Wartsila Dual Fuel Engine

Diunggah oleh

Sriram BalasubramanianHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Wartsila Dual Fuel Engine

Diunggah oleh

Sriram BalasubramanianHak Cipta:

Format Tersedia

RT-flex engines has the additional benefit of helping to keep the economiser cleaner with less soot deposition.

HIGH-EFFICIENCY WHR IN SERVICE

The first installation of this new high-efficiency WHR plant entered service in the 7500 TEU container ship Gudrun Mrsk of the A.P. Moller-Maersk Group in June 2005. It successfully confirmed the benefits of the new WHR plant concept. During sea trials and in operation, the performance of the WHR plant exceeded expectations. Similar WHR plants are also now in normal operation in the complete class of six 7500 TEU sister ships. The WHR plant for these vessels was developed in a joint effort headed and integrated by Odense Steel Shipyard Ltd in cooperation with Wrtsil, Siemens AG, Peter Brotherhood Ltd and Aalborg Industries Ltd. The ships are each propelled by a Wrtsil 12RT-flex96C low-speed common-rail engine with a maximum continuous power output of 68,640 kW at 102 rpm. Exhaust gases pass through an dual-pressure exhaustgas economiser from Aalborg Industries to generate superheated steam which is utilised in a 6 MWe turbogenerator set from Peter Brotherhood. The turbogenerator sets incorporate both a multi-stage dual-pressure steam turbine and an exhaust-gas power turbine. The generated electricity is supplied

CASE STUDY

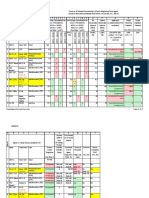

The economic benefits of the high-efficiency WHR system can be illustrated by the case of a container ship powered by a 12-cylinder Wrtsil RT-flex96C engine. In the case, the engine would operate at an average of 85% load for about 6500 hours a year on bunkers costing US$ 250/tonne, with an average total electrical load of 5350kW, including reefer containers. The annual operating costs for the main and auxiliary engines, including fuel, maintenance and lubricating oil, would be US$ 19.54 million without a WHR plant and US$ 17.29 million with a high-efficiency WHR plant. There would thus be annual savings of US$ 2.25 million. If the bunker price increased from US$ 250 to US$ 400/tonne, then the annual savings would increase to about US$ 3.48 million. The complete high-efficiency WHR plant and its installation would call for an investment cost of about US$ 9.5 million. This would thus have an expected payback time of less than five years.

HIGH-EFFICIENCY WHR: CASE STUDY

Basis ship: Main engine: Wrtsil 12RT-flex96C CMCR power, kW: 80,080 Annual operating hours: 6500 Average engine load, %: 85 Total electrical load, kW: 5350 Auxiliary engines, kWe: 4 x 3000 Bunker fuel price, US$/tonne: 250 Cylinder lubricating oil price, US$/tonne: 1500 Annual engine operating costs Fuel costs, US$: Maintenance costs, US$: Lubricating oil costs, US$: Total, US$: Annual savings, US$ at US$ 250/tonne fuel: at US$ 400/tonne fuel: Investment cost, US$ basis ship 18,449,000 486,000 602,000 19,537,000 with WHR 16,359,000 333,000 559,000 17,287,000 2,250,000 3,482,000 9,500,000

