Inflatable Packer Applications

Diunggah oleh

tangkokhongHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Inflatable Packer Applications

Diunggah oleh

tangkokhongHak Cipta:

Format Tersedia

Inflatable Packer Applications

INFLATABLE PACKER APPLICATIONS

By Clem Rowe - Age Developments Pty. Ltd.

1.0 Introduction

Inflatable packers have been used extensively in the oil drilling and production industries for more than 50 years. They have also found application in water and mineral drilling and production as well as in geotechnical testing work. With the increasing availability of inflatables designed specifically for economical use in industries other than the oil business the areas of application are constantly broadening. Consultants and contractors are becoming increasingly aware of the benefits to be gained by using inflatable packers in a wide range of situations. Some of the more common and interesting applications are described in the following. The packers are inflated using either air or water via a small bore tube run from the surface in parallel with the rig wireline. (Some systems use an integral inflation and lowering umbilical.) The top seal assembly is then activated to seal around the wireline and inflation tube. Permeability testing can then be performed by pumping down through the coring string and the packer assembly and into the now isolated bottom section of the cored hole. On completion of testing the packer assembly is replaced with the inner core barrel and coring continues ahead. The wireline testing method is also applicable where straddle testing is required. In this configuration a second open-hold packer is attached to the bottom of the standard packer assembly via a perforated pipe of predetermined length. This packer is inflated together with the other two packers thus isolating an open-hole zone between the two bottom packers. Permeability testing can then be carried out on this straddled zone as before. The actual permeability testing consists of pumping a fluid, usually water, into the formation under either constant pressure or flow conditions over an extended period of time with all parameters being logged as required. The data so gathered may then be manipulated to determine the average permeability for the test zone. b) Drill string packer testing In this method the packer assembly is deployed directly on drill pipe, or similar, in a predrilled hole. Figure 2 shows a typical drill string packer assembly in both single packer and straddle packer configurations. Both of these configurations offer simple methods of testing the permeability of the zone isolated with the packers. That is, below the single packer or between the packers for the straddle situation. The method of testing is simply to run the packer/s to the required depth, inflate to isolate the test zone and then pump down through the drill pipe to perform the actual tests. The packers can then be deflated and reset at other zones of interest. The actual testing procedure employed is similar to that described for the wireline packer method. Using drill pipe deployment allows the option of inflating the packers either via an external small bore tube (as in the wireline packer case) or of inflating through the drill string. Each of these methods has relative advantages and disadvantages, which should be addressed in light of the actual application being considered

2.0 Testing

2.1 Permeability Tests Formation permeability testing using inflatable packers may be performed in a number of ways. For example., a) using coring string and wireline packers b) drill string packer method c) failing head tests The choice of which of these methods is used depends on the circumstances of the Individual project being undertaken. For example, if the permeability testing forms part of an overall investigation project, which Includes coring operations, then use of wireline packer testing is the most likely choice. Conversely, if testing is to be performed in down-hole hammer drilled holes then drill string deployed packers are a more likely candidate. a) Wireline packer testing Wireline packer testing through a coring string is illustrated in Figure 1. The basic procedure is as follows: Following identification of the zone to test via inspection of the core the wireline core inner barrel is retrieved to the surface and the string is lifted off bottom to expose the test zone. A top seal assembly is then screwed on to the top of the coring string. The packer assembly is connected to the rig wireline in place of the inner tube overshot and run through the seal assembly and coring string to seat in the bit as shown.

