151

Diunggah oleh

Ilarion CiobanuDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

151

Diunggah oleh

Ilarion CiobanuHak Cipta:

Format Tersedia

Workshop Manual

PB

REVISION 0 FORMAT N 151 14.05.2009

English

Irizar PB WorkShop Manual

INDEX

HEADLIGHT SET OPENING AND LAMPS REPLACE

1 HEADLIGHT SET OPENING AND LAMPS REPLACE

5

7

FRONT, CENTRAL AND REAR DOORS ADJUSTMENT

2 FRONT, CENTRAL AND REAR DOORS ADJUSTMENT

2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 INTRODUCTION DOOR SYSTEM PARTS DOORS MOVEMENT FEATURES TO BE CONSIDERED DURING THE ADJUSTMENT GEOMETRICAL ALIGNMENT SEALING DOOR BODY PARALELISM DOOR HEIGHT DOOR CENTRAL ALIGMENT OTHER FACTORS THAT CAN INFLUENCE THE DOOR OPERATION STANDARD MEASURES

9

11

11 11 12 13 13 14 15 15 16 16 18

LUGGAGE COVERS ADJUSTMENT

3 LUGGAGE COVERS ADJUSTMENT

3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11 3.12 3.13 3.14 AJDUSTMENT OF THE PANTHOGRAPHIC SYSTEM ARMS HORIZONTAL DISPLACEMENT PARALELISM ADJUSTMENT LOCKS AJDUSTMENT STANDARD FEATURES NOTES PNEUMATIC ADJUSTMENTS PNEUMATIC OIL RE-FILLING ELECTRO-VALVE CLEANESS LUGGAGE SEALING RUBBERS CHECKING BOLTS AND FLANGES LUGGAGE ACTUATOR CYLINDER MAINTENANCE CYLINDER PLAIN GEAR CLEANESS REPLACE CYLINDER REPAIR

19

21

21 21 22 23 24 24 25 25 25 26 26 27 27 28

EXTERNAL REARVIEW MIRROR MAINTENACE

4 EXTERNAL REARVIEW MIRROR MAINTENACE

29

31

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 3

Irizar PB WorkShop Manual

4.1 4.2 4.3

NECESSARY TOOLS DRIVEMOTOR REMOVAL CHANGING THE MIRRORS MOUNTING BRACKET (DOVE TAIL)

31 33 34

WINDSHIELD WIPERS ADJUSTMENT AND MAINTENANCE

5 WINDSHIELD WIPERS ADJUSTMENT AND MAINTENANCE

37

39

INTERNAL DIGITAL CLOCK TIME ADJUSMENT

6 INTERNAL DIGITAL CLOCK TIME ADJUSMENT

43

45

TOILET DOOR SPRING FORCE ADJUSTMENT

7 TOILET DOOR SPRING FORCE ADJUSTMENT

47

49

WINDSCREEN REPLACEMENT

8 WINDSCREEN REPLACEMENT

8.1 8.2 MATERIALS AND TOOLS PREPARATION 8.2.1 TABLE OF SUPPORT 8.2.2 REMOVING WINDSCREEN WIPERS 8.2.3 WINDSCREEN WIPES FUSE 8.2.4 REMOVAL OF THE REARVIEW MIRROR 8.2.5 PROTECTION OF THE BORDERS REMOVING THE CRACKED WINDSCREEN 8.3.1 CUTTING GLASS 8.3.2 REMOVING THE GLASS RESIDUES (SIDES, TOP AND BOTTOM) CLEANING 8.4.1 CLEANING BODY FRAME 8.4.2 CLEANING THE WINDSCREEN APPLICATION 8.5.1 PROTECTION OF THE WINDSCREEN 8.5.2 APPLICATION 8.5.3 PRIMER APPLICATION 8.5.4 WINDSCREEN SUPPORT 8.5.5 APPLYING SIKAFLEX BOUNDER THE WINDSCREEN 8.6.1 FITTING THE WINDSCREEN

51

53

53 53 53 54 55 55 56 56 56 56 57 57 57 58 58 58 59 59 60 60 61

8.3 8.4 8.5

8.6

/ 4

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

HEADLIGHT SET OPENING AND LAMPS REPLACE

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 5

Irizar PB WorkShop Manual

HEADLIGHT SET OPENING AND LAMPS REPLACE

Open the inspection cover and remove the headlight fixing bolts. Push the bolt as indicated by the red arrow.

Turn the headlight set as indicated in the picture at the left side, combining with the movements indicated by the red arrows.

Remove the seal cover of the headlight set.

Unlock the lightbulb support.

Do the closing operations alway taking care of assure a good seal of the headlight with the seal covers.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 7

Irizar PB WorkShop Manual

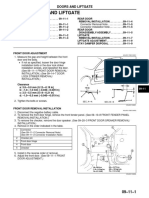

FRONT, CENTRAL AND REAR DOORS ADJUSTMENT

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 9

Irizar PB WorkShop Manual

2

2.1

FRONT, CENTRAL AND REAR DOORS ADJUSTMENT

INTRODUCTION

Door are considered not adjusted when: 2.2 Rattles. Do not close adequately and permits water, air or dust leaks sealing problems Presents difficulties to open or close. Takes akes too much time to open or close. Needs external help to open or close.