to the ships main switchboard and employed both in a Siemens shaft motor/generator to assist in ship propulsion, and in shipboard services. A portion of the steam from the exhaust economiser is utilised in shipboard heating services. The calculated output of the turbogenerator set is based upon ISO standard reference conditions which include an ambient temperature of 25C. During the sea trials of the first ship, this performance was exceeded as such output was already achieved at the ambient temperature of 14C. The vessels are also each equipped with three eight-cylinder Wrtsil 32 diesel generating sets having a combined electrical output of 11.2 MWe. The high-efficiency WHR plant enables each ship to be fitted with one fewer diesel generating sets than it would otherwise have. The high-efficiency WHR concept has been taken a step further in the new 11,000 TEU container ships of the A.P. Moller-Maersk Group. The first of this class, the Emma Mrsk, was delivered in September 2006 from Odense Steel Shipyard. She has since been joined by a number of sister ships. The ships are each powered by a 14-cylinder Wrtsil RT-flex96C common-rail engine. These are the worlds first 14-cylinder in-line engines and also the worlds most powerful electronically-controlled engines with an MCR power of 80,080 kW each at 102 rpm. This propulsion power is augmented by two shaft motors in each vessel. The main engines are each associated with a high-efficiency WHR plant incorporating a turbogenerator set having a nominal output of 8.5 MWe. This operates in conjunction with each ships five diesel generating sets that have a combined output of 20.7 MWe.

SOLELY FOR SHIPS SERVICE ELECTRICITY

A simplified version of the high-efficiency WHR system described above is offered for ships that require the recovered energy to be only sufficient to cover all shipboard electricity demand while the ship is at sea. This avoids the running of auxiliary engines

while at sea with the corresponding savings in

fuel, maintenance and spare parts costs, as well

as reductions in exhaust gas emissions.

Such cases may apply for engines such as the Wrtsil RT-flex82C, RT-flex82T and RT-flex84T-D types. The waste heat recovery plant is similar to the higher-output described above but energy is usually only recovered from an exhaustgas economiser to generate steam for a turbine-driven generator. If necessary, heat is also recovered from the engines scavenge air and jacket cooling water for feedwater heating. The economiser also operates at a single steam pressure. However the quantity of energy recovered from the exhaust gases is increased by adapting the engine to the lower air intake temperatures that are available by drawing intake air from outside the ship (ambient air) instead of from the ships engine room. The engine turbochargers are matched for the lower air intake temperatures thereby increasing the exhaust energy.

As todays high-efficiency turbochargers have surplus capacity at the engines upper load range when matched for ambient air intake, less exhaust gas flow is necessary for the turbochargers. Thus about 89% of the

engines exhaust gas flow can bypass the turbochargers to give a further increase in recoverable exhaust gas energy. The overall result of this concept is that the quantity of energy recoverable in an exhaustgas economiser is increased without affecting the air flow through the engine. There is thus no increase in the thermal loading of the engine and there is no adverse effect on engine reliability. For example, a high-efficiency WHR plant associated with a 29,400 kW seven-cylinder Wrtsil RT-flex84T-D engine in a VLCC (very large crude oil carrier) could deliver 1645 kWe at engine full load under ISO conditions with 9% exhaust gas bypass using a singlepressure steam system. As such a vessel would need only 10001100 kWe for ship services while at sea, the tanker could operate without running its auxiliary engines while at sea under a wide range of ship speeds. It would save more than 1400 tonnes of fuel a

WASTE HEAT RECOVERY

WASTE HEAT RECOVERY (WHR): FUEL SAVINGS WITH LESS EMISSIONS

New concept for high-efficiency waste heat recovery (WHR) associated with Wrtsil RT-flex common-rail low-speed marine engines allows up to 12% of main engine shaft power to be recovered as electrical power for use as additional ship propulsion power and for shipboard services. A number of such high-efficiency WHR installations have entered service since the first in June 2005. Pressure is on the shipping industry to gain further reductions in air pollution from the exhaust gases of marine diesel engines. Thus discussion and development is on either further controlling the generation of the emissions inside engine cylinders, removing the emissions by aftertreatment of the exhaust gases, or in the case of SOX emissions restricting the fuel specification. However, more fundamental ideas about ship design and operation will be necessary to meet the growing need for significantly less carbon dioxide (CO2) emissions as part of the fight against global warming. There is very little margin left in the large marine diesel engine for reducing CO2 emissions through improving engine thermal efficiency. After the 1973 Oil Crisis, considerable investment was put into reducing engine fuel consumption and for some years the largest-bore engines have had an overall thermal efficiency of around 50%, depending on engine size. There is also the natural trade-off between engine fuel consumption and NOX emissions with any reductions in specific fuel consumption involving a natural increase in NOX emissions. Yet there is one solution that can help: waste heat recovery is the only technology commercially available today that provides both lower fuel consumption and lower exhaust-gas emissions, including lower CO2 emissions, without a reduction in ship service speeds. In the new concept developed by Wrtsil the quantity of energy available for recovery is increased by drawing engine intake air from outside the engine room (ambient air) instead of from within the engine room.

