Assignement8 PDF

Diunggah oleh

Thangadurai Senthil Ram PrabhuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Assignement8 PDF

Diunggah oleh

Thangadurai Senthil Ram PrabhuHak Cipta:

Format Tersedia

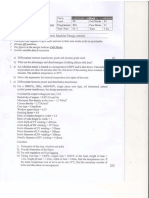

ASSIGNMENT 8

1. The composition (% by weight) of nomonic 75 alloy is given in the accompanying table: Element % by weight Atomic Weight Valency Density

i)

Ni 72

Cr 20

Fe 5

Ti 0.5

Si 1 28.09 4 2.33

Mn 1 54.94 2,4,6,7 7.43

Cu 0.5 63.5 1,2 8.96

58.71 51.99 55.85 47.90 2,3 8.9 2,3,4 7.19 2,3 7.89 3,4 4.51

Calculate MRR (specific MRR and volumetric MRR) when a current of 2000 A is used. Use the lowest valency of dissolution in each case. Determine the equilibrium gap if applied voltage = 15V, Over potential =1.5 V , specific resistance = 0.21 ohm cm and feed is 1mm/min Calculate the rise in temperature for the following machining conditions: feed rate =0.05 mm/s, room temperature =38 deg, electrolyte density = 1.05 g/cm3 , efficiency = 100 %. Electrolyte flow rate = 120 LPM. Flow velocity = 2000 cm/s and specific heat = 1.06 cal/g C. Geometry of the work piece surface with single curvature is given by the following equation y = 10 x0.20x -0.05 x2, where x and y are in centimeters. The following details are as follows: Applied voltage =15 V. Over potential =0.67 V, feed rate = 0.75 mm/min, work material = copper (atomic weight = 63.57 and valency = 1) density = 8.96 g/cm3 . specific resistance = 0.2 ohm cm

ii)

iii)

iv)

6. Show that in a constant current ECM drilling process, the hole size decreases inversely as a function of square root of feed rate.

7. Prove mathematically that, in a constant feed rate ECM system, the machining process is inherently self regulated since the MRR tend to approach the feed rate. 8. What is Joule heating as applied to ECM; derive an expression for the flow rate of electrolyte to prevent boiling and velocity of the electrolyte flow.

Practice problems

1. In a ECM process, for machining of iron, a metal removal rate of 1cm3 /min is desired. Determine the necessary current; assume atomic weight of iron to be 56. Its valency 2 and density 7.8 gm/cm3. Faradays constant may be taken as 96540 coulombs. 2. Estimate the MRR of an alloy containing 18% cobalt, 62% nickel, 20% chromium, during electro chemical machining with a current of 500 amperes. The density of the alloy is 8.28 gm/cc. The following data is available.

Metal Gram Atomic Weight Cobalt 58.63 Nickel 58.71 Chromium 51.99 Faradays constant = 96500 coulombs /mole

Valency 2 2 6

3.A dc power supply of 18 Volts and 5000 A was used in ECM using copper electrode and sodium chloride solution. A tool work gap of 0.5 cm was maintained. The data for Iron anode may be taken as: Atomic weight = 56, valency = 2, density = 7.87 g/cm3. Calculate the machining rate and electrode feed rate for the following data for the electrolyte

4. An ECM with copper electrode and NaCl as electrolyte is used for machining of iron. The ECM has the following dimensions: Electrode area = 2.54 x2.54 cm, Electrode work gap=0.0254 cm. The electrolyte properties are : specific heat= 4.17 J/g-k, Density= 1g/cm3, specific resistance = 3 ohm cm. Estimate the permissible fluid flow velocity, if the maximum permissible temperature of electrolyte is 95 deg and ambient temperature is 30 deg. Applied voltage is 12 V. Calculate the maximum MRR if the current density is 160 cm/cm2

Anda mungkin juga menyukai

- CHEM E6180 Assignment 5 2017Dokumen2 halamanCHEM E6180 Assignment 5 2017Joshua LunguBelum ada peringkat

- StudyDokumen9 halamanStudysarangBelum ada peringkat

- Exercise 6 ElectrowinningDokumen2 halamanExercise 6 Electrowinningहरिओम हरी100% (4)

- Lecture 24 - ECMDokumen32 halamanLecture 24 - ECMDivyam GargBelum ada peringkat

- Qand ADokumen4 halamanQand AAnuj SharmaBelum ada peringkat

- SheetDokumen3 halamanSheetBarun BeheraBelum ada peringkat

- GDokumen2 halamanGBhupendra Verma0% (1)

- Tu 1Dokumen9 halamanTu 1Anuj SharmaBelum ada peringkat

- GAANN Exp 2 Avogadros NumberDokumen9 halamanGAANN Exp 2 Avogadros NumberSultan MahmudBelum ada peringkat

