Performance-Based Design of Confinement Reinforcement in RC Bridge Wall Pier

Diunggah oleh

Kader Newaj SakibHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Performance-Based Design of Confinement Reinforcement in RC Bridge Wall Pier

Diunggah oleh

Kader Newaj SakibHak Cipta:

Format Tersedia

ACI Structural Journal/January-February 2001 3

ACI Structural Journal, V. 98, No. 1, January-February 2001.

MS No. 99-204 received October 14, 1999, and reviewed under Institute publica-

tion policies. Copyright 2001, American Concrete Institute. All rights reserved,

including the making of copies unless permission is obtained from the copyright pro-

prietors. Pertinent discussion will be published in the November-December 2001 ACI

Structural Journal if received by July 1, 2001.

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

The objective of this research was to develop an approach that

relates the confinement reinforcement in the plastic hinge zone of

bridge pier walls to the displacement ductility capacity. An analyt-

ical model to predict the seismic response of bridge pier walls was

developed and verified using test data. A parametric study was

conducted using a computer program named Pier to study pier

walls with a wide range of parameters. Based on the results of the

parametric study, a new performance-based design method was

developed. The proposed method can be used to design the con-

finement reinforcement based on a target displacement ductility

level. Conversely, the method can be used to estimate the ductility

capacity of an existing wall with a known amount of confinement

reinforcement. Depending on the ductility demand, the result can

be used to determine if retrofit of the wall is necessary.

Keywords: ductility; load; pier; reinforced concrete.

INTRODUCTION

The practice of designing pier walls in the weak direction

based on the provisions for columns is primarily driven by

judgment and not actual test data. Whether this practice is

appropriate has not been investigated in detail and is yet to be

verified by tests. The minimum confinement reinforcement

limits also appear to be judgmental and are perhaps approxi-

mately based on the minimum shrinkage reinforcement re-

quirements. In plastic hinge zones, the compressive strain

capacity of unconfined concrete is inadequate to achieve the

desired ductility level without excessive spalling of the cover

concrete. Transverse reinforcement is provided to confine the

concrete core and to prevent buckling of the longitudinal bars.

Confining the concrete core improves its strength and com-

pressive strain capacity. Comprehensive data and analysis of

the effect of transverse reinforcement on the seismic perfor-

mance of pier walls for out-of-plane loading are lacking.

The American Association of State Highway and Trans-

portation Officials (AASHTO) design specifications

1

have

no specific provisions to design bridge pier walls.

AASHTO

1

requires pier walls to be designed as shear walls

in the strong direction and as columns in the weak direction.

The California Department of Transportation (Caltrans

2

) de-

sign specifications require bridge pier walls to be designed

as columns, with certain limits for the reinforcement ratio

and spacing that are specific to walls.

AASHTO

1

adapted the ACI

3

code requirement for the lat-

eral reinforcement spacing. The maximum spacing limit is

the smallest of 1/4 of the minimum member dimension, and

102 mm. Caltrans

2

requires the maximum spacing of the lat-

eral reinforcement to be the smallest of 1/5 of the column

minimum dimension, 203 mm, and six times the longitudinal

bar diameter. The last limit is intended to prevent buckling

of the longitudinal bars. In designing the confinement rein-

forcement in the plastic hinge zones of bridge pier walls,

AASHTO

1

considers the gross and the confined section di-

mensions, and the material properties. In addition to the pa-

rameters considered by AASHTO,

1

Caltrans

2

considers the

effect of the axial load. Neither of the two design specifica-

tions explicitly considers the displacement ductility capacity

of the pier walls.

In contrast to walls, several methods are available for de-

sign of confinement reinforcement in columns. Three of the

methods are based on a ductility capacity for the columns.

Paulay and Priestley

4

developed an equation that accounts

for the axial load level and the curvature ductility capacity.

Wehbe, Saiidi, and Sanders

5

proposed an equation to calcu-

late the lateral reinforcement in rectangular bridge columns

based on a target displacement ductility. Sheikh and

Khoury

6

proposed a modification to the current ACI

3

code

equation. The modified equation contained two parameters

to account for the effect of the axial load level and the curva-

ture ductility demand for the column.

The objectives of this research were to study the seismic

response of bridge pier walls with a wide range of parame-

ters and to develop a practical design approach that relates

the confinement reinforcement in the plastic hinge zones of

bridge pier walls to a target displacement ductility capacity.

Such a design method can be a useful tool in performance-

based design of concrete bridges.

RESEARCH SIGNIFICANCE

Current design provisions require pier walls to be designed

as columns in the out-of-plane direction. No performance-

based design methods for the confinement reinforcement of

walls for out-of-plane loading are available. Three methods,

however, can be found in the literature for columns. This pa-

per introduces a method for pier walls and examines the ap-

plicability of existing methods that are developed for

columns.

ANALYTICAL MODEL

An analytical model was developed to determine the out-

of-plane seismic response of bridge pier walls.

7

The lateral

deflection of a reinforced concrete pier wall includes flexure,

bond slip, and shear components. The Kent and Park

8

model

Title no. 98-S1

Performance-Based Design of Confinement Reinforcement

in Reinforced Concrete Bridge Pier Walls for Out-of-Plane

Seismic Loads

by Nagi A. Abo-Shadi, M. Saiid Saiidi, and David H. Sanders

ACI Structural Journal/ January-February 2001 4

and the modified Mander, Priestley, and Park

9

model were

used to model the cover concrete and the confined concrete,

respectively. The confinement effectiveness coefficient,

which relates the area of the effectively confined core to the

nominal core area bounded by the centerline of the confine-

ment reinforcement, was taken as 0.6, as recommended by

Paulay and Priestley.

4

Furthermore, the stress in the confine-

ment reinforcement was assumed to be 60% of the steel yield

stress. The stress reduction in the confinement reinforcement

was based on the observations during the tests of the wall

specimens at the University of Nevada, Reno. To model the

steel stress-strain relationship, the model proposed by

Mander

10

was used.

The deformation due to flexure was calculated by taking

the static moment of the area under the idealized curvature

profile along the height of the pier wall taken about its free

end. The idealized curvature at the ultimate state included

the effect of the plastic hinge by replacing the actual plastic

hinge length with an equivalent plastic hinge length that

would result in the same plastic displacement at the free end.

The plastic rotation was assumed to be concentrated at the

middle of the equivalent plastic hinge length. The proposed

empirical expression by Paulay and Priestley

4

to calculate

the equivalent plastic hinge length of reinforced concrete

members was adopted in this study. In calculating the dis-

placement between the yield and the ultimate, it was as-

sumed that the plastic hinge length at a displacement

ductility

d

of 1 is equal to 50% of the calculated value using

the equation by Paulay and Priestley,

4

while it is equal to

100% at

d

of 4 or higher. These values are based on judg-

ment, and they appear to be reasonable. A linear interpola-

tion for the plastic hinge length was assumed between

displacement ductility levels of 1 and 4.