The turbogenerator set of the Gudrun Mrsk-class container ships. (Photo: Peter Brotherhood Ltd)

Single-pressure exhaust gas economiser

Ship service steam

LEADING WHR CONCEPT

A new concept for high-efficiency waste heat recovery combined with Wrtsil RT-flex common-rail low-speed engines is leading the way in the magnitude of both fuel economy and lower exhaust emissions achieved.

This leaflet focuses on WHR plants for higher-output engines such as the Wrtsil RT-flex96C engines for which the energy recovered is sufficient to make assisting propulsion financially worthwhile with reasonable payback periods, as well as providing for all shipboard electricity requirements. In such cases, the new high-efficiency WHR plant can recover up to about 12% of the engine shaft power using both Rankine cycle and turbocompound principles. Exhaust energy is applied in both a steam turbine and an exhaust-gas power turbine to generate electrical power. The electrical power can be employed either in a shaft motor to aid propulsion or in supplying shipboard services. When the WHR plant can meet all shipboard electrical requirements while the ship is at sea, it will usually be possible to fit one less auxiliary diesel generating set thereby saving on installation costs as well as auxiliary engine running costs.

Single-pressure steam turbine

Ship service electricity G

Turbochargers G Main engine G

Aux. engines

Schematic of a simplified high-efficiency WHR plant as might be employed with a Wrtsil 7RT-flex84T-D engine for a large tanker with the turbogenerator supplying all ships service electricity while the ship is at sea.

year, with corresponding savings in all types of air emissions, especially CO2.

CONCLUSION

The high-efficiency waste heat recovery plant concept is attracting much attention from shipowners interested in saving fuel costs and reducing CO2 emissions. It must be remembered that modern large, low-speed engines are very highly developed and there is little potential for achieving significant savings

in fuel consumption, and thereby reducing CO2 emissions by engine developments alone. Yet major improvements can be gained by using proven technology and hardware through applying the high-efficiency WHR plant. It is thus a practical path forward. The combination of a Wrtsil RT-flex engine with high-efficiency WHR plant is a major contribution to reducing the environmental impact of shipping.

HIGH-EFFICIENCY WHR BENEFITS Benefits to shipowners of WHR system are thus fourfold: Lower annual fuel costs Lower running costs for auxiliary engines Lower exhaust emissions: CO , NO , 2 X SOX, etc. Improved competitiveness in the freight market.

PAYBACK TIME LESS THAN 5 YEARS

WRTSIL is a registered trademark. Copyright 2007 Wrtsil Corporation.

WARTSILA.COM

Overall efficiency 49.3%

Shaft power 49.3%

Overall efficiency 54.9%, Gain = 11.4%

Shaft power 49.0% Electrical power 5.9% Condenser 8.6%

10000 8000

35C 35C

Turbogenerator output, kWe

LP evaporator LP superheater

166C

3.8 bar(g) 150.3C LP

Ambient 35C max.

