Pages From ASME B31.8 - 2012 - Valve PDF

Diunggah oleh

Anant RubadeJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pages From ASME B31.8 - 2012 - Valve PDF

Diunggah oleh

Anant RubadeHak Cipta:

Format Tersedia

ASME B31.

8-2012

Chapter III Piping System Components and Fabrication Details

830 PIPING SYSTEM COMPONENTS AND FABRICATION DETAILS 830.1 General

(a) The purpose of this Chapter is to provide a set of standards for piping systems covering (1) specifications for and selection of all items and accessories that are a part of the piping system, other than the pipe itself (2) acceptable methods of making branch connections (3) provisions to care for the effects of temperature changes (4) approved methods for support and anchorage of exposed and buried piping systems (b) This Chapter does not include (1) pipe materials (see Chapter I) (2) welding procedures (see Chapter II) (3) design of pipe (see Chapter IV) (4) installation and testing of piping systems (see Chapter IV) (5) special conditions for offshore application (see Chapter VIII) (6) special conditions for sour gas application (see Chapter IX) ASME B16.33 Manually Operated Metallic Gas Valves for Use in Gas Piping Systems up to 125 psi (Sizes NPS 12 Through NPS 2) Valves Flanged, Threaded, and Welded End Large Metallic Valves for Gas Distribution (Manually Operated, NPS 212 to 12, 125 psig Maximum) Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution Systems Cast Iron Gate Valves, Flanged and Threaded Ends Gray Iron Swing Check Valves, Flanged and Threaded Ends Cast Iron Plug Valves, Flanged and Threaded Ends

ASME B16.34 ASME B16.38

ASME B16.40

MSS SP-70 MSS SP-71 MSS SP-78

831 PIPING SYSTEM COMPONENTS

All components of piping systems, including valves, flanges, fittings, headers, special assemblies, etc., shall be designed in accordance with the applicable requirements of this section and recognized engineering practices to withstand operating pressures and other specified loadings. Components shall be selected that can withstand the design, operating, and test conditions of the system in which the component is to be used without failure or leakage and without impairment of their serviceability.

(b) Valves having shell (body, bonnet, cover, and/or end flange) components made of cast ductile iron in compliance with ASTM A 395 and having dimensions conforming to ASME B16.1, ASME B16.33, ASME B16.34, ASME B16.38, API 6D/ISO 14313, or ASME B16.40 may be used at pressures not exceeding 80% of the pressure ratings for comparable steel valves at their listed temperature, provided the pressure does not exceed 1,000 psi (6 900 kPa), and welding is not employed on any ductile iron component in the fabrication of the valve shells or their assembly as part of the piping system. (c) Valves having shell components made of cast iron shall not be used in gas piping components for compressor stations.

831.1.2 Threaded Valves. Threaded valves shall be threaded according to ASME B1.20.1, API 5L, or API 6A. 831.1.3 Pressure Reducing Devices. Pressure reducing devices shall conform to the requirements of this Code for valves in comparable service conditions.

831.1 Valves and Pressure-Reducing Devices

831.1.1 Valves Without Threads. Valves shall conform to standards and specifications referenced in this Code and shall be used only in accordance with the service recommendations of the manufacturer. (a) Valves manufactured in accordance with the following standards may be used: API 6A Specification for Wellhead and Christmas Tree Equipment API 6D/ISO 14313 Pipeline Valves

23

Copyright ASME International Provided by IHS under license with ASME No reproduction or networking permitted without license from IHS

831.2 Flanges

831.2.1 Flange Types and Facings (a) The dimensions and drilling for all line or end flanges shall conform to one of the following standards:

ASME B16.1 Cast Iron Pipe Flanges and Flanged Fittings Classes 25, 125, and 250

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- 2332 RotaryBrochure-ENrev00Dokumen8 halaman2332 RotaryBrochure-ENrev00Anant RubadeBelum ada peringkat

- FPFM+ K VKSJ Pqjaqxqu: Igyk IkbDokumen4 halamanFPFM+ K VKSJ Pqjaqxqu: Igyk IkbSubodh JindalBelum ada peringkat

- Astm E119-2000 PDFDokumen22 halamanAstm E119-2000 PDFMohammed TariqBelum ada peringkat

- Astm A743 PDFDokumen6 halamanAstm A743 PDFzafarbadal100% (2)

- APIA PE Code of Practice summaryDokumen180 halamanAPIA PE Code of Practice summaryAnant RubadeBelum ada peringkat

- Astm A 694Dokumen3 halamanAstm A 694Kelly BatesBelum ada peringkat

- Astm d2992Dokumen11 halamanAstm d2992Firas Maitig100% (2)

- Passive Corrosion Prevention For Flanges and Valves: Product InformationDokumen3 halamanPassive Corrosion Prevention For Flanges and Valves: Product InformationAnant RubadeBelum ada peringkat

- Densoplast - Tape: Product InformationDokumen2 halamanDensoplast - Tape: Product InformationAnant RubadeBelum ada peringkat

- A325Dokumen8 halamanA325Ramon LiraBelum ada peringkat

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDokumen5 halamanSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceAnant RubadeBelum ada peringkat

- Astm A297-1998 PDFDokumen3 halamanAstm A297-1998 PDFMohammed TariqBelum ada peringkat

- Nace TM0177 PDFDokumen36 halamanNace TM0177 PDFAnant RubadeBelum ada peringkat

- Astm A707 PDFDokumen5 halamanAstm A707 PDFCristian OtivoBelum ada peringkat

- STD 174Dokumen40 halamanSTD 174Anant RubadeBelum ada peringkat

- List of StandardsDokumen6 halamanList of StandardsAnant RubadeBelum ada peringkat

- Oisd STD 194Dokumen49 halamanOisd STD 194pohary100% (1)

- List of Standards SubjectwiseDokumen8 halamanList of Standards SubjectwiseAnant RubadeBelum ada peringkat

- Reference Check FormDokumen2 halamanReference Check FormAnant RubadeBelum ada peringkat

- Green Gas Specification - GAIL & IOCLDokumen6 halamanGreen Gas Specification - GAIL & IOCLAnant RubadeBelum ada peringkat

- September 18, 2000 01:10:10 Information Handling Services, 2000Dokumen8 halamanSeptember 18, 2000 01:10:10 Information Handling Services, 2000Anant RubadeBelum ada peringkat

- Drying & Cleanning SpecificationDokumen5 halamanDrying & Cleanning SpecificationAnant Rubade100% (1)

- General Guidelines For Squeezing Off Polyethylene Pipe in Water, Oil and Gas ApplicationsDokumen7 halamanGeneral Guidelines For Squeezing Off Polyethylene Pipe in Water, Oil and Gas ApplicationsAnant RubadeBelum ada peringkat

- Welder Certification ProcedureDokumen28 halamanWelder Certification ProcedureAnant Rubade100% (1)

- Locate IOCL Petrol Pumps by District MapDokumen3 halamanLocate IOCL Petrol Pumps by District MapAnant Rubade50% (2)

- General Guidelines For Squeezing Off Polyethylene Pipe in Water, Oil and Gas ApplicationsDokumen7 halamanGeneral Guidelines For Squeezing Off Polyethylene Pipe in Water, Oil and Gas ApplicationsAnant RubadeBelum ada peringkat

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDokumen5 halamanSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceAnant RubadeBelum ada peringkat

- Scanned With CamscannerDokumen27 halamanScanned With CamscannerAnant RubadeBelum ada peringkat

- Painting SpeciationDokumen27 halamanPainting SpeciationAnant RubadeBelum ada peringkat

- General Guidelines For Squeezing Off Polyethylene Pipe in Water, Oil and Gas ApplicationsDokumen7 halamanGeneral Guidelines For Squeezing Off Polyethylene Pipe in Water, Oil and Gas ApplicationsAnant RubadeBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Sarthak WorksheetDokumen15 halamanSarthak Worksheetcyber forensicBelum ada peringkat

- SVIMS-No Que-2Dokumen1 halamanSVIMS-No Que-2LikhithaReddy100% (1)

- MR23002 D Part Submission Warrant PSWDokumen1 halamanMR23002 D Part Submission Warrant PSWRafik FafikBelum ada peringkat

- FB77 Fish HatcheriesDokumen6 halamanFB77 Fish HatcheriesFlorida Fish and Wildlife Conservation CommissionBelum ada peringkat

- Piping Material Classes GuideDokumen98 halamanPiping Material Classes GuideLuis Pottozen VillanuevaBelum ada peringkat

- Heat Exchanger Sodium SilicateDokumen2 halamanHeat Exchanger Sodium SilicateChristopher BrownBelum ada peringkat

- History of The Stethoscope PDFDokumen10 halamanHistory of The Stethoscope PDFjmad2427Belum ada peringkat

- MAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFDokumen2 halamanMAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFXavi AnpiBelum ada peringkat

- Pictorial History of AOTADokumen5 halamanPictorial History of AOTAThe American Occupational Therapy Association0% (4)

- Immune System Quiz ResultsDokumen6 halamanImmune System Quiz ResultsShafeeq ZamanBelum ada peringkat

- FinalsDokumen8 halamanFinalsDumpBelum ada peringkat

- Synthesis, Experimental and Theoretical Characterizations of A NewDokumen7 halamanSynthesis, Experimental and Theoretical Characterizations of A NewWail MadridBelum ada peringkat

- Rudraksha - Scientific FactsDokumen20 halamanRudraksha - Scientific FactsAkash Agarwal100% (3)

- Design and Built-A4Dokumen2 halamanDesign and Built-A4farahazuraBelum ada peringkat

- 1 Colmac DX Ammonia Piping Handbook 4th EdDokumen64 halaman1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoBelum ada peringkat

- Completed Manuscript 1 5Dokumen52 halamanCompleted Manuscript 1 5SAMANTHA LACABABelum ada peringkat

- Block 1 Board Review - Lecture NotesDokumen127 halamanBlock 1 Board Review - Lecture NotesCece RereBelum ada peringkat

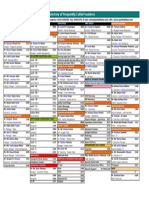

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDokumen1 halamanDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoBelum ada peringkat

- 2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and ChildDokumen3 halaman2.1. Pharmacological Therapeutics. 2.2. Basic Cardiac Life Support (BCLS) and Advanced Cardiac Life Support (ACLS) in Neonates and Childclint xavier odangoBelum ada peringkat

- Construction and Operation 1. Air Conditioning Control PanelDokumen18 halamanConstruction and Operation 1. Air Conditioning Control PanelRoma KuzmychBelum ada peringkat

- Speaking Coursebook C1.1Dokumen80 halamanSpeaking Coursebook C1.1Yến VõBelum ada peringkat

- Treatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Dokumen5 halamanTreatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Victoria LeahBelum ada peringkat

- Assessment Formal AssessmentDokumen7 halamanAssessment Formal Assessmentashish33% (3)

- Health 6 Q 4 WK 6 Module 6 Version 4Dokumen16 halamanHealth 6 Q 4 WK 6 Module 6 Version 4Kassandra BayogosBelum ada peringkat

- Q1 Tle 4 (Ict)Dokumen34 halamanQ1 Tle 4 (Ict)Jake Role GusiBelum ada peringkat

- Esaote MyLabX7Dokumen12 halamanEsaote MyLabX7Neo BiosBelum ada peringkat

- Cellular Basis of HeredityDokumen12 halamanCellular Basis of HeredityLadyvirdi CarbonellBelum ada peringkat

- Nursing Care PlansDokumen10 halamanNursing Care PlansGracie S. Vergara100% (1)

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Dokumen3 halamanTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARBelum ada peringkat

- Calm Your Aggressive DogDokumen58 halamanCalm Your Aggressive DogASd33475% (4)