DOOR SYSTEM PARTS

Upper Triggers Set Limits the doors oors vertical movement during the closing phase.

A (door)

B (body frame)

Coupling

Lower Triggers Set Controls the doors seal during the closing moviment phase.

A (door)

B (body frame)

Coupling

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 11

Irizar PB WorkShop Manual

Electric System (BODE) Responsible for the doors moviment.

Internal Pillar

Counter Arm

Electric Driven Motor External Mount

2.3

DOORS MOVEMENT

Paralell to the bus

Perpendicular to the bus Movement responsible for the doors seal.

/ 12

- Revision 0 - Format N 151 - 14/05/2009 /05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

Vertical This movement is responsible for coupling the door with the with body frame, assuring rigidity of the set, combining the vertical and perpendicular movements on the door system.

2.4

FEATURES TO BE CONSIDERED DERED DURING THE ADJ ADJUSTMENT

GEOMETRICAL ALIGNMENT SEALING PARALELISM WITH THE BODY DOORS HEIGHT DOORS CENTRAL ALIGNMENT SENSITIVE SYSTEM

2.5

GEOMETRICAL ALIGNMENT

The geometrical alignmen alignment is correlated with the door x body frame alignment, alignm as seen in the illustration. This feature is controlled by the wedges set and by the positioning of the doors mounts. mounts

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 13

Irizar PB WorkShop Manual

General alignment problems can be generated by bad wedges coupling. Such defect can be observed pulling up the door rubber after its closure. Another reason might be bad ajdustment of the doors fixing arms.

In the case of poor geometrical alignment, the adjusment of the wedges set and the external door fixation can help. In order to adjust the external mounting plates, just free the mounts, one by time, and use the rubber hammer to ajdust its position.

2.6

SEALING

The door seal is very important to prevent air, dust or water leaks, and even prevent noise from the unwanted air inlet. The upper wedges set are responsible for bring the door close to the body. Excess of sealing force implies on over stress on the wedges wich reduce its lifespan and can cause damage in body frame rubber. Its possible to achieve good seal when the doors surface gets aligned with the bodys lateral surface. Lack of seal can have as natural cause the poor coupling of the wedges, as can be seen in the pictures below.

/ 14

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

2.7

DOOR BODY PARALELISM

This feature is defined by the rod located in the lower part of the door. The doors displacement with the body frame must be paralel, wich means the two sides of the doors must touck the body frame simultaneously.

ROD

When just a single side of the door touch the body frame, one of the wedges set will couple first, causing closing problems. In these cases, we might have problems with the geometrical aligment and poor coupling of the not-yet coupled triggers. To prevent such problems the rod must be correctly adjusted trough the bolts that fix the rod in the body trough slots holes as can be seen in the picture aside.

2.8

DOOR HEIGHT

The door must be aligned with the bodys side lines, with the body frame on the lower part. Such alignment can be obtained by ajdusting the lower wedges, with limitation of the doors rising movement.

Not Aligned

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 15

Irizar PB WorkShop Manual

That ajustment is important to prevent air, dust or water inlets and therefore the noise production production. The procedure of adjusting the doors height can be done by loosening the bolts indicated by the picture below. . Using the rubber hammer, the arms position can be changed with soft strikes.

ARM2

ARM1

Warning: NEVER LOOSEN THE TWO ARMS AS THE SAME.

2.9

DOOR CENTRAL ALIGMENT

The gaps between the body frame and the door must be equal both sides. Such features can be achieved combining the past adjustments.

2.10 OTHER FACTORS THAT CAN INFLUENCE THE DOOR O OPERATION Misuse of Equipment Transit with open doors;

/ 16

- Revision 0 - Format N 151 - 14/05/2009 /05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

CENT ER

Irizar PB WorkShop Manual

Lack of maintenance of the neumatic system.

Torques that need to be applied in the bolts that fix the door. 40 N.m 30 N.m

40 N.m 30 N.m

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 17

Irizar PB WorkShop Manual

2.11 STANDARD MEASURES

In the external mounting bearings, the distance betwen the work nut and the bolt nut must be 20mm.

The maximum gap between the triggers set during the closing phase must be 2mm.

/ 18

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

LUGGAGE COVERS ADJUSTMENT

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 19

Irizar PB WorkShop Manual

LUGGAGE COVERS ADJUSTMENT

3.1

AJDUSTMENT OF THE PANTHOGRAPHIC SYSTEM ARMS

The bolts indicated in the pic.1 are responsible for the position of the pantographic system. The fig. 2 indicates the movement allowed at the system adjustment.

3.2

HORIZONTAL DISPLACEMENT

After ajdusted the structure arms, the cover must be adjusted according the panel and the adjacent covers. The gas dumper allow s 10mm of horizontal dislocation, as seen in the drawing below.