The deformation due to bond slip was found using a mod-

ified version of a model that was proposed by Wehbe, Saiidi,

and Sanders

5

The Wehbe method ignores the yield plateau in

the stress-strain diagram for steel, which can lead to unrea-

sonable results immediately after the yield point. In the mod-

ified version, the yield plateau was included. The steel stress-

strain curve was modeled by a trilinear relationship, with

strain hardening stage represented by a line.

The shear deformation was based on empirical equations

developed by Park and Paulay

8

for uncracked and cracked

reinforced concrete members. The equations were used to

calculate the shear stiffness per unit length of the member.

Park and Paulay found that the shear stiffness of a diagonally

cracked member is approximately 10 to 30% of that of the

uncracked members, depending on the amount of the shear

reinforcement. For pier walls with very low or no shear rein-

forcement, a minimum cracked shear stiffness of 10% of the

uncracked stiffness was used.

The yield point was assumed to have been reached when

the tensile strain in the vertical reinforcing bars is equal to the

yield strain of the steel. The total lateral deflection and curva-

ture of the pier wall at the yield point are called the yield dis-

placement and the yield curvature, respectively. The failure

point was calculated, taking into account the load history. The

mode of failure in the model was controlled by compression

failure in the confined concrete or fatigue fracture of the ver-

tical bars. When the strain in the concrete core reached the ul-

timate strain of the confined concrete, the wall was assumed

to have failed in compression of the concrete. The Manson-

Coffin

11

model for the strain-fatigue life relationship and the

linear damage model by Miner

12

were used to calculate the

damage index, which identifies fracture of the vertical bars

due to low cycle-fatigue. The total lateral deflection and cur-

vature of the pier wall at the failure point are called the ulti-

mate displacement and the ultimate curvature, respectively.

The displacement ductility capacity is defined as the ratio of

the ultimate displacement to the yield displacement, while the

curvature ductility capacity is defined as the ratio of the ulti-

mate curvature to the yield curvature.

Computer implementation

A personal computer-based special-purpose program was

developed to implement the analytical model described in

the previous section. The program calculates the confined

concrete properties and develops the stress-strain curves for

unconfined and confined concrete and the steel. The pro-

gram performs the moment-curvature analysis in the weak

direction for piers with two longitudinal reinforcement cur-

tains subjected to a known axial load. The effect of spalling

of the cover concrete is included. The program calculates the

deflections at the top of cantilever piers due to flexure, shear,

and bond slip. It defines the moment and curvature for crack-

ing and yield points. The program incorporates a low cycle-

fatigue model and a linear damage model that are used to cal-

culate the damage index. The damage index identifies frac-

ture of the longitudinal bars due to low-cycle fatigue. The

ultimate displacement at which a limit state is reached is cal-

culated. Two possible limit states have been identified: 1) the

maximum compression strain in the confined concrete is

equal to the ultimate strain of the confined concrete; and 2)

the damage index of the vertical reinforcing bars is equal to

unity (meaning fracture of bars).

The required data to run the program are the pier geomet-

rical properties, the vertical and confinement reinforcement,

the unconfined concrete compressive strength, and the steel

properties. The program results are the mode of failure, the

displacement ductility capacity, and a breakdown of the dis-

placements due to flexure, shear, and bond slip at the crack-

ing, yield, and ultimate points.

Verification of analytical model

The pier wall specimens were tested at the University of

Nevada, Reno,

7

and the University of California-Irvine

(UCI),

13,14

and were analyzed using Pier. To evaluate the

ACI member Nagi A. Abo-Shadi is an engineer at Robert Englekirk, Inc., Los Ange-

les, Calif. He received his BSc in civil engineering and MSc in structural engineering

from Mansoura University, Egypt, and his PhD from the University of Nevada, Reno,

Nev. He is a member of ACI Committees 341, Earthquake-Resistant Concrete Bridges;

and 342, Evaluation of Concrete Bridges and Bridge Elements. His research interests

include analysis and design of reinforced concrete and post-tensioned structures with

an emphasis on seismic analysis.

M. Saiid Saiidi, FACI, is the UNR-Foundation Professor of Civil Engineering at the

University of Nevada, Reno, Nev. He is a member and former chair of ACI Committee

341, Earthquake-Resistant Concrete Bridges, and is a member of ACI Committees

342, Evaluation of Concrete Bridges and Bridge Elements; 343, Concrete Bridge

Design; and 352, Joints and Connections in Monolithic Concrete Structures. His

research interests include analysis and shake-table studies of reinforced concrete

bridges.

David H. Sanders, FACI, is an associate professor of civil engineering at the Univer-

sity of Nevada, Reno. He is the chair of ACI Committee 341, Earthquake-Resistant

Concrete Bridges, and a member of ACI-ASCE Committees 423, Prestressed Con-

crete; and 445, Shear and Torsion. His research interests include all aspects of struc-

tural concrete response, with an emphasis on seismic performance, including shake-

table testing.

ACI Structural Journal/January-February 2001 5

performance of the analytical model, the analytical results

were compared with the experimental results.

Comparison with results from pier wall specimens

tested at University of Nevada, Reno

Seven half-scale pier wall specimens that were tested at

the University of Nevada, Reno,

7

under out-of-plane cyclic

loads, were analyzed using Pier. The test was conducted to

evaluate the seismic behavior of representative existing

bridge pier walls in the U.S. Details of the test specimens

were based on representative existing bridge pier walls in the

U.S. Representative pier walls were established based on a

survey

7

of state departments of transportation. Forty-seven

cases were included in the database.

The wall cross section was 300 mm thick and 1500 mm

wide. The height measured from the top of the footing to the

centerline of the lateral actuator was 2850 mm. The number,

size, ratio, and spacing of the bars are listed in Table 1 and 2.

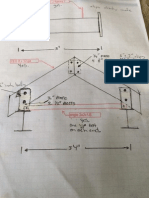

Figure 1 shows details of reinforcement for Specimen 1.

Crossties with standard hooks of 90 and 135 degree legs

were used.

The measured material properties were used in the analy-

sis. Good agreement was found when comparing the enve-

lopes of the lateral load-displacement relationships with the

calculated responses in all seven walls. Figure 2 and 3 show

two representative samples of the lateral load-displacement

envelopes for walls with low (0.75%) and high (1.5%) lon-

gitudinal reinforcement ratios, respectively. It can be seen

that the analytical model led to a reasonable estimate of the

initial stiffness, the yield point, and the ultimate point. The

peak load capacities were also close. The descending portion

of the postyielding region was not present in the calculated

result. This is because the concrete in the actual wall deteri-

orated at a faster rate than that assumed in the model by

Mander

10

for confined concrete. Six out of seven wall spec-

imens failed due to fracture of the vertical reinforcing bars.

The program successfully predicted the same observed mode

of failure of the wall specimens.

