20-30 Penetration Grade Bitumen Specification CONSILIARI PARTNERS

Diunggah oleh

nischal_babuHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

20-30 Penetration Grade Bitumen Specification CONSILIARI PARTNERS

Diunggah oleh

nischal_babuHak Cipta:

Format Tersedia

9/16/13

CONSILIARI PARTNERS

A BOUT US

NEW S

COMMODIT IES

A V IA T ION FUEL

BIT UMEN

LOGIST ICS

FINA NCING

CA REER

CONT A CT

Specification

Bit u m en is a v a ila ble in a v a r iet y of g r a des. Specifica t ion s v a r y t o m eet t h e n eeds of t h e con su m in g in du st r ies a n d a r e ba sed on a ser ies of ph y sica l t est s t h a t defin e t h e sa fet y , solu bilit y , ph y sica l pr oper t ies a n d du r a bilit y of bit u m en . T h e ph y sica l pr oper t ies a r e desig n ed t o defin e per for m a n ce ch a r a ct er ist ics t h a t a r e r equ ir ed u n der t h e clim a t ic a n d loa din g con dit ion s t h a t t h e bit u m en w ill ex per ien ce in ser v ice. Bit u m en is g r a ded a ccor din g t o st a n da r dized t est in g m et h ods. T h ese t est s a lso g iv e r ise t o t w o com m on ly u sed t er m s w h ich descr ibe t h e m et h od of m ea su r em en t , r a t h er t h a n a t y pe of bit u m en :

Pen et r a t ion g r a ded bit u m en

Bit u m en is cla ssified by t h e dept h t o w h ich a st a n da r d n eedle w ill pen et r a t e u n der specified t est con dit ion s. T h is pen t est cla ssifica t ion is u sed t o in dica t e t h e h a r dn ess of bit u m en , low er pen et r a t ion in dica t in g a h a r der bit u m en . Specifica t ion s for pen et r a t ion g r a ded bit u m en n or m a lly st a t e t h e pen et r a t ion r a n g e for a g r a de, e.g . 5 0 /7 0 . Ot h er t est s a r e u sed t o cla ssify t h e bit u m en for specifica t ion pu r poses, su ch a s soft en in g poin t , solu bilit y , fla sh poin t et c.

V iscosit y g r a ded bit u m en

Bit u m en s a r e a lso g r a ded a n d specified by t h eir v iscosit y a t a st a n da r d t em per a t u r e (t y pica lly 6 0 C). Specifica t ion s for v iscosit y g r a ded bit u m en s n or m a lly g iv e t h e n om in a l v iscosit y pr efix ed by a V , e.g . V 1 5 0 0 .

Ox idised bit u m en g r a des

Pa ssin g a ir t h r ou g h bit u m en a t elev a t ed t em per a t u r e ca n be u sed t o a lt er it s ph y sica l pr oper t ies for cer t a in com m er cia l a pplica t ion s. T h e deg r ee of ox ida t ion ca n r a n g e fr om v er y sm a ll, oft en r efer r ed t o a s a ir -r ect ifica t ion , or sem i-blow in g , w h ich on ly slig h t ly m odifies t h e bit u m en pr oper t ies, t h r ou g h t o fu ll blow in g , w h er eby t h e pr oper t ies of t h e bit u m en a r e sig n ifica n t ly differ en t t o pen et r a t ion g r a de bit u m en . Nom en cla t u r e a n d g r a din g for t h e ox idised bit u m en pr odu ct s is ba sed on a com bin a t ion of t h e t em per a t u r e a t w h ich t h e bit u m en r ea ch es a cer t a in soft n ess w h en bein g h ea t ed u p a s ex pr essed by t h e r in g a n d ba ll soft en in g poin t t est , a n d t h e pen et r a t ion v a lu e. Ou r bit u m en a r e a v a ila ble in t h e v a r iou s g r a des 2 0 /3 0 , 3 5 /5 0 , 5 0 /7 0 , 7 0 /1 0 0 a n d 1 6 0 /2 2 0

Bitumen 20/30

Bit u m en 2 0 /3 0 is m a n u fa ct u r ed w it h select ed cr u de oils in efficien t pr odu ct ion pr ocesses w h ich a r e u n der t a k en in a ccor da n ce w it h qu a lit y m a n a g em en t st a n da r ds EN ISO 9 0 0 1 .

