SAIC-B-2015 Rev 2

Diunggah oleh

ரமேஷ் பாலக்காடுHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SAIC-B-2015 Rev 2

Diunggah oleh

ரமேஷ் பாலக்காடுHak Cipta:

Format Tersedia

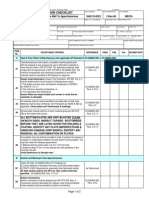

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

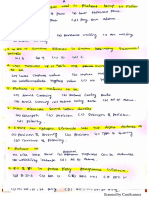

ACCEPTANCE CRITERIA General Requirements (As Applicable) Special protection for fixed extinguishing/suppression systems: A) Fixed carbon dioxide (CO2) (See Sect 2, 3 Checklists) B) Fixed dry chemical system (Section 4, 5, 6 Checklists) C) Fixed wet chemical system (Section 7, 8 Checklists) D) Fixed Halon 1301 system (Section 9, 10 Checklists) E) Other Fixed systems (approved by Chief Fire Prevention Eng.) Areas covered by special fixed equipment are as follows: A) Kitchen exhaust hood & vent systems & cooking appliances B) Gas turbine enclosures C) Special labs & chemical storage rooms D) Communications rooms in critical communications facilities E) Computer rooms in central computer facilities F) Rotating power generating equipment enclosures. Where fixed extinguishing systems protect enclosures of rotating equipment, those systems are furnished by the equipment vendor. These systems have 100% spare agent cylinders readily available. All new fire protection equipment is inspected and tested by the Fire Protection Department before placing in service. Fixed CO2 Systems (NFPA 12 & GI-1781.001 Supplement 29) CO2 systems are prohibited for normally manned areas. CO2 system design & installation follows NFPA 12 requirements and Saudi Aramco SAES-B-019 exceptions listed below. CO2 systems have an alarm warning device that activates 30 seconds prior to any discharge of CO2 into the area. Lock-out device to disarm CO2 systems if personnel are present is installed (unless omission is approved by Chief Fire Prevention Eng) Enclosed rooms have an exterior exit door with panic hardware. Air-moving power & fire dampers (HVAC system) shut down upon system actuation. Determine proper CO2 system installation & functionality. Follow NFPA 12, Section 1-7.3 checklist items listed below. Completed CO2 systems are inspected and tested using qualified personnel to meet the approval of the authority having jurisdiction. Only listed or approved equipment and devices are used in system.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

SAES-B-019 Para 6.1

A2

SAES-B-019 Para 6.1

A3

SAES-B-019 Para 6.1 GI-1781.001, Section 4.1

A4 B B1

SAES-B-019 Para. 6.2 SAES-B-019 Para. 6.2 SAES-B-019 Para. 6.2 SAES-B-019 Para. 6.2 SAES-B-019 Para. 6.2 SAES-B-019 Para. 6.2 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3

B2

B3

B4

B5

B6

B7

B8

B9

Page 1 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. B10

ACCEPTANCE CRITERIA A thorough visual inspection of the installed CO2 system and hazard area has been performed (walkdown) Piping, operational equipment & discharge nozzles are inspected for proper size and location. Locations of alarms and manual emergency releases are correct. Configuration of the hazard is compared to the original hazard specification and is within design limits. The hazard is inspected closely for unclosable openings & sources of agent loss that could have been overlooked in the original spec. Labelling of devices is checked as follows: A) Proper designations and instructions exist. B) Nameplate data on storage containers matches specifications. Nondestructive operational tests are performed on devices (includes detection & actuation) to assure proper system function. A full discharge test is performed on all systems. Where multiple hazards are protected from a common supply, a full discharge test is performed for each hazard. Prior to testing, proper safety procedures are reviewed. Fixed CO2 Systems (GI-1781.001 Supp. 29 Insp & Testing) Control panels main power indicator is ON. (Weekly) System activation indicator on the fire alarm control panel is "OFF. Automatic fire detection system (AFDS) is on-line & operating. Normal power supply indicator is ON." Battery power indicator reads 12/ 24 VDC. Master alarm visual indicator is "OFF. Master trouble visual indicator is "OFF. Zone trouble visual indicator is "OFF. Lamp test lights all visual indicators when activated. Manual pull stations are in normal operational condition. Automatic fire detectors are in normal operational condition. All visual and audible alarms operate when tested.* Batteries support operation of the system when tested.* Alarm signal from tests* is received at remote monitoring stations. Logbook is provided & utilized Zone layout plan is available. Inspection tag (interval) and logbook are up-to-date. This 14-step AFDS checklist is used for all type fixed systems Pipe manifolds are painted & pipe is not subject to external loading

REFERENCE NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3 NFPA 12, Section 1-7.3

PASS

FAIL

N/A

RE-INSP DATE

B11

B12

B13

B14

B15

B16

B17

B18

C C1

GI-1781.001, Supplement 29 GI-1781.001, Supplement 29

C2

C3

GI-1781.001, Supplement 29

C4

GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29

C5

Pipe hangers are not damaged, loose, or missing.