The numerical values of the measured and calculated total

displacements at the yield and ultimate points and the dis-

placement ductility capacities are listed in Table 3, while a

graphical interpretation is presented in Fig. 4 and 5. The dif-

ference between the measured and calculated total displace-

ments and ductilities is presented for comparison. The

average difference between the measured and calculated to-

tal yield displacements was 6.3% with a standard deviation

of 10.2%, while it was 11.9% with = 5.8% for the ulti-

mate displacements. An average difference of 5.7% with =

5.1% was found between the measured and the calculated

displacement ductility capacity.

Fig. 1Details of Specimen 1.

Fig. 2Measured and calculated lateral load-displacement

for Specimen 1.

Fig. 3Measured and calculated lateral load-displacement

for Specimen 4.

6 ACI Structural Journal/January-February 2001

Comparison with results from pier wall specimens

tested at UCI

The as-built specimens

13

that were tested in the weak di-

rection and had Class C splice (28d

b

) were selected to be an-

alyzed. Wall specimens with shorter lap-splices were not

analyzed because the analytical model does not consider the

lap-splice length. The specimens represented a 1/2-scale

model of existing pier walls. The height and thickness of the

specimens were 3175 and 250 mm, respectively. The width

was 913 mm in Specimen WCI, while it was 950 mm for

Specimens WC2 and WC3. The wall specimens did not in-

clude lateral reinforcement or crossties in the short direction.

The specified yield stress of the vertical bars was 276 MPa,

while it was 483 MPa for the deformed wires. The specified

concrete compressive strength was 27.6 MPa.

The vertical and lateral reinforcement ratios, the measured

concrete compressive strength, and the applied axial load are

presented in Table 4.

The wall specimens that were tested in the second study

14

were approximately 1/2-scale models of existing pier walls.

The typical dimensions of these wall specimens were 3175

mm high, 2400 mm wide, and 250 mm thick. Table 4 pre-

sents data for the wall specimens. The specified concrete

compressive strength was 27.6 MPa, while the steel yield

stress for the vertical bars and the deformed wires were 414

and 620 MPa, respectively.

The measured and calculated yield and ultimate displace-

ments and displacement ductility for the UCI

13,14

wall spec-

imens are presented in Table 5. The percentage differences

between the measured and calculated values are presented

for comparison. An average difference of 0.8% with =

7.1% was found between the measured and calculated yield

Table 3Comparison of measured and calculated displacements and displacement ductilities for

University of Nevada, Reno wall specimens

Specimen

no.

Yield point Ultimate point Ductility

Calculated

curvature,

10

5

rad/mm

Displacement, mm

Calculated

curvature,

10

4

rad/mm

Displacement, mm

Calculated

curvature

ductility

Displacement ductility

d

Calculated Measured

Difference,

% Calculated Measured

Difference,

% Calculated Measured

Difference,

%

1 743 32.6 32.5 0.2 1224 211.3 230.5 9.1 16.5 7.1 6.5 8.7

2 728 32.2 27.5 16.9 1212 192.5 227.8 18.3 16.6 7.1 7.0 1.2

3 731 30.3 25.0 21.0 1204 187.5 224.8 19.9 16.5 7.4 7.5 0.9

4 786 41.9 41.5 1.0 1243 240.7 259.3 7.7 15.8 6.2 5.8 6.6

5 804 42.6 42.5 0.3 1301 242.3 271.3 12.0 16.2 6.4 5.7 11.6

6 798 39.7 42.5 6.5 1298 257.7 267.0 3.6 16.3 6.7 6.1 10.9

7 686 19.5 17.5 11.1 1074 157.5 177.8 12.9 15.7 9.1 9.0 1.6

Average 6.3 11.9 5.7

10.2 5.8 5.1

Table 1Vertical and transverse reinforcement for wall specimens tested at

University of Nevada, Reno

Specimen

Vertical reinforcement Transverse reinforcement

No.

Reinforcing

bar

v

, % S

h

, mm

No.

Reinforcing

bar

1

, % S

v

, mm

1 18 16 0.78 180 16 10 0.14 320

2 18 16 0.78 180 28 10 0.25 182

3 18 16 0.78 180 28 10 0.25 182

4 24 19 1.47 130 16 10 0.14 320

5 24 19 1.47 130 28 10 0.25 182

6 24 19 1.47 130 28 10 0.25 182

7 10 13 0.28 360 16 10 0.14 320

Table 2Crosstie reinforcement for wall specimens tested at University of

Nevada, Reno

Specimen

Lower crosstie reinforcement Upper crosstie reinforcement

H, mm No. Bar

c

, % S

v

, mm

H, mm No. Bar

c

, % S

v

, mm

1 956 21 10 0.10 320 63.75 35 10 0.10 320

2 910 20 10 0.10 182 65.50 36 10 0.10 182

3 910 40 10 0.20 182 65.50 36 10 0.10 182

4 956 18 10 0.09 320 63.75 30 10 0.09 320

5 910 20 10 0.10 182 65.50 36 10 0.10 182

6 910 40 10 0.20 182 65.50 36 10 0.10 182

7 1275 20 10 0.07 255 51.00 20 10 0.07 255

ACI Structural Journal/January-February 2001 7

displacements, while it was 0.9% with = 8.8% for the ulti-

mate displacement. As for the displacement ductility capac-

ity, the average difference was 1.5% with = 8.9%.

Based on the good correlation between the analytical and

experimental results, it was concluded that the analytical

model is a reliable tool for seismic response analysis of pier

walls for out-of-plane loading.

PARAMETRIC STUDY

In performing the parametric study, 120 pier walls were

analyzed using the computer program Pier. The low-cycle

fatigue of the vertical bars was considered by applying two

cycles at each displacement ductility level. The parameters

included in this study were the ratio of the wall height to its

thickness, the vertical reinforcement ratio, the confinement-

reinforcement ratio, and the axial load index. The reinforce-

ment ratio is defined as the area of the reinforcing bars to the

cross-sectional area of the wall normal to the bars direction.

The confinement-reinforcement ratio included the transverse

(running parallel to the long direction of the wall section)

and crosstie reinforcement ratios. The axial load index is de-

fined as the axial load divided by the product of the gross

sectional area of the wall and the specified concrete com-

pressive strength. The selected ranges for the parameters

were based on the state departments of transportation sur-

vey.

7

Table 6 lists the range of the parameters in the survey

and the selected values for the parametric study. The general

rule to select the values for different parameters was to

choose those that are more likely to be critical in terms of

their values and presence in the database, taking into account

the mean and standard deviation values. For example, the

confinement-reinforcement ratio was limited to 0.4%, even

though some walls in the database had a reinforcement ratio

exceeding 1%. Note that the average value for confinement-

reinforcement ratio in the database was 0.19%, and the stan-

dard deviation was 0.17%.