T h e con sist en t ly h ig h qu a lit y is ba sed on t h e m et icu lou s select ion of t h e r a w m a t er ia l a n d ca r efu l pr ocessin g . Con st a n t qu a lit y con t r ol a n d a ddit ion a l com pr eh en siv e t est s en su r e t h e u n pr oblem a t ic u se of Bit u m en 2 0 /3 0 in t h e a sph a lt m ix in g pla n t .

Bit umen 20/30 fulfils t he requirement s for paving grade bit umen in accordance wit h EN 12591.

A r ea s of A pplica t ion

Bit umen 20/30 is recommended for t he manufact ure of t he following asphalt t y pes:

Ma st ic a sph a lt (MA )

T r a n spor t a n d Pr ocessin g

Bit u m en 2 0 /3 0 is deliv er ed by t a n k t r u ck (fillin g t em per a t u r e m a x im u m 2 0 0 C). T h e st or a g e t em per a t u r e in t h e a sph a lt m ix in g pla n t sh ou ld n ot ex ceed 2 0 0 C. For pr olon g ed st or a g e, a r edu ct ion in t em per a t u r e t o a ppr ox . 1 2 0 C is r ecom m en ded. Recom m en ded Pr ocessin g T em per a t u r e Pr odu ct ion t em per a t u r e m a x im u m 2 3 0 C

Sa fet y a n d t h e En v ir on m en t

www.consiliari.pl/specification.html

1/4

9/16/13

CONSILIARI PARTNERS

Bit u m en 2 0 /3 0 is a n on -h a za r dou s pr odu ct a n d is t h er efor e n ot su bject t o m a n da t or y la bellin g .

Pr odu ct Specifica t ion - Bit u m en 2 0 /3 0 in a ccor da n ce w it h EN 1 2 5 9 1

Requ ir em en t / Ch a r a ct er ist ic Con sist en cy a t in t er m edia t e ser v ice t em per a t u r e Pen et r a t ion a t 2 5 C Con sist en cy a t elev a t ed ser v ice t em per a t u r e Soft en in g poin t Du r a bilit y (r esist a n ce t o h a r den in g a t 1 6 3 C) Ch a n g e of m a ss Ret a in ed pen et r a t ion Soft en in g poin t a ft er h a r den in g In cr ea se in soft en in g poin t Ot h er ch a r a ct er ist ics Fla sh poin t Fr a a ss br ea k in g poin t Solu bilit y Dy n a m ic V iscosit y a t 6 0 C Kin em a t ic v iscosit y a t 1 3 5 C Pa r a ffin con t en t

Un it

Ra n g e of v a lu es

x 0 ,1 m m

20 - 30

55 - 63

% % C C

< 0 ,5 > 46 > 57 <8

C C % (m /m ) Pa .s m m 2 /s % (m /m )

> 240 <-5 > 99 > 440 > 530 < 2 ,2

Bitumen 35/50

Bit umen 35/50 is m a n u fa ct u r ed w it h select ed cr u de oils in efficien t pr odu ct ion pr ocesses w h ich

a r e u n der t a k en in a ccor da n ce w it h qu a lit y m a n a g em en t st a n da r ds EN ISO 9 0 0 1 . T h e con sist en t ly h ig h qu a lit y is ba sed on t h e m et icu lou s select ion of t h e r a w m a t er ia l a n d ca r efu l pr ocessin g . Con st a n t qu a lit y con t r ol a n d a ddit ion a l com pr eh en siv e t est s en su r e t h e u n pr oblem a t ic u se of Bit u m en 3 5 /5 0 in t h e a sph a lt m ix in g pla n t .

Bit umen 35/50 fulfils t he requirement s for paving grade bit umen in accordance wit h EN 12591.