C6

Manual discharge is in normal standby mode.

Page 2 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. C7

ACCEPTANCE CRITERIA Solenoid/pneumatic discharge valves are firmly attached to the cylinder head. Discharge nozzles are unobstructed.

REFERENCE GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29 GI-1781.001, Supplement 29

PASS

FAIL

N/A

RE-INSP DATE

C8

C9

Cylinder brackets are firmly attached to the cylinders.

C10

Operating instructions are posted and legible.

C11

All system hoses have valid hydrotest date (every five years). Master/pilot cylinder pressure gauge indicates correct pressure for ambient temperature. All cylinders are weighed and are fully charged.

C12

C13

C14

Cylinders have valid hydrostatic test date (every five years).

C15

Safety/warning signs are posted identifying the protected area.

C16

Protected space has not been altered. System alarm & equipment activates & operates properly. Alarm signals to building alarm control panel & remote stations test Test results are recorded in the logbook. Inspection tags are installed & updated (logbook utilized) Fixed Dry Chemical Systems (NFPA 17) Dry chemical systems are designed & installed per NFPA 17

C18

C19 D D1

SAES-B-019 Para 6.3 NFPA 17, Section 10.4 NFPA 17, Section 10.4 NFPA 17, Section 10.4 NFPA 17, Section 10.4 NFPA 17, Section 10.4 NFPA 17, Section 10.4 NFPA 17, Section 10.4

D2

The completed system is tested by qualified personnel. Tests determine that the system has been properly installed & will function as intended. Installers certify that installations are made in accordance with the approved plans and the listing of a testing laboratory. Acceptance tests include discharge of dry chemical in sufficient amount to verify the system is properly installed and functional. The method of verification shall be acceptable to the authority having jurisdiction. Piping is not hydrostatically tested. Dry gas is used as the medium.

D3

D4

D5

D6

D7

D8

Labeling of devices show proper designations & instructions exist.

Page 3 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. D9

ACCEPTANCE CRITERIA After discharge of dry chemical, all piping & nozzles are blown clean using compressed dry air or nitrogen. System is properly charged & placed in the normal "set" condition.

REFERENCE NFPA 17, Section 10.4 NFPA 17, Section 10.4 NFPA 17, Section 10.5

PASS

FAIL

N/A

RE-INSP DATE

D10

D11 E E1

Owner has manufacturer's installation & maintenance manuals

GI-1781.001 Supp. 30 (Dry Chemical System - Kitchen Hood Testing & Inspection) Control panels main power indicator is ON. (Weekly) System activation indicator on the fire alarm control panel is "OFF. Automatic fire detection system (AFDS) is on-line & operating. The 14-step AFDS checklist (see 3C) is applied Dry chemical level is "FULL." GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30 GI-1781.001, Supplement 30

E2

E3

E4

E5

Valves, pipes, and pipefittings are painted and not corroded.

E6

Manual actuators are unobstructed.

E7

Nozzle caps are intact and undamaged.

E8

Tamper indicators and seals are intact.

E9

Manual discharge button is provided with sealed safety pin.

E10

Fusible link/heat detectors are clean and not damaged.

E11

Cylinder/hose assemblies have valid hydrotest (every 12 years).

E12

Hoods & filters are free of combustibles & debris (accumulations).

E13

Operating instructions are posted and legible. System alarm & equipment activates & operates properly. Alarm signals to building alarm control panel & remote stations test Test results are recorded in the logbook. Inspection tags are installed & updated (logbook utilized)

E14

E15 F F1

GI-1781.001 Supp. 32 (Dry Chemical System - Industrial Plant Testing & Inspection) Control panels main power indicator is ON. (Weekly) GI-1781.001, Supplement 32

Page 4 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. F2

ACCEPTANCE CRITERIA System activation indicator on the fire alarm control panel is "OFF. Automatic fire detection system (AFDS) is on-line & operating. The 14-step AFDS checklist (see 3C) is applied Pilot cylinder disc/pneumatic valve is intact/closed.

