Culvert Design For Maraval River, Trinidad (Exclusion of AutoCAD Drawing)

Diunggah oleh

Nerro SeunarineJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Culvert Design For Maraval River, Trinidad (Exclusion of AutoCAD Drawing)

Diunggah oleh

Nerro SeunarineHak Cipta:

Format Tersedia

Introduction A culvert is a short, closed covered conduit that conveys storm water runoff under an embankment, usually a roadway.

The primary purpose of a culvert is to convey surface water , but proper design can be used to restrict flow and reduce downstream peak flows. In this case, 4 different culverts are to be designed to carry water from Maraval River safely under Audrey Jeffers Highway. The culverts that must be designed are: 1) 2) 3) 4) Single rectangular Single circular Double rectangular Double circular

These culverts are to be designed for 50 year storm interval and checked with a 2 year flood interval for discharge and velocity checks. In addition to the hydraulic function, the design of a culvert also carries structural design considerations such as construction, railroad and other traffic and earth loads. This culvert design is only initiated towards the hydraulic aspects. The design of a culvert, including inlet and the outlet, requires a balance between cost, hydraulic efficiency, purpose and topography at the culvert site. Culverts are available in a variety of sizes, shapes and materials. Sizes may vary from small circular pipes to extremely large arch sections that are sometimes used in the place of bridges. Design criteria Apart from what type of culvert chosen, it should conform to proper design standards with regards to alignment with the channel, capacity, debris control and energy dissipation. The following must be performed: 1) The culvert with its appurtenant entrance and outlet structures should efficiently discharge water, bed load and floating debris at all stages of flow. 2) It should cause no direct or indirect damage. 3) The good culverts design must also take into consideration land development; increased urbanization and its effects. Construction of buildings, houses, roadways associated with urban development will cause an increase in surface water run-offs. This will increase the C value (coefficient of discharge) in the equation Q=CiA, leading to higher discharge rates. Increase in paved areas will reduce the amount of water being able to flow into the soil and into the water table. Urbanization is also associated with deforestation and clearing of the land so there will also be fewer trees to absorb the water. Increase in population densities in nearby areas increases the amount of water utilized by the people. The culvert capacity will increase and so too would the erosive forces of the water. 4) It should be economical to build, hydraulically adequate to handle and design discharge, structurally durable and easy to maintain. 5) It should be designed to avoid excessive ponding at the entrance which may cause property damage, accumulation of sediment, culvert clogging, saturation of fills or detrimental upstream deposits of debris.

6) Energy dissipaters should be simple, easy to build, economical and reasonably self cleaning during periods of low flow. 7) Alignment should be such that water enters and exits the culvert directly.

Flood Routing and Culvert design Flood routing through a culvert is a practice that evaluates the effect of temporary upstream ponding caused by the culverts backwater. If flood routing is not considered, it is possible that the findings from culvert analyses will be conservative. If the selected allowable headwater is accepted without flood routing, then costly over design of both the culvert and outlet protection may result, depending on the amount of temporary storage involved. Calculation of design discharge rate for the culvert On the digital maps provided, the outline of the catchment area was drawn. From AutoCAD 2012 the catchment area is 7009104.6 m2. Table 1 shows the Contributing coefficients of the design catchment area. Land use or Type Average C value (run off coefficient) Estimate percentage area of total catchment area (%) 50 Contributing coefficient 0.1375

1) Forested areas 0.275 with Steep Slopes. 2) Steep, Rocky 0.7 land 3) Residential, 0.55 Moderately Steep 4) Asphalt 0.85 Pavement Total contributing coefficient, C=

5 40

0.035 0.22

0.0425 0.435

The time of concentration, Tc is most defined as the time required for a particle of water to travel from the most hydrologically remote point in a watershed to the point of collection. An alternative definition is the maximum or peak runoff rate from small areas usually results from a rain that covers the area uniformly and lasts long enough so that there is a concentration of runoff from all parts of the watershed. It is the key parameter in predicting runoff. There are various methods and formulas to calculate the time of concentration. The method that will be utilized in this design is the Kirpich Method. For watershed with well defined channels and steep slopes (3 to 10%), ( ) Where Tc is the time of concentration in minutes, L is the maximum hydraulic flow length and H is the difference in elevation between the outlet of the watershed and the hydraulically most remote point in the watershed. The values for L and H are both in feet (ft).