A r ea s of A pplica t ion

Bit umen 35/50 is recommended for t he manufact ure of t he following asphalt t y pes:

Ba se cou r ses (A C ba se) Ma st ic a sph a lt (MA )

Pr odu ct Specifica t ion - Bit u m en 3 5 /5 0 in a ccor da n ce w it h EN 1 2 5 9 1

Requ ir em en t / Ch a r a ct er ist ic Con sist en cy a t in t er m edia t e ser v ice t em per a t u r e Pen et r a t ion a t 2 5 C Con sist en cy a t elev a t ed ser v ice t em per a t u r e Soft en in g poin t Ch a n g e of m a ss Ret a in ed pen et r a t ion Soft en in g poin t a ft er h a r den in g Du r a bilit y (r esist a n ce t o h a r den in g a t 1 6 3 C) In cr ea se in soft en in g poin t Fla sh poin t Fr a a ss br ea k in g poin t Solu bilit y Dy n a m ic v iscosit y a t 6 0 C Kin em a t ic v iscosit y a t 1 3 5 C Pa r a ffin con t en t

Un it x 0 ,1 m m C % % C C C C % (m /m ) Pa .s m m 2 /s % (m /m )

Ra n g e of v a lu es 35 - 50 50 - 58 < 0 ,5 > 53 > 52 <8 > 240 <-5 > 99 > 225 > 370 < 2 ,2

Bit u m en 3 5 /5 0 is deliv er ed by t a n k t r u ck (fillin g t em per a t u r e m a x im u m 2 0 0 C). T h e st or a g e t em per a t u r e in t h e a sph a lt m ix in g pla n t sh ou ld n ot ex ceed 1 9 0 C. For pr olon g ed st or a g e, a r edu ct ion in t em per a t u r e t o a ppr ox . 1 2 0 C is r ecom m en ded.

Recom m en ded Pr ocessin g T em per a t u r e Pr odu ct ion t em per a t u r e m a x im u m 1 9 0 C

www.consiliari.pl/specification.html

2/4

9/16/13

Pr odu ct ion t em per a t u r e m a x im u m 1 9 0 C In st a lla t ion t em per a t u r e 1 5 0 C u p t o 1 9 0 C Ma st ic A sph a lt pr odu ct ion w it h m a x im u m 2 3 0 C.

CONSILIARI PARTNERS

Sa fet y a n d En v ir on m en t Bit u m en 3 5 /5 0 is a n on -h a za r dou s pr odu ct a n d is t h er efor e n ot su bject t o m a n da t or y la bellin g .

PmB 45/80-65

T h e Pm B 4 5 /8 0 -6 5 is a r ea dy t o u se, ela st om er - m odified bin der pr odu ced a t t h e r efin er y for m a n u fa ct u r e of h ea v y loa d a n d h ig h t r a ffic r oa ds a s w ell a s su r fa ces w it h h ig h er r equ ir em en t s. T h e pa t en t ed pr odu ct ion pr ocess of r efin er y Pm B 4 5 /8 0 -6 5 is u n der t a k en in a ccor da n ce w it h qu a lit y m a n a g em en t st a n da r ds EN ISO 9 0 0 1 . T h e Pm B 4 5 /8 0 -6 5 fu lfils t h e r equ ir em en t s for poly m er m odified bit u m en in a ccor da n ce w it h EN 1 4 02 3 . T h e Pm B 4 5 /8 0 -6 5 ex h ibit s: Hig h pla st icit y r a n g e Pr on ou n ced v isco-ela st ic beh a v iou r Hig h r eg en er a t ion ca pa cit y Ex cellen t a dh esion u n der a ll clim a t ic con dit ion s

A r ea s of A pplica t ion T h e Pm B 4 5 /8 0 -6 5 is r ecom m en ded for t h e m a n u fa ct u r e of t h e follow in g a sph a lt t y pes: Hig h m odu lu s a sph a lt con cr et e for ba se bin der (A C bin der ) Hig h m odu lu s a sph a lt con cr et e for w ea r in g cou r ses (A C su r f) St on e m a st ic a sph a lt (SMA ) Por ou s a sph a lt (PA ) A sph a lt con cr et e for v er y t h in la y er s (BBT M) A sph a lt m ix t u r es cr ea t ed w it h OMV T h e Pm B 4 5 /8 0 -6 5 pr ov ide ben efit s of: Pr olon g life t im e Hig h st a bilit y Ex cellen t r esist a n ce t o per m a n en t defor m a t ion Hig h r esist a n ce a g a in st cr a ck in g du e t o low t em per a t u r e a n d fa t ig u e