Inflatable Packer Applications

Inflatable Packer Applications As to the relative merits of using a single packer system as opposed to a straddle arrangement this is again a matter for Individual project assessment. In general, the straddle system offers greater control and flexibility as to delineation of the test zone. The single packer assembly is less expensive and may produce more reliable results when used in conjunction with staged drilling. A possible advantage of this system for use in deep holes or where high quality data is essential is that downhole pressure measurement via electronic transducers may be readily incorporated. This offers considerable accuracy advantages over the usual surface pressure recoding system due to the elimination of such factors as pipe friction, variable static head, etc. c) Falling head tests These are more-or-less similar to the drill string type tests except that fluid injection occurs freely under gravity instead of being forced by a pump. The arrangement normally used consists of a drill pipe packer complete with a plug in the packer which can be operated from the surface. This assembly is run to the required depth on pipe. The packer is inflated to isolate the zone of interest, the pipe is filled with water to the surface and the plug is then opened to suddenly apply the head of water in the pipe to the test zone. Following application of the head to the test zone measurements of head versus time are made till an equilibrium condition is reached. This data may then be interpreted to give an estimate of in-situ permeability. This type of test is normally limited to application in relatively shallow holes. One of the difficulties associated with these tests is that of measuring the head changes at initially very small time Increments. This Is often overcome through the use of time based logging of downhole electronic pressure transducers.

3 The testing procedure involves gradually increasing the pressure between the straddle packers until a sudden pressure-drop indicating fracture is noted. The pressure may then be shut-in to monitor the crack closing pressure. Subsequent repetition of this procedure is often employed to further assess the formation response.

2.3 Casing Integrity

Casing integrity testing may be considered as a special case of "permeability' testing which is applicable to casing. The intention being to either ensure the casing is not leaking or to determine the location of a leak or leaks. The method of test is similar to that employed for permeability testing using drill pipe packers. Using a single packer, the packer is run on pipe to inflate in

2.2 Fracture Tests

Fracture testing Is a geotechnical test method used to assess the in-situ strength and stress condition of rock formations. The packer methods commonly employed in fracture testing are basically the same as the wireline and drill string methods already described for permeability testing. The principal difference being that the pressure required for fracture work is usually significantly greater than that required for permeability testing. Fracture testing is also far more likely to use straddle packer configurations both to reduce the packer anchoring requirements and to limit the test zone to a cylindrical section of known length.

Inflatable Packer Applications the bottom of the casing. This packer is capped on the bottom so that inflation totally seals the casing above the packer. The casing is then pressurized either through the lowering pipe or directly and the pressure is shut-in and monitored for evidence of leakage. Assuming a leak occurs, the location of the leak may be more precisely defined by moving the packer uphole in stages and repeating the leak test at each stage. A more accurate and reliable method of locating the leak is to use a straddle packer assembly. Through stage-wise testing of the casing followed by gradual reduction of the straddle length both single leaks and multiple leaks may be accurately located and defined. cementing operations. Two of the most common applications are described in the following sections.

3.1 Casing Grouting

One of the commonly employed methods of casing grouting is illustrated in Figure 3. This system employs a single-use packer, which is grouted in during the cementing operation. The packer is built on a section of casing identical to the casing which is being installed. The packer is made-up to the bottom joint of the casing and run in to the required depth. Prior to grouting, the packer is inflated to seal the casing to hole annulus above the packer thereby protecting the open hole below the casing from grout contamination. Packer inflation is normally via a small bore flexible tube run on the outside of the casing to the surface.

3.0 CEMENTING OPERATIONS

One of the areas in which inflatable packers have been most extensively applied is that of assisting in

Inflatable Packer Applications An alternative inflation method uses a separate straddle packer assembly run on a pipe string inside the casing and inflated to straddle a casing packer inflation valve. The casing packer is then inflated by pumping down through the straddle packer system. Following this the straddle packers are deflated moved up and re-inflated to straddle a second valve. This second valve gives access to the casing/hole annulus. Should annular clearance be insufficient to allow grouting via this method a straddle packer system isolating a casing grouting valve may be used.

5 Optimum treatment may require more stages of grouting in which further grouting and fracture processes are performed at some or all of the valves. The process may in fact be repeated for as long as the TAM remains accessible and sufficient pressure may be applied to fracture the previously placed grout. This system of pressure grouting presents considerable advantages in terms -of control of the grouting process and therefore, of the efficiency of the treatment.