For the design of this culvert, the value of H is the difference between the peak elevation bordered by the outline of the catchment and L is the hydraulic flow length referencing this peak height. From the catchment area AutoCAD map: Elevation of the highest part of the watershed, H2=575m Elevation at the Audrey Jeffers highway crossing, H2 (approximately) =5m Difference in elevation, H=570m Therefore, H=1870ft Distance between the highway crossing and the highest part of the watershed, L=5101.01m Therefore, L= 16800ft Using Kirpich equation: Tc = Tc = 32.559mins Tc = 33mins. Using the Intensity-Duration-frequency curve of the closest station: River estate to the design catchment, duration time=Tc of 34minutes corresponds to a rainfall intensity of 120mm/hr for the design of a 50year storm. Rainfall intensity, i =120mm/hr Therefore, i =3.33x10-5m/s Now required to find the design discharge; Q = CiA Q = (0.435)*(3.33x10-5)*(7009104.6) Q = 101.6m3/s Using the Intensity-Duration-frequency curve of the closest station: River estate to the design catchment, duration time=Tc of 33minutes corresponds to a rainfall intensity of 53mm/hr for the design of a 2-year interval flood. Rainfall intensity, i=53mm/hr Therefore, i =1.472x10-5m/s Therefore, Q = (0.435)*(1.472x10-5)*(7009104.6) Q=44.88m3/s ( ) ( )

Alignment of the designed culverts The channel is not skewed with respect to the culvert location under the Audrey Jeffers Highway crossing. The alignment is normal to the embankment and the water enters and exits the culvert directly and scouring is minimised. The alignment is shown below:

This alignment is optimum to prevent any abrupt change in direction at either end will retard the flow and cause ponding, erosion or a build-up of debris at the culvert entrance. All of these conditions could lead to failure.

1. Design of a single rectangular culvert

Box culverts can be designed to pass large flows and is easy to fit into any site condition. A box rectangular culvert provides itself more readily than other shapes to low allowable headwater situations since the height may be decreased and the span increased to satisfy the location requirement. The culvert material is concrete because of its high structural strength, high roughness, and abrasion and corrosion resistance. The culvert is located in a generally flat area of land, assuming slope of the culvert, s=0.004. Levelling can be used to determine the slope of the land where the culvert is to be designed. It is also the minimum slope needed to avoid excessive ponding at the entrance which may cause property damage, accumulation of sediment, culvert clogging, saturation of fills or detrimental upstream deposits of debris. For optical culvert design, the width, b to depth, d ( ) ratio=2.

B=2d Where n= Mannings friction coefficient (for concrete n=0.015), m=hydraulic radius = , s=slope of design culvert= 0.004. For a 50year storm interval Calculating the minimum headwater depth of culvert; 101.6= Rearranging equation to obtain, d 19.13= This depth is the minimum headwater depth to allow for adequate flow of the culvert, dmin= 3.02m This width is the minimum width to allow for adequate flow of the culvert, bmin=6.05m With the allowance of an 18(0.4572m) freeboard as standard, determining if a culvert size of 3.5x7m would be suitable. To check the new depth of flow in this culvert, again using Mannings equation: 101.6= ( ) ( ) ( ) ( )

3.442=(

The new depth of flow in this selected culvert is 2.63m OK Efficiency of the culvert= OK

This size of culvert is chosen because of its high efficiency and its size is very economical with respect to the capacity of water that it has to carry under the highway. There is also limitation of space under the existing highway and proper utilization of the space below for the design essential. The culvert is designed to be partially full because if a 50 year storm occurs, branches of trees can break off and debris from urban and residential areas can enter the river and float down towards the culvert. In this case, the excess or freeboard height of 1.42m of the culvert is to allow debris and branches to flow freely through it without blocking the water passageway which can be detrimental as this can lead to flooding of the Audrey Jeffers Highway and nearby residential areas such as Aripita Avenue, and urban areas like Mucurapo and Fatima further damages. Velocity of flow, ( )

Using this to determine Froude number, ( ) ( )

The flow rate that was computed is considered high and should be avoided in the culvert design as scouring and erosion of the culvert is a high possibility. Calculating the Froudes number just upstream of the culverts inlet shows that the incoming water is at supercritical flow. Supercritical flow is difficult to manage without causing a hydraulic jump or other surface irregularity. Generally velocities should not exceed values of 3-4m/s so that the erosive power of the water would be suppressed. Critical velocity may be sufficient to cause erosion problems requiring protection adjacent to the basin exit. A safe rate of flow in the culvert would be lower than critical velocity, vc. At critical flow, Froudes number is equal to 1 but first critical depth must be determined.