GAS STAY

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 21

Irizar PB WorkShop Manual

3.3

PARALELISM ADJUSTMENT

The rod indicated aside controls cover paralelism during the opening and closing movements. Such feature must be controled correctly to prevent poor sealing during the closing phase, preventing water or dust inlet trough the luggages. Below we have indicated the work nut in the rod adjustment. Freeing the nut and using the wrench makes possible to enlarge or reduce the rod. Ps: The screw is inverted

Increasing the Rod lenght a displacecment to the positive side of the angly will happen, reducing the lenght the effect is the oposite.

/ 22

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

The covers must be always aligned with the imediately adjacent doors and with the lateral panel. Trough the device shown aside it is possible to change the covers height in a zone of 10mm, like seen below. That adjustment is very important in order to assure the aligment with the external panel and prevent water and air inlets in the lugagges.

3.4

LOCKS AJDUSTMENT

The locks must be aligned always according the strutucutres pin. The locks can be adjusted in the 5mm zone according the pictures below.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 23

Irizar PB WorkShop Manual

3.5

STANDARD FEATURES

The standard gaps between the covers and the lateral panel are shown schematicaly in the drawing below.

3.6

NOTES

All the covers have a excess of metal around it to permit the correct after-factory adjustments .

The structure of the covers are reinforced with aluminium sheetmetal where the the rod fixation holes shall be made.

/ 24

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

3.7

PNEUMATIC ADJUSTMENTS

The luggage compartment opening system is automatic operated by air. For this reason, regular maintenance stoppings must be accomplished for the proper operation of the vehicle. All the works described on the following items must be accomplished each 50.000km or 6 months of operation.

3.8

PNEUMATIC OIL RE-FILLING

1 - Purge the System Humidity. 2 Complete the lubricant level, 30 cm3.

3.9

ELECTRO-VALVE CLEANESS

It is very important remove the solenoids and clena the electro-valves sealing ring housing to avoid air leaks during the operation.

Clean the sealing ring housing

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 25

Irizar PB WorkShop Manual

3.10 LUGGAGE SEALING RUBBERS CHECKING The Sealing rubber conditions is quite important to avoid water leaks. So on each maintenance stopping, sealing rubbers must receive a visual check and be replaced if necessary.

Rubber A dimension not less than 23mm.

3.11 BOLTS AND FLANGES A visual check on indicated bolts and flanges are important to prevent failures. This work must be performed at least each 6 months of operation.

/ 26

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

3.12 LUGGAGE ACTUATOR CYLINDER MAINTENANCE The Luggage actuator is responsible to open the luggage doors. The clearances between the plain gear and the main gear must be removed as long as it appears. Follow the steps below, each 6 months, to prevent premature wear and tear of the gears.

A- Slightly loosen bolts 1, 2 and 3. B- Move the cylinder up turning over point 2. C- Compensate all clearance between the plain gear and gear on turning bar. D- Tight the bolts strongly.

3.13 CYLINDER PLAIN GEAR CLEANESS

Clean the Plain gear with wet cloth and apply grease.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 27

Irizar PB WorkShop Manual

3.14 REPLACE CYLINDER REPAIR Replace actuator cylinder repairing kit, if necessary.

/ 28

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

EXTERNAL REARVIEW MIRROR MAINTENACE

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 29

Irizar PB WorkShop Manual

4

4.1

EXTERNAL REARVIEW MIRROR MAINTENACE

NECESSARY TOOLS

Rubber Hammer. 5mm long-rod hex-key. Ratchet hex key with 8mm sockets.

Find the locking-bolt at the lower side of of the Loosen the locking-bolt with the long-rod hex key. mirrors arm.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 31

Irizar PB WorkShop Manual

Remove the fixation lock from the mirrors arm.

To remove the mirrors arm, push up the arm with both hands. Disconnect the cable the eletrical motor and mirrer demister circuit.

To remove the morror, use a screw driver to make a lever and lift the fixing plastic point.

All mirror sets are composed by a plastic base and glass. There are not screw a fixation to facilitate the maintenance.

/ 32

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

See all the left image the mirrors removed.

By two conector wich must be desconected in order to remove the mirror. Both mirrors have a demister system and the harness must be disconnected in order to remove the mirror.

The glass and the plastic base are single parts and can not be separated.

4.2

DRIVEMOTOR REMOVAL

Locate the three fixing bolts on the mirror support and loosen them to remove the support.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 33

Irizar PB WorkShop Manual

After remove the mirrorss pad, we have access to the mirrors drivemotor.

To remove the drivemotor, loosen the four bolts located behind it, using the long-rod hex key.

4.3

CHANGING THE MIRRORS MOUNTING BRACKET (DOVE TAIL)

Before reassembly the mirror, inspect the mounting bracket for possible damage or cracks.

/ 34

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

Find the four m8 bolts on the mounting bracket of the To remove the mounting bracket remove the four bolts mirrors arm. using the long-rod hex-key.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 35

Irizar PB WorkShop Manual

WINDSHIELD WIPERS ADJUSTMENT AND MAINTENANCE

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 37

Irizar PB WorkShop Manual

WINDSHIELD WIPERS ADJUSTMENT AND MAINTENANCE

Tools needed: 13mm and 17mm wrench The windshield whipper adjustment is done foremost on the synchronism rod wich controls the start angle of the arms.