3.2 TAM Pressure Grouting 4.0 FRACTURING

Pressure grouting using a Tube a Manchette or TAM system offers an efficient, cost effective means of grouting for structural reinforcement and/or waterproofing of foundations, tunnels and mines. This system is based around the TAM which basically consists of a length of pipe with small holes drilled around the circumference and at equal intervals along the length of the pipe. Each set of holes is covered by a rubber sleeve (or manchette), which allows the whole arrangement to act as a series of one-way valves. That is, flow out through the holes is permitted by expansion of the rubber sleeve but flow in the opposite direction is prevented by the sleeve collapsing onto the pipe. During grouting operations, each of the TAM valves is accessed individually by a set of inflatable packers which are run inside the TAM pipe and inflated so that they straddle the valve. The actual sequence of operations normally consists of two or more separate stages of grouting as illustrated in Figure 4. In the first stage the TAM is installed in a predrilled hole and grouted in place using a light "sleeve" grout or a gravel packing for low pressure applications. This operation being required to seal the Tam into the borehole and to prevent flow of grout, under pressure, up the borehole/TAM interface. The second stage is the actual pressure grouting. In this phase, the level to be grouted is isolated with the straddle packers which are run on a separate string inside the TAM. The sleeve grout around the valve is fractured by pumping water under high pressure down the packer string and out through the isolated valve. Grout is then pumped in through this valve up to the permissible maximum injection pressure or volume. This process is repeated at subsequent valve levels normally proceeding from the bottom up.

4.1 Water Wells

In water wells the use of fracturing is principally directed at increasing bore yield whereas in the fracturing application previously discussed the intention was to determine geotechnical characteristics of the formation. The basic procedure applied for water well fracturing is almost the same as that used for geotechnical fracturing work. The only major difference being that this application requires the use of much larger flow rates in order to propagate any fractures as far as possible. Also, on occasion, a propping agent is introduced into the injected water to assist in keeping fractures open when the pressure is released. Straddle packer arrangements are frequently used for this work as they allow the use of higher pressures and control the length of the interval being fractured. This system has the potential of creating more fractures and thereby greater increases in well yield. Typical yield increases of 5 to 10 times are realizable though obviously the increase cannot be predicted except on the basis of knowledge of the hydrological characteristics of the region to be treated.

4.2 Other Fracture Applications

Recently, fracturing, as per the method to increase water well yield, has been used to fracture overburden in a long-wall coat mining operation. The intention in this case was to create sufficient instability by way of fractures in the overburden to ensure controlled collapse as mining progressed forward.

Inflatable Packer Applications Another fracturing application for mining, which is currently under development employs small diameter straddle packers inserted into rock-bolt holes to measure the fracture strength of the rock. The rock stresses in the region of the Initiated fracture which are deduced from the pressurization record and fracture geometry are used to determine the mine support requirements.

6 In this arrangement the packer is attached to the top of an electric submersible pump with the pump output passing through the packer bore. The packer/pump assembly is lowered to the top of the bottom aquifer and the packer is inflated. This seals the bottom aquifer from the rest of the well and allows pump-out testing of this aquifer in isolation, to check yield and water quality On completion of testing at this level the packer is deflated and whole assembly is raised to the top of the next aquifer up-hole. Repetition of the previous procedure at this level gives results, which are a combination of the yields of the two aquifers now open to testing. Results applicable to the present location, in isolation, may then be determined by subtraction of the results of the previous level. This method of test may be repeated at each subsequent aquifer moving up-hole. Various different combinations of pump and packers are used for a wide variety of similar applications such as, pump-out tests, blocking silt or contaminated water zones, flow meter tests, etc.