REFERENCE GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32

PASS

FAIL

N/A

RE-INSP DATE

F3

F4

F5

Nitrogen cylinder(s) gauge reads 2000-2500 psig.

F6

Cylinder brackets are firmly attached.

F7

Nitrogen cylinder(s) has valid hydrotest date (every five years). Fusible links/automatic fire detection devices are all in normal standby mode, clean, and show no sign of damage. Pneumatic valves of each nitrogen cylinder are firmly attached.

F8

F9

F10

Nozzles are clean and not damaged.

F11

Cylinder/hose assemblies have valid hydrotest date (every 12 yrs).

F12

Operating instructions are posted and legible. System alarm & equipment activates & operates properly. Alarm signals to building alarm control panel & remote stations test Test results are recorded in the logbook. Inspection tags are installed & updated (logbook utilized) Fixed Wet Chemical Systems (NFPA 17A) for Kitchens Wet Chemical Systems are designed & installed per NFPA 17A. Kitchen exhaust and vent systems and other applications (requested by Chief Fire Prevention Engineer) utilize wet chemicals. Completed wet chemical systems are tested by trained personnel per manufacturers listed installation and maintenance manual. The system passed tests for properly installation & functionality Installers certified that the system was installed per approved plans and the manufacturers listed installation and maintenance manual. Where required by Company, the approval tests include discharge of wet chemical to verify system installation is functional. The owner shall be provided with a copy of the manufacturers listed installation and maintenance manual or listed owners manual.

F13

F14 G G1

SAES-B-019 Para 6.4 SAES-B-019 Para 6.4 NFPA 17A, Section 6.4 NFPA 17A, Section 6.4 NFPA 17A, Section 6.4 NFPA 17A, Section 6.4 NFPA 17A, Section 6.4

G2

G3

G4

G5

G6

G7

Page 5 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. H H1

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

GI-1781.001 Supp. 31 (Wet Chemical System - Hood Type Testing & Inspection) Control panels main power indicator is ON. (Weekly) System activation indicator on the fire alarm control panel is "OFF. Automatic fire detection system (AFDS) is on-line & operating. The 14-step AFDS checklist (see 3C) is applied Manual actuators are unobstructed. GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31 GI-1781.001, Supplement 31

H2

H3

H4

H5

Tamper indicators and seals are intact.

H6

Maintenance tag or certificate is in place.

H7

No obvious physical damage or condition exists to hinder operation.

H8

Pressure gauges, if provided, are in operable range.

H9

Nozzle blowout caps are intact and undamaged.

H10

Wet chemical pressure gauge reads full.

H11

Fusible links/heat detectors are clean and not damaged.

H12

Cylinder/hose assemblies have valid hydrotest date (every 12 yrs).

H13

Hoods & filters are free of combustibles & debris (accumulations).

H14

Operating instructions are posted and legible.

H15

System alarm & equipment activates & operates properly. Alarm signals to building alarm control panel & remote stations test Inspection tags are installed & updated (logbook utilized) GI-1781.001 Supp. 32 Control panels main power indicator is ON. (Weekly) System activation indicator on the fire alarm control panel is "OFF. Automatic fire detection system (AFDS) is on-line & operating. The 14-step AFDS checklist (see 3C) is applied

H16 I I1

GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32

I2

I3

Page 6 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. I4

ACCEPTANCE CRITERIA

REFERENCE GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32 GI-1781.001, Supplement 32

PASS

FAIL

N/A

RE-INSP DATE

Pilot cylinder disc/pneumatic valve is intact/closed.

I5

Nitrogen cylinder(s) gauge reads 2000-2500 psig.

I6

Cylinder brackets are firmly attached.

I7

Nitrogen cylinder(s) has valid hydrotest date (every five years). Fusible links/automatic fire detection devices are all in normal standby mode, clean, and show no sign of damage. Pneumatic valves of each nitrogen cylinder are firmly attached.

I8

I9

I10

Nozzles are clean and not damaged.

I11

Cylinder/hose assemblies have valid hydrotest date (every 12 yrs).

I12

Operating instructions are posted and legible. System alarm & equipment activates & operates properly. Alarm signals to building alarm control panel & remote stations test Test results are recorded in the logbook. Inspection tags are installed & updated (logbook utilized) GI-1781.001 Supp. 28 (Halon System Testing & Inspection) Control panels main power indicator is ON. System activation indicator on fire control panel is "OFF. Automatic fire detection system (AFDS) is on-line & operating. The 14-step AFDS checklist (see 3C) is applied Pipe manifolds are painted & pipe is not subject to external loading

I13

I14 J J1

GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28

J2

J3

J4

J5

Pipe hangers are not damaged, loose, or missing.