There are two synchronism rods located each one at each side of the mechanism behind the front cover, each one fixed by two m8 bolts in elongated holes.

In the right synchronism rod the bolts must be in the center of the elongated holes.

The Adjustments are done in the right arm of the mechanism, by loosening the bolts behind the synchronism rod with the help of the 13 wrench and sliding the wiper blades to the desired position.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 39

Irizar PB WorkShop Manual

There must be observed that, at the start of the movement, the wiper blade is paralel to the synchronism rod. At the end of the movement the blade must be at least 50mm from the column border. Important: To test the work of the wipers, the mechanism must operate at second speed, on a wet windshield.

/ 40

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Irizar PB WorkShop Manual

In order to remove the motor of the windshield wiper, remove the three bolts m10 that holds the motor, with the 17 wrench; Remove the the m8 bolt with the 13 wrench, moving the motor downwards.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 41

Irizar PB WorkShop Manual

INTERNAL DIGITAL CLOCK TIME ADJUSMENT

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 43

Irizar PB WorkShop Manual

INTERNAL DIGITAL CLOCK TIME ADJUSMENT

The digital clock time is adjuted by using a magnetic. All vehicles tools sets accompains a magnetc stick. Any magnetic with suitable size can be applied for this work. Place the magnetic on the position below to adjust the hour:

Place the magnetic on the position below to ajust the minutes:

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 45

Irizar PB WorkShop Manual

TOILET DOOR SPRING FORCE ADJUSTMENT

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 47

Irizar PB WorkShop Manual

TOILET DOOR SPRING FORCE ADJUSTMENT

The toilet door hinge spring must be adjusted as long as some complains about door opening during the bus operation appear. Excessive force on hinge reduces the time life or generates eventual breaks. Release the pressure over the hinge pin by slightelly turning the top bolt to the left.

Remove the pin

Tight bolt to left in of turn.

Hold the allen tool and put the pin back.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 49

Irizar PB WorkShop Manual

WINDSCREEN REPLACEMENT

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 51

Irizar PB WorkShop Manual

WINDSCREEN REPLACEMENT

The installation of the windscreen, it should only be done by experienced professionals, in case of doubt during the installation, contact the one of our technical representative available on technical assistance network list that joints the bus body manual or available in the internet www.irizar-sat.com.br.

8.1

MATERIALS AND TOOLS

Below, the list of materials and tools, that will be used for the change of the windscreen.

Pic. 1

Pic. 2

Pic. 3

Pic. 4

Pic. 5

Pic. 6

Pic.7

Pic.8

Pic.9

Pic.1: Grainer with diamond disc Pic.2: Pneumatic knife Pic.3: Sika Aktivator and Sika Primer-206 G+P Pic.4: Sikaflex Pic.5: Primer Aplication bottle

Pic.6: Windscreen Support Pic.7: Allen Key, #5 Pic.9: Windy Handly Pic.10: Sika Gun

8.2 8.2.1

PREPARATION TABLE OF SUPPORT

This table is for the instalation to have the necessary support to handle the windscreen procedures with total safety. See the images below:

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 53

Training Training in Maintenance

image of the support table

image of the support table

8.2.2

REMOVING WINDSCREEN WIPERS

It is necessary to remove the windscreen wiper to facilitate the process and to be possible to fit the windscreens support. Use a wrench no. 17.

Wiper arm fixing Point

Removing the arm

/ 54

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

8.2.3

WINDSCREEN WIPES FUSE

Remove the fuse that protects the wiper motor working to avoid accidents while support for windscreen is placed on wiper blade axles.

Fuse box

8.2.4

REMOVAL OF THE REARVIEW MIRROR

Irizar indicates to remove the rearview mirrors off to avoid accidents and damages during the windscreen removal. It also provides better conditions for finishing procedures. Follow the steps below to have a successful operation:

Remove the fixing screw Allen 5

Use a rubber hammer to start the sliding movement

Mirror harness must be disconnected.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 55

Training Training in Maintenance

8.2.5

PROTECTION OF THE BORDERS

The border where is fit in the glasses must be protected with masking tape for not scratching the painting while the cracked glass is removed. The masking tape must surround the windscreen hole. Masking paper must be applied on front dome.

Masking tape surrounding the windscreen hole

Masking paper on front dome

8.3

REMOVING THE CRACKED WINDSCREEN

8.3.1

CUTTING GLASS

Remove the center of old windscreen using the grainer with diamond disc.

A distance from the column must be maintained along the cut to avaid damages in the internal finishing of the vehicle.

8.3.2

REMOVING THE GLASS RESIDUES (SIDES, TOP AND BOTTOM)

/ 56

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

The the adhesive residues shall be removed with the Pneumatic cutter. The process must be carefully handle to avoid the green primer layer removing. This primer layer is responsible to protect the vehicle structure against corrosion. As long as it is removed, corrosion spots would appear later. It is necessary to remove the excess of the eraser, it is not necessary to remove completely, only enough, to leave from 1 to 2 mm layer, the new bounder cord can be applied over the old one suitably prepared.