5.0 WATER WELL TESTING 5.1 Well Yield Testing

Applications for packers in association with pump tests are many and varied. One of the most common, which is used to determine water quality and yield from a well which produces from aquifers at several different levels, is illustrated in Figure. 5

5.2 Multi-Level Sampling

The use of inflatable packers for water quality sampling also provides an efficient means of monitoring several different levels from a single borehole. Figure 6 shows a typical multilevel sampling system. This system basically consists of a series of intake ports separated by inflatable packers all on a single casing string. All packers and sample ports are connected to the surface via small-bore flexible tubes. Samples are collected either by means of a vacuum pump (for sampling depths of less than 6m) or via airlift. This system also permits head measurement at each isolated sampling level by using either the air lift line as a bubbler tube or a small diameter water level probe run inside the sampling tube.

Inflatable Packer Applications

6.0 SCREEN INSTALLATION 6.1 INSTALLATION

A special type of Inflatable packer, illustrated in Figure 7, which has friction coated grip or anchoring strips bonded to the outside of the rubber has found application for the Installation of water well screens in gravel packed bores. This packer essentially takes the place of a 'back-off' joint. The packer is installed inside the top of the screen, inflated to grip the screen and then connected to standard drill rods, which are used to lower the screen with the packer supporting the screen weight. When the screen has been lowered to the required depth, gravel for packing may be introduced directly Into the casing from the surface since the packer blocks off the top of the screen. On completion of gravel packing, simple deflation of the packer releases the lowering string from the screen. This eliminates the usual problems with mechanical disconnect systems such as over or under rotation together with the subsequent risk of damaging the screen.

6.2 Fishing

This type of packer also finds application in fishing operations. Where the fish is thin-wall pipe or screen and is therefore likely to split using conventional fishing tools such as taper taps this packer offers a viable alternative. The packer Is run in on drill pipe to locate inside the fish and then simply inflated to create a fiction connection. Depending on the diameter and length of the packer used this friction connection can have In excess of 50 tonnes capacity. Should this friction capacity not be sufficient to move the fish then the packer is readily released by deflation.

7.0 INJECTION

Although several of the applications already described have dealt with what are principally methods of injecting a fluid using packers, two further uses deserve mention under this separate heading.

7.1 Chemical Grouting

Chemical grouts are principally used to provide either formation strengthening or water-proofing. Usual methods of application are similar to either the TAM grouting procedure or the drill string permeability test method. Using the TAM procedure the chemical grout is injected into the formation exactly as the cement grout would be normally, except that precautions are taken to avoid fracturing the formation during

Inflatable Packer Applications injection, Fractures are generally to be avoided as the intention is usually to create a uniformly treated region by permeation of the grout through the formation. Using the permeability type procedure, the chemical grout is applied to the formation as though performing a permeability test using the drill string, single packer method and grout instead of water as the injected fluid. When employing reusable packers for this application, special precautions to avoid grouting in the packers, such as over pumping, are required.

7.2 Liquid Waste Disposal

One of the common methods of liquid waste disposal involves pumping the waste into a deep aquifer under an impermeable layer. Packers may be employed in this application for both well construction, to ensure competent grouting of the casing, and for sealing the waste injection string into the casing. The method of application for injection is similar to the chemical grouting procedure using a single drill string packer. Depending on the nature of the waste, multiple packers each with separate inflation are sometimes used to provide fail-safe sealing.

Anda mungkin juga menyukai

- Halliburton: Slip JointDokumen2 halamanHalliburton: Slip Jointsaeed65Belum ada peringkat

- The Ultimate Resistance of Rigid Piles Against Transversal ForcesDokumen5 halamanThe Ultimate Resistance of Rigid Piles Against Transversal ForcestangkokhongBelum ada peringkat

- Kallang Formation in SingaporeDokumen1 halamanKallang Formation in SingaporetangkokhongBelum ada peringkat

- Shear Strenght ExampleDokumen11 halamanShear Strenght ExamplealvinBelum ada peringkat

- Instruction Manual ControltromikDokumen10 halamanInstruction Manual ControltromikVoştinar IoanBelum ada peringkat

- Packer Testing Program Design and Management: August 2013Dokumen7 halamanPacker Testing Program Design and Management: August 2013wily784Belum ada peringkat