) ( )

Since q=14.514m3/s/m

Critical depth, dc=2.78m>depth of flow for a 50 year storm interval, d=2.63m OK

Then critical velocity, vc

Since 5.51m/s>5.22m/s NOT OK Protection is required Protection-Wingwalls & Aprons From the AutoCAD drawing, the width of Maraval River was measured as 15.61m at the Audrey Jeffers highway crossing. Since flow is normal to the embankment, both wing walls must cover a horizontal spread of 5m on either ends, flared outwards at an angle with respect to the culvert axis so that the channel water can be gradually guided towards the culvert, avoiding excessive turbulence. Wingwalls are also necessary since the width of the culvert is smaller than the width of the river (15.61m>7m). The wing walls, as well as, the culvert width therefore spans a total of 17m for safety just in case the river exceeds its already maximum capacity. The wing walls are also used to protect the soil against erosion. To prevent the soil at the river banks from eroding, upstream of the wingwalls thick vegetative cover can be adequate protection. Weepholes are designed to relieve the pore water pressure of the nearby soil to reduce the lateral earth pressures on the culvert walls and wing walls. Since the flow velocity near the inlet indicates high possibilities of scour that can threaten the stability of the wingwall footings, a concrete apron between the wingwalls is an effective mean of erosion protection. They support the wingwalls as cantilevers. These aprons are reinforced to control cracking and designed with a sill allowing the water to drop to the natural channel height (small energy dissipated by this) and flowing downstream at a rate in which erosion cannot occur. The thickness of the reinforced concrete apron should be at least 8 inches thick and the length determined from the equation below:

Where L is the length of apron, V is the velocity of discharge and D is the height of the box culvert or diameter of pipe culvert. =3.86m The design length of the apron is 3.86m/s Rip-rap apron is a cheaper, sustainable alternative for energy dissipation than the concrete apron and can be used at the culverts outlet in order to reduce the flow rate under a safe value of 4m/s. This apron should be extended a length equivalent to the depth of the culvert, that is, the length equalling 7m. The following equation (from Urban drainage and flood control district in Denver Colorado (UD&FCD 2004) was developed for box culverts: ( ( ) ) ( )

D50=riprap size, Q=discharge, D=culvert rise, B=culvert width, TW=Tailwater depth.

Since tailwater depth is unknown, it will be used as TW=0.4D. ( ( ) ) ( )

Design of the rip rap boulder sizes assuming they are spherical. The value of 0.28m is the minimum size of boulders required for the rip rap apron in order for it not to be moved by waters. The larger the boulder, the more effective dissipater it is. Generally, the stones used are not spherical but are irregularly shaped with sharp edges which allowing for more effective energy dissipation than smooth spherical shaped stones. The use of stilling basins to create a hydraulic jump is very expensive and not applicable for flows with Froude numbers under 1.7. Estimating scour at culvert outlets if protection was not designed There are two types of scour: local and channel degradation. Local scour is typified by a scour hole produced at the culvert outlet. General stream degradation is a natural occurrence of lowering of the streambed over time due to the erosion effects of the stream or river. Estimating erosion at culvert outlets is difficult because of the many complex factors affecting erosion. Some of these factors are discharge, culvert shape, soil type, duration of flow, culvert slope, culvert height above the bed and tail water depth. Maintenance history, site reconnaissance and data on soils, flows and flow duration provide the best estimate of the potential scour hazard at the culvert outlet. Estimating scour hole geometry in a cohesionless soil. Using the soil map of Trinidad and Tobago (see Appendix), [ } ( )( ) ( ) )

Peak flow duration is estimated to be 30minutes. Rc is hydraulic radius. Standard deviation, for the granded sandy soil is 1.87. Since slope just upstream of the culverts inlet is approximately equal to 0, the CsCh=1. Coefficients: Depth of scour, hs Width of scour, Ws Length of scour, Ls Volume of scour, Vs 2.27 6.94 17.10 127.08 0.39 0.53 0.47 1.24 0.06 0.08 0.10 0.18 Cs 1.00 1.00 1.00 1.00 Ch 1.00 1.00 1.00 1.00

Calculations of scour hole geometries are shown in the table below: Scour hole geometry in dimensionless form hs/Rc Ws/Rc Ls/Rc Vs/Rc^3 For a 2year flood interval Determining the minimum depth and width required for flow respectively. Using Mannings equation: ( ) Rearranging equation to obtain, d 8.45= ( ) Values 0.539626 1.065496 2.960378 2.132036 Scour hole dimensions Depth, hs Width, Ws Length, Ls Volume, Vs