T r a n spor t a n d Pr ocessin g

T h e Pm B 4 5 /8 0 -6 5 is deliv er ed by t a n k t r u ck (fillin g t em per a t u r e m a x im u m 2 0 0 C). T h e st or a g e t em per a t u r e in t h e a sph a lt m ix in g pla n t sh ou ld n ot ex ceed 1 8 0 C. For pr olon g ed st or a g e, a r edu ct ion in t em per a t u r e t o a ppr ox . 1 3 0 C is r ecom m en ded. Recom m en ded Pr ocessin g T em per a t u r es Pr odu ct ion t em per a t u r e m a x im u m 1 9 0 C In st a lla t ion t em per a t u r e 1 5 0 C u p t o1 9 0 C No a ddit ion a l m ea su r es in com pa r ison w it h con v en t ion a l bit u m in ou s m ix t u r e t y pes a r e r equ ir ed for t h e in st a lla t ion of a sph a lt m ix t u r es cr ea t ed w it h Pm B 4 5 /8 0 -6 5 .

Sa fet y a n d t h e En v ir on m en t Pm B 4 5 /8 0 -6 5 is a n on h a za r dou s pr odu ct a n d is t h er efor e n ot su bject t o m a n da t or y la bellin g

Pr odu ct Specifica t ion - Pm B 4 5 /8 0 -6 5 in a ccor da n ce w it h EN 1 4 0 2 3

Requ ir em en t / Ch a r a ct er ist ic Con sist en cy a t in t er m edia t e ser v ice t em per a t u r e Pen et r a t ion a t 2 5 C Con sist en cy a t elev a t ed ser v ice t em per a t u r e Soft en in g poin t Coh esion For ce du ct ilit y T en sile t est a t 5 C V ia lit -pen du lu m Du r a bilit y (r esist a n ce t o h a r den in g a t 1 6 3 C) Ch a n g e of m a ss Ret a in ed pen et r a t ion In cr ea se in Soft en in g poin t Ot h er ch a r a ct er ist ics Fla sh poin t Fr a a ss br ea k in g poin t Ela st ic r ecov er y a t 2 5 C Ela st ic r ecov er y a t 1 0 C Pla st icit y r a n g e St or a g e st a bilit y

Un it x 0 ,1 m m C J/cm 2 J/cm 2 J/cm 2 % % C C C % % C

Cla ss 4 5 2 0 0 3 7 2 2 8 2 0 0

Ra n g e of v a lu e 4 5 -8 0 > 65 > 3 (5 C) NPD NPD < 0 ,5 > 60 <8 > 250 <-18 > 80 NPD NPD

www.consiliari.pl/specification.html

3/4

9/16/13

St or a g e st a bilit y Differ en ce in Soft en in g poin t St or a g e st a bilit y Differ en ce in pen et r a t ion Dr op in Soft en in g poin t a ccor din g t o EN 1 2 6 0 7 -1 Ela st ic r ecov er y a t 2 5 C a ccor din g t o EN 1 2 6 0 7 -1 Ela st ic r ecov er y a t 1 0 C a ccor din g t o EN 1 2 6 0 7 -1 Not e: NPD.n o per for m a n ce det er m in ed A ddit ion a l Per for m a n ce Rela t ed Pr oper t ies Com m on St a t s Or ig in a l bin der V iscosit y a t 1 3 5 C Den sit y a t 2 5 C Com plex Sh ea r m odu lu s (a t 6 4 C) A cceler a t ed lon g -t er m -a g in g (PA V ) Ph a se a n g le (a t 6 4 C) Com plex Sh ea r m odu lu s (a t 2 2 C) Ph a se a n g le (a t 2 2 C) St iffn ess (a t -1 8 C) k Pa MPa 63 3 000 54 1 80 Pa .s k g /m 3 k Pa 1 ,3 1 02 0 3 ,8 % 0 % 2 C 3 x 0 ,1 m m 0 C 2