- Packer Test Guide: Straddle Packer Tests Hydraulic Conductivity Tests, Geological Consulting-Ankan BasuDokumen71 halamanPacker Test Guide: Straddle Packer Tests Hydraulic Conductivity Tests, Geological Consulting-Ankan BasuAnkan Basu80% (5)

- Steps Packer TestingDokumen26 halamanSteps Packer Testingbinod2500Belum ada peringkat

- Spe 36761 MSDokumen13 halamanSpe 36761 MSKarla CotesBelum ada peringkat

- Inflatable Packers Fixed End Vs Sliding EndDokumen1 halamanInflatable Packers Fixed End Vs Sliding EndRipe PackersBelum ada peringkat

- Cementing & Casing Accessories Davis-Lynch Equipment CatalogDokumen19 halamanCementing & Casing Accessories Davis-Lynch Equipment CatalogfarajBelum ada peringkat

- Titan Micros Jan2009Dokumen16 halamanTitan Micros Jan2009Anonymous Q7ELJ5TBelum ada peringkat

- Guide To Instrumentation Installing PiezometerDokumen5 halamanGuide To Instrumentation Installing PiezometerdetkomerdeviBelum ada peringkat

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDokumen8 halamanBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightBelum ada peringkat

- 1PackerSystem PackerAccessories&tools PDFDokumen21 halaman1PackerSystem PackerAccessories&tools PDFAnand aashishBelum ada peringkat

- Hydraulic Setting Tool Product BrochureDokumen4 halamanHydraulic Setting Tool Product BrochureEvolution Oil ToolsBelum ada peringkat

- (J. A Short) Drilling A Source Book On Oil and Ga PDFDokumen588 halaman(J. A Short) Drilling A Source Book On Oil and Ga PDFZana QadirBelum ada peringkat

- VersaFlex ELH Cementing Plug System - H06448Dokumen2 halamanVersaFlex ELH Cementing Plug System - H06448rodrigo788Belum ada peringkat

- Homco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealDokumen8 halamanHomco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealHamed NazariBelum ada peringkat

- Watson - Packer CatalogDokumen60 halamanWatson - Packer CatalogAnonymous rey6aU3ZBelum ada peringkat

- SPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDDokumen8 halamanSPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDehsanBelum ada peringkat

- Tam Anulus Casing PackersDokumen20 halamanTam Anulus Casing Packersallan_lennoxBelum ada peringkat

- 5 Liner HangersDokumen26 halaman5 Liner HangersAjar Waspodo50% (2)

- Botil Model BTCN Mechanical Set PackerDokumen2 halamanBotil Model BTCN Mechanical Set PackerReivaj JavierBelum ada peringkat

- Grouting Methods: and EquipmentDokumen88 halamanGrouting Methods: and EquipmentSushmit SharmaBelum ada peringkat

- 06 Openhole IsolationDokumen24 halaman06 Openhole IsolationMuhammad ShahrukhBelum ada peringkat

- (Hedge Et Al. 2015) Using Trees, Bagging, and Random Forest To Predict ROP During DrillingDokumen12 halaman(Hedge Et Al. 2015) Using Trees, Bagging, and Random Forest To Predict ROP During DrillingKleberson CarvalhoBelum ada peringkat

- Seal Assemblies (Locator, Anchor, Latch)Dokumen2 halamanSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanBelum ada peringkat

- 0620000008Dokumen6 halaman0620000008mahsaBelum ada peringkat

- Seal Bore Packer System - RetrievableDokumen8 halamanSeal Bore Packer System - RetrievableFabio ParceroBelum ada peringkat

- Wellbore Quality Characterization For Drilling and Casing Running in Challenging WellsDokumen54 halamanWellbore Quality Characterization For Drilling and Casing Running in Challenging WellsDVScherbakovBelum ada peringkat