6.616m 13.063m 36.290m 3928.8m3

This depth is the minimum headwater depth to allow for adequate flow of the culvert, dmin= 2.22m This width is the minimum width to allow for adequate flow of the culvert, bmin= 4.45m With the allowance of an 18 (0.4572m) freeboard as standard, the depth= 2.68m Determining the depth of flow for the selected 3.5x7m single rectangular box culvert. 44.88= 1.52=( ) ( ) ( )

The new depth of flow for this selected culvert is 1.48m With the allowance of an 18(0.4572m) freeboard as standard, the total depth required= 1.9372m Velocity of flow, ( ) which is greater than 4m/s

NOT OK but with the protection designs recommended this velocity will be significantly reduced.

2. Design of a single circular culvert This circular culvert will be designed for the same discharge; Q of 101.6m3/s. Circular culvert is designed for a 50year storm and can be referred to as a storm sewer. This storm sewer will be designed to flow partially full. The material used for the design is corrugated steel. Special end sections for corrugated metal pipe add little to the overall cost of the culvert and have the advantages of less maintenance around the inlet, less damage from maintenance work and from accidents compared to a projecting entrance and increased hydraulic efficiency. Mannings friction coefficient for corrugated steel is 0.022 and the slope of the culvert is the same (0.004). Using Mannings equation and designing firstly for the circular culvert completely full: ( ) ( )

( ) Simplifying to get;

The minimum diameter, D calculated for this culvert was 5.84m. Using a design diameter, D1=6m

D= 6m

Calculating

( )

Using the graph of Ratio of depth to flow to diameter y/D versus Hydraulic elements in terms of hydraulic for full section, corresponding Qdesign/Qfull ratio. From the graph, y/D=76. Efficiency of the culvert is 76%. , the y/D ratio can be determined for this

Therefore headwater depth of flow, y= 0.76*6=4.56m. With a y/D ratio of 76, this corresponds to a Q/Qfull area ratio of 0.70. Area of m2

Therefore, flow area, A=0.70*9=19.8m2 Velocity of flow, ( ) which is greater than 4m/s NOT OK

Protection-Wingwalls and aprons Since Flow is normal to the embankment, both wing walls cover a horizontal spread of 5m. The wingwalls are flared to help further retain and protect the embankment and by acting as a funnel to guide the flow from the wider natural river channel to the narrower culvert width. The wing walls and the culvert width, span a total of 16m for design safety. The wing walls are also used to protect the soil against erosion. If just upstream of the channel there are soils which are easily erodible, a thick vegetative cover can be adequate protection. Weepholes are designed to relieve the pore water pressure of the nearby soil to reduce the lateral earth pressures on the culvert walls and wing walls. Since the flow velocity near the inlet indicates high possibilities of scour that can threaten the stability of the wingwall footings, a concrete apron between the wingwalls is an effective mean of erosion protection. They support the wingwalls as cantilevers. The apron are reinforced to control cracking and is designed with a sill causing the water to drop (some energy dissipated) to the natural channel height and flowing downstream at a rate in which erosion cannot occur. This concrete apron extends until where the edge of the wing wall ends (approximately 5m). Rip-rap apron is a cheaper, sustainable alternative for energy dissipation than the concrete apron and can be used at the culverts outlet in order to reduce the flow rate under a safe value of 4m/s. This apron should be extended a length equivalent to the depth of the culvert, that is, the length equalling 6m.

The following equation (from Fletcher and Grace, Reference) was developed for circular culverts: ( )

( D50=rip rap size Since tailwater depth is unknown, TW=0.4D.

) ( (

( )

In the design of the rip rap boulder sizes, the minimum boulder diameter is 0.80m assuming they are spherical. AutoCAD drawing of a storm sewer is shown below. For a 2year flood interval Using a design diameter, D1=6m

Using the graph of Ratio of depth to flow to diameter y/D versus Hydraulic elements in terms of hydraulic for full section, corresponding Qdesign/Qfull ratio. From the graph, y/D=45. Efficiency of the culvert is 45%. Therefore headwater depth of flow, y= 0.45*6=2.7m. With a y/D ratio of 45, this corresponds to a Q/Qfull area ratio of 0.44. Area of m2 , the y/D ratio can be determined for this