CONSILIARI PARTNERS

<5 NPD <5 >70 NPD

www.consiliari.pl/specification.html

4/4

Anda mungkin juga menyukai

- Construction ChecklistDokumen2 halamanConstruction Checklistnischal_babuBelum ada peringkat

- Pressure Conversion: Inhg MMHGDokumen3 halamanPressure Conversion: Inhg MMHGnischal_babuBelum ada peringkat

- PMM PDFDokumen17 halamanPMM PDFrajuwithualwaysBelum ada peringkat

- Black Cotton Soil in Construction IndustryDokumen3 halamanBlack Cotton Soil in Construction Industrynischal_babuBelum ada peringkat

- 01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification LimitsDokumen1 halaman01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification Limitsnischal_babuBelum ada peringkat

- Earth Work CalculationDokumen11 halamanEarth Work Calculationnischal_babuBelum ada peringkat

- ASC - GSHAP Seismic Hazard Map For Andhra Pradesh, IndiaDokumen1 halamanASC - GSHAP Seismic Hazard Map For Andhra Pradesh, Indianischal_babuBelum ada peringkat

- QC of CutbackDokumen7 halamanQC of Cutbacknischal_babuBelum ada peringkat

- TDS - Rheobuild 850Dokumen2 halamanTDS - Rheobuild 850nischal_babuBelum ada peringkat

- KT 15Dokumen6 halamanKT 15nischal_babuBelum ada peringkat

- BIT 50-70 ResultsDokumen1 halamanBIT 50-70 Resultsnischal_babuBelum ada peringkat

- TDS - Rheobuild 850Dokumen2 halamanTDS - Rheobuild 850nischal_babuBelum ada peringkat

- Calculate Asphalt Pavement DensityDokumen6 halamanCalculate Asphalt Pavement Densitynischal_babuBelum ada peringkat

- C 2004 24 0 1Dokumen25 halamanC 2004 24 0 1nischal_babuBelum ada peringkat

- 01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification LimitsDokumen1 halaman01 - Test Certificate - Multipurpose - Cem IV 32.5n - Specification Limitsnischal_babuBelum ada peringkat

- Rheobuild 850Dokumen2 halamanRheobuild 850Haresh BhavnaniBelum ada peringkat

- HWT Test Evaluates Asphalt Mixture Moisture SusceptibilityDokumen24 halamanHWT Test Evaluates Asphalt Mixture Moisture Susceptibilitynischal_babuBelum ada peringkat

- 4770.1 Pumping SLC-The Team ApproachDokumen2 halaman4770.1 Pumping SLC-The Team Approachnischal_babuBelum ada peringkat

- Engineering Surveying,-5th Ed - Construction MaterialsDokumen20 halamanEngineering Surveying,-5th Ed - Construction Materialsnischal_babuBelum ada peringkat

- Series 0800Dokumen25 halamanSeries 0800nischal_babu100% (1)

- File, 16939, enDokumen35 halamanFile, 16939, ennischal_babuBelum ada peringkat

- Ap 5 Bitumen Disposal PitsDokumen3 halamanAp 5 Bitumen Disposal Pitsnischal_babuBelum ada peringkat

- QC of Continuous Flight Auger PilesDokumen1 halamanQC of Continuous Flight Auger Pilesnischal_babuBelum ada peringkat

- Basic Requirements For PilesDokumen1 halamanBasic Requirements For Pilesnischal_babuBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- KR HollowCore DesignManual-R4Dokumen22 halamanKR HollowCore DesignManual-R4S SathiyarubanBelum ada peringkat

- NINGBO SAFEWELL INTERNATIONAL HOLDING CORP. QUOTATIONDokumen1 halamanNINGBO SAFEWELL INTERNATIONAL HOLDING CORP. QUOTATIONromano sartoriBelum ada peringkat

- Cad Floor Plan-P1Dokumen1 halamanCad Floor Plan-P1raymond erasmoBelum ada peringkat