Remaining Adhesive layer (1 to 2mm thick)

8.4

CLEANING

8.4.1

CLEANING BODY FRAME

The structure must be compressed air and be free of any grease, oil or humidity. A piece of cloth with isopropyl Alcohol must be applied and process must continue after 20 minutes.

8.4.2

CLEANING THE WINDSCREEN

The new windscreen must be cleanead with alcohol and wait for 5 minutes before continue the process. Special care must be given on windscreen borders where adhesive will have contact.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 57

Training Training in Maintenance

8.5 8.5.1

APPLICATION PROTECTION OF THE WINDSCREEN

Internally, the windscreen must receive a masking tape protection, distant 20mm from windscreen border. On this are, the Sika Aktivator and primer will be applyied.

8.5.2

APPLICATION

Apply the Sika Aktivator wainting for 15 minutes to solvent evaporation before continue the process.

/ 58

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

Aktivator must also be applied along the windscreen border face as shown aside.

Pic. 11

8.5.3

PRIMER APPLICATION

The Primer 206 G+P must be applied where Sika activator was used. It is important to apply a uniform primer strip, including the windscreen border face. Wait for 15 minutes before fit the glass on the body frame.

Sika Primer 206 G+P

8.5.4

WINDSCREEN SUPPORT

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 59

Training Training in Maintenance

Irizar indicates the windscreen support to help during the process. It maintains the alignment and supports the windscreen weight while the bounder is being cured, avoiding non-wanted displacement of the glss. The T support is applied on wiper arms axle.

8.5.5

APPLYING SIKAFLEX BOUNDER

Using the Sika Gum, apply a uniform Sika cord surrounding the windscreen hole. Mind the corners where the junction between fiber glass and structure is done. Wrong sika application would generate water and dust leaks. Afte fit the new windscreen; the time for cure is minimum 8 hours to avoid displacing of the glass.

8.6

THE WINDSCREEN

/ 60

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

8.6.1

FITTING THE WINDSCREEN

The new windscreen must be fitted over the supports, minding the top and bottom alignment with the body. In general, when the support is used, no alignment problems appear.

The suitable finishing must be applied on sika cord removing the bounder excess.

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 61

Training Training in Maintenance

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 63

Training Training in Maintenance

/ 64

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 65

Training Training in Maintenance

/ 66

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 67

Training Training in Maintenance

/ 68

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Training Training in Maintenance

Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

/ 69

Training Training in Maintenance

/ 70

- Revision 0 - Format N 151 - 14/05/2009 Marechal Rondon Highway, KM 252,5, BOTUCATU SP- BRAZIL Phone: 55 14 3811 8000 irizar@irizar.com.br

Anda mungkin juga menyukai

- Movfr: Door Operator Installation and Adjusting ManualDokumen19 halamanMovfr: Door Operator Installation and Adjusting ManualMohd Abu AjajBelum ada peringkat

- AG SL: Installation, Operation and Maintenance Manual Stop Gate Stop LogDokumen15 halamanAG SL: Installation, Operation and Maintenance Manual Stop Gate Stop Logkim haroldBelum ada peringkat

- Install, Operate & Maintain Manual for AG Stop Gates & SL Stop LogsDokumen15 halamanInstall, Operate & Maintain Manual for AG Stop Gates & SL Stop LogsMohamed Ismail ShehabBelum ada peringkat

- Split Wall MountedDokumen100 halamanSplit Wall Mountedfaizmansur100% (1)

- Premier Slide ManualDokumen28 halamanPremier Slide Manualinfo2378Belum ada peringkat

- Bandlock 2 Horizontal QOCDokumen24 halamanBandlock 2 Horizontal QOCARNOUXBelum ada peringkat

- Smart 452Dokumen14 halamanSmart 452Macovei Lucian FlorinBelum ada peringkat

- ML-190 Parts Manual Phase 7Dokumen34 halamanML-190 Parts Manual Phase 7Lakshmanan SekarBelum ada peringkat

- Blum ModulDokumen24 halamanBlum ModulmartinskruBelum ada peringkat

- MOVFR Installation ManualDokumen52 halamanMOVFR Installation ManualMark NelsonBelum ada peringkat

- En Nex AirlineDokumen52 halamanEn Nex AirlineJoão SilvaBelum ada peringkat

- Facteurs Géométriques Qui Influencent L'esthétique Véhicule Fini B.I.WDokumen9 halamanFacteurs Géométriques Qui Influencent L'esthétique Véhicule Fini B.I.WsopanBelum ada peringkat

- G300 Brake BleederDokumen7 halamanG300 Brake BleederluisBelum ada peringkat

- Dom Bobr WagonDokumen42 halamanDom Bobr WagonShantanu Dutta100% (2)

- Manual Fold Door 8920PLDokumen40 halamanManual Fold Door 8920PLCristian Luis Mansilla SilvaBelum ada peringkat

- 05 Iris1Dokumen15 halaman05 Iris1AndiosoBelum ada peringkat

- Clip Top Blumotion: Everything InsideDokumen62 halamanClip Top Blumotion: Everything Insideanon_676432303Belum ada peringkat

- CSA 5,5 - 7,5 - 10 - 15 - 20 HP: Rotary Screw CompressorDokumen8 halamanCSA 5,5 - 7,5 - 10 - 15 - 20 HP: Rotary Screw CompressorJohnny Diaz VargasBelum ada peringkat

- Assembling Instructions and Regulation of Cabin Doors: Automatic Doors For LiftsDokumen16 halamanAssembling Instructions and Regulation of Cabin Doors: Automatic Doors For LiftsБахтияр ЮмачиковBelum ada peringkat

- FLC Ids (RS) Bm1 (Flrsbm1) en 20131121 BMWDokumen17 halamanFLC Ids (RS) Bm1 (Flrsbm1) en 20131121 BMW111techBelum ada peringkat

- C-PAC Gas R22Dokumen22 halamanC-PAC Gas R22Leed ENBelum ada peringkat

- Operation and Service Manual for Valveworks USA Model M and MSG Gate ValvesDokumen26 halamanOperation and Service Manual for Valveworks USA Model M and MSG Gate ValvesAshok SureshBelum ada peringkat

- Otis Engineering Center Gien Field Component ManualDokumen13 halamanOtis Engineering Center Gien Field Component Manualnr1wolf_co_69529906100% (5)

- 273034installation Guidelines For Kirloskar Bliss DG SetsDokumen10 halaman273034installation Guidelines For Kirloskar Bliss DG SetsJayaram GowdaBelum ada peringkat

- Doors and LiftgateDokumen9 halamanDoors and LiftgateSebastian SirventBelum ada peringkat

- Bm33 Uc Manual en-USA 2011 06Dokumen32 halamanBm33 Uc Manual en-USA 2011 06dangomezvBelum ada peringkat

- Pattern Failures: Plagued With Problems by DesignDokumen2 halamanPattern Failures: Plagued With Problems by DesignavinashjhamechxBelum ada peringkat

- User'S Operation ManualDokumen27 halamanUser'S Operation ManualDams MonsalveBelum ada peringkat

- Water Cooled Fcu Piping DetailsDokumen14 halamanWater Cooled Fcu Piping Detailsfernandoreyes893Belum ada peringkat

- Wafer & Lug-Type Butterfly Valves & Vacuum: What To Consider When Selecting An Appropriate DesignDokumen5 halamanWafer & Lug-Type Butterfly Valves & Vacuum: What To Consider When Selecting An Appropriate DesignDachyiBelum ada peringkat

- Compact Piston Air Motors ATEX II-2-GDc-T5 ExDokumen7 halamanCompact Piston Air Motors ATEX II-2-GDc-T5 Extaufiqsy0% (1)

- Catalogo Clack cmp450LDokumen78 halamanCatalogo Clack cmp450LandersonBelum ada peringkat

- Installation Manual-Perfect YORKDokumen19 halamanInstallation Manual-Perfect YORKjesBelum ada peringkat

- Kobelt Installation Maintenance For Disc BrakesDokumen18 halamanKobelt Installation Maintenance For Disc Brakesclara gordilloBelum ada peringkat

- Accident Preventing Printing PressDokumen5 halamanAccident Preventing Printing PressIyappanBelum ada peringkat

- VVVF 4+manual (English)Dokumen16 halamanVVVF 4+manual (English)Felix Romero67% (3)

- GFDokumen211 halamanGFCatalin StoicescuBelum ada peringkat

- Ad-81 p7 Opl S.A.F.E. Parts Manual Pn-450230 (r1) 4903Dokumen30 halamanAd-81 p7 Opl S.A.F.E. Parts Manual Pn-450230 (r1) 4903naokito AkemiBelum ada peringkat

- ROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Dokumen6 halamanROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Daniel Arbeláez0% (1)

- Fermator vvvf-4+Dokumen20 halamanFermator vvvf-4+paul100% (3)

- Fabrication of Automatic Pneumatic Ramming MachineDokumen3 halamanFabrication of Automatic Pneumatic Ramming MachineRaja SelvarajBelum ada peringkat

- SIM Lock System - Support PackDokumen15 halamanSIM Lock System - Support PackfrizardBelum ada peringkat

- Design and Fabrication of m10 Hexagonal Nut DeburringDokumen24 halamanDesign and Fabrication of m10 Hexagonal Nut DeburringGobz Christo EliezerBelum ada peringkat

- Euro 24 Parts Manual GuideDokumen42 halamanEuro 24 Parts Manual Guidenaokito AkemiBelum ada peringkat

- AW 50-42 Valve BodyDokumen8 halamanAW 50-42 Valve BodyHR Mecanica Integral75% (4)

- AD-78 Parts Manual PN450184 R3 032403Dokumen34 halamanAD-78 Parts Manual PN450184 R3 032403naokito AkemiBelum ada peringkat

- Freightliner Fld120Dokumen19 halamanFreightliner Fld120LO Consigo Antofagasta75% (4)

- Asv Brochure2015Dokumen22 halamanAsv Brochure2015Wen Jie LiowBelum ada peringkat

- Alignment and Installation Procedure For UW EqptsDokumen79 halamanAlignment and Installation Procedure For UW EqptsSanthosh Kumar100% (1)

- Jeep Wrangler Water Leak Diagnosis & Repair ManualDokumen26 halamanJeep Wrangler Water Leak Diagnosis & Repair ManualKathy AkersonBelum ada peringkat

- 722.4 Vacuum ProcedureDokumen28 halaman722.4 Vacuum ProcedurePatricio Bacigalupi83% (6)

- FAT Snaglist - InternalDokumen6 halamanFAT Snaglist - InternalOmkarBelum ada peringkat

- Mercedes 722.6Dokumen2 halamanMercedes 722.6Kelvin Tan Boon Lork100% (5)

- Boge Oil-Free Screw Compressors - SO SeriesDokumen16 halamanBoge Oil-Free Screw Compressors - SO SeriesAir Repair, LLCBelum ada peringkat

- SupraMatic Operator E2 Garage Door OperatorDokumen46 halamanSupraMatic Operator E2 Garage Door OperatorFlorin GeorgeBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneDari EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneBelum ada peringkat

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsDari EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsPenilaian: 5 dari 5 bintang5/5 (5)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Dari EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Belum ada peringkat

- Ebook - How To - The Morrow Guide To Knots (647 Knots in Color) - Quill (English, Illustrated, Crafts, Macrame, Bondage)Dokumen253 halamanEbook - How To - The Morrow Guide To Knots (647 Knots in Color) - Quill (English, Illustrated, Crafts, Macrame, Bondage)Isacio San Gon100% (2)

- 2954 2460 02 - Oah 2-Oav 4 - enDokumen34 halaman2954 2460 02 - Oah 2-Oav 4 - enIlarion CiobanuBelum ada peringkat

- 445028019 Renault Logan после 2009 Sandero Sandero Stepway 1 4 1 6 8V 1 6 16VDokumen1 halaman445028019 Renault Logan после 2009 Sandero Sandero Stepway 1 4 1 6 8V 1 6 16VIlarion CiobanuBelum ada peringkat

- Esr 5000Dokumen84 halamanEsr 5000Ilarion CiobanuBelum ada peringkat

- Data SourcesDokumen1 halamanData SourcesIlarion CiobanuBelum ada peringkat

- Atlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDDokumen36 halamanAtlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDRay Cepeda Mena100% (5)

- Bomba HidraulicaDokumen16 halamanBomba HidraulicaIlarion Ciobanu100% (1)

- Capacidades y EspecificacionesDokumen16 halamanCapacidades y EspecificacionesIlarion CiobanuBelum ada peringkat

- Cabina Del OperadorDokumen20 halamanCabina Del OperadorIlarion Ciobanu100% (1)

- 2954 2990 00 - QAS 330 John Deere - ENDokumen52 halaman2954 2990 00 - QAS 330 John Deere - ENIlarion Ciobanu100% (1)

- 2954 4650 00 - Qas 600 - enDokumen58 halaman2954 4650 00 - Qas 600 - enIlarion CiobanuBelum ada peringkat

- Gear CalcDokumen2 halamanGear CalcIlarion CiobanuBelum ada peringkat

- Alternador Con ReguladorDokumen26 halamanAlternador Con ReguladorIlarion Ciobanu100% (1)

- 2954 4960 01 - Branded EU Lighting Tower - ENDokumen50 halaman2954 4960 01 - Branded EU Lighting Tower - ENIlarion Ciobanu100% (1)

- 2954 2980 00 - QAS 250 John Deere - ENDokumen52 halaman2954 2980 00 - QAS 250 John Deere - ENIlarion CiobanuBelum ada peringkat

- 2954 2960 03 - Qas 125-150 - enDokumen108 halaman2954 2960 03 - Qas 125-150 - enIlarion CiobanuBelum ada peringkat

- MT - Manual TransaxelDokumen64 halamanMT - Manual TransaxelIlarion CiobanuBelum ada peringkat

- SMJ - Super Multiple JunctionDokumen7 halamanSMJ - Super Multiple JunctionIlarion CiobanuBelum ada peringkat

- MT - Manual TransaxelDokumen64 halamanMT - Manual TransaxelIlarion CiobanuBelum ada peringkat

- MA - MaintenanceDokumen28 halamanMA - MaintenanceIlarion CiobanuBelum ada peringkat

- SampleDokumen2 halamanSampleIlarion CiobanuBelum ada peringkat

- FE - Accelerator Control, Fuel & Exhaust SystemsDokumen10 halamanFE - Accelerator Control, Fuel & Exhaust SystemsIlarion CiobanuBelum ada peringkat

- Primera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXDokumen2 halamanPrimera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXIlarion CiobanuBelum ada peringkat

- ST - Steering SystemDokumen34 halamanST - Steering SystemIlarion CiobanuBelum ada peringkat

- FE - Accelerator Control, Fuel & Exhaust SystemsDokumen10 halamanFE - Accelerator Control, Fuel & Exhaust SystemsIlarion CiobanuBelum ada peringkat

- Primera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXDokumen2 halamanPrimera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXIlarion CiobanuBelum ada peringkat

- SMJ - Super Multiple JunctionDokumen7 halamanSMJ - Super Multiple JunctionIlarion CiobanuBelum ada peringkat

- SU - Front & Rear SuspensionDokumen26 halamanSU - Front & Rear SuspensionIlarion CiobanuBelum ada peringkat

- BT - Body & TrimDokumen62 halamanBT - Body & TrimIlarion CiobanuBelum ada peringkat

- Speccifications 1Dokumen236 halamanSpeccifications 1garage ô tô CarmaxBelum ada peringkat

- Steering SystemsDokumen48 halamanSteering SystemsOscar Coaquira FelicianoBelum ada peringkat

- Trax Pass - Price List With Effect From 14.06.2021 (PAN India) - BS6Dokumen1 halamanTrax Pass - Price List With Effect From 14.06.2021 (PAN India) - BS6Pratik SahuBelum ada peringkat

- CAT992Dokumen24 halamanCAT992Miriam Ruiz Cabellos100% (1)

- 05 TitanDokumen344 halaman05 TitanDavid ChalkerBelum ada peringkat

- 111 Final ReportDokumen12 halaman111 Final Reportapi-301976712Belum ada peringkat

- Lind HeimDokumen14 halamanLind HeimAyush GargBelum ada peringkat

- 2012 NV200 (X11M) Body Builder's Guide Level 1 Review Copy 7-13-12Dokumen165 halaman2012 NV200 (X11M) Body Builder's Guide Level 1 Review Copy 7-13-12Ramon MartinezBelum ada peringkat

- Vdocuments - MX Caterpillar 926e Manuals Volu Caterpillar Wheel Loader Powershift ManualDokumen7 halamanVdocuments - MX Caterpillar 926e Manuals Volu Caterpillar Wheel Loader Powershift ManualAbdelbagi100% (1)

- Product Management Assignment - Tata Indica - Group2Dokumen5 halamanProduct Management Assignment - Tata Indica - Group2monk0062006Belum ada peringkat

- New Golf Dimensions - 5-DoorDokumen2 halamanNew Golf Dimensions - 5-DoorJayBelum ada peringkat

- Awareness On TrafficDokumen14 halamanAwareness On TrafficISLAVATH SANDHYABelum ada peringkat

- Toyota CH-R Service Manual - Passenger Side Buckle Switch Circuit Malfunction (B1771) - Occupant Classification SystemDokumen13 halamanToyota CH-R Service Manual - Passenger Side Buckle Switch Circuit Malfunction (B1771) - Occupant Classification SystemJulius ThomasBelum ada peringkat

- Braking SystemDokumen3 halamanBraking SystemIrvandi QernBelum ada peringkat

- Haval Brochure H6 HEVDokumen12 halamanHaval Brochure H6 HEVMaira TariqBelum ada peringkat

- Lamborghini Aventador LP 700 4 EngDokumen28 halamanLamborghini Aventador LP 700 4 EngFelipe MartinezBelum ada peringkat

- COS-MAC-022 - 250t Spooling WinchDokumen2 halamanCOS-MAC-022 - 250t Spooling WinchElsad HuseynovBelum ada peringkat

- Swing Motor - Test - Measurement of Case Drain OilDokumen4 halamanSwing Motor - Test - Measurement of Case Drain Oilmekanicobucaro100% (1)

- Kent Bulldozer TY220SDokumen1 halamanKent Bulldozer TY220SMOZAMBiCARBelum ada peringkat

- Tecnam p2008 JC Question BankDokumen32 halamanTecnam p2008 JC Question BankJoy Andriyas100% (1)

- KYRON Owner's Manual English LHDDokumen289 halamanKYRON Owner's Manual English LHDHugo Marín DBelum ada peringkat

- Slick 540 Aerobatic Aircraft Pilots Operating Handbook-AERO-CAM (Pty) LTD (2004)Dokumen16 halamanSlick 540 Aerobatic Aircraft Pilots Operating Handbook-AERO-CAM (Pty) LTD (2004)crocomodxBelum ada peringkat

- Old Car Start-Up Procedure: "Basic Training Camp"Dokumen3 halamanOld Car Start-Up Procedure: "Basic Training Camp"jessito2Belum ada peringkat

- Pre Trip Inspection Manual For CDLDokumen11 halamanPre Trip Inspection Manual For CDLMaxim100% (1)

- Black + Decker Cordless Drill and 100 Accessories KitDokumen5 halamanBlack + Decker Cordless Drill and 100 Accessories Kitming_zhu10Belum ada peringkat

- Ñõåìà ABS-ESPDokumen7 halamanÑõåìà ABS-ESPJustinas RackauskasBelum ada peringkat

- RhinoDokumen16 halamanRhinoRicardo VladimirBelum ada peringkat

- Efficient Farm Vehicles Tractor Tyre SelectionDokumen4 halamanEfficient Farm Vehicles Tractor Tyre SelectionFrimpong Justice AlexBelum ada peringkat

- STIHL 021 023 025 Workshop Manual PDFDokumen52 halamanSTIHL 021 023 025 Workshop Manual PDFBoth JánosBelum ada peringkat

- Volvo Launches New 400 Series With Styling and Safety UpdatesDokumen42 halamanVolvo Launches New 400 Series With Styling and Safety UpdatesBruceseeBelum ada peringkat