- Adjustable Motor PDFDokumen9 halamanAdjustable Motor PDFsaeed65Belum ada peringkat

- Prevention, Fishing and Casing Repair - Jim Short - Part 2Dokumen249 halamanPrevention, Fishing and Casing Repair - Jim Short - Part 2MitsúMilagrosToroSayasBelum ada peringkat

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDokumen13 halamanC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanBelum ada peringkat

- High Pressure Inflatable Packer ToolsDokumen3 halamanHigh Pressure Inflatable Packer ToolsKim MissonBelum ada peringkat

- Polish Top LinerDokumen12 halamanPolish Top LinerLenis CeronBelum ada peringkat

- Halliburton Packer ShoesDokumen22 halamanHalliburton Packer ShoesTong Chaipanyakul100% (1)

- Coiled Tubing Smart-J Tension Packer Technical DatasheetDokumen4 halamanCoiled Tubing Smart-J Tension Packer Technical DatasheetEvolution Oil ToolsBelum ada peringkat

- DPC PDFDokumen94 halamanDPC PDFjquevedo8237Belum ada peringkat

- Product Bulletin No.: TDS-02-14 Release Top Drive Drilling SystemDokumen2 halamanProduct Bulletin No.: TDS-02-14 Release Top Drive Drilling SystemcarlosorizabaBelum ada peringkat

- WOT - Tech Data Sheets PDFDokumen43 halamanWOT - Tech Data Sheets PDFAmbroise RICHARDBelum ada peringkat

- Unu-Gtp-Sc-06-42 Geothermal Drilling and Well PumpsDokumen13 halamanUnu-Gtp-Sc-06-42 Geothermal Drilling and Well PumpsPrince MubaiwaBelum ada peringkat

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDokumen15 halamanPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Belum ada peringkat

- DRT Motor Manual 6-16-10Dokumen55 halamanDRT Motor Manual 6-16-10sumsolcaggBelum ada peringkat

- Davis-FET CatalogDokumen19 halamanDavis-FET CatalogfarajBelum ada peringkat

- Casing LeaksDokumen8 halamanCasing LeaksDavid LuhetoBelum ada peringkat

- 24 Pilot Mill 2Dokumen2 halaman24 Pilot Mill 2jorge vargas zapataBelum ada peringkat

- Half Mule Shoe Guide 88050307Dokumen2 halamanHalf Mule Shoe Guide 88050307satyendraBelum ada peringkat

- Davis Lynch Cementing PDFDokumen30 halamanDavis Lynch Cementing PDFWilliam0% (1)

- Collet Catcher SubDokumen1 halamanCollet Catcher SubjasonBelum ada peringkat

- The Most Accurate Whipstock OrientationDokumen2 halamanThe Most Accurate Whipstock OrientationSaeed AraBelum ada peringkat

- Parveen Packer Milling Tool: General DescriptionDokumen2 halamanParveen Packer Milling Tool: General Descriptionjavad salimiBelum ada peringkat

- MDT Formation Pressure DataDokumen6 halamanMDT Formation Pressure DataAngelo Kristoff MacarioBelum ada peringkat

- Pressure Rating For SSII Float EquipmentDokumen2 halamanPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikBelum ada peringkat

- Packer Setting MechanismDokumen3 halamanPacker Setting MechanismYougchu Luan67% (3)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDari EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsBelum ada peringkat

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesDari EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesBelum ada peringkat

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDari EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersBelum ada peringkat

- Packar MethodologyDokumen6 halamanPackar Methodologyaitzaz561Belum ada peringkat

- New Casing Cementing MethodsDokumen7 halamanNew Casing Cementing MethodsSherif Mohamed ElSayedBelum ada peringkat

- Prof. Dr. Eng: - Ahmed El-Gibaly: Suez Canal University Faculty of Pet. & Min. Eng. Petroleum Engineering DeptDokumen22 halamanProf. Dr. Eng: - Ahmed El-Gibaly: Suez Canal University Faculty of Pet. & Min. Eng. Petroleum Engineering Deptcmrig74Belum ada peringkat