Therefore, flow area, A=0.44*9=12.44m2 Velocity of flow, ( ) which is less than 4m/s. Greater than 0.5m/s so

sedimentation and breeding of mosquitoes is eliminated. OK

3. Design of double rectangular culverts For a 50year storm interval For the design of 2 rectangular culverts for the design discharge rate, it is assumed that both culverts work with the same efficiency, therefore, each culvert would carry a discharge rate of 50.8m3/s. For optical culvert design, the width, b to depth, d ( ) ratio=2. The culvert is located in a generally flat area of land, assuming slope of the culvert, s=0.004 Using Mannings equation, Calculating the minimum depth of culvert; 50.8= Rearranging equation to obtain, d 9.563= ( ) ( )

This depth is the minimum headwater depth to allow for adequate flow of the culvert, dmin= 2.33m This width is the minimum width to allow for adequate flow of the culvert, bmin=4.66m With the allowance of an 18(0.4572m) freeboard as standard, determining if a culvert size of 3x6m would be suitable. To check the new depth of flow in this culvert, again using Mannings equation: 50.8= 2=( ) ( ) ( )

The new depth of flow in this selected culvert is 1.84m OK

Efficiency of the culvert= Velocity of flow, ( )

OK

Using this to determine Froude number, ( ) ( )

Since Fr>1, supercritical flow occurring in the culvert and v=4.6m/s>4m/s permitted velocity. NOT OK

) ( )

Since q=8.466m3/s/m

Critical depth, dc=1.94m>depth of flow for a 50 year storm interval, d=1.84m OK Then critical velocity, vc ( ) ( ) .

Since 4.6m/s>4.36m/s NOT OK Protection is required Flared wingwall since the velocity is greater than 6 feet per second (1.81m/s) at the culvert inlet. 8 inch thick rip rap apron protection of approved rocks will be required for inlet protection from scouring and erosion. Rip rap is used instead of reinforced concrete aprons since they are cheaper and more sustainable. Thick vegetative cover should be planted on both sides of the river banks further upstream to reduce soil erosion of the banks. For a 2year flood interval Determining the depth of flow for the selected 3.5x7m single rectangular box culvert; 22.44= 1.3=( ) ( ) ( )

The new depth of flow for this selected culvert is 1.3m With the allowance of an 18 (0.4572m) freeboard as standard, the total depth required= 1.7572m Velocity of flow, ( ) which is less than 4m/s and greater than 0.5m/s so

sedimentation and breeding of mosquitoes is eliminated. OK

4. Design of a double circular culvert For a 50year storm interval 2 circular culverts for a total discharge rate, Q of 101.6m3/s, it is assumed that both culverts work with the same efficiency, therefore, each culvert would carry a discharge rate of 50.8m3/s. Both storm sewers designed to flow partially full not completely full. The material used for the design is corrugated steel. Mannings friction coefficient for corrugated steel is 0.022 and the slope of the culvert is the same (0.004). Using Mannings equation and designing firstly for the circular culvert completely full: ( ) ( )

( ) Simplifying to get;

The minimum diameter, D calculated for this culvert was 4.55m. Using a design diameter, D1=5m Calculating = ( )

( )

Using the graph of Ratio of depth to flow to diameter y/D versus Hydraulic elements in terms of hydraulic for full section, corresponding Qdesign/Qfull ratio. From the graph, y/D=64. Efficiency of the culvert is 64%. Therefore headwater depth of flow, y= 0.64*5=3.2m. With a y/D ratio of 64, this corresponds to a Q/Qfull area ratio of 0.69. Area of m2 , the y/D ratio can be determined for this

Therefore, flow area, A=0.69*25/4=13.55m2 Velocity of flow, ( ) which is less than 4m/s OK

Protection-Rip rap gabions and endwalls Rip rap gabions are used for inlet control to dissipate some of the energy of the water so that the flow rate in the culvert and downstream be a safe and comfortable one. Endwall structure are designed to sufficiently support the culvert ends. For a 2year flood interval Using a design diameter, D1=6m

Using the graph of Ratio of depth to flow to diameter y/D versus Hydraulic elements in terms of hydraulic for full section, corresponding Qdesign/Qfull ratio. From the graph, y/D=40. Efficiency of the culvert is 40%. Therefore headwater depth of flow, y= 0.40*5=2m. With a y/D ratio of 40, this corresponds to a Q/Qfull area ratio of 0.385. Area of m2 , the y/D ratio can be determined for this

Therefore, flow area, A=0.385*25/4=7.56m2 Velocity of flow, ( ) which is less than 4m/s and greater than

0.5m/s so sedimentation and breeding of mosquitoes is eliminated. OK

Inlet control without affecting the culvert design The selected sizes of the culverts were chosen based on the combination of high hydraulic efficiency, economical size, structural strength, durability and ease of maintenance. One way of reducing the inlet velocity is by adjusting the culverts slope. The culverts slope can be adjusted by excavating one part of the channel and evenly filling the upstream parts so there would be a higher elevation difference between where the inlet will be located and the outlet will be located. Another possible way of reducing the flow rate towards the designed culverts inlet is by excavation of the natural channel. This can be done to create a larger flow area. Increasing the flow area for the same designed discharge rate, will reduce the flow rate (since v=Q/A). It is the alternative method of reducing flow velocity without adjusting the culvert slope, since this is generally difficult to perform.