J6

Manual discharge & abort switches are in normal standby mode.

J7

Cylinder transfer key is set to primary.

J8

Cylinder brackets are firmly attached. Solenoid & pneumatic discharge valves are firmly attached to the cylinder head.

J9

Page 7 of 8

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Special Fixed Extinguishing Equipment - Installation Inspection & Testing

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-B-2015

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. J10

ACCEPTANCE CRITERIA

REFERENCE GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28 GI-1781.001, Supplement 28

PASS

FAIL

N/A

RE-INSP DATE

Discharge nozzles are unobstructed & blow-off caps are in place

J11

Discharge flexible hoses are in good condition.

J12

Cylinder(s) are fully charged to correct pressure (ambient temp)

J13

Manual & automatic actuating devices are operational

J14

Manual & automatic devices meet mfg's recommendations.

J15

As applicable, pneumatic type CO2 cartridge disc is intact.

J16

Hose assemblies have valid hydrotest date (every five years).

J17

Cylinders have valid hydrostatic test date (every five years).

J18

Safety/warning signs are posted identifying the protected area.

J19

Operating instructions are posted and legible.

J20

Protected space has not been altered. System alarm & equipment activates & operates properly. Alarm signals to building alarm control panel & remote stations test Test results are recorded in the logbook. Inspection tags are installed & updated (logbook utilized)

J21

J22

REMARKS: REFERENCE DOCUMENTS: 1- Saudi Aramco GI-1781.001 -- Inspection, Test, and Maintenance of Fire Protection Equipment, 25 May 2002 2- SAES-B-019 -- Portable, Mobile and Special Fixed Firefighting Equipment, (15 March 2006)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 8 of 8

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Vedic Maths TutorialDokumen12 halamanVedic Maths TutorialNitin Jain100% (15)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Power System Protection (Vol 3 - Application) PDFDokumen479 halamanPower System Protection (Vol 3 - Application) PDFAdetunji TaiwoBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Study Notes - Google Project Management Professional CertificateDokumen4 halamanStudy Notes - Google Project Management Professional CertificateSWAPNIL100% (1)

- SAIC-D-2022 Rev 2Dokumen5 halamanSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- Bharti Airtel Strategy FinalDokumen39 halamanBharti Airtel Strategy FinalniksforloveuBelum ada peringkat

- Duties of A Welding Inspector 1Dokumen12 halamanDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுBelum ada peringkat

- Codes Standards and SpecificationsDokumen15 halamanCodes Standards and Specificationsரமேஷ் பாலக்காடுBelum ada peringkat

- Welding Processes ModuleDokumen27 halamanWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Entrepreneurship - PPTX Version 1 - Copy (Autosaved) (Autosaved) (Autosaved) (Autosaved)Dokumen211 halamanEntrepreneurship - PPTX Version 1 - Copy (Autosaved) (Autosaved) (Autosaved) (Autosaved)Leona Alicpala67% (3)

- SAIC-D-2023 Rev 2Dokumen2 halamanSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-D-2023 Rev 2Dokumen2 halamanSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-D-2023 Rev 2Dokumen2 halamanSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-E-2001 Rev 2Dokumen7 halamanSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- Kallatam of Kallatar (In Tamil Script Tscii Format)Dokumen78 halamanKallatam of Kallatar (In Tamil Script Tscii Format)rprabhuBelum ada peringkat

- Norman, K. R., Pali Philology & The Study of BuddhismDokumen13 halamanNorman, K. R., Pali Philology & The Study of BuddhismkhrinizBelum ada peringkat

- SAIC-D-2006 Rev 2Dokumen2 halamanSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-D-2006 Rev 2Dokumen2 halamanSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- S-Sapfico-Satyanarayanamaterial 121212Dokumen183 halamanS-Sapfico-Satyanarayanamaterial 121212mpsing1133Belum ada peringkat

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Dokumen62 halamanSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுBelum ada peringkat

- Online Reg Certfct PDF PDFDokumen2 halamanOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுBelum ada peringkat

- Saudi Computer Exam For QC WeldingDokumen4 halamanSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDokumen2 halamanOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுBelum ada peringkat