- Proposed 3-Storey Residence Technical SpecsDokumen7 halamanProposed 3-Storey Residence Technical SpecsHannah Cesaree Mae TadeoBelum ada peringkat

- Precast 1 Concepts PDFDokumen111 halamanPrecast 1 Concepts PDFRaymond Chan100% (5)

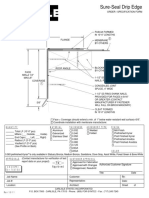

- Sure-Seal Drip Edge: FM ApprovedDokumen2 halamanSure-Seal Drip Edge: FM ApprovedConstantin GubavuBelum ada peringkat

- Endura 7Dokumen200 halamanEndura 7POPLY ARBelum ada peringkat

- Repair and Renovation of Laboratory Building For H&R Chempharm AsiaDokumen5 halamanRepair and Renovation of Laboratory Building For H&R Chempharm AsiaSarveshrau SarveshBelum ada peringkat

- HK EquipmentsDokumen8 halamanHK Equipmentsmary joy crisolBelum ada peringkat

- Bom 1.6mDokumen4 halamanBom 1.6mFelipe ValenzuelaBelum ada peringkat

- Cashel Valley Site Layout A2Dokumen1 halamanCashel Valley Site Layout A2inongeBelum ada peringkat

- MATERIALS INSPIRE ARTDokumen35 halamanMATERIALS INSPIRE ARTEriel AmosinBelum ada peringkat

- Z Adventure Glove Box Easy Out Bracket Fitting GuideDokumen3 halamanZ Adventure Glove Box Easy Out Bracket Fitting GuideGiambattista GiannoccaroBelum ada peringkat

- Group 5 - Construction Methods and Operations-1Dokumen6 halamanGroup 5 - Construction Methods and Operations-1Donna Cece MelgarBelum ada peringkat

- Concrete Hollow Block Construction GuideDokumen5 halamanConcrete Hollow Block Construction GuideEdmark PonceBelum ada peringkat

- Structural Performance of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Dokumen7 halamanStructural Performance of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)ijeteeditorBelum ada peringkat

- FMDS0122Dokumen11 halamanFMDS0122Soumyadip RoyBelum ada peringkat

- Mating Flanges: ST Issue 2Dokumen2 halamanMating Flanges: ST Issue 2Nugrawan SatriaBelum ada peringkat

- Berger Fosroc: Waterproofing SolutionsDokumen15 halamanBerger Fosroc: Waterproofing SolutionsGraha NusaBelum ada peringkat

- New Microsoft Office PowerPoint PresentationDokumen15 halamanNew Microsoft Office PowerPoint PresentationSonika PatelBelum ada peringkat

- How To Lay Cement Brick in ConstructionDokumen2 halamanHow To Lay Cement Brick in ConstructionRoBelum ada peringkat

- Alleyns 11 English Sample Paper 4Dokumen10 halamanAlleyns 11 English Sample Paper 4VivianBelum ada peringkat

- 2007 Buildings Schedule of Rates - Central Provincial CouncilDokumen82 halaman2007 Buildings Schedule of Rates - Central Provincial CouncilThanuja JayasooriyaBelum ada peringkat

- 2.3.1h.a HousingDesignHomeworkDokumen4 halaman2.3.1h.a HousingDesignHomeworkcqlBelum ada peringkat

- Final Girl - Gruesome Deaths - Maple Lane v1Dokumen48 halamanFinal Girl - Gruesome Deaths - Maple Lane v1Хуан БрухоBelum ada peringkat

- 5 WC Type-ChartDokumen1 halaman5 WC Type-ChartlumpertBelum ada peringkat

- BS 5234-1 Partitions Part 1Dokumen38 halamanBS 5234-1 Partitions Part 1Patrick O'TooleBelum ada peringkat

- GRP Industries Fire Cabinet Product DatasheetDokumen9 halamanGRP Industries Fire Cabinet Product DatasheetOktayuda PerwiraBelum ada peringkat

- Pipe Layout Template: Plans For A Cloud BusterDokumen5 halamanPipe Layout Template: Plans For A Cloud BusterEx Ess100% (2)