The ratio of the wall height to its thickness ranged from 2

to 15 to represent a wide range of short to tall walls. Walls

with higher aspect ratio were excluded because of their very

low population in the database. The transverse and crosstie

reinforcement ratios were taken equal to each other. An axial

load index of 10% is believed to be the upper bound for

bridge pier walls and should account for extra loads due to

the vertical earthquake component. The wall cross section

was taken as 300 x 1500 mm. The concrete compressive

strength was taken as 31 MPa, while the steel yield stress

was taken as 448.2 MPa. The yield strain, strain hardening,

and ultimate strain of the steel were taken as 0.0022, 0.01,

and 0.1, respectively. The ultimate steel stress was assumed

as 620 MPa. Data for selected representative cases are pre-

sented in Table 7.

Results of parametric study

The analysis results for selected cases are presented in

Table 8. The relationship between the yield displacement

y

and the ratio of the wall height to its thickness H/t at an axial

load index of 5% and a confinement-reinforcement ratio of

0.1% is presented in Fig. 6. Figure 7 shows the ultimate dis-

placement versus H/t at a confinement-reinforcement ratio of

0.1% and an axial load index of 5%. The relationship between

the displacement ductility capacity

d

and H/t ratio at an axial

load index of 5% is presented in Fig. 8 to 10. Figure 11 to 13

show the

d

and H/t relationship at an axial load index of 10%.

When the vertical reinforcement ratio

v

was increased for

cases with the same H/t and confinement reinforcement, the

yield curvature and moment were increased as expected.

Fig. 4Measured and calculated lateral displacements for

test specimens.

Fig. 5Measured and calculated displacement ductility for

test specimens.

Table 4Data for wall specimens tested at UCI

13,14

Specimen

Vertical

steel ratio

v

, %

Lateral

steel ratio

1

, %

Crosstie

steel ratio,

c

, %

Measured

concrete

strength,

MPa

Axial load,

kN

WC1

13

0.56 0.15 NA 26.6 275.8

WC2

13

0.56 0.15 NA 36.9 275.8

WC3

13

0.56 0.15 NA 38.6 275.8

LN

14

1.30 0.25 NA 28.4 880.8

LP

14

1.30 0.25 0.16 25.3 880.8

LU

14

1.30 0.25 0.08 25.3 880.8

HN

14

2.30 0.25 NA 32.2 1000.9

HP

14

2.30 0.25 0.16 28.4 1000.9

HU

14

2.30 0.25 0.08 32.2 1000.9

8 ACI Structural Journal/January-February 2001

Because the cracked wall stiffness was independent of

v

,

the deflections due to flexure and shear at the yield point

were increased (Fig. 6). In most cases with confinement-re-

inforcement ratios of 0.25 and 0.4%, and vertical reinforce-

ment ratios of 0.5 and 1%, the ultimate point was controlled

by low-cycle fatigue of the vertical bars (Fig. 9, 10, 12, and

13). The cases that failed in low-cycle fatigue resulted in the

irregularity of the curves (Fig. 9, 10, and 13) because of the

discrete character of the low-cycle fatigue model. When the

failure was controlled by compression crushing of concrete,

high

v

reduced the ultimate deflection. On the contrary, high

v

increased the ultimate displacement when the failure was

controlled by low-cycle fatigue. Nevertheless, the displace-

ment ductility capacity dropped for both failure modes because

of relatively high yield displacement (the denominator in duc-

tility ratio). A similar trend was observed when the axial load

index was increased from 5 to 10%.

In cases with confinement-reinforcement ratio of 0.1%

(lower than 0.25%, the minimum required by AASHTO

1

and

Caltrans

2

) and the axial load index of 5%, the displacement

ductility capacity was nearly constant for walls with the

same vertical reinforcement ratio and H/t 4 (Fig. 8). On the

Table 5Comparison of measured and calculated displacements and

displacement ductilities for UCI wall specimens

13,14

Specimen

Yield displacement, mm Ultimate displacement, mm Displacement ductility

Measured Calculated

Difference,

% Measured Calculated

Difference,

% Measured Calculated

Difference,

%

WC1 17.8 20.1 11.5 153.3 195.6 21.7 8.6 9.8 11.5

WC2 16.5 16.4 0.5 195.0 200.8 2.9 11.8 12.2 3.3

WC3 16.5 16.0 3.1 195.0 203.6 4.2 11.8 12.7 7.1

LN 46.5 45.7 1.7 202.5 190.4 6.4 4.4 4.2 4.6

LP 44.8 47.4 5.6 275.0 252.7 8.8 6.1 5.3 15.3

LU 44.8 47.5 5.7 252.5 247.0 2.2 5.6 5.2 8.4

HN 62.0 58.4 6.2 250.0 242.9 2.9 4.0 4.2 3.1

HP 66.8 61.3 8.8 298.8 297.9 0.3 4.5 4.9 7.8

HU 64.3 58.8 9.3 260.0 260.4 0.2 4.0 4.4 8.6

Average 0.8 0.9 1.5

7.1 8.8 8.9

Fig. 6Yield displacement versus H/t for P/(f

c

.A

g

) = 5%

and

1

and

c

= 0.1%.

Fig. 7Ultimate displacement versus H/t for P/(f

c

.A

g

) =

5% and

1

and

c

= 0.1%.

Table 6Selected values for parameters

Parameter Units

Survey

7

range

Selected

values Minimum Maximum Average

Wall height to its thickness ratio H/t 2.75 18.22 10.27 3.28

2, 4, 7, 10,

15

Vertical steel ratio

v

% 0.21 3.77 1.26 0.86

0.5, 1.0,

1.75, 2.5

Confinement-reinforcement ratio

1

and

c

% 0.01 1.02 0.19 0.17 0.1, 2.5, 0.4

Axial load index P/A

g

. f

c

% 0.90 6.70 3.57 1.67 5, 10

ACI Structural Journal/January-February 2001 9

contrary, in walls with H/t < 4, the displacement ductility ca-

pacity was sensitive to H/t. Another important observation in

Fig. 8 is that, despite the very low amount of confinement re-

inforcement, ductile behavior is expected for walls as long as

the vertical reinforcement ratio is 1% or less. This indicates that

it is the relative value of the confinement reinforcement and the

vertical reinforcement that affects the ductility capacity. When

the axial load index was raised from 5 to 10%, the displacement

ductility capacity dropped and was nearly the same for wall cas-

es with H/t 4 (Fig. 11). The displacement ductility capacity

was improved considerably when the confinement-reinforce-

ment ratio was raised from 0.1 to 0.25%, particularly for high

vertical reinforcement ratios (Fig. 8 and 9). The change in

d

was not that significant for walls with an axial load index of 5%

when the confinement-reinforcement ratio was changed from

0.25 to 0.4% (Fig. 9 and 10). When the axial load index was

10% and the vertical reinforcement ratio was equal to 1.75% or

more,

d

was enhanced significantly by increasing the confine-

ment reinforcement (Fig. 11 to 13).