- Best Practices For Obtaining Quality Permeability Data With CBM Matrix Injection-Falloff TestingDokumen11 halamanBest Practices For Obtaining Quality Permeability Data With CBM Matrix Injection-Falloff TestinggonloveyouBelum ada peringkat

- API RP 96 - Deepwater Well Design and Construction. Annex C - Inflow Test ExamplesDokumen5 halamanAPI RP 96 - Deepwater Well Design and Construction. Annex C - Inflow Test ExamplesjuanBelum ada peringkat

- A Numerical Analysis of Anchored Diaphragm Walls For A Deep Basement in Kuala Lumpur, Malaysia.Dokumen6 halamanA Numerical Analysis of Anchored Diaphragm Walls For A Deep Basement in Kuala Lumpur, Malaysia.tangkokhongBelum ada peringkat

- Introduction To Singapore FormationDokumen10 halamanIntroduction To Singapore FormationtangkokhongBelum ada peringkat

- UntitledDokumen17 halamanUntitledtangkokhongBelum ada peringkat

- Design, Construction & Performance of Hand-Dug Caissons in Kuala Lumpur Granitic FormationDokumen4 halamanDesign, Construction & Performance of Hand-Dug Caissons in Kuala Lumpur Granitic Formationtangkokhong100% (1)

- Failure of An Embankment Treated With Vacuum Preloading MethodDokumen4 halamanFailure of An Embankment Treated With Vacuum Preloading MethodtangkokhongBelum ada peringkat

- Buildability Score CalculationDokumen4 halamanBuildability Score CalculationtangkokhongBelum ada peringkat

- Case Studies of Rock-Socketed PilesDokumen9 halamanCase Studies of Rock-Socketed PilestangkokhongBelum ada peringkat

- Basic Soil Properties From CPT in Bangkok Clay For Highway DesignDokumen8 halamanBasic Soil Properties From CPT in Bangkok Clay For Highway DesigntangkokhongBelum ada peringkat

- Randolph Formula For Pile Elastic SettlementDokumen1 halamanRandolph Formula For Pile Elastic SettlementtangkokhongBelum ada peringkat

- Analysis of Self-Boring Pressuremeter Tests in Overconsolidated ClaysDokumen5 halamanAnalysis of Self-Boring Pressuremeter Tests in Overconsolidated ClaystangkokhongBelum ada peringkat

- Analysis of Tremie Technique in Concreting of Bottom Plug of WellsDokumen16 halamanAnalysis of Tremie Technique in Concreting of Bottom Plug of Wellstangkokhong67% (3)

- Interpretations of Instrumented Bored Piles in Kenny Hill FormationDokumen8 halamanInterpretations of Instrumented Bored Piles in Kenny Hill Formationtangkokhong100% (1)

- Buckling Analysis Design of Steel FramesDokumen0 halamanBuckling Analysis Design of Steel FramestangkokhongBelum ada peringkat

- Analysis of Piles Subject To Lateral Soil MovementsDokumen7 halamanAnalysis of Piles Subject To Lateral Soil Movementstangkokhong100% (1)

- An Approach For Seismic Design in Malaysia Following The Principles of Eurocode 8Dokumen13 halamanAn Approach For Seismic Design in Malaysia Following The Principles of Eurocode 8tangkokhongBelum ada peringkat

- Micropiles - An OverviewDokumen76 halamanMicropiles - An OverviewtangkokhongBelum ada peringkat

- Inflatable Packer FundamentalsDokumen8 halamanInflatable Packer FundamentalstangkokhongBelum ada peringkat

- Mobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperDokumen2 halamanMobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperTEKLEWEYNI TsegayBelum ada peringkat

- Physics Cun It PacketsDokumen226 halamanPhysics Cun It PacketsRana MukherjeeBelum ada peringkat