- Electrorecovery ProcessesDokumen2 halamanElectrorecovery ProcessesThembi MatebulaBelum ada peringkat

- ME 388 Assignment - NTMDokumen3 halamanME 388 Assignment - NTMGanesh ChelluboyinaBelum ada peringkat

- Welding - GATE QuestionsDokumen1 halamanWelding - GATE QuestionsJo75% (4)

- AM Week 2 ECM NOTESDokumen19 halamanAM Week 2 ECM NOTESa38659158Belum ada peringkat

- 83 To MSJDokumen6 halaman83 To MSJSella Ntuwh EldaBelum ada peringkat

- Ass#4 - Fall 2017 (Q)Dokumen3 halamanAss#4 - Fall 2017 (Q)Omar BahgatBelum ada peringkat

- DR Paper 1Dokumen15 halamanDR Paper 1Malik Al TurkiBelum ada peringkat

- ElectrochemistryDokumen5 halamanElectrochemistryNeel SiddhpuraBelum ada peringkat

- Sheet 4 (Answers)Dokumen49 halamanSheet 4 (Answers)يوسف عادل حسانينBelum ada peringkat

- Advanced Electrochemistry Tutorial 2Dokumen2 halamanAdvanced Electrochemistry Tutorial 2kasun1237459Belum ada peringkat

- Problem SheetDokumen2 halamanProblem SheetUsman FarooqBelum ada peringkat

- Anie202014384 Sup 0001 Misc - InformationDokumen13 halamanAnie202014384 Sup 0001 Misc - InformationswapnilBelum ada peringkat

- Electrochemistry - Numerical WSDokumen4 halamanElectrochemistry - Numerical WSrishima sapruBelum ada peringkat

- Enhancement of Material Removal Rate of Electrochemical Machining by Using Rotating Tool ON AISI 1035Dokumen4 halamanEnhancement of Material Removal Rate of Electrochemical Machining by Using Rotating Tool ON AISI 1035kaushalshah28598Belum ada peringkat

- Faraday's Law WorksheetDokumen4 halamanFaraday's Law WorksheetBrianna MalcolmBelum ada peringkat

- Electrical Machine 3Dokumen4 halamanElectrical Machine 3AbhishekBelum ada peringkat

- Week 9-Assignment 9 SolutionDokumen3 halamanWeek 9-Assignment 9 SolutionDivyansh WaghmareBelum ada peringkat

- Designng ECM ExperimentDokumen2 halamanDesignng ECM ExperimentShale_BernardBelum ada peringkat

- Design TheoryDokumen12 halamanDesign Theoryr.anushyaBelum ada peringkat

- Utilization of Electrical Energy (U2)Dokumen5 halamanUtilization of Electrical Energy (U2)menilanjan89nLBelum ada peringkat

- Heat Treatment of Metal Surfaces by A Conformal Electron BeamDokumen6 halamanHeat Treatment of Metal Surfaces by A Conformal Electron BeamM Hadyan MuslihanBelum ada peringkat

- Electrical Machine DesignDokumen6 halamanElectrical Machine DesignDeepak ThapaBelum ada peringkat

- Production Technology - II: Tutorial Sheet 7Dokumen1 halamanProduction Technology - II: Tutorial Sheet 7Shravan PagrutBelum ada peringkat

- Emd QBDokumen7 halamanEmd QBAditya ShrivastavBelum ada peringkat

- Question Bank: UNIT-1 Conducting MaterialsDokumen6 halamanQuestion Bank: UNIT-1 Conducting MaterialspriyaBelum ada peringkat

- Design of EW CircuitDokumen8 halamanDesign of EW Circuitpatrick.harris881Belum ada peringkat

- Si Unit 2 NumericalsDokumen12 halamanSi Unit 2 NumericalsHarshit kumarBelum ada peringkat

- Chapter-1 Electric Heating and Welding: Electrical Power Utilization (10ee72)Dokumen2 halamanChapter-1 Electric Heating and Welding: Electrical Power Utilization (10ee72)Akshay RajBelum ada peringkat

- BPUT Question Bank For Material ScienceDokumen4 halamanBPUT Question Bank For Material ScienceMr.S UpenderBelum ada peringkat

- Design of High Strength Bainitic SteelsDokumen6 halamanDesign of High Strength Bainitic SteelsK S RamakrishnaBelum ada peringkat

- XIIElectrochemistryDokumen3 halamanXIIElectrochemistryAyush KumarBelum ada peringkat

- Final Exam AT 2018 AnsDokumen8 halamanFinal Exam AT 2018 AnsHassan AzouzBelum ada peringkat