Temperature, C

-5C

Combined output

3.5 bar(g) / 190C

300

HP service steam Waste gate Scavenge air Main engine Exhaust gas

Exhaust gas side

Scav. air cooler

6000

Exhaust gas 25.4% Scavenge air cooling water 14.1% Jacket water 6.3% Lubricating oil 4.3% Radiation 0.6% Exhaust gas 12.6% Scavenge air cooling water 12.9% Jacket water 6.2% Lubricating oil 4.2% Radiation 0.6%

HP evaporator HP 9.5 bar(g) 182C HP superheater 9.0 bar(g) / 260C Exhaust turbine 36C 12 bar Condenser 85C Jacket cooling water 90C Turbocharger

4000

45C

Steam turbine

200

Steam/water side 9.5 bar(g), 182C

199C 17C 194C 5C 166C 15.7C 3.8 bar(g) 150.3C Heat transferred

2000 Power turbine 0 50 60 70 80 90 100 Engine load, %

G Steam turbine

140

HP superheater

HP evaporator

LP evaporator LP superheater

Fuel input 100% (171 g/kWh)

Fuel input 100% (172 g/kWh)

Left: Engine room air suction. Right: Ambient air suction from outside the ships engine room.

Energy recovered (kWe) by the turbogenerator set in a high-efficiency WHR plant on a 12RT-flex96C engine with Delta Tuning (for improved part-load fuel savings) and ambient suction.

Process diagram for the high-efficiency waste heat recovery plant.

Typical economiser diagram for the high-efficiency waste heat recovery plant.

Even with the high, 50% efficiency of modern low-speed engines there is still 50% of fuel input energy not being put to productive use. The possibilities are illustrated by this comparison of Sankey diagrams for Wrtsil 12RT-flex96C engines without heat recovery (left) and with the high-efficiency waste heat recovery plant (right) showing in this case an 11.4% gain in overall efficiency with WHR.

In any case, the resulting payback time would depend upon the installation design and bunker fuel prices but should in general be about five years which is commercially attractive. Increasing fuel prices make such plants more attractive. A WHR plant thus leads to considerable financial benefits over a ships life. The new concept developed by Wrtsil follows the well-established arrangement of passing the exhaust gases of the ships main engine through an exhaust-gas economiser to generate steam for a turbine-driven generator. However, the quantity of energy recovered from the exhaust gases is maximised by adapting the engine to the lower air intake temperatures that are available by drawing intake air from outside the ship (ambient air) instead of from the ships engine room. Usually marine engines are designed for intake temperatures of up to 45C for tropical conditions with turbochargers drawing intake air from the engine room. If instead the intake air is drawn from outside the engine room through an air intake duct, the maximum intake temperature can be assumed to be no more than 35C. In such a case, the lower air intake temperature allows the turbochargers to be

rematched to return the thermal load of the engine back down to what prevails for the intake temperature at 45C. When considering such a tuning to reach an increased exhaust gas temperature, it is important that the thermal load of the adapted engine is no greater than that of the usual engine so as not to jeopardise engine reliability. Even with a certain quantity of exhaust gas branched off for the power turbine and therefore not then available for the turbocharger, the thermal loading of the engine remains the same as for the conventional engine. This is possible because the special turbocharger matching in combination with the exhaust power turbine allows full utilisation of the available efficiency of the turbocharger, and also because of the ambient suction tuning. This adapted tuning, however, incurs a penalty in a slightly increased fuel consumption at ISO reference conditions. But the gain in recovered energy more then compensates for the loss in efficiency from the higher fuel consumption. The engine needs to be equipped with an air waste gate to ensure that the maximum cylinder pressure stays within permissible limits at very low ambient temperature.

Modern, high-efficiency turbochargers also have a small surplus in efficiency capability in the upper load range. This allows a certain exhaust gas flow to be branched off before the turbocharger to drive a gas turbine, or as it is called in this application an exhaust power turbine. With normal engine tuning it is not worth taking advantage of this possibility. However, the rematched turbochargers for ambient suction allow even more exhaust gas to be branched off under ISO conditions compared with the conventional tuning with maximum 45C suction air temperature. Therefore, the rematched engine supercharging system gives an increased exhaust gas energy and allows a good amount of exhaust gas to be branched off before the turbocharger thereby allowing a worthwhile heat recovery potential to be achieved. Heat is also recovered from the engines scavenge air and jacket cooling water for feedwater heating. The scavenge air coolers are designed in such a way that the boiler feed water can be heated close to the evaporation temperature. The overall result of the new concept is that the quantity of energy recoverable in an exhaust-gas economiser and in the exhaust power turbine is increased without affecting the air flow through the engine. There is thus no increase in the thermal loading of the engine and there is no adverse effect on engine reliability.

