Voltage Sag Immunity Standards

Diunggah oleh

Amany HamdyDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Voltage Sag Immunity Standards

Diunggah oleh

Amany HamdyHak Cipta:

Format Tersedia

Pacific Gas and Electric Company

Power Quality Bulletin No. 3

Voltage Sag Immunity Standards SEMI F47 and F42

As you may already be aware, interruptions in manufacturing processes can be very costly.potentially millions of dollars in revenue per day. Such interruptions can be due to voltage sag events which are the most important power quality problem facing many industrial customers, especially those with a process. A voltage sag is defined as a decrease in voltage magnitude below 90% of nominal, but not a complete interruption. The typical duration is from 3 to 10 cycles or 50 to 167 milliseconds. The results from a Distribution Power Quality (DPQ) project prepared by the Electric Power Research Institute Power Electronics Applications Center (EPRI-PEAC) concluded that a typical customer could on average experience 12 voltage sags per year from the utility. Voltage sags caused by severe weather conditions, car pole accidents, utility equipment operations or failures, and adjacent customers are beyond your control. However, voltage sags caused internally in your facility can be resolved using different mitigation techniques before implementing the following standards. To help improve the robustness or voltage sag ride-through capabilities in the procurement of new equipment and improvements in equipment system design, the industry association for the semiconductor industry known as Semiconductor Equipment and Materials International (SEMI) has developed the following two voltage sag immunity standards. 1. SEMI F47-0200, Specification for Semiconductor Processing Equipment Voltage Sag Immunity. Specifies the required voltage sag tolerance for semiconductor fabrication equipment. SEMI F42-0600, Test Method for Semiconductor Processing Equipment Voltage Sag Immunity. Explains the method on how to test compliance with SEMI F47.

2.

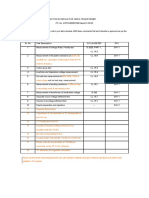

SEMI F47 requires that semiconductor processing equipment tolerate voltage sags connected onto their AC power line. They must tolerate sags to 50% of equipment nominal voltage for duration of up to 200 ms, sags to 70% for up to 0.5 seconds, and sags to 80% for up to 1.0 second. These requirements are defined by values shown in Table 1.

VOLTAGE SAG DURATION

Second (s) <0.05 s 0.05 to 0.2 s 0.2 to 0.5 s 0.5 to 1.0 s >1.0 s Milliseconds (ms) <50 ms 50 to 200 ms 200 to 500 ms 500 to 1000 ms >1000 ms Cycles at 60 hz <3 cycles 3 to 12 cycles 12 to 30 cycles 30 to 60 cycles >60 cycles Cycles at 50 hz <2.5 cycles 2.5 to 10 cycles 10 to 25 cycles 25 to 50 cycles >50 cycles

VOLTAGE SAG

Percent (%) of Equipment Nominal Voltage Not specified 50% 70% 80% Not specified

Table 1- Voltage Sag Duration and Percent Deviation from Equipment Nominal Voltage August 2007 1

Power Quality Bulletin No. 3

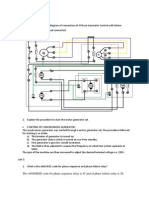

Figure 1 is a required voltage sag ride-through capability curve in which semiconductor processing, metrology, and automated test equipment must be designed and built to conform. The equipment must be able to continuously operate without interruption during conditions identified in the area above the defined solid black line.

Figure 1- Required Semiconductor Equipment Voltage Sag Ride-Through Capability Curve Note: Equipment must continue to operate without interruption during voltage above the line.

There are additional thresholds recommended by SEMI F47 but are not requirements of the standard. These include that equipment tolerate sags to 0% for 1.0 cycle, sags to 80% for 10 seconds, and continuous sags to 90% as shown in Figure 2.

Duration of Voltage Sag in Seconds

0.01 0.02 0.1 1 10 100 100 90 80 70 60 50 40 30 20 10 0

Area included in Specification 0.05 to 1 second

Percent of Equipment Nominal Voltage

August 2007

Figure 2 - Recommended Semiconductor Equipment Voltage Sag Ride-Through Capability Curve from 0 to 100 Seconds

Power Quality Bulletin No. 3

For New Equipment: SEMI F47 suggests that semiconductor users may use this sag standard when procuring new equipment to specify the capability of equipment ride-through requirements to the equipment manufacturer. In addition, semiconductor processing equipment manufacturers may in turn specify ride-through requirements to component and module suppliers. SEMI F42 defines the testing procedures and test equipment required to characterize the susceptibility of equipment to voltage sags by showing voltage sag duration and magnitude performance data for the equipment. Also, it describes safety precautions, processing modes, test sequences, phase connections, reporting requirements, and determining compliance with the requirements and recommendations of SEMI F47.

For Existing Equipment:

There are several third-party consultants that can come into a customers facility and conduct a thorough investigation of equipment immunity to voltage sags and momentary interruptions. Portable instrumentation such as a sag generator, are designed specifically to test compliance with SEMI F47 and SEMI F42 standards for equipment ride-through of voltage sags. Therefore, process vulnerabilities and weak elements can be determined with the creation of an electrical disturbance in the power that supplies critical process equipment. There are several simple ways in which you can increase voltage sag immunity yourself. The best place to start is to find and fix the problem. Once you know what the problem is, it will be much easier to fix. The following are examples of simple corrections that can be implemented to help increase voltage sag immunity 1. Switch power supply settings. Many power supplies can be set to accommodate different voltage ranges. Choose a range where your nominal voltage is near the top of the range to allow more room for voltage sags. 2. Connect your single-phase power supply phase-to-phase. You can get a 70% margin in available voltage by connecting phase-to-phase, if you can stay within your power supplys acceptable voltage range and have three-phase power available. 3. Reduce the load on your power supply. If you can determine that a particular power supply is causing your equipment to misoperate during voltage sag, consider moving some of its loads to another power supply. 4. Increase the rating of your power supply. If you can not move the loads, use a larger supply for the same load relative to its rating. It will then be more lightly loaded. 5. Use a three-phase power supply instead of a single-phase power supply. A properly designed (and lightly loaded) three-phase power supply will effectively tolerate voltage sags on one or two phases that would shut down a single-phase power supply. 6. Run your power supply from a DC bus. If possible, substitute a DC-operated power supply for an AC-sourced supply. This will narrow down your problems to supporting a DC bus, which can often be done with simple capacitors or batteries.

August 2007

Power Quality Bulletin No. 3

7. Change the trip settings. If you can identify an unbalance relay, an under voltage relay, or an internal reset or protection circuit that is inadvertently tripping during a voltage sag, change its settings. Consider changing the threshold and/or the trip delay. This solution resolves trip settings set too conservatively to begin with. However, trips are useful and important so use good judgment as to not eliminate them completely. 8. Slow the relay down. Use a relay with more mechanical mass, such as a contactor or use a relay hold-in accessory. 9. Get rid of the voltage sag itself. As a last resort, consider installing a quick-operating voltage regulator on your AC supply. There are a variety of technologies including ferroresonant transformers, solid-state voltage compensation, etc. Be careful not to make the problem worse if the original cause of the voltage sag is downstream from your voltage sag regulator. The voltage sags will actually get deeper and longer.

For additional information on voltage tolerance relating to these standards, please see our Power Note titled Voltage Tolerance Boundary: http://www.pge.com/includes/docs/pdfs/biz/power_quality/power_quality_notes/voltage_tolerance.pdf.

August 2007

Anda mungkin juga menyukai

- Voltage Sags-Equipment Behavior: 5.1.1 Voltage Tolerance and Voltage-Tolerance CurvesDokumen71 halamanVoltage Sags-Equipment Behavior: 5.1.1 Voltage Tolerance and Voltage-Tolerance CurvesOscar Felipe C.Belum ada peringkat

- Power Quality Reference GuideDokumen104 halamanPower Quality Reference GuideSaeed Osman Mohamed100% (2)

- Voltage Sag Analysis Case StudiesDokumen7 halamanVoltage Sag Analysis Case Studiesmonirul_ahmedBelum ada peringkat

- Voltage Sag Mitigation August 2012 Technical Note 11Dokumen16 halamanVoltage Sag Mitigation August 2012 Technical Note 11Hitarth BuchBelum ada peringkat

- Semi Standards 1Dokumen4 halamanSemi Standards 1SebastianCicognaBelum ada peringkat

- Voltage SagsDokumen12 halamanVoltage SagsSai SivaBelum ada peringkat

- SchneiderDokumen18 halamanSchneideruddinnadeemBelum ada peringkat

- Dhaval VDRDokumen57 halamanDhaval VDRPriyanth AcharyaBelum ada peringkat

- The ANSI/IEEE Code For Phase Sequence Relay Is 47 and of Phase Failure Relay Is 58Dokumen9 halamanThe ANSI/IEEE Code For Phase Sequence Relay Is 47 and of Phase Failure Relay Is 58ax33m144Belum ada peringkat

- Fixing Low Voltage-Undervoltage ProblemsDokumen7 halamanFixing Low Voltage-Undervoltage ProblemsAmany HamdyBelum ada peringkat

- 12 Chapters PDFDokumen74 halaman12 Chapters PDFlokiBelum ada peringkat

- Voltage Regulation: Lecture 9 &10Dokumen42 halamanVoltage Regulation: Lecture 9 &10Syed Muhammad UbaidBelum ada peringkat

- Ipi5998 PDFDokumen16 halamanIpi5998 PDFUzhansEell-neinoBelum ada peringkat

- Catalogo ProgrammaDokumen132 halamanCatalogo Programmakammun007100% (1)

- Voltage Quality Improvement DVRDokumen30 halamanVoltage Quality Improvement DVRKeerthi PriyankaBelum ada peringkat

- Short-Circuit Current Making and Breaking TestsDokumen16 halamanShort-Circuit Current Making and Breaking TestsFelipe Mafioletti Schuartz100% (1)

- Zenergy Power mFCL Protects Electrical GridDokumen8 halamanZenergy Power mFCL Protects Electrical GridBruno SousaBelum ada peringkat

- Stamford AC Generator Fault Finding ManualDokumen29 halamanStamford AC Generator Fault Finding Manual3efooBelum ada peringkat

- Enhance Ride-Through Capability of ASDs Using UltracapacitorsDokumen7 halamanEnhance Ride-Through Capability of ASDs Using UltracapacitorsadmarcovieiraBelum ada peringkat

- Electrical contractors guide to voltage dropDokumen4 halamanElectrical contractors guide to voltage dropAnonymous NcB95G6Xw100% (1)

- Primary Injection Testing On Low-Voltage Circuit Breakers - NETAWORLD JOURNALDokumen13 halamanPrimary Injection Testing On Low-Voltage Circuit Breakers - NETAWORLD JOURNALneoph138Belum ada peringkat

- How Advanced On-Line Partial Discharge Diagnostics Can MakeDokumen12 halamanHow Advanced On-Line Partial Discharge Diagnostics Can MakeBucur Ilie100% (1)

- Power Quality Lab Manual (EE-801)Dokumen12 halamanPower Quality Lab Manual (EE-801)ASHU KBelum ada peringkat

- Resistance GroundingDokumen4 halamanResistance Groundingjawad_13Belum ada peringkat

- 50SDMS01Dokumen11 halaman50SDMS01amazonia1954Belum ada peringkat

- Sine Wave Inverter With PICDokumen50 halamanSine Wave Inverter With PICmtrapkBelum ada peringkat

- PQE 2 MarksDokumen8 halamanPQE 2 MarksfvijayamiBelum ada peringkat

- Reducing Fault Impact on Sensitive LoadsDokumen12 halamanReducing Fault Impact on Sensitive LoadsIAMATMABelum ada peringkat

- 12.1-12 Transf PDFDokumen12 halaman12.1-12 Transf PDFKalpesh LallooBelum ada peringkat

- Solid State On Load Tap Changer For Transformer Using ArduinoDokumen59 halamanSolid State On Load Tap Changer For Transformer Using ArduinoAkhileswara RaoBelum ada peringkat

- 1C.6.1-Voltage Disturbances: 1 ScopeDokumen10 halaman1C.6.1-Voltage Disturbances: 1 ScopeMouna NjBelum ada peringkat

- Mitigating Voltage Sags and Swells Using DSTATCOMDokumen7 halamanMitigating Voltage Sags and Swells Using DSTATCOMMinakshi Bhakkad BhattadBelum ada peringkat

- Electric Power Voltage Sag Solutions-The PQSI Coil-LockDokumen18 halamanElectric Power Voltage Sag Solutions-The PQSI Coil-LockKoti Reddy DoddaBelum ada peringkat

- Voltage Sags ArticleDokumen3 halamanVoltage Sags Articlemonirul_ahmedBelum ada peringkat

- Testing Equipment Manual PDFDokumen114 halamanTesting Equipment Manual PDFSelva MaharajanBelum ada peringkat

- Dielectric Breakdown Voltage of Insulating Liquids Using VDE ElectrodesDokumen5 halamanDielectric Breakdown Voltage of Insulating Liquids Using VDE ElectrodesJavier NegretteBelum ada peringkat

- New Approach to Multifunctional DVR for Distribution SystemsDokumen75 halamanNew Approach to Multifunctional DVR for Distribution Systemsrajesh_d84Belum ada peringkat

- (TI) Frequency Response Measurements For Switching Power SuppliesDokumen13 halaman(TI) Frequency Response Measurements For Switching Power Suppliesdsshin_psBelum ada peringkat

- Compensation of Single-Phase and Three-Phase Voltage Sag and Swell Using Dynamic Voltage RestorerDokumen16 halamanCompensation of Single-Phase and Three-Phase Voltage Sag and Swell Using Dynamic Voltage RestorerBhagya ShreeBelum ada peringkat

- DEE Module 5.3 AllDokumen55 halamanDEE Module 5.3 AllVusi MabuzaBelum ada peringkat

- Voltage Influence On Typical Protection and Controls ForDokumen22 halamanVoltage Influence On Typical Protection and Controls ForM Kumar MarimuthuBelum ada peringkat

- Iaetsd-Minimization of Voltage Sags and Swells Using DVRDokumen8 halamanIaetsd-Minimization of Voltage Sags and Swells Using DVRiaetsdiaetsdBelum ada peringkat

- Current Transformer Testing SWP: 1. Purpose and ScopeDokumen9 halamanCurrent Transformer Testing SWP: 1. Purpose and ScopeDEADMANBelum ada peringkat

- Component Tests: Insulation Test System OverviewDokumen12 halamanComponent Tests: Insulation Test System OverviewYi Fang YueBelum ada peringkat

- IJEDR2001087Dokumen3 halamanIJEDR2001087Maneesh kumar YadavBelum ada peringkat

- PDF Split PDFDokumen24 halamanPDF Split PDFAayush guptaBelum ada peringkat

- Simulation of STATCOM for Reduction of T.H.D Using FLCDokumen5 halamanSimulation of STATCOM for Reduction of T.H.D Using FLCdeepikaBelum ada peringkat

- Tap ChangerDokumen33 halamanTap ChangerMadhavasrinivasan Sathiamoorthy100% (2)

- Technical Manual LSC AlternatorsDokumen51 halamanTechnical Manual LSC Alternatorsramakantinamdar80% (5)

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDari EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesBelum ada peringkat

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesDari EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesBelum ada peringkat

- Practical Switching Power Supply DesignDari EverandPractical Switching Power Supply DesignPenilaian: 2 dari 5 bintang2/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDari EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- IEEE Std 1268™-1997-guide-for-safety-in-the-installation-of-mobile-substation-eDokumen26 halamanIEEE Std 1268™-1997-guide-for-safety-in-the-installation-of-mobile-substation-eAmany HamdyBelum ada peringkat

- Hitachi_Energy_MV_Surge_Arrester_Application_GuidelinesDokumen31 halamanHitachi_Energy_MV_Surge_Arrester_Application_GuidelinesAmany HamdyBelum ada peringkat

- Four Aspects of The Quality of Life The Balance MoDokumen11 halamanFour Aspects of The Quality of Life The Balance MoAmany HamdyBelum ada peringkat

- 16MVA Transformer Inspection ScheduleDokumen1 halaman16MVA Transformer Inspection ScheduleAmany HamdyBelum ada peringkat

- Transformer Losses CalculationDokumen4 halamanTransformer Losses CalculationAmany HamdyBelum ada peringkat

- Handling Objection-FinalDokumen49 halamanHandling Objection-FinalAmany HamdyBelum ada peringkat

- Les Taches Actualisé 25 2 2016Dokumen3 halamanLes Taches Actualisé 25 2 2016Amany HamdyBelum ada peringkat

- Force Calculation 28 MvaDokumen12 halamanForce Calculation 28 MvaAmany HamdyBelum ada peringkat

- WIE Affiity Group Petition FormDokumen1 halamanWIE Affiity Group Petition FormAmany HamdyBelum ada peringkat

- MTG Contest Proposal Power - Within - GenerationsDokumen3 halamanMTG Contest Proposal Power - Within - GenerationsAmany HamdyBelum ada peringkat

- Induction MotorDokumen59 halamanInduction MotorAkama Kulasekara100% (3)

- CALCULATION 10 MVA Short Circuit PDFDokumen4 halamanCALCULATION 10 MVA Short Circuit PDFLevi Franco Carvalho100% (2)

- The Impact of Job Stress On Employee Productivity During Covid-19Dokumen12 halamanThe Impact of Job Stress On Employee Productivity During Covid-19Amany HamdyBelum ada peringkat

- Behavioral Public Administration Ad FontesDokumen18 halamanBehavioral Public Administration Ad FontesAmany HamdyBelum ada peringkat

- Transformer ProtectiponDokumen116 halamanTransformer ProtectiponAmany HamdyBelum ada peringkat

- Digitization of The Economy of Ukraine StrategicDokumen8 halamanDigitization of The Economy of Ukraine StrategicAmany HamdyBelum ada peringkat

- Preparing Transformer SpecsDokumen56 halamanPreparing Transformer SpecsahmaborashedBelum ada peringkat

- Wor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Dokumen11 halamanWor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Amany HamdyBelum ada peringkat

- 5459 22850 1 PBDokumen23 halaman5459 22850 1 PBDARIO BIDESBelum ada peringkat

- The Reality of Resistance To Change Behaviour at The Department ofDokumen14 halamanThe Reality of Resistance To Change Behaviour at The Department ofAmany HamdyBelum ada peringkat

- The Impact of COVID-19 On The Efficiency of Packing Lines inDokumen16 halamanThe Impact of COVID-19 On The Efficiency of Packing Lines inAmany HamdyBelum ada peringkat

- Towards Effective Mitigation of The Digital Transformation andDokumen22 halamanTowards Effective Mitigation of The Digital Transformation andAmany HamdyBelum ada peringkat

- Digital Government Transformation Barriers and EnablersDokumen2 halamanDigital Government Transformation Barriers and EnablersAmany HamdyBelum ada peringkat

- Enhancing Performance of Mwasalat Misr Company in GreaterDokumen16 halamanEnhancing Performance of Mwasalat Misr Company in GreaterAmany HamdyBelum ada peringkat

- World BankDokumen16 halamanWorld BankNathaniel Felix Syailendra PrasetyoBelum ada peringkat

- 2022 OpenNursingJournal theModerationEffectofAffectiveDokumen9 halaman2022 OpenNursingJournal theModerationEffectofAffectiveAmany HamdyBelum ada peringkat

- The New Era of Digital Transformation and COVID-19 Effect On TheDokumen27 halamanThe New Era of Digital Transformation and COVID-19 Effect On TheAmany HamdyBelum ada peringkat

- IEEE C37.99-2000-Shunt Capacitor BankDokumen107 halamanIEEE C37.99-2000-Shunt Capacitor BankAmany HamdyBelum ada peringkat

- Barczak Sotysik Jarosz Zakrzewska KozowskiDokumen18 halamanBarczak Sotysik Jarosz Zakrzewska KozowskiAmany HamdyBelum ada peringkat

- 1LAB000277 VOC Data Sheet enDokumen2 halaman1LAB000277 VOC Data Sheet enRafat ThongBelum ada peringkat

- Novel AC-AC converter commutation techniqueDokumen6 halamanNovel AC-AC converter commutation techniqueBui DaiBelum ada peringkat

- EM-5 Synchronizing An Alternator With The GridDokumen3 halamanEM-5 Synchronizing An Alternator With The GridYogesh KhandelwalBelum ada peringkat

- Diesel Generator User ManualDokumen24 halamanDiesel Generator User Manualابو عمر الغزي100% (2)

- It Server Room Power RequirementsDokumen20 halamanIt Server Room Power RequirementsRajsinghBelum ada peringkat

- Ig 5 ADokumen1 halamanIg 5 AMarcos AldrovandiBelum ada peringkat

- Sensorless Control of Three-Phase PWM RectifiersDokumen128 halamanSensorless Control of Three-Phase PWM RectifiersSaidah BaisaBelum ada peringkat

- Baylor ManualDokumen28 halamanBaylor ManualEliecer Diaz100% (3)

- Balanced Faults ExplainedDokumen31 halamanBalanced Faults ExplainedFaiza Tabassam 546-FET/BSEE/F19Belum ada peringkat

- Ideal AutotransformerDokumen10 halamanIdeal AutotransformerBT21EE017 Gulshan RajBelum ada peringkat

- HF-320 Series Inverter Instruction ManualDokumen103 halamanHF-320 Series Inverter Instruction Manualmoshik99100% (8)

- Power System HarmonicsDokumen74 halamanPower System HarmonicsTana AzeezBelum ada peringkat

- Voltage Stabilisers Technical DataDokumen28 halamanVoltage Stabilisers Technical DataPetar HosticBelum ada peringkat

- CEB Past Papers PDFDokumen2 halamanCEB Past Papers PDFAnuradha Jayathilaka86% (14)

- Final Exam Circuits and SystemsDokumen6 halamanFinal Exam Circuits and SystemsMr KBelum ada peringkat

- IMG - 0537 EE PreBoard Exam 15Dokumen1 halamanIMG - 0537 EE PreBoard Exam 15let ramBelum ada peringkat

- HPV 600 AC Elevator Drive: Technical ManualDokumen172 halamanHPV 600 AC Elevator Drive: Technical ManualShadi MattarBelum ada peringkat

- EHV AC/DC Transmission and Electric Drives Protection SyllabusDokumen7 halamanEHV AC/DC Transmission and Electric Drives Protection SyllabusManmohan MeenaBelum ada peringkat

- GE CatalogDokumen3 halamanGE CatalogBob sageBelum ada peringkat

- EE6501 Power System AnalysisDokumen161 halamanEE6501 Power System AnalysisMahendiran CrBelum ada peringkat

- DET40073 - Topic 2cDokumen26 halamanDET40073 - Topic 2cKuhaanProBelum ada peringkat

- Induction MotDokumen15 halamanInduction Motsuresh krishnanBelum ada peringkat

- Rotary Tablet Press TP27 MANUALDokumen53 halamanRotary Tablet Press TP27 MANUALEnrique AltuveBelum ada peringkat

- Control and Operation of A DC Grid-Based WindDokumen10 halamanControl and Operation of A DC Grid-Based WindDr. Gollapalli NareshBelum ada peringkat

- ElectricityDokumen7 halamanElectricityArabela MapaladBelum ada peringkat

- Ditribution SystemDokumen17 halamanDitribution SystemPRITAM RAJBelum ada peringkat

- Centrifugal pumps for clean water and agricultural/industrial useDokumen4 halamanCentrifugal pumps for clean water and agricultural/industrial usekhusnulBelum ada peringkat

- EPM - 07 - 07S - Manual - ENTESDokumen4 halamanEPM - 07 - 07S - Manual - ENTESAhmed Mohamed Kamal El-DeenBelum ada peringkat

- Basic Mepf Design For A Mix-Use BLDGDokumen91 halamanBasic Mepf Design For A Mix-Use BLDGKristopher San JoseBelum ada peringkat

- IJEEI Journal Template ExampleDokumen9 halamanIJEEI Journal Template ExampleFadjar RahinoBelum ada peringkat

- 205 Power TransientDokumen315 halaman205 Power TransientPrateek DavidBelum ada peringkat