PROPOSED METHOD

Based on the results of the parametric study, an approach

to relate the confinement reinforcement to the displacement

ductility capacity of pier walls was developed. The analyti-

cal models used in the parametric study were checked by an-

alyzing pier wall specimens that were tested at the University

of Nevada, Reno, and UCI. Good agreement was found

when comparing the analytical and experimental results for

Fig. 8Ductility versus H/t for P/(f

c

.A

g

) = 5% and

1

and

c

= 0.1%.

Table 7Data for selected cases in parametric

study

Wall case

Wall height

to thickness

H/t

Wall

height, mm

Vertical

steel ratio,

v

, %

Confine-

ment steel

ratio

1

and

c

, %

Axial load

index,

P/(A

g

.f

c

),

%

C-1 2 600 0.50 0.10 5

C-2 4 1200 0.50 0.10 5

C-3 7 2100 0.50 0.10 5

C-4 10 3000 0.50 0.10 5

C-5 15 4500 0.50 0.10 5

C-61 2 600 0.50 0.10 10

C-62 4 1200 0.50 0.10 10

C-63 7 2100 0.50 0.10 10

C-64 10 3000 0.50 0.10 10

C-65 15 4500 0.50 0.10 10

C-116 2 600 2.50 0.40 10

C-117 4 1200 2.50 0.40 10

C-118 7 2100 2.50 0.40 10

C-119 10 3000 2.50 0.40 10

C-120 15 4500 2.50 0.40 10 Fig. 9Ductility versus H/t for P/(f

c

.A

g

) = 5% and

1

and

c

= 0.25%.

Fig. 10Ductility versus H/t for P/(f

c

.A

g

) = 5% and

1

and

c

= 0.4%.

10 ACI Structural Journal/January-February 2001

the pier wall specimens. The confinement-reinforcement ra-

tio was normalized relative to the vertical reinforcement ra-

tio and used in the equation. Figure 14 to 17 show the

relationships between the displacement ductility capacity and

the normalized confinement-reinforcement ratio. Two H/t

ranges were considered to distinguish between tall walls and

short walls. The selection of the H/t ranges was based on the

results of the parametric study. Note that in all the analyses,

the lateral and crosstie reinforcement ratios were assumed to

be the same. A best fit was used for each axial load index.

The best-fit curve is given by the following equation

(1)

where

d

a b

t

v

----- + =

t

= confinement-reinforcement ratio (in this study, tak-

en equal to

1

, lateral steel ratio, or

c

, crosstie steel ratio);

and

a, b = fitting constants.

Equation 1 was developed for

t

/

v

in the range of 0.04

and 0.8. Table 9 presents the fitting constants (a, b) for each

axial load index and H/t range. For an axial load index of 5%,

the first constant a was 3.0 and 2.5 for H/t 4 and H/t < 4,

respectively. When the axial load index was 10%, the con-

stant a was 1.5 for H/t 4, while it was 1.1 for H/t < 4. The

constant b was found to be 8.3 for all axial load indexes and

H/t values.

The following equations were developed for the best fit

curves:

For axial load index of 5% and H/t 4

Table 8Results for selected cases in parametric study

Case

Yield deflections, mm Ultimate deflections, mm

d

d

f

d

b

d

sh

d

t

d

f

d

b

d

sh

d

t

C-1 1.0 0.9 2.6 4.4 15.7 5.6 3.0 24.3 5.47

C-2 3.8 1.8 2.6 8.2 43.8 11.2 3.0 58.0 7.12

C-3 11.5 3.1 2.6 17.2 106.9 19.6 3.0 129.4 7.51

C-4 23.5 4.4 2.6 30.6 195.1 28.0 3.0 226.1 7.40

C-5 52.6 8.4 2.6 63.5 418.5 52.3 3.0 473.8 7.46

C-61 1.1 1.0 3.6 5.6 10.1 2.9 3.7 16.7 2.97

C-62 4.4 2.0 3.6 9.9 28.8 5.8 3.7 38.3 3.89

C-63 13.3 3.4 3.6 20.3 71.7 10.1 3.7 85.5 4.22

C-64 27.2 4.9 3.6 35.6 132.3 14.5 3.7 150.4 4.23

C-65 61.7 9.2 3.5 74.4 285.4 27.0 3.7 316.1 4.25

C-116 1.7 2.9 2.5 7.2 24.0 13.5 3.1 40.5 5.66

C-117 6.9 5.8 2.5 15.2 65.7 26.9 3.1 95.6 6.28

C-118 21.1 10.1 2.5 33.8 152.0 47.1 3.1 202.2 5.98

C-119 43.1 14.5 2.5 60.1 267.1 67.3 3.1 337.4 5.61

C-120 97.0 21.7 2.5 121.2 522.5 100.9 3.1 626.4 5.17

Fig. 11Ductility versus H/t for P/(f

c

.A

g

) = 10% and

1

and

c

= 0.1%.

Fig. 12Ductility versus H/t for P/(f

c

.A

g

) = 10% and

1

and

c

= 0.25%.

ACI Structural Journal/January-February 2001 11

(2)

For axial load index of 5% and H/t < 4

(3)

For axial load index of 10% and H/t 4

(4)

For axial load index of 10% and H/t < 4

(5)

Curves parallel with the best fit

d

versus

t

/

v

curves were

plotted (Fig. 14 to 17) to establish the lower bound of the dis-

placement ductility capacity. No particular rules were applied

to obtain the lower bound curves except that they needed to be

below nearly all the points. The lower-bound curves are in-

tended to be conservative and are recommended for design of

confinement reinforcement for a target displacement ductility

d

3.0 8.3

t

v

----- + =

d

2.5 8.3

t

v

----- + =

d

1.5 8.3

t

v

----- + =

d

1.1 8.3

t

v

----- + =

or to determine a conservative estimate of

d

for a given pier

wall.

For axial load index of 5% and H/t 4

(6)

For axial load index of 5% and H/t < 4

(7)

d

1.75 8.3

t

v

----- + =

d

1.25 8.3

t

v

----- + =

Fig. 13Ductility versus H/t for P/(f

c

.A

g

) = 10% and

1

and

c

= 0.4%. Fig. 14Displacement ductility versus

t

/

v

for P/(f

c

.A

g

) =

5% and H/t 4.

Fig. 15Displacement ductility versus

t

/

v

for P/(f

c

.A

g

) =

5% and H/t < 4.

Table 9Fitting constants

Axial load index P/(f

c

.A

g

)

H/t

Best fit Lower bound

a b a b

5%

4 3.0 8.3 1.75 8.3

< 4 2.5 8.3 1.25 8.3

10%

4 1.5 8.3 0.50 8.3

< 4 1.1 8.3 0.00 8.3

12 ACI Structural Journal/January-February 2001

For axial load index of 10% and H/t 4

(8)

For axial load index of 10% and H/t < 4

(9)

d

0.5 8.3

t

v

----- + =

d

8.3

t

v

----- =

Equation (6) and (8) were combined into one equation

(Eq. (10)), while Eq. (7) and (9) were combined into another

(Eq. (11)). The ductility ratio was assumed to be a linear func-

tion of the axial load in combining the equations.