- Trujillo PDFDokumen12 halamanTrujillo PDFVerdy A. KoehuanBelum ada peringkat

- Cobalt Chromium Implant Grade TubingDokumen2 halamanCobalt Chromium Implant Grade Tubingkunalkp88Belum ada peringkat

- 2005 - Theoretical Analysis of Dehumidification Process in A Desiccant WheelDokumen10 halaman2005 - Theoretical Analysis of Dehumidification Process in A Desiccant WheelzebrazerozeroBelum ada peringkat

- Intergraph Caesar Course ContentDokumen2 halamanIntergraph Caesar Course ContentValesh MonisBelum ada peringkat

- Spare Parts For Powerplant-And Marine Diesel EnginesDokumen3 halamanSpare Parts For Powerplant-And Marine Diesel EnginesJavedBelum ada peringkat

- Dr.M.uthayakumar - Google Scholar CitationsDokumen13 halamanDr.M.uthayakumar - Google Scholar CitationsrkBelum ada peringkat

- Thermodynamics: AllenDokumen9 halamanThermodynamics: AllenronakBelum ada peringkat

- Lecture No: 10 (Lubrication in I.C.E) : 10.1 Function of Lubricating SystemDokumen5 halamanLecture No: 10 (Lubrication in I.C.E) : 10.1 Function of Lubricating Systemمصطفى العباديBelum ada peringkat

- Quiz 2 2013 ThermodynamicDokumen2 halamanQuiz 2 2013 ThermodynamicPaartiban PaneerselvamBelum ada peringkat

- Turbine RepairDokumen67 halamanTurbine RepairFrancisco Novoa Rodriguez50% (2)

- BlowerGB 2Dokumen6 halamanBlowerGB 2Kiyarash BarmakizadehBelum ada peringkat

- PC2 - Practice Exam WorkedDokumen12 halamanPC2 - Practice Exam WorkednomsyBelum ada peringkat

- D399 AttachmentDokumen50 halamanD399 AttachmentNOUR ZAINBelum ada peringkat

- Thakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingDokumen4 halamanThakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingAshwini ChaurasiaBelum ada peringkat

- RecitationDokumen4 halamanRecitationSavaliya HardikBelum ada peringkat

- Powerpoint Images: Failures Resulting From Static LoadingDokumen11 halamanPowerpoint Images: Failures Resulting From Static LoadingKTMOBelum ada peringkat

- Flange TableDokumen0 halamanFlange TablemkstngrBelum ada peringkat

- 1-Fundamentals of Creep in MaterialsDokumen6 halaman1-Fundamentals of Creep in MaterialsLucianoBorasiBelum ada peringkat

- Strengthening of Reinforced Concrete Beams Using FRP Technique: A ReviewDokumen16 halamanStrengthening of Reinforced Concrete Beams Using FRP Technique: A ReviewHÙNG Trần MạnhBelum ada peringkat

- For Cylinders and Blocks: Compression MachinesDokumen4 halamanFor Cylinders and Blocks: Compression MachineshistoBelum ada peringkat

- V Clic Workshop ManualDokumen44 halamanV Clic Workshop ManualWG-Friend IvybridgeBelum ada peringkat

- D2 Tool Steel - Heat Treatment Process PDFDokumen3 halamanD2 Tool Steel - Heat Treatment Process PDFGayathriRajasekaranBelum ada peringkat

- Engine Manual of WeichaiDokumen121 halamanEngine Manual of Weichaizein zee100% (9)

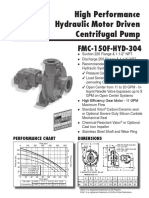

- FMC-150F-HYD-304 - 04-13 Bomba AceDokumen2 halamanFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesBelum ada peringkat

- Compiled By: Sir Sumair: KinematicsDokumen6 halamanCompiled By: Sir Sumair: KinematicsHasan NawazBelum ada peringkat

- Valves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Dokumen34 halamanValves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Oscar CalaBelum ada peringkat