- Gouging 01Dokumen2 halamanGouging 01ரமேஷ் பாலக்காடுBelum ada peringkat

- Pew205 Slide ShowDokumen23 halamanPew205 Slide Showரமேஷ் பாலக்காடுBelum ada peringkat

- Responabilities of A Welding InspectorDokumen13 halamanResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுBelum ada peringkat

- Air Carbon Arc Gouging: ElectrodeDokumen1 halamanAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுBelum ada peringkat

- Computer Kerala - 4 Folder LockDokumen2 halamanComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுBelum ada peringkat

- 0 Wis10 Contents ListDokumen1 halaman0 Wis10 Contents ListSangram RoutarayBelum ada peringkat

- Computer Kerala - 4 Folder LockDokumen2 halamanComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-E-2002 Rev 2Dokumen7 halamanSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- Computer Kerala - 4 Folder LockDokumen2 halamanComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுBelum ada peringkat

- API 510 Examination Sample ItemsDokumen3 halamanAPI 510 Examination Sample ItemsMagira PasaribuBelum ada peringkat

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDokumen362 halamanPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneBelum ada peringkat

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDokumen1 halamanSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுBelum ada peringkat

- SAIC-F-2007 Rev 2Dokumen1 halamanSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDokumen4 halamanSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுBelum ada peringkat

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDokumen3 halamanSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுBelum ada peringkat

- Flipkart Labels 06 Jul 2022 09 52Dokumen37 halamanFlipkart Labels 06 Jul 2022 09 52Dharmesh ManiyaBelum ada peringkat

- Lab Science of Materis ReportDokumen22 halamanLab Science of Materis ReportKarl ToddBelum ada peringkat

- Aharonov-Bohm Effect WebDokumen5 halamanAharonov-Bohm Effect Webatactoulis1308Belum ada peringkat

- You Can't Blame A FireDokumen8 halamanYou Can't Blame A FireMontana QuarterlyBelum ada peringkat

- Chapter1 Intro To Basic FinanceDokumen28 halamanChapter1 Intro To Basic FinanceRazel GopezBelum ada peringkat

- Joomag 2020 06 12 27485398153Dokumen2 halamanJoomag 2020 06 12 27485398153Vincent Deodath Bang'araBelum ada peringkat

- Index: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsDokumen5 halamanIndex: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsZidi BoyBelum ada peringkat

- Air Blower ManualDokumen16 halamanAir Blower ManualshaiknayeemabbasBelum ada peringkat

- Quotation - 1Dokumen4 halamanQuotation - 1haszirul ameerBelum ada peringkat

- This Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiDokumen7 halamanThis Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiIvo BogoevskiBelum ada peringkat

- Ford Focus MK2 Headlight Switch Wiring DiagramDokumen1 halamanFord Focus MK2 Headlight Switch Wiring DiagramAdam TBelum ada peringkat

- Communication Skill - Time ManagementDokumen18 halamanCommunication Skill - Time ManagementChấn NguyễnBelum ada peringkat

- Pediatric Fever of Unknown Origin: Educational GapDokumen14 halamanPediatric Fever of Unknown Origin: Educational GapPiegl-Gulácsy VeraBelum ada peringkat

- Art Integrated ProjectDokumen14 halamanArt Integrated ProjectSreeti GangulyBelum ada peringkat

- Journal of Molecular LiquidsDokumen11 halamanJournal of Molecular LiquidsDennys MacasBelum ada peringkat

- Monitor 14sepDokumen2 halamanMonitor 14sepabhaymvyas1144Belum ada peringkat

- DHA - Jebel Ali Emergency Centre + RevisedDokumen5 halamanDHA - Jebel Ali Emergency Centre + RevisedJam EsBelum ada peringkat

- Outlook of PonDokumen12 halamanOutlook of Ponty nguyenBelum ada peringkat

- Acceptable Use Policy 08 19 13 Tia HadleyDokumen2 halamanAcceptable Use Policy 08 19 13 Tia Hadleyapi-238178689Belum ada peringkat

- Lesson Plan For DemoDokumen9 halamanLesson Plan For DemoJulius LabadisosBelum ada peringkat

- Linux ProgramDokumen131 halamanLinux ProgramsivashaBelum ada peringkat

- Ethical Hacking IdDokumen24 halamanEthical Hacking IdSilvester Dian Handy PermanaBelum ada peringkat

- Brain Injury Patients Have A Place To Be Themselves: WHY WHYDokumen24 halamanBrain Injury Patients Have A Place To Be Themselves: WHY WHYDonna S. SeayBelum ada peringkat