- Lec3 - Machining Equipment - PRE 314 - NewDokumen18 halamanLec3 - Machining Equipment - PRE 314 - NewMahmoud EldesoukiBelum ada peringkat

- CH Instruments BrochureDokumen44 halamanCH Instruments BrochureMIGUEL OMAR VILLANUEVA VILLANUEVABelum ada peringkat

- Assignment Cum Tutorial Sheet - 7 (With Solution)Dokumen2 halamanAssignment Cum Tutorial Sheet - 7 (With Solution)HARSHVARDHAN SINGH RATHOREBelum ada peringkat

- Assignment Non Conventional MachiningDokumen5 halamanAssignment Non Conventional Machiningkapun kumar nayak100% (1)

- Recitation 2Dokumen11 halamanRecitation 2Theodore Teddy JBelum ada peringkat

- Lec2 - Machining Equipment - PRE 314Dokumen70 halamanLec2 - Machining Equipment - PRE 314Mahmoud EldesoukiBelum ada peringkat

- Electrochemistry Set ADokumen1 halamanElectrochemistry Set AAvinashChauhanBelum ada peringkat

- Electrochemical Machining: Dr. P KuppanDokumen35 halamanElectrochemical Machining: Dr. P KuppanMandar ChikateBelum ada peringkat

- Isro Scientist Me 2020 Paper 80c39244Dokumen20 halamanIsro Scientist Me 2020 Paper 80c39244Elsa PoirotBelum ada peringkat

- Experiment 3: Determination of Avogadro's Number Using ElectrogravimetryDokumen15 halamanExperiment 3: Determination of Avogadro's Number Using ElectrogravimetryatikahBelum ada peringkat

- Practical 6Dokumen7 halamanPractical 6Farid FazamyBelum ada peringkat

- Taller Sobre Propiedades Eléctricas-2016-2Dokumen2 halamanTaller Sobre Propiedades Eléctricas-2016-2alejo ossaBelum ada peringkat

- Practice ProblemsDokumen2 halamanPractice Problemsanon_915449609Belum ada peringkat

- LESSON 4 (B)Dokumen12 halamanLESSON 4 (B)learntomindyourownbusinessokayBelum ada peringkat

- 14 - DEM AP11 - OptDokumen3 halaman14 - DEM AP11 - OptvnatarajanBelum ada peringkat

- OF Inductances. Charles Steinmetz.: To TheDokumen47 halamanOF Inductances. Charles Steinmetz.: To TheAlfredo Brumnić FredoBelum ada peringkat

- A Modern Course in Statistical PhysicsDari EverandA Modern Course in Statistical PhysicsPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Calculation of The Crosswind Displacement of PantographsDokumen16 halamanCalculation of The Crosswind Displacement of PantographsThangadurai Senthil Ram PrabhuBelum ada peringkat

- Definition of Quality & Dimensions of QualityDokumen8 halamanDefinition of Quality & Dimensions of QualityThangadurai Senthil Ram PrabhuBelum ada peringkat

- c34 ECM MBI PDFDokumen55 halamanc34 ECM MBI PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- En0175 12 PDFDokumen7 halamanEn0175 12 PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- Mggassign 1Dokumen2 halamanMggassign 1Thangadurai Senthil Ram PrabhuBelum ada peringkat

- ConductivityDokumen36 halamanConductivityThangadurai Senthil Ram PrabhuBelum ada peringkat

- En0175 10 PDFDokumen7 halamanEn0175 10 PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- En0175 07 PDFDokumen6 halamanEn0175 07 PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- En0175 09 PDFDokumen9 halamanEn0175 09 PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- En0175 08 PDFDokumen6 halamanEn0175 08 PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- En0175 05 PDFDokumen6 halamanEn0175 05 PDFThangadurai Senthil Ram PrabhuBelum ada peringkat

- E e e e e E: We Continue On The Mathematical Background. Base Tensors: (Dyadic Form)Dokumen6 halamanE e e e e E: We Continue On The Mathematical Background. Base Tensors: (Dyadic Form)Thangadurai Senthil Ram PrabhuBelum ada peringkat

- CAM Part II: Intersections:) ), 0.0) Tolerance) X - F (X) /F' (X)Dokumen5 halamanCAM Part II: Intersections:) ), 0.0) Tolerance) X - F (X) /F' (X)Thangadurai Senthil Ram PrabhuBelum ada peringkat

- Switchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Dokumen62 halamanSwitchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Suvendu Sekhar SabatBelum ada peringkat

- Detailed Lesson Plan (DLP) Format: Nowledge ObjectivesDokumen2 halamanDetailed Lesson Plan (DLP) Format: Nowledge ObjectivesErwin B. NavarroBelum ada peringkat

- Power World Simulator 8 TutorialDokumen8 halamanPower World Simulator 8 TutorialMauricio VargasBelum ada peringkat

- A1 - Full Papers PS1 10834 2022Dokumen18 halamanA1 - Full Papers PS1 10834 2022DmitryBelum ada peringkat

- The Nature of Mathematics: "Nature's Great Books Is Written in Mathematics" Galileo GalileiDokumen9 halamanThe Nature of Mathematics: "Nature's Great Books Is Written in Mathematics" Galileo GalileiLei-Angelika TungpalanBelum ada peringkat

- Class 8 Aakash JEE MAINDokumen9 halamanClass 8 Aakash JEE MAINrohitBelum ada peringkat

- Cuda GDBDokumen64 halamanCuda GDBVinícius LisboaBelum ada peringkat

- Internal Floating Roof DesignDokumen38 halamanInternal Floating Roof DesigncrnewsomBelum ada peringkat

- I Twin Technology: Submitted in Partial Fulfillment of The Requirements For The Award of The Degree ofDokumen30 halamanI Twin Technology: Submitted in Partial Fulfillment of The Requirements For The Award of The Degree ofBarma RajkumarBelum ada peringkat

- Chapter Two Second Order Ordinary Differential Equation (SOODE)Dokumen11 halamanChapter Two Second Order Ordinary Differential Equation (SOODE)BennyBelum ada peringkat

- Proceedings of Spie: Design and Simulation Analysis of A Magnetic Shielding Box For Ring Laser GyroscopeDokumen9 halamanProceedings of Spie: Design and Simulation Analysis of A Magnetic Shielding Box For Ring Laser GyroscopeTanzil ZaidiBelum ada peringkat

- Siesta TutorialDokumen14 halamanSiesta TutorialCharles Marcotte GirardBelum ada peringkat

- Registro Evaluacion Ergonomica ROSADokumen6 halamanRegistro Evaluacion Ergonomica ROSAEryade Grace ValenzuelaBelum ada peringkat

- Toolpost Attachment For A High Speed Rotary ToolDokumen32 halamanToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- TomatoDokumen19 halamanTomatoaravind kishanBelum ada peringkat

- Strion Led HL - SupDokumen2 halamanStrion Led HL - SupPatrickBelum ada peringkat

- Sorting in ALV Using CL - SALV - TABLE - SAP Fiori, SAP HANA, SAPUI5, SAP Netweaver Gateway Tutorials, Interview Questions - SAP LearnersDokumen4 halamanSorting in ALV Using CL - SALV - TABLE - SAP Fiori, SAP HANA, SAPUI5, SAP Netweaver Gateway Tutorials, Interview Questions - SAP LearnerssudhBelum ada peringkat

- MNED G12MNEDMockP22017MemoDokumen11 halamanMNED G12MNEDMockP22017MemoChey1242Belum ada peringkat

- FMS 304 Research Methodology - 0 PDFDokumen188 halamanFMS 304 Research Methodology - 0 PDFvicky100% (2)

- Alpha New Trader GuideDokumen9 halamanAlpha New Trader GuideChaitanya ShethBelum ada peringkat

- WORK (Diwa, Angela Marie M.)Dokumen17 halamanWORK (Diwa, Angela Marie M.)Angela Miranda DiwaBelum ada peringkat

- Thesis - AN Fertiliser Properties Applic and Safety FinlandDokumen256 halamanThesis - AN Fertiliser Properties Applic and Safety FinlandGonzalo O'ortiz Araneda's IIIBelum ada peringkat

- CMC Assignment 45 For Boys Girl StudentsDokumen2 halamanCMC Assignment 45 For Boys Girl StudentsRAMAKRISHNA VBelum ada peringkat

- MPLS PDLDokumen47 halamanMPLS PDLSandro R. S. MacielBelum ada peringkat

- BFC3042 BFC31802Dokumen13 halamanBFC3042 BFC31802Zuliyah ZakariaBelum ada peringkat

- Physics ProjectDokumen11 halamanPhysics ProjectDimpySurya44% (25)

- Specalog For Cat 938K Sugarcane Handler AEHQ8046-02Dokumen1 halamanSpecalog For Cat 938K Sugarcane Handler AEHQ8046-02diegosoareshotmail.frBelum ada peringkat

- AN78M20FDokumen10 halamanAN78M20FFrantsiskoBelum ada peringkat

- Transformer Health IndicesDokumen12 halamanTransformer Health IndicesIngenieria APABelum ada peringkat

- Danyar Et Al., 2020 - FinalDokumen24 halamanDanyar Et Al., 2020 - FinalSardar SaleemBelum ada peringkat