For H/t 4

(10)

For H/t < 4

(11)

Equation (10) and (11) can be rewritten as following

(12)

where is a factor that depends on H/t; = 1.2 for H/t 4;

and = 1 for H/t < 4.

Equation (12) is plotted for axial load index values ranging

from 5 to 10% in Fig. 18 and 19. The figures or Eq. (12) can

be used to design the confinement reinforcement or to esti-

mate the displacement ductility capacity of given pier walls

following the steps shown in the following section.

Design of confinement reinforcement

1. Determine the axial load index based on the axial load,

probable concrete strength, and cross section dimensions;

2. Estimate the displacement ductility demand from a non-

linear analysis or based on other criteria;

3. Use the curves in Fig. 18 or 19 (depending on the H/t)

or Eq. (12) to determine the required

t

/

v

. Use linear inter-

polation for axial load indices between 5 and 10% if using

the plots;

4. Design the transverse reinforcement and crossties using

t

for each; and

5. If the axial load index is less than 5%, use the 5% curve

for a conservative estimate of

t

/

v

.

Estimate of displacement ductility capacity

1. Determine the axial load index based on the axial load,

probable concrete strength, and cross section dimensions;

2. Determine

t

as the average of lateral and crosstie re-

inforcement ratio;

3. Determine

t

/

v

;

4. Using

t

/

v

and Eq. (12) or the appropriate curve for H/t

and the axial load index, determine the displacement ductility.

Use linear interpolation for axial load indices between 5 and

l0%; and

5. If the axial load index is less than 5%, use the 5% curve

for a conservative estimate of

d

.

COMPARISON OF PROPOSED AND OTHER

METHODS

No performance-based design methods for the confine-

ment reinforcement of walls for out-of-plane loading are

available. Three methods can be found, however, in the liter-

ature for columns. Paulay and Priestley

4

developed an equa-

tion that accounts for the axial load level and the curvature

ductility capacity. Wehbe, Saiidi, and Sanders

5

proposed an

equation to calculate the lateral reinforcement in rectangular

d

3 25

P

A

g

f

c

------------ 8.3

t

v

----- + =

d

2.5 25

P

A

g

f

c

------------ 8.3

t

v

----- + =

d

2.5 25

P

A

g

f

c

------------ 8.3

t

v

----- + =

Fig. 16Displacement ductility versus

t

/

v

for P/(f

c

.A

g

) =

10% and H/t 4.

Fig. 17Displacement ductility versus

t

/

v

for P/(f

c

.A

g

) =

10% and H/t < 4.

ACI Structural Journal/January-February 2001 13

bridge columns based on a target displacement ductility.

Sheikh and Khoury

6

modified the ACI

3

code equation for

the confinement reinforcement of columns to account for the

axial load level and the curvature ductility demand.

The displacement ductility capacity and the curvature duc-

tility capacity for the seven wall specimens reported in Refer-

ence 7 were calculated using the proposed approach, the

Wehbe, Saiidi, and Sanders

5

method, and the Sheikh and

Khoury

6

method for the purpose of comparison. The Paulay

and Priestley

4

method was not considered for comparison be-

cause it can be used only in columns with an axial load index

of 8% or more while the axial load index of the wall speci-

mens was 5%.

Because the proposed approach and the Wehbe, Saiidi, and

Sanders

5

method relate the confinement-reinforcement ratio

to

d

, while the Sheikh and Khoury

6

method relates the con-

finement-reinforcement ratio to

, the analysis results of the

wall specimens

7

using Pier were used to relate the displace-

ment ductility to the curvature ductility (Table 3). The average

ratio of

d

/

was found to be 0.44, with a standard deviation

of 0.01 for Specimens 1, 2, and 3. For Specimens 4, 5, and 6,

the average ratio of

d

/

was 0.40, with a standard deviation

of 0.01. The

d

/

ratio was found to be 0.58 for Specimen

7.

Wehbe, Saiidi, and Sanders

5

equation

Wehbe, Saiidi, and Sanders

5

proposed the following equa-

tion to calculate the amount of lateral reinforcement in the

plastic hinge zone of rectangular bridge columns with differ-

ent levels of confinement based on the attainable displace-

ment ductility

(13)

where

A

sh

= lateral reinforcement area;

s = spacing of transverse reinforcement along the mem-

ber axis;

h

c

= dimension of column core measured center-to-cen-

ter of confining reinforcement;

d

= the target displacement ductility;

f

c,n

= specified concrete compressive strength;

f

ce

= expected concrete compressive strength;

f

ye

= expected longitudinal steel yield stress;

P = axial load;

A

g

= sectional gross area;

1

= longitudinal reinforcement ratio;

f

y

= specified longitudinal steel yield stress; and

f

s,n

= specified steel yield stress.

Equation (13) was verified against experimental results

obtained from test on flexure-dominated rectangular and

square bridge columns with an axial load index below 60%.

Sheikh and Khoury

6

equation

Sheikh and Khoury

6

proposed a design approach for the

confinement reinforcement in tied columns based on the ex-

perimental results of 29 column specimens. The relationship

between the amount of lateral reinforcement as recommend-

ed by the ACI

3

code A

sh,c

and the suggested amount of later-

al reinforcement A

sh

is given by

(14)

where Y is a factor expressed as

(15)

A

sh

sh

c

-------- 0.1

d

f

c n ,

f

ce

-------- 0.12

f

ce

f

ye

-------- 0.5 1.25

P

f

ce

A

g

-------------- +

,

_

+ =

0.13

1

f

y

f

s n ,

--------

,

_

0. 01

A

s h

A

s h c ,

( )Y =

Y Y

p

Y

=

Fig. 18Displacement ductility versus

t

/

v

for H/t 4

(design curve).

Fig. 19Displacement ductility versus

t

/

v

for H/t < 4

(design curve).

ACI Structural Journal/January-February 2001 14

The parameters Y

p

and Y

take into account the effect of

axial load level and the section ductility demand, respective-

ly. The factor is used to account for the confinement effi-

ciency. Three categories for lateral reinforcement configuration

were identified. Category I represents columns with single-pe-

rimeter hoops. Categories II and III represent columns with

perimeter hoops and ties to support the longitudinal bars. For

Category I, the average value of is equal to 2.5, while it is

equal to unity for Categories II and III. The following ex-

pression is the proposed final form to calculate the amount of

lateral reinforcement in tied columns

(16)

A

sh,c

is the greater of

(17)

and

(18)

where

P = applied axial load

P

o

= ultimate load capacity

= curvature ductility factor;

A

ch

= cross section area measured out-to-out of transverse

reinforcement; and

f

yh

= specified steel yield stress for lateral reinforcement.

Comparison of results

The displacement ductility capacity of the pier wall

specimens

7

was evaluated using the proposed approach and

the Wehbe, Saiidi, and Sanders

5

methods. Measured materi-

al properties were used. The displacement ductility listed

under Sheikh and Khoury

6

was based on the curvature duc-

tilities and used the

d

/

ratios that were discussed in the

previous section. Table 10 presents a comparison of the

measured and the calculated displacement ductilities. Table

11 lists the curvature ductilities. The ductilities listed under

the proposed and the Wehbe, Saiidi, and Sanders

5

methods

were based on

d

and the

d

/

ratios presented in the pre-

vious section, while those listed under Sheikh and Khoury

6

were found directly from Eq. (16). Note that Sheikh and We-

hbe methods were developed for columns and not walls.

They are presented in this paper to explore their applicabil-

ity to walls.

Because the displacement and curvature ductilities were

proportional, the calculated and measured ratios were the

same for both (Table 10 and 11). It can be seen in the tables

A

s h

1 13

P

P

o

------

,

_

5

+

)

' ;

( )

1.15

2 9

------------------A

s h c ,

=

A

s h c ,

0.3sh

c

f

c

f

y

-----

A

g

A

ch

--------

,

_

1 =

A

s h c ,

0.09sh

c

f

c

f

yh

------ =

Table 10Measured and calculated displacement ductilities

d

Specimen

Measured

d

Calculated displacement

ductility

d

Ratio of calculated to measured

d

Proposed

approach

7

Sheikh and

Khoury

6

Wehbe, Saiidi,

and Sanders

5

Proposed

approach

7

Sheikh and

Khoury

6

Wehbe, Saiidi,

and Sanders

5

1 6.50 5.01 1.73 3.74 0.77 0.27 0.58

2 7.00 5.68 1.73 6.79 0.81 0.25 0.97

3 7.50 6.21 2.99 6.65 0.83 0.40 0.89

4 5.80 4.12 1.46 3.15 0.71 0.25 0.54

5 5.70 4.61 1.82 5.95 0.81 0.32 1.04

6 6.10 5.00 3.18 5.86 0.82 0.52 0.96

7 9.00 6.83 1.72 4.39 0.76 0.19 0.49

Average 0.79 0.31 0.78

Standard deviation 0.04 0.11 0.24

Table 11Measured and calculated curvature ductilities

Specimen

Measured

Calculated displacement

ductility

Ratio of calculated to measured

Proposed

approach

7

Sheikh and

Khoury

6

Wehbe, Saiidi,

and Sanders

5

Proposed

approach

7

Sheikh and

Khoury

6

Wehbe, Saiidi,

and Sanders

5

1 14.92 11.49 3.97 8.59 0.77 0.27 0.58

2 16.07 13.04 3.97 15.59 0.81 0.25 0.97

3 17.22 14.25 6.86 15.26 0.83 0.40 0.89

4 14.50 10.30 3.64 7.87 0.71 0.25 0.54

5 14.25 11.53 4.56 14.87 0.81 0.32 1.04

6 15.25 12.49 7.95 14.65 0.82 0.52 0.96

7 15.49 11.76 2.96 7.56 0.76 0.19 0.49

Average 0.79 0.31 0.78

Standard deviation 0.04 0.11 0.24

ACI Structural Journal/January-February 2001 15

that the ductility calculated based on the proposed method

ranged between 71 and 83% of the measured ductility, with

an average of close to 80% and standard deviation of 4%.

The Wehbe, Saiidi, and Sanders

5

method slightly overesti-

mated the ductility capacity of Specimen 5. The calculated

ductility using the Wehbe Saiidi, and Sanders.

5

method

ranged between 58 and 106% with an average of 78% and

of 24%. Using the Sheikh and Khoury

6

method, the calcu-

lated ductility ranged between 19 and 52%, with an average

of 31% and of 11%. The results demonstrate that the pro-

posed method leads to a reliable, yet conservative estimate

of wall ductilities. The relatively wide scatter in the correla-

tion between Wehbes results and test data suggests that

Wehbes method for columns is not applicable for walls.

The data also show that Sheikhs method for columns

should not be used for walls.

CONCLUSIONS

A new performance-based design method for the confine-

ment reinforcement in the plastic hinge zone of bridge pier

walls subjected to out-of-plane loading was developed. The

proposed method is recommended for design of walls be-

cause, unlike other available methods that are based on tests

of columns, the proposed method is calibrated against pier

wall data.

The proposed method can also be used to evaluate the

ductility capacity of bridge pier walls. The mean calculated

ductility capacity for the pier walls specimens

7

using the

proposed method was nearly 80% of the measured value

with a standard deviation of 4%. By comparing the ductility

demand and capacity, bridge pier walls that need retrofit can

be identified.

The parametric studies showed that for lightly reinforced

walls (longitudinal reinforcement ratio of less than 1%)

when the axial load index is 5% or less, which is typical in

bridge pier walls, a displacement ductility capacity of 6 or

more would be expected even with lateral reinforcement ra-

tios that violate the code by 60%.

ACKNOWLEDGMENTS

The research presented in this paper was sponsored by the Federal High-

way Administration (FHWA) through the Multidisciplinary Center for

Earthquake Engineering Research (MCEER) at the State University of New

York, Buffalo, N.Y.

REFERENCES

1. American Association of State Highway and Transportation Officials

(AASHTO), Standard Specifications for Highway Bridges, 15th Edition,

1992.

2. Department of Transportation: State of California, Bridge Design

Specifications, June, 1990.

3. ACI Committee 318, Building Code Requirements for Reinforced

Concrete (ACI 318-95) and Commentary (318R-95), American Concrete

Institute, Farmington Hills, Mich., 1995, 369 pp.

4. Paulay, T., and Priestley, M. J. N., Seismic Design of Reinforced

Concrete and Masonry Buildings, John Wiley & Sons, Inc., New York,

1992.

5. Wehbe, N.; Saiidi, M.; and Sanders, D., Seismic Performance of

Rectangular Bridge Columns with Moderate Confinement, ACI Structural

Journal, V. 96, No. 2, Mar.-Apr. 1999, pp. 248-258.

6. Sheikh, S., and Khoury, S., A Performance-Based Approach for the

Design of Confining Steel in Tied Columns, ACI Structural Journal, V. 94,

No. 4, July-Aug. 1997, pp. 421-431.

7. Abo-Shadi, N.; Saiidi, M.; and Sanders, D., Seismic Response of

Bridge Pier Walls in the Weak Direction, Civil Engineering Department,

University of Nevada, Reno, Report No. CCEER-99-3, Apr. 1999.

8. Park, R., and Paulay, T., Reinforced Concrete Structures, John Wiley

& Sons, New York, 1975.

9. Mander, J. B.; Priestley, M. J. N.; and Park, R., Theoretical Stress-

Strain Model for Confined Concrete Columns, ASCE Journal of Struc-

tural Engineering, V. 114, No. 8, Aug. 1988, pp. 1804-1826.

10. Mander, J. B., Seismic Design of Bridge Piers, PhD thesis, Univer-

sity of Canterbury, New Zealand, 1983, 442 pp.

11. Manson, S. S., Behavior of Materials under Conditions of Thermal

Stresses, Heat Transfer Symposium, University of Michigan Engineering

Research Institute, Ann Arbor, Mich., 1953, pp. 9-75.

12. Miner, M. A., Cumulative Damage in Fatigue, Transactions, ASME,

Journal of Applied Mechanics, V. 67, 1945, pp. A159-A164.

13. Haroun, M. A.; Pardoen, G. C.; Shepherd, R.; Hagag, H. A.; and

Kazanjy, R. P., Cyclic Behavior of Bridge Pier Walls for Retrofit, Final

Report to the California Department of Transportation, Dec. 1993.

14. Haroun, M. A.; Pardoen, G. C.; Shepherd, R.; Hagag, H. A.; and Kaza-

njy, R. P., Assessment of Cross-Tie Performance in Bridge Pier Walls,

Final Report to the California Department of Transportation, Dec. 1994.

Anda mungkin juga menyukai

- Powerhouse Mandoor Canopy As-Built DrawingDokumen2 halamanPowerhouse Mandoor Canopy As-Built DrawingKader Newaj SakibBelum ada peringkat

- NBCC2010 Earthquake DesignDokumen20 halamanNBCC2010 Earthquake DesignKader Newaj Sakib100% (1)

- Tut 1Dokumen5 halamanTut 1Kader Newaj SakibBelum ada peringkat

- Quran Arabic Translation Bangla Hight QualityDokumen1.131 halamanQuran Arabic Translation Bangla Hight Qualityallbdbooks100% (6)

- UBC Okanagan Calendar Fees 14 15Dokumen19 halamanUBC Okanagan Calendar Fees 14 15Kader Newaj SakibBelum ada peringkat

- LVDT 2012Dokumen2 halamanLVDT 2012Kader Newaj SakibBelum ada peringkat

- ATC 58 50percentdraftDokumen332 halamanATC 58 50percentdraftKader Newaj SakibBelum ada peringkat

- Assignment-1 Tall BuildingDokumen5 halamanAssignment-1 Tall BuildingKader Newaj SakibBelum ada peringkat

- Fema 461Dokumen138 halamanFema 461Kader Newaj Sakib100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Cataloque Torc-Tensionador-TentecDokumen11 halamanCataloque Torc-Tensionador-TentecDeividas BBelum ada peringkat

- 4301 L 2 - 2006Dokumen23 halaman4301 L 2 - 2006Indra H BasriBelum ada peringkat

- Reginald Anesu Tobaiwa: Professional ProfileDokumen2 halamanReginald Anesu Tobaiwa: Professional ProfileARUN VISHWAKARMABelum ada peringkat

- MACNEAL - Perspective On Finite Elements For Shell AnalysisDokumen12 halamanMACNEAL - Perspective On Finite Elements For Shell AnalysisTakis PlimirasBelum ada peringkat

- User Manual: BA and BA-C SeriesDokumen138 halamanUser Manual: BA and BA-C SeriesNAHASALI11Belum ada peringkat

- Manual de Entrenamiento cfm56Dokumen216 halamanManual de Entrenamiento cfm56Reinaldo Orejuela100% (2)

- Stability-Calculation For PipelineDokumen2 halamanStability-Calculation For PipelineGeorge100% (1)

- Marine Elevators (200902)Dokumen6 halamanMarine Elevators (200902)Arky HarkyanBelum ada peringkat

- Sans Titre PDFDokumen1 halamanSans Titre PDFjoker63000Belum ada peringkat

- Flexible Grouted ClampDokumen14 halamanFlexible Grouted ClampMiroslav AleksicBelum ada peringkat

- Ficha Cat Excavadorahidraulica 324DLDokumen32 halamanFicha Cat Excavadorahidraulica 324DLAnthony Arturo Mestiza SalinasBelum ada peringkat

- SudcoCatalogRetailPriceList2012 2Dokumen173 halamanSudcoCatalogRetailPriceList2012 2Rodney Dale CollesterBelum ada peringkat

- AirsuspensionDokumen4 halamanAirsuspensionistvan szilard zoldBelum ada peringkat

- Atb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesDokumen4 halamanAtb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesAleBelum ada peringkat

- Conveyors and Conveying Systems (Lec1b)Dokumen81 halamanConveyors and Conveying Systems (Lec1b)Rhizhail100% (1)

- Population Balance Modelling To Describe The Particle Aggregation Process: A ReviewDokumen18 halamanPopulation Balance Modelling To Describe The Particle Aggregation Process: A ReviewAlexander FierroBelum ada peringkat

- 2004 Model T Ignition and TimingDokumen5 halaman2004 Model T Ignition and Timingjorge Angel LopeBelum ada peringkat

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Dokumen16 halamanEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Nicoleta cristianBelum ada peringkat

- IJSTM17451382214600Dokumen14 halamanIJSTM17451382214600Viraj GaonkarBelum ada peringkat

- Design of Shells (Example Problem)Dokumen5 halamanDesign of Shells (Example Problem)AkarshGowdaBelum ada peringkat

- CH 3 Review Load and Stress AnalysisDokumen33 halamanCH 3 Review Load and Stress AnalysisAnas TubailBelum ada peringkat

- IFC Series Y-Strainers: NotesDokumen30 halamanIFC Series Y-Strainers: Notesmarsha.fsdBelum ada peringkat

- Rotary Valve Functions BookletDokumen17 halamanRotary Valve Functions Bookletamahmoud3Belum ada peringkat

- Transport PhenomenaDokumen8 halamanTransport PhenomenawaqaskhanBelum ada peringkat

- A Technical Seminar On: Suspension SystemDokumen24 halamanA Technical Seminar On: Suspension SystemRanjan suvarnaBelum ada peringkat

- Briggs and Stratton 133412 - 0059 01 PartsMan (EN)Dokumen31 halamanBriggs and Stratton 133412 - 0059 01 PartsMan (EN)Gisell ZapataBelum ada peringkat

- Assignment - I 26 04 2020Dokumen2 halamanAssignment - I 26 04 2020JackBelum ada peringkat

- Comparison of Five Major Wind Codes PDFDokumen15 halamanComparison of Five Major Wind Codes PDFjoaobarbosa22Belum ada peringkat

- MachineryDokumen8 halamanMachineryPalapa 1Belum ada peringkat

- Fluid Mechanics 3 - 4: Incompressible Potential FlowsDokumen28 halamanFluid Mechanics 3 - 4: Incompressible Potential FlowsDrEmadEl-SaidBelum ada peringkat