Exhaust gas economiser Steam turbine Exhaust turbine G

Ship service steam Ship service power

Aux. engines T u rbo c h a rg e rs Motor/generator M Main engine G G G G

Schematic of a high-efficiency waste heat recovery plant typical for large container ships with the turbogenerator supplying both assisted propulsion and ships service power. The shaft motor can also serve as a shaft generator for added flexibility in operation.

drum. The economiser outlet temperature is not less then 160C to avoid sulphur corrosion in the economiser outlet. Saturated steam is drawn from the HP steam drum for ship service heating. In a first stage, the feed water is heated from the engines jacket cooling water to a temperature of 85C. Only the feed water for the high-pressure section is further heated in the engines scavenge air cooler to about 150C to 170C. The scavenge air cooler is designed such that the feed water heating section can run dry with the total scavenge heat dissipated in the scavenge air cooler. STEAM TURBINE A dual-pressure steam turbine running at about 6750 rev/min is used. The highpressure side works at about 8.09.0 bar(g) inlet pressure. This requires three turbine stages at a condenser pressure of 0.065 bar. With an economiser outlet temperature of 160C, a low-pressure steam pressure at the turbine inlet of 3.03.5 bar(g) pressure is considered. This requires six turbine stages at a condenser pressure of 0.065 bar. A speedreduction gear between steam turbine and generator reduces the turbine speed to 1800 rev/min generator speed. EXHAUST POWER TURBINE The power turbine uses a part of the exhaust gas stream (about 10%) from the diesel

The change in engine suction also has the benefit of reducing the electrical power required for engine-room ventilation with consequent fuel cost savings. In the case of a container ship with a 12RT-flex96C engine, the total power for ventilation fans may be cut from 400 to 200 kW.

alternator system. In the rematched system, about 10% of the engines exhaust gas flow can be employed to drive an exhaust power turbine which is incorporated in the turbogenerator set. ECONOMISER The exhaust gas economiser consists of a high-pressure part with HP evaporator and superheating section and a low-pressure part with LP evaporator and superheating section. The pressure in the high-pressure steam drum is at about 9.5 bar(g) pressure, and about 3.8 bar(g) in the low-pressure steam

WHR PLANT CONFIGURATION

The high-efficiency WHR plant consists of a dual-pressure economiser, a multiple-stage dual-pressure steam turbine, an exhaust power turbine, an alternator driven by both the steam turbine and the power turbine, a feed water pre-heating system and a shaft motor/

engine to generate shaft power which can be added to the steam turbine driving the generator. The turbine is a derivative of a wellproven model of turbocharger turbine with minor adaptations for use as a power turbine. A special matching of the power turbine is necessary for the application in a waste heat recovery system because the turbine operates on a constant-speed operating profile as it is coupled to the generator unlike in a turbocharger with a free-running rotor. The torque of the power turbine is fed to the steam turbine rotor through a reduction gear and an overrunning clutch. The power turbine operates between 55% and 100% engine load. The flow of exhaust gas from the exhaust gas manifold is controlled by an orifice at the outlet of the exhaust gas manifold. At less than 55% engine load, the gas flow to the power turbine is shut off as the efficiency of the turbochargers at less than 55% load is not sufficiently high and therefore does not allow exhaust gas to be branched off to drive a power turbine. As the power turbine has about the same expansion ratio and efficiency as the turbochargers of the engine, the outlet temperature of the exhaust gas is about the same as from the turbochargers. WASTE GATE The engine is tuned to operate within the intake temperature range of 5C to 35C.

The engine maximum pressure stays within the permissible range when the engine operates within this intake suction temperature range. If the ship shall be operated at ambient temperatures below 5C, the engine has to be protected from excessive maