Engro'S Experience: in The Construction and Start Up of A Jumbo-Scale Plant

Diunggah oleh

Ajay SastryJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Engro'S Experience: in The Construction and Start Up of A Jumbo-Scale Plant

Diunggah oleh

Ajay SastryHak Cipta:

Format Tersedia

INAMULLAH NAVEED KHAN

VP MANUFACTURING

ENGRO FERTILIZERS LTD

PAKISTAN

IN THE CONSTRUCTION

AND START UP OF

A JUMBO-SCALE PLANT

ENGROS EXPERIENCE

EnVen1.3 PROJECT OVERVIEW

HaldorTopsoeAmmonia Plant with 2,194 MTD

SAIPEMUrea Plant with 3,835 MTD

Largest Single Train Urea Plant in the World

One of the largest Urea Complex in the World

Tallest PrillTower of the World (125 m)

CO2Recovery (350 MTD) fromFurnace Flue Gases

Environmentally Compliant Plant with Flare System

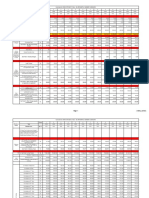

TRIR & Man-hours Trend

Statistics

May-11

2.2

5.7 11.2

20.1

32.0

43.0

50.0 51.6

0.45

1.3

2011

Consciousness

Jun-07

Dec-07

Jun-08

Dec-08

Jun-09

Dec-09

Jun-10

Dec-10

0

0.19

0.18

0.16

0.22

0.22 0.25

0.28

0.27

TRIR & Man-hours TRIR

0.2

8

Man-hours

51.6

Jun-11

COD

Land Leveling

Earth Movement

Excavation

Air Condition/ HVAC

Precast Bar Bending

Foundation work

Concrete work

MANNING

H

A

Z

A

R

D

Refractory works

Insulation on grounds

Low Hazard/

High Manning

Low Hazard/

Low Manning

High Hazard/

Low Manning

High Hazard/

High Manning

Prill Tower Slipforming

STR-101/ Concrete work at heights

Painting & insulation at height

Cutting

Welding

Grinding

Vessel Entry

Structure Steel Erection

Rigging

Startup

Gas in

Scaffolding at Height

Piping erection at height

Hydro-test

Blowing

Process Fluid

2Q 07

4Q 07

1Q 08

4Q 08

1Q 09

2Q 09

4Q 10

- Machinery Startup

- Heavy Rigging

- Electrical Circuit

Energization

- Prill Tower External

Painting at Height

- Excavations post startup of UG

services

1.3

2011

Technology

Project Executive

SOC Chairman

Sub

SOC

(P)

Sub

SOC (M)

Sub

SOC

(I&E)

Sub

SOC

Civil

Sub SOC

Environment

Sub

SOC

IRRC

Safety

Advisor

Safety Engineer (1)

Safety Facilitator with

Construction Dpt. (35)

Safety Supervisor (1)

Safety Facilitator (11)

Descon HSE Team

Manager (1)

Engineer (20)

Officers/ Sup (40)

Assistant (20)

Doctor (1)

Paramedic (2)

HSE Or gani zat i on

Pr oj ect SOC & Sub SOCs

Saf et y sect i on r ol e and

r esponsi bi l i t i es

Cont r act or s Saf et y

Or gani zat i on

Saf et y f aci l i t at or f or ever y

const r uct i on j ob

I ndi vi dual Char t er f or SOCs

avai l abl e

HSE Organization

PROJECT

EXECUTIVE

PLANNING &

CONTRACTS

MANAGER

ENGINEERING

MANAGER

CONSTRUCTION

MANAGER

AMMONIA, UREA

CONSTRUCTION

MANAGER

UTILITIES

SAFETY

ADVISOR

Planning,

Contracts &

Procurement

Engineers

Process, Project

Machinery,

Civil, I&E

Engineers

Project,

Inspection,

Civil, Machinery

Safety

Engineers

CEO

OPERATIONS &

START-UP

MANAGER

Operations

Engineers &

Supervisors

CONSTRUCTION

MANAGER

I & E

I & E Engineers

Project,

Inspection,

Civil, Machinery

I&E Engineers

SENIOR ADVISOR

QA/QC

QA/QC

Engineer

ENGINEERS: 85

OPERATORS &

TECHNICIANS: 152

TOTAL: 237

ENVEN 1.3 PROJECT CONTRACTING

STRATEGY

Overall Project Management

EP

Ammonia, Urea

Selected Utilities

Saipem

Engineering

SP Netherlands

Purchase & Supply

Of Equipment

Saipem, Madeira

Limited Construction

SupervisionSaipem, Italy

CONSTRUCTION

Ammonia, Urea

Utilities & PM&S

Descon

EP

Utilities,PM&S

EFERT

LSTK

Offsite Facilities

Descon

EPC

CO2 Recovery Project

Descon

EP-WLGE

CONS-Descon

Ammonia Storage Proj

1

Based on Schedule

Descon

35%

EFERT

Engineering &

Procurment

15%

Saipem

Engineering &

Procurement

45%

Commissioning

5%

1

ENVEN 1.3 PROJ ECT

SAFETY

TRIR <0.5

PSRM& PSM

PHA / HAZOP

Project Specific

Systems

Contractor Safety

Monitoring &

Reporting

Incident Investigation

QUALITY

FATs & SATs

Construction Quality

Quality Assurance

Checklists

Hold point concept

Internal quality

reviews

Limited Construction

supervision

COST

Regular

Monitoring

Independent

Reporting

Monthly &

Quarterly

Variance

reports

InterimReviews

SCHEDULE

Integrated Team

Use of modern softwares

for monitoring & reporting.

Monthly & Quarterly Reports

Proactive Approach to

mitigate

Positive variance

InterimReviews

0

10

20

30

40

50

60

70

80

90

100

M

a

r

-

0

7

A

p

r

-

0

7

M

a

y

-

0

7

J

u

n

-

0

7

J

u

l

-

0

7

A

u

g

-

0

7

S

e

p

-

0

7

O

c

t

-

0

7

N

o

v

-

0

7

D

e

c

-

0

7

J

a

n

-

0

8

F

e

b

-

0

8

M

a

r

-

0

8

A

p

r

-

0

8

M

a

y

-

0

8

J

u

n

-

0

8

J

u

l

-

0

8

A

u

g

-

0

8

S

e

p

-

0

8

O

c

t

-

0

8

N

o

v

-

0

8

D

e

c

-

0

8

J

a

n

-

0

9

F

e

b

-

0

9

M

a

r

-

0

9

A

p

r

-

0

9

M

a

y

-

0

9

J

u

n

-

0

9

J

u

l

-

0

9

A

u

g

-

0

9

S

e

p

-

0

9

O

c

t

-

0

9

N

o

v

-

0

9

D

e

c

-

0

9

J

a

n

-

1

0

F

e

b

-

1

0

M

a

r

-

1

0

A

p

r

-

1

0

M

a

y

-

1

0

J

u

n

-

1

0

J

u

l

-

1

0

A

u

g

-

1

0

S

e

p

-

1

0

O

c

t

-

1

0

N

o

v

-

1

0

D

e

c

-

1

0

%

C

u

m

m

u

l

a

t

i

v

e

P

r

o

g

r

e

s

s

0

1

2

3

4

5

6

7

8

%

M

o

n

t

h

l

y

P

r

o

g

r

e

s

s

Monthly Planned Baseline

Monthly Planned Forecast 4

Monthly Revised Actual Progress

Monthly Planned Progress (August

2009)

Cummulative Planned Progress

Baseline

Cumulative Planned Forecast 4

Cumulative Revised Actual Progress

Cummulative Planned Progress (August

Planned : 100.00%

Actual : 99.96%

1.- 2010

1

Engg&Procurement

Snamprogetti

ECPL

Const / Mechanical Completion

Utilities

Ammonia

Urea

Critical Path Items

Cooling Water Pumps

Process Air Compressor

Ammonia Piping

Primary Reformer

Sub-Critical Path Items

Offsite EPC Contracts

Ammonia Storage

Commissioning

Pre-Commissioning

Commissioning

Production

end-Aug 2009

end-March 2010

17 J an 2010

25 April 2010

18 J une 2010

31 Oct 2009 mid-Aug 2009

15 April 2010

mid-Oct 2009

mid-May 2008

25 April 2010

06 April 2010 end-Aug 2008

01 J uly 2007 30 May 2009

mid-May 2007

J une 2009

May 2009

Oct, 2010

J an 2010

Dec, 2010

Increase in construction quantities.

De-watering Surprise on start of Civil Works

Industrial peace issues & their impact

Unprecedented rains & floods in 2010.

Failure of weld joints on critical path systems towards the end.

Commissioning delay by 22 days due to fire at syncomp.

COD delays due to non-availability of gas

PWHT machines must be audited properly before acceptance.

Construction contractor must not be given full authority on QA/QC

QA/QC functions must be directly reporting to Project Executive

Average experience of QA/QC team must be around 10 years

Work on radiography scope from the initial phase of construction

Killed carbon steel material must be marked before fabrication

Welding of heavy thickness piping must be done first

N

o

.

o

f

W

e

l

d

s

Techniques Used

Team Build-up

Procedures development

More than 530 procedures were developed for operational activities

Training

400 man hours per person thru following trainings;

In house classroom training

Similar technology plants

Training by technology licensors

Training on Operator Training simulator (OTS)

Pre-commissioning

High pressure test of Synthesis loop at 200 Kg/cm

2

in addition to normal activities

Commissioning & Start-up

Frontend commissioned in 05 days

Back-end commissioned in 07 days

Urea on-spec achieved with-in 48 hours of ammonia production

Same vendor was selected for DCS & OTS

A number of potential shut downs were saved by

OTS trained operators

Front end was normalized in record 05 days

Malfunctions & Controller behaviors were well-

understood upfront and fixed.

OTS HALL

Control Room

OTS HALL

Control Room

System-wise requirements audit

Pre-startup Safety Reviews (PSSR) recommendations closure

Temporary gaskets audit

Piping conformity audit by SAIPEM for frontend

Instrument air leakage audit

Pre-startup PHA recommendations closure

Audit for completion of permissive for feed-in

Housekeeping & Combustible Material Audit

OTS HALL

Control Room

CW low

pressure

on pump

change-

over

A wrong

signal was

generated by

cooling water

pumps ESD

which

resulted in

nuisance I-1

Control

Power

failure to

reformer

ID fan

speed

probes

due to

tripping of

power

distribution

cabinet.

I-1 was

manually

activated due

to fire at

synthesis

machine.

Air

compressor

tripped and

protection

steam in air

convection coil

was not

established in

time due to

slow response

of protection

steam flow

control valve.

DATE MONTH Milestones / Activities

4-Apr-2007 0 Effective date of contract

19-Dec-2009 32

nd

Start of Steam blowing

12-Jun-2010 39

th

Air compressor commissioned

20-Aug-2010 41

st

Ammonia storage commissioned

11-Nov-2010 43 m 7 days Feed-in to Primary Reformer

16-Nov-2010 43 m 12 days Frontend Normalized in 05 days

17-Nov-2010 43 m 13 days Backend start-up heldback due to gas limitation

29-Nov-2010 43 m 25 days Fire at SynCompressor

20-Dec-2010 44 m 16 days Restart of Synthesis Compressor

26-Dec-2010 44 m22 days AmmoniaProduction

29-Dec-2010 44 m25 days Urea Production

GAS CONSUMPTION DURING PRE-COM& COMMISSIONING

Energy for Pre-commissioning 550,000 G cal

Energy for commissioning & startup 650,000 G cal

Total Energy consumption 1,200,000 G cal

Front end Startup & normalizationfrom feed in 05 days

Backend startup & Production 07 days

Effective Ammonia plant startup time barring thegas 12 days

outage & Syn comp incident

Total waste water generated 26 Million US Gal

Construction completion timefrom effective date of contract 43 months 22 days

EmergencyResponse

The machine was immediately shutdown by using

fieldmanual switch.

The fire was extinguished immediately by operating

delugesystem(water sprinkler).

RemedialMeasures

Carried out quality assurance checks of all thermo-

wells &instrument hook-ups on all critical / hazardous

systemsandseal welded.

Install all thermo-wells as per standard practice given

inANSI StandardonNPTthreads.

Background

During pressurization of syncompressor, thermocouple

at recycle suction dislodged.

Dislodging of a thermo-well resulted in Fire.

Flames from the fire hit air compressor turbine.

Faulty installation of threadolet, which didnt allowed the

thermo-well to be fully tightened.

Excessive root penetration hindered thermo-well

insertion

Thredolet 3

rd

Suction Line after Flame Impingement

Ammonia feed pump, P-01B tripped on high vib

security, restarted but tripped again.

Ebara responded proactively & impeller hub was

shortened.

Similar modification was done at the other pump

CO2compressor surging on 02 occasions

Min governor speed was changed from 5693 to

6476 rpm

Extensive training of manpower and well-structured utilization of

Thorough and once through pre-commissioning

Several layers of audits performed

All circuits pressure tested

Synthesis loop was tested at 200 Kg/cm2 pressure with nitrogen

All critical circuits were pressure tested with nitrogen / air.

Frontend was pressure tested with nitrogen and soap test was carried out.

April 2007

November 2010

Apr 2007 Sep 2007

Oct 2007 Nov 2007 Dec 2007

Jan 2008

Feb 2008 Mar 2008

Apr 2008

May 2008

Jun 2008 Jul 2008

Furnace in Operation

Purification Post at Night

450 Tons Synthesis Converter Reactor Rigging by 1200T Crane

365T Urea Reactor (R-01) erected using 1200T Crane

165T LP/HP Flash Drum (V-301/302) erected using 1200T Crane

385T CO2 Absorber (C-302) erection using 1200T Crane

450T Prill Tower Truss Structure lifted to 109m Elevation

Ammonia Storage Tank Commissioned

5000 MT NH3Capacity

Double-Walled Tank

Men @ Work

Men @ Work

Men @ Work

Safety Talk

DAHARKI EXPANSION

Anda mungkin juga menyukai

- USP Presentation MunicipalDokumen20 halamanUSP Presentation Municipalcoolvishal2003Belum ada peringkat

- DH3-31HFC-T-SCT-0010 Commissioning Procedure of Coal Pulverizing System REV.0Dokumen11 halamanDH3-31HFC-T-SCT-0010 Commissioning Procedure of Coal Pulverizing System REV.0hungBelum ada peringkat

- 5.NTPC Simhadri Presentation On Best Practices of O&MDokumen22 halaman5.NTPC Simhadri Presentation On Best Practices of O&Mswaroop351100% (1)

- U.K. Shakyawar - ERDMPDokumen32 halamanU.K. Shakyawar - ERDMPPanchdev KumarBelum ada peringkat

- Contact: Mumtaz Abbas, Power Plant Operations EngineerDokumen5 halamanContact: Mumtaz Abbas, Power Plant Operations EngineerMuhammad Hamza NaveedBelum ada peringkat

- Materi Kuliah Umum - Steam and Energy Conservation Technology UNSRIDokumen123 halamanMateri Kuliah Umum - Steam and Energy Conservation Technology UNSRIAndiga UtamiBelum ada peringkat

- BP Texas Oil RefineryDokumen21 halamanBP Texas Oil Refinerymuhammad saifullahBelum ada peringkat

- Project at A Glance: 3 X 660 MW Boilers and Auxiliary InstallationDokumen16 halamanProject at A Glance: 3 X 660 MW Boilers and Auxiliary InstallationSumit Agrawal100% (1)

- Case Study Troubleshooting Centrifugal Compressor TripsDokumen13 halamanCase Study Troubleshooting Centrifugal Compressor TripsiJordanScribdBelum ada peringkat

- Vibration Induced Fatigue Safety MomentDokumen9 halamanVibration Induced Fatigue Safety MomentAnthony BarnesBelum ada peringkat

- Environment Impact Assessment CommentDokumen4 halamanEnvironment Impact Assessment Commentyoga nayagi punichelvanaBelum ada peringkat

- KBRDokumen28 halamanKBRYulianto Triyono HadiBelum ada peringkat

- Lifting Operations and Lifting Equipment Regulations 1998 LOLERDokumen34 halamanLifting Operations and Lifting Equipment Regulations 1998 LOLERfaiz_oe100% (1)

- Alaoji Pre-Comm & Comm ProcedureDokumen15 halamanAlaoji Pre-Comm & Comm ProcedureIshola TaiwoBelum ada peringkat

- EPC Proposal 3x660 MWDokumen11 halamanEPC Proposal 3x660 MWSameer BetalBelum ada peringkat

- Advanced Onsite Hydrogen Generation For Power Plants - India - 2011 - PDFDokumen67 halamanAdvanced Onsite Hydrogen Generation For Power Plants - India - 2011 - PDFkaruna346100% (1)

- Work Procedure For The Construction of CO2 Cylinder HouseDokumen9 halamanWork Procedure For The Construction of CO2 Cylinder HouseJoyce GordonioBelum ada peringkat

- Clock Spring BrochureDokumen63 halamanClock Spring BrochureJomer J Simpson100% (1)

- 11-12 PrecommissioningDokumen2 halaman11-12 PrecommissioningEleonoraBelum ada peringkat

- Engineered Flow ChutesDokumen33 halamanEngineered Flow ChutesBrianBelum ada peringkat

- Mock DrillDokumen34 halamanMock DrillvhlactaotaoBelum ada peringkat

- Summer Internship @essar Projects (I) Ltd.Dokumen44 halamanSummer Internship @essar Projects (I) Ltd.ROHAN CHOPDEBelum ada peringkat

- Green Co Best Practice Award 2016 PresentationDokumen22 halamanGreen Co Best Practice Award 2016 PresentationSivakumaran RajuBelum ada peringkat

- Propane Gas System Scope of WorkDokumen10 halamanPropane Gas System Scope of WorkaeliusmanoBelum ada peringkat

- Prmary Reformer Catastrophic FailureDokumen9 halamanPrmary Reformer Catastrophic FailureRizwan GujjarBelum ada peringkat

- Explosion at The Conoco Humber Refinery - Lessons Learned PDFDokumen29 halamanExplosion at The Conoco Humber Refinery - Lessons Learned PDFMuhammad IqmalBelum ada peringkat

- Plantas de ChancadoDokumen29 halamanPlantas de Chancadoeiner1110_609484259Belum ada peringkat

- FGD Design and Operating CriteriaDokumen52 halamanFGD Design and Operating CriteriaTomek100% (1)

- Kentz Global - Summary PresentationDokumen22 halamanKentz Global - Summary PresentationNatarajan RavisankarBelum ada peringkat

- Hazira Eeplc Presentation 8-12-2011Dokumen54 halamanHazira Eeplc Presentation 8-12-2011Khalid MahmoodBelum ada peringkat

- EPC Execution of Borealis Ethane Tank Project TGE enDokumen20 halamanEPC Execution of Borealis Ethane Tank Project TGE enLEEBelum ada peringkat

- Plant Process Audits2 PDFDokumen38 halamanPlant Process Audits2 PDFvilas bollabathiniBelum ada peringkat

- Purification KATALCO Mar 07Dokumen16 halamanPurification KATALCO Mar 07SimEnzBelum ada peringkat

- EIA Kamachi EngDokumen12 halamanEIA Kamachi Engsureshkumar908Belum ada peringkat

- Compressor Rotor Failure Due To FoulingDokumen6 halamanCompressor Rotor Failure Due To FoulingAbdelkader TayebiBelum ada peringkat

- Clorosur FinalDokumen23 halamanClorosur FinalvasucristalBelum ada peringkat

- Directive 54 - CNRL 2012 PAW Annual Review SurfaceDokumen79 halamanDirective 54 - CNRL 2012 PAW Annual Review SurfaceEmma PullmanBelum ada peringkat

- The Alter NRG Plasma Gasification Process - Turner Valley PresentationDokumen19 halamanThe Alter NRG Plasma Gasification Process - Turner Valley PresentationPerro Col100% (1)

- OGDCL Internship Report SummaryDokumen25 halamanOGDCL Internship Report Summarytrick masterBelum ada peringkat

- CV - E&I EngineerDokumen3 halamanCV - E&I EngineerAbeer Haris0% (1)

- Duyen Hai 3 Thermal Power Project Commissioning ProcedureDokumen24 halamanDuyen Hai 3 Thermal Power Project Commissioning ProcedureLan Rung100% (1)

- Role of Nuclear Power in India'S Power-MixDokumen19 halamanRole of Nuclear Power in India'S Power-MixsureshBelum ada peringkat

- Ruby Pipeline Pre-Commissioning (Rev)Dokumen32 halamanRuby Pipeline Pre-Commissioning (Rev)Dheeraj Chowdary Dhanekula100% (1)

- OIL India EOI for Lakwagaon OCS and ETP ProjectDokumen7 halamanOIL India EOI for Lakwagaon OCS and ETP ProjectSunil WadekarBelum ada peringkat

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaDokumen21 halamanCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaBelum ada peringkat

- Advanced Well CompletionDokumen25 halamanAdvanced Well CompletionM.c. Tim LimBelum ada peringkat

- Project ExecutionDokumen56 halamanProject ExecutionSoni Mishra Tiwari100% (2)

- Com .& Start-Up Strategy 120926Dokumen24 halamanCom .& Start-Up Strategy 120926rodinsendiong100% (1)

- Boilers Commisioning: BY Thermax Babcock & WilcoxDokumen20 halamanBoilers Commisioning: BY Thermax Babcock & WilcoxBv RaoBelum ada peringkat

- Operational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionDokumen6 halamanOperational Audit: An Effective Way FOR Enhancement of Plant Productivity and Savings in Energy ConsumptionJoshua JordanBelum ada peringkat

- 00 - Dri Operations Update To Damam Delegation - Aak - 04102010Dokumen27 halaman00 - Dri Operations Update To Damam Delegation - Aak - 04102010SalmanEjazBelum ada peringkat

- Power Zone Company ProfileDokumen31 halamanPower Zone Company ProfileDanish HamidBelum ada peringkat

- Resource PilingDokumen38 halamanResource PilingtatonyBelum ada peringkat

- Introduction to Petroleum Process SafetyDari EverandIntroduction to Petroleum Process SafetyPenilaian: 3 dari 5 bintang3/5 (2)

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDari EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Thermal Power Plant: Pre-Operational ActivitiesDari EverandThermal Power Plant: Pre-Operational ActivitiesPenilaian: 4 dari 5 bintang4/5 (4)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDari EverandModeling, Control, and Optimization of Natural Gas Processing PlantsPenilaian: 5 dari 5 bintang5/5 (1)

- Petron Petcoke Project Schedule - Rev 01-1Dokumen41 halamanPetron Petcoke Project Schedule - Rev 01-1Ajay SastryBelum ada peringkat

- Lecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack EffectDokumen3 halamanLecture 25 Design of Stack: Key Words: Stack, Chimney, Draft, Natural Draft What Is Stack Effectkarthikraja21Belum ada peringkat

- Petron Cost Estimate For ARR Only - Rev 01 Nov 03, 2012Dokumen2 halamanPetron Cost Estimate For ARR Only - Rev 01 Nov 03, 2012Ajay SastryBelum ada peringkat

- Construction InformationDokumen8 halamanConstruction InformationAjay SastryBelum ada peringkat

- Storage Capacity Analysis For Petron Petcoke Project: Case No. 1 Case No. 2 CASE No. 3 (2 X 25,000MT Capacity)Dokumen1 halamanStorage Capacity Analysis For Petron Petcoke Project: Case No. 1 Case No. 2 CASE No. 3 (2 X 25,000MT Capacity)Ajay SastryBelum ada peringkat

- Boq (Site Work) 100 Villa (For Fewa) - AhccDokumen8 halamanBoq (Site Work) 100 Villa (For Fewa) - AhccAjay SastryBelum ada peringkat

- Rate Analysis - UniqueDokumen3 halamanRate Analysis - UniqueAjay SastryBelum ada peringkat

- Dome Type WarehouseDokumen3 halamanDome Type WarehouseAjay SastryBelum ada peringkat

- 00 Boq 177702Dokumen4 halaman00 Boq 177702Ajay SastryBelum ada peringkat

- Petron Cost Estimate For ARR Only - Rev 01 Nov 03, 2012Dokumen2 halamanPetron Cost Estimate For ARR Only - Rev 01 Nov 03, 2012Ajay SastryBelum ada peringkat

- Abu Dhabi WaterDokumen2 halamanAbu Dhabi WaterAjay SastryBelum ada peringkat

- Inventory-Cost of Goods Sold Analysis1Dokumen2 halamanInventory-Cost of Goods Sold Analysis1Ajay SastryBelum ada peringkat

- HDPE Analysis To Sammy - 29-03-2010Dokumen16 halamanHDPE Analysis To Sammy - 29-03-2010Ajay SastryBelum ada peringkat

- Lifetime Cost Template 5Dokumen12 halamanLifetime Cost Template 5Sree NivasBelum ada peringkat

- Nitin Stock Strategy Builder 2015Dokumen2 halamanNitin Stock Strategy Builder 2015Ajay SastryBelum ada peringkat

- Nitin Stock Strategy Builder 2015Dokumen2 halamanNitin Stock Strategy Builder 2015Ajay SastryBelum ada peringkat

- Agriculture Cost EstimateDokumen41 halamanAgriculture Cost EstimateAjay SastryBelum ada peringkat

- Civilwork Exibition and Convention CentreDokumen37 halamanCivilwork Exibition and Convention CentreAjay SastryBelum ada peringkat

- Construction Equipment & Machinery Spare PartsDokumen7 halamanConstruction Equipment & Machinery Spare PartsAjay SastryBelum ada peringkat

- OCTOBER..2010: S.No Filling T.No Party Name Product Place Place L.W U.LDokumen10 halamanOCTOBER..2010: S.No Filling T.No Party Name Product Place Place L.W U.LAjay SastryBelum ada peringkat

- Ganesh Builders Weight Records and Sales ReportsDokumen23 halamanGanesh Builders Weight Records and Sales ReportsAjay SastryBelum ada peringkat

- CamparisionDokumen12 halamanCamparisionajaymrBelum ada peringkat

- 3bhk - NL Aryavarta Cost Sheet at 9099Dokumen3 halaman3bhk - NL Aryavarta Cost Sheet at 9099Ajay SastryBelum ada peringkat

- Financial FreedomDokumen1 halamanFinancial FreedomAjay SastryBelum ada peringkat

- Construction Equipment & Machinery RentalDokumen12 halamanConstruction Equipment & Machinery RentalAjay Sastry0% (1)

- Plumbing Items IndiaDokumen16 halamanPlumbing Items IndiaAjay SastryBelum ada peringkat

- Rate Analysis - Lease Cap Works 4.03.15Dokumen4 halamanRate Analysis - Lease Cap Works 4.03.15Ajay SastryBelum ada peringkat

- 2design AspectDokumen14 halaman2design AspectAjay SastryBelum ada peringkat

- Building Rates-Break UpDokumen4 halamanBuilding Rates-Break Uppravi3434Belum ada peringkat

- Road Mythapur To CherlakondapurDokumen79 halamanRoad Mythapur To CherlakondapurAjay SastryBelum ada peringkat

- "Coromandel International Limited Q1 FY2020 Earnings Conference Call" July 23, 2019Dokumen23 halaman"Coromandel International Limited Q1 FY2020 Earnings Conference Call" July 23, 2019mealokranjan9937Belum ada peringkat

- A Review On Maize-Legume Intercropping For Enhancing The Productivity and Soil Fertility For Sustainable Agriculture in IndiaDokumen15 halamanA Review On Maize-Legume Intercropping For Enhancing The Productivity and Soil Fertility For Sustainable Agriculture in IndiaEarl Adam LambacoBelum ada peringkat

- Crop Husbandry and Horticulture by Ifiokobong AkpanDokumen16 halamanCrop Husbandry and Horticulture by Ifiokobong AkpanIfiokobong AkpanBelum ada peringkat

- Activity Sheets w1 2Dokumen26 halamanActivity Sheets w1 2Leonilyn CompraBelum ada peringkat

- Green RoofsDokumen20 halamanGreen RoofsEmília GarcezBelum ada peringkat

- Module 2. Prepare Land....Dokumen38 halamanModule 2. Prepare Land....Row Kneel100% (2)

- Crop Residue Burning in India: Policy Challenges and Potential SolutionsDokumen19 halamanCrop Residue Burning in India: Policy Challenges and Potential SolutionsRNBelum ada peringkat

- AF60 Inst ForPDFDokumen6 halamanAF60 Inst ForPDFAndrea BusettaBelum ada peringkat

- SDS Ammonium SulphateDokumen11 halamanSDS Ammonium SulphateAlexandruTudoranBelum ada peringkat

- Fauji Fertilizer Bin qasim-INTRODUCTIONDokumen2 halamanFauji Fertilizer Bin qasim-INTRODUCTIONSaqib Ejaz MalikBelum ada peringkat

- Sustainable Management of The Nitrogen Cycle in Agriculture and MitigationDokumen32 halamanSustainable Management of The Nitrogen Cycle in Agriculture and MitigationAndresMariaBelum ada peringkat

- Organic Agriculture in BhutanDokumen56 halamanOrganic Agriculture in BhutanShakti Shivanand50% (2)

- How To Grow More VegetablesDokumen168 halamanHow To Grow More Vegetablesautarkyintheuk100% (5)

- Plant Food FertilizersDokumen15 halamanPlant Food FertilizersRonald Cortezano100% (1)

- Stanhay Brochure Page Structure DIGITAL2018Dokumen40 halamanStanhay Brochure Page Structure DIGITAL2018Waqas RiazBelum ada peringkat

- Machinery and Equipment Cost Worksheet: Shaded Numbers Are Calculated, Others Must Be EnteredDokumen4 halamanMachinery and Equipment Cost Worksheet: Shaded Numbers Are Calculated, Others Must Be EnteredInaam Ullah MughalBelum ada peringkat

- Agriboom DPDokumen3 halamanAgriboom DPudaya kumarBelum ada peringkat

- 5070 s11 QP 22 PDFDokumen20 halaman5070 s11 QP 22 PDFNeural Spark Physics CieBelum ada peringkat

- Essential Nutrients For Plant GrowthDokumen25 halamanEssential Nutrients For Plant GrowthmanojbanBelum ada peringkat

- John Sundar PaperDokumen29 halamanJohn Sundar PaperarathinamBelum ada peringkat

- RP Kelapa SawitDokumen6 halamanRP Kelapa SawitTimothy Glare JoniunBelum ada peringkat

- Chemical NameDokumen21 halamanChemical Nameochilliane_45Belum ada peringkat

- Organic Vegetable GardeningDokumen20 halamanOrganic Vegetable GardeningSchool Vegetable Gardening100% (2)

- Soil Sampling Guide Improves Nutrient Use EfficiencyDokumen8 halamanSoil Sampling Guide Improves Nutrient Use EfficiencyJeff EnsBelum ada peringkat

- Soil Improvement From Application of BiocharDokumen4 halamanSoil Improvement From Application of BiocharJean RisquezBelum ada peringkat

- Montmorillonite ClayDokumen8 halamanMontmorillonite Claygreenelephant150Belum ada peringkat

- Soil ErosionDokumen57 halamanSoil Erosionsunnybzu3Belum ada peringkat

- Factors Affecting Pineapple Quality KPIs 2014Dokumen116 halamanFactors Affecting Pineapple Quality KPIs 2014Floreid100% (1)

- Muluken ProposalDokumen30 halamanMuluken ProposalKumsa SanbataBelum ada peringkat

- CBSE Class 12 Biology Question Paper Delhi With Answers 2017Dokumen22 halamanCBSE Class 12 Biology Question Paper Delhi With Answers 2017Laliteshwar BhardwajBelum ada peringkat