PharDose Tablet Processing Problems

Diunggah oleh

Fleur Jeizl PerezHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PharDose Tablet Processing Problems

Diunggah oleh

Fleur Jeizl PerezHak Cipta:

Format Tersedia

38 Tequillo, Hazel Joy M.

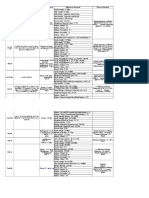

2FPh PROBLEMS ILLUSTRATION DEFINITION This occurs when the coating fills in the lettering or logo on the tablet and is typically caused by improper application of the solution, poor design of the tablet embossing, high coating viscosity, high percentage of solids in the solution, or improper atomization pressure. REMEDY

Logo Bridging

Increasing the plasticizer content or changing the plasticizer can decrease the incidence of bridging.

Twinning

This is the term for two tablets that stick together, and its a common problem with capsule shaped tablets.

Assuming you dont wish to change the tablet shape, you can solve this problem by balancing the pan speed and spray rate. Try reducing the spray rate or increasing the pan speed. In some cases, it is necessary to modify the design of the tooling by vary slightly

38 Tequillo, Hazel Joy M. 2FPh changing the radius. The change is almost impossible to see, but it prevents the twinning problem. Intagliation filled with either particles of dried polymer or solidified foam, due to bubble or foam Add alcohol or formation use spray because of air nozzle capable spraying of of finer polymer atomization. solution and over drying of spray or excessive foaming of coating solution. This can be the result of soft or friable tablets (and the pan turning too fast), an overwetted tablet surface, inadequate drying, or lack of tablet surface length. The defect whereby pits occur in the Modifying the drying (inlet air)

Logo Infilling

Core Erosion

Pitting

38 Tequillo, Hazel Joy M. 2FPh surface of a temperature tablet core such that the without any temperature visible of the tablet disruption of core is greater the film than the coating melting point because the of the batch temperature of of the the tablet core additives is greater than used. the melting point of the materials used in the tablet formulation. It is a defect of film coating whereby volcanic-like craters appears exposing the Use efficient tablet surface and optimum because the drying coating conditions and solution increase penetrates the viscosity of surface of the coating tablet, often at solution to the crown decrease where the spray surface is application more porous, rate. causing localized disintegration of the core and disruption of the coating. Coating Decrease becomes dull plasticizer immediately or concentrations after a prolong and increase

Cratering

Blooming

38 Tequillo, Hazel Joy M. 2FPh storage. Film becomes detached from a substrate forming a blister due to love molecular weight plasticizers included in the coating formulation. It is a defect best described as whitish specks or haziness in the film due to precipitated polymer exacerbated by the use of high coating temperature at or above the thermal gelation temperature of the polymers. When coated tablets require further drying in ovens, too rapid evaporation of the solvent from the core and the effect of high temperature on the strength, elasticity, and adhesion of molecular weight of plasticizer.

Blushing

Decrease drying air temperature and avoid use of sorbitol with Hydroxy Propyl Cellulose, Hydroxy Propyl Methyl Cellulose, Methyl Cellulose, and Cellulose Ethers.

Blistering

Milder drying conditions are warranted in this case.

38 Tequillo, Hazel Joy M. 2FPh the film may result in blistering. Using keying in tooling, i.e. inset a key alongside of the punch, so that it fits the punch and prevents punch rotation.

Double Impression

Free rotation of either upper punch or lower punch during ejection of a tablet.

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Theobroma Cacao SP., Popularly Known As Chocolates, Is Popular For Their Distinct TasteDokumen1 halamanTheobroma Cacao SP., Popularly Known As Chocolates, Is Popular For Their Distinct TasteFleur Jeizl PerezBelum ada peringkat

- Simple PendulumDokumen1 halamanSimple PendulumFleur Jeizl PerezBelum ada peringkat

- Physics Prelims ADokumen4 halamanPhysics Prelims AFleur Jeizl PerezBelum ada peringkat

- Physics Prelims ADokumen4 halamanPhysics Prelims AFleur Jeizl PerezBelum ada peringkat

- Formal Report TemplateDokumen1 halamanFormal Report TemplateFleur Jeizl PerezBelum ada peringkat

- The Clinical PharmacistDokumen12 halamanThe Clinical PharmacistFleur Jeizl PerezBelum ada peringkat

- Simple and Fractional DistillationDokumen3 halamanSimple and Fractional DistillationFleur Jeizl PerezBelum ada peringkat

- Sea Salt IcecreamDokumen1 halamanSea Salt IcecreamcorwinniusBelum ada peringkat

- Processing Problems, Pharmaceutical Dosage FormsDokumen3 halamanProcessing Problems, Pharmaceutical Dosage FormsFleur Jeizl Perez100% (1)

- PHL 5 First Week ReviewDokumen1 halamanPHL 5 First Week ReviewFleur Jeizl PerezBelum ada peringkat

- BioScie 3 First Week Review (Biological Apparatus)Dokumen3 halamanBioScie 3 First Week Review (Biological Apparatus)Fleur Jeizl PerezBelum ada peringkat

- Factors That Affect The Chemical Reaction RateDokumen2 halamanFactors That Affect The Chemical Reaction RateFleur Jeizl PerezBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Venturi, Orifice, RotameterDokumen34 halamanVenturi, Orifice, RotameterVinod VadithyaBelum ada peringkat

- Isomers HandoutDokumen5 halamanIsomers HandoutMohamed MeeranBelum ada peringkat

- Summary Notes - Topic 3 Waves - Edexcel Physics IGCSEDokumen5 halamanSummary Notes - Topic 3 Waves - Edexcel Physics IGCSEVarsha PBelum ada peringkat

- HL Bonding Revision QuestionsDokumen9 halamanHL Bonding Revision QuestionsMrunal JadhavBelum ada peringkat

- Electronics-I (EEE 231) : Syed Bilal JavedDokumen68 halamanElectronics-I (EEE 231) : Syed Bilal JavedNihala KhalidBelum ada peringkat

- Wire Guage Awg SWGDokumen3 halamanWire Guage Awg SWGjagadeesh_kumar_20100% (1)

- Lapse Rates and Stability PDFDokumen26 halamanLapse Rates and Stability PDFVerra Myza AratBelum ada peringkat

- Phy 122Dokumen7 halamanPhy 122Oyedotun TundeBelum ada peringkat

- Material PropertiesDokumen2 halamanMaterial PropertiesCelineKevinBelum ada peringkat

- IQ TestDokumen16 halamanIQ TestAnant Catalyst ShuklaBelum ada peringkat

- 2016 Updated Objectives With Answer Key & Topic Wise Numericals With Formulae Physics XI PDFDokumen95 halaman2016 Updated Objectives With Answer Key & Topic Wise Numericals With Formulae Physics XI PDFSameer AhmedBelum ada peringkat

- Solutions ManualDokumen478 halamanSolutions ManualBraden Henderson100% (1)

- Friday 15 May 2020: PhysicsDokumen28 halamanFriday 15 May 2020: PhysicsAyaBelum ada peringkat

- Chapter # 12Dokumen82 halamanChapter # 12Kamil Rasheed SiddiquiBelum ada peringkat

- Bearing Dynamic Static Load Carrying Capacity PDFDokumen11 halamanBearing Dynamic Static Load Carrying Capacity PDFmanimeczBelum ada peringkat

- Syllabus For Eee 801Dokumen3 halamanSyllabus For Eee 801Eze UkiweBelum ada peringkat

- Quantum Idealism: An Idealist Consciousness Model For Collapsing The Quantum Wave FunctionDokumen36 halamanQuantum Idealism: An Idealist Consciousness Model For Collapsing The Quantum Wave FunctionramponnetBelum ada peringkat

- 1903 Er19031211Dokumen22 halaman1903 Er19031211Tullio OpattiBelum ada peringkat

- Thermal BucklingDokumen11 halamanThermal BucklingAnonymous wWOWz9UnWBelum ada peringkat

- How Boomerangs WorkDokumen9 halamanHow Boomerangs Workchey007Belum ada peringkat

- Aircraft Systems - Booster CoilDokumen2 halamanAircraft Systems - Booster CoilzcrackBelum ada peringkat

- ch5 6 7Dokumen1 halamanch5 6 7Jeff MartinBelum ada peringkat

- Khuner DaayDokumen19 halamanKhuner DaayShameem AhmadBelum ada peringkat

- CMC Chapter 08Dokumen125 halamanCMC Chapter 08MattBelum ada peringkat

- TS8 - Accounting Research (Ho)Dokumen40 halamanTS8 - Accounting Research (Ho)edzateradoBelum ada peringkat

- Introduction To CMOS Logic CircuitsDokumen176 halamanIntroduction To CMOS Logic CircuitsrdanwaraBelum ada peringkat

- Physical Sciences Baseline Test Gr11Dokumen7 halamanPhysical Sciences Baseline Test Gr11Midyondzi ngobeniBelum ada peringkat

- Madhuri Question PaperDokumen4 halamanMadhuri Question PaperprasadsuriBelum ada peringkat

- Rangkuman TRK (Deva Punya)Dokumen4 halamanRangkuman TRK (Deva Punya)gamalielBelum ada peringkat