 halamanMakinis Matibay pa na PLAINCRETE BlocksJim Bryan RazBelum ada peringkat

- Shielded Metal Arc Welding (Stick Welding)Dokumen26 halamanShielded Metal Arc Welding (Stick Welding)Anonymous mRBbdopMKfBelum ada peringkat

- f150 ManualDokumen312 halamanf150 ManualJon KnoppeBelum ada peringkat

- Canon CP660 Service ManualDokumen407 halamanCanon CP660 Service ManualdjokanomcaBelum ada peringkat

- Vehicle Coverage 10B0Ver Asian 1 DAIHATSUDokumen6 halamanVehicle Coverage 10B0Ver Asian 1 DAIHATSUSyed Zeeshan ShahBelum ada peringkat

- GSM Alarm System en Ver 180209Dokumen25 halamanGSM Alarm System en Ver 180209Adnan Brkic0% (1)

- Grillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종Dokumen8 halamanGrillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종tyuBelum ada peringkat

- Syncrowave 250 Technical Manual PDFDokumen84 halamanSyncrowave 250 Technical Manual PDFwilliam ortizBelum ada peringkat

- What Is BiobutanolDokumen21 halamanWhat Is BiobutanolKirito KazutoBelum ada peringkat

- Greenberg Clement 1955 1961 American-Type Painting PDFDokumen11 halamanGreenberg Clement 1955 1961 American-Type Painting PDFVel Murugan100% (1)

- Mobile Computing Perspective on Distributed SystemsDokumen141 halamanMobile Computing Perspective on Distributed Systemsbecks23tdBelum ada peringkat

- Safe Clean Drinking Water Vertical Turbine PumpDokumen1 halamanSafe Clean Drinking Water Vertical Turbine PumpFayez Al-ahmadiBelum ada peringkat