A d

Anda mungkin juga menyukai

- Enhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsDari EverandEnhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsBelum ada peringkat

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Dari EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Belum ada peringkat

- Bridge Hydrology ClassDokumen16 halamanBridge Hydrology ClassAbhishek100% (1)

- Flexible Overlay DesignDokumen4 halamanFlexible Overlay DesignPODBelum ada peringkat

- BoxDokumen16 halamanBoxAlfred KameyaBelum ada peringkat

- Schedule BDokumen43 halamanSchedule Bhardik sorathiyaBelum ada peringkat

- Hydrology Report Major StreamDokumen24 halamanHydrology Report Major Streamdushyantjadaun100% (1)

- 6 Lect Canal DesignDokumen36 halaman6 Lect Canal DesignNumair Ahmad FarjanBelum ada peringkat

- Chapter 4 Flexible Pavement Design AASHTO MethodDokumen16 halamanChapter 4 Flexible Pavement Design AASHTO MethodNamukasa DivinaBelum ada peringkat

- Open Channels PDFDokumen31 halamanOpen Channels PDFVOJBelum ada peringkat

- Preparation of DPR - Hydrological StudiesDokumen30 halamanPreparation of DPR - Hydrological Studiesmathur_nkBelum ada peringkat

- Basic Concepts: Hour) Peak Within Flow of Rate (Peak V 4 Hour Peak During (PHF) Factor Hour PeakDokumen5 halamanBasic Concepts: Hour) Peak Within Flow of Rate (Peak V 4 Hour Peak During (PHF) Factor Hour PeakAbdirizak HussienBelum ada peringkat

- TUTORIAL Unsignalised 2017Dokumen5 halamanTUTORIAL Unsignalised 2017Nur Hazirah SadonBelum ada peringkat

- CVEN 2401 Workshop Wk2 SolutionDokumen8 halamanCVEN 2401 Workshop Wk2 SolutionMichael BoutsalisBelum ada peringkat

- Bridge Deck Expansion Joints PDFDokumen10 halamanBridge Deck Expansion Joints PDFVCBelum ada peringkat

- Design of R.C.C Tee Beam Bridge 5.1 Design of Deck Slab 5.1.1 DATADokumen24 halamanDesign of R.C.C Tee Beam Bridge 5.1 Design of Deck Slab 5.1.1 DATANithin M.TBelum ada peringkat

- Ns 18 Steel DesignDokumen50 halamanNs 18 Steel DesignproahyBelum ada peringkat

- Drainage Drawing Check ListDokumen2 halamanDrainage Drawing Check ListzeroicesnowBelum ada peringkat

- Chapter 5Dokumen41 halamanChapter 5tewele brhaneBelum ada peringkat

- CCIP Errata Worked Examples To Eurocode 2 Jan2012Dokumen13 halamanCCIP Errata Worked Examples To Eurocode 2 Jan2012fan_luc89Belum ada peringkat

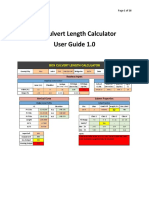

- Box Culvert Length Calculator User Guide 1.0Dokumen16 halamanBox Culvert Length Calculator User Guide 1.0aamir kalimBelum ada peringkat

- AASHTO LRFD Live LoadDokumen3 halamanAASHTO LRFD Live LoadFranjo JohaBelum ada peringkat

- Trench Drain PDFDokumen2 halamanTrench Drain PDFMax ViejaBelum ada peringkat

- Design Flexible ATJ 5I85 2013 2022Dokumen33 halamanDesign Flexible ATJ 5I85 2013 2022Leediya AfrinaBelum ada peringkat

- Catch Basin DetailDokumen1 halamanCatch Basin DetailNoel Montana100% (1)

- "Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionDokumen19 halaman"Rectbeam" - Rectangular Concrete Beam Analysis/Design: Program DescriptionOmar FarukBelum ada peringkat

- Lecture 4 - House DesignDokumen18 halamanLecture 4 - House Designkkhan_451062Belum ada peringkat

- Hydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxDokumen1 halamanHydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxelfitaBelum ada peringkat

- Scour CalDokumen2 halamanScour CalAnonymous O404LiV4CBelum ada peringkat

- Question Bank: Cem701 Design of Reinforced Concrete Structures Ii Unit 1Dokumen7 halamanQuestion Bank: Cem701 Design of Reinforced Concrete Structures Ii Unit 1RaBelum ada peringkat

- EarthworkDokumen12 halamanEarthworkJohny Lou LuzaBelum ada peringkat

- RCP 24 Inch Class 2Dokumen5 halamanRCP 24 Inch Class 2noto.sugiartoBelum ada peringkat

- Hydraulic Analysis of Major BridgeDokumen10 halamanHydraulic Analysis of Major BridgeUmar KarimiBelum ada peringkat

- NS18steeldesign 3 PDFDokumen51 halamanNS18steeldesign 3 PDFLemark R.Belum ada peringkat

- Chapter 3.1 Geometric Design of HighwaysDokumen85 halamanChapter 3.1 Geometric Design of HighwaysAmanuel AshenafiBelum ada peringkat

- VM 01 Gravity WallDokumen31 halamanVM 01 Gravity WallD SRINIVASBelum ada peringkat

- Chapter 3-0Dokumen45 halamanChapter 3-0chaltu TerefeBelum ada peringkat

- Geotechnical Engineering GATE Previous QuestionsDokumen35 halamanGeotechnical Engineering GATE Previous QuestionsSurya ChejerlaBelum ada peringkat

- Culvert DesignDokumen64 halamanCulvert Designharpreet_9211Belum ada peringkat

- Hydraulic Calculations and Hydraulic Design of The BridgeDokumen3 halamanHydraulic Calculations and Hydraulic Design of The BridgeJoe A. CagasBelum ada peringkat

- Load TypesDokumen5 halamanLoad TypesKutty MansoorBelum ada peringkat

- ColumnsDokumen66 halamanColumnsArchana GSBelum ada peringkat

- Bridge Report KhwopaDokumen89 halamanBridge Report KhwopaPradip Thapa100% (1)

- BD 12.01 PDFDokumen55 halamanBD 12.01 PDFstavros_stergBelum ada peringkat

- Geometric Design of HighwaysDokumen75 halamanGeometric Design of Highwayssuman subediBelum ada peringkat

- Codes Standards: AASHTO Vehicle Live LoadingDokumen4 halamanCodes Standards: AASHTO Vehicle Live LoadingdxzaberBelum ada peringkat

- Questions of Model For ExamDokumen19 halamanQuestions of Model For Examnatinael.tigistuBelum ada peringkat

- Beam Column Joint GKMDokumen31 halamanBeam Column Joint GKMSathish Kumar CivilBelum ada peringkat

- Pavement Design in Road ConstructionDokumen8 halamanPavement Design in Road ConstructionAshis MingalaBelum ada peringkat

- Is.10430.2000 Design of Lined CanalsDokumen19 halamanIs.10430.2000 Design of Lined CanalstnvishBelum ada peringkat

- Solution Report For: Engineering Hydrology Part 1Dokumen4 halamanSolution Report For: Engineering Hydrology Part 1Gogireddy Srinivasareddy1346Belum ada peringkat

- Chapter 4 Design of Sewers 4 1 Design ofDokumen11 halamanChapter 4 Design of Sewers 4 1 Design ofSuchitra PandaBelum ada peringkat

- Culverts 2015Dokumen40 halamanCulverts 2015KwakuBelum ada peringkat

- Chap 5 and 6Dokumen4 halamanChap 5 and 6Daisy MaghanoyBelum ada peringkat

- HW I Chapter 5 - Highway DrainageDokumen43 halamanHW I Chapter 5 - Highway DrainageSolomon DesalegnBelum ada peringkat

- CH 4 Sewers DesignDokumen11 halamanCH 4 Sewers DesignmavessBelum ada peringkat

- Optimum Hydraulic and Structural Design of Inverted SiphonDokumen15 halamanOptimum Hydraulic and Structural Design of Inverted SiphonMuhammad EhtshamBelum ada peringkat

- Highway Engineering: Highway Drainage Design Aspects of Surface Drainage SystemDokumen7 halamanHighway Engineering: Highway Drainage Design Aspects of Surface Drainage SystemmanjunathaBelum ada peringkat

- Design of SewersDokumen7 halamanDesign of SewersXyrene Ashley MagatBelum ada peringkat

- Chute Spillway 2Dokumen6 halamanChute Spillway 2Fasil GeberemeskelBelum ada peringkat

- Tourist Places of ColombiaDokumen4 halamanTourist Places of ColombiaMaroly Lo AgudeloBelum ada peringkat

- Magnetic Compass PDFDokumen19 halamanMagnetic Compass PDFHashil Naseer100% (1)

- ES - Week 1-Four Subsystems of EarthDokumen6 halamanES - Week 1-Four Subsystems of EarthEric AblingBelum ada peringkat

- Hydraulic Design Manual - HydrologyDokumen1 halamanHydraulic Design Manual - HydrologyEnoch ArdenBelum ada peringkat

- q4m1 w1 Coordinate-System SummativeDokumen8 halamanq4m1 w1 Coordinate-System SummativeMelanie Tagudin TrinidadBelum ada peringkat

- GEOG 100 - Climate Conditions and Weather SystemsDokumen3 halamanGEOG 100 - Climate Conditions and Weather SystemsMagnusBelum ada peringkat

- 2D Seismic ProjectDokumen28 halaman2D Seismic ProjectIrfan Baig100% (1)

- ACTIVITY 2 SheetDokumen3 halamanACTIVITY 2 SheetMary Joselyn Bodiongan60% (5)

- ICAT - Agriculture - GHG - 2Dokumen2 halamanICAT - Agriculture - GHG - 2Yanjinlkham GiimaaBelum ada peringkat

- Ramos, 2009 - Geological - JournalDokumen24 halamanRamos, 2009 - Geological - Journalfrancarlos de la cruz chuquimangoBelum ada peringkat

- Recent Format Discotinuty Data SheetDokumen10 halamanRecent Format Discotinuty Data SheetSusett M TBelum ada peringkat

- The Midterm Test E8Dokumen4 halamanThe Midterm Test E8PhuongBelum ada peringkat

- Science in Ohio Blizzard Bag 2Dokumen6 halamanScience in Ohio Blizzard Bag 2api-239855791Belum ada peringkat

- Long Quiz.. Exogenic ProcessDokumen3 halamanLong Quiz.. Exogenic ProcessSheryl Lou AngelesBelum ada peringkat

- Foliations LineationsDokumen36 halamanFoliations LineationsNurul AstutiBelum ada peringkat

- Presentation On Shelter Belt Saloni Bhandari 23066Dokumen15 halamanPresentation On Shelter Belt Saloni Bhandari 23066rekhanegi2356Belum ada peringkat

- MetamorphismDokumen35 halamanMetamorphismjerry100% (1)

- Geodynamic Settings of Mineral Deposit System - FullDokumen12 halamanGeodynamic Settings of Mineral Deposit System - FullDede Astuti100% (1)

- Science3 q4 Module 2Dokumen34 halamanScience3 q4 Module 2Mjel Kezhia Barrieta100% (2)

- Design of Hydraulic Structure - 4 Student 2018-2019Dokumen13 halamanDesign of Hydraulic Structure - 4 Student 2018-2019aland pshtiwanBelum ada peringkat

- Yellow River黃河 hs presentationDokumen14 halamanYellow River黃河 hs presentationsky animal girlBelum ada peringkat

- Ar 302 Architectural Design-V: 6 SemesterDokumen19 halamanAr 302 Architectural Design-V: 6 SemesterTushar KBelum ada peringkat

- Ocean Acidification Lab ReportDokumen4 halamanOcean Acidification Lab Reportapi-267601782Belum ada peringkat

- Part1.4 Stratigraphic Interpretation PDFDokumen26 halamanPart1.4 Stratigraphic Interpretation PDFNurulBelum ada peringkat

- Wen, J. Et Al. (2013) - Biogeography, Where Do We Go From HereDokumen16 halamanWen, J. Et Al. (2013) - Biogeography, Where Do We Go From HereJuan David Rodriguez HurtadoBelum ada peringkat

- Liquefaction AnalysisDokumen16 halamanLiquefaction AnalysisKristi Engineering Services Pvt. Ltd.Belum ada peringkat

- Synoptic and Prognostic ChartsDokumen88 halamanSynoptic and Prognostic ChartsDENWIL VINCENT MONERABelum ada peringkat

- Deformation of CrustDokumen2 halamanDeformation of CrustMary Jane Tamondong BaniquedBelum ada peringkat

- Soil Science ExamsDokumen23 halamanSoil Science ExamsLeonna Jhocel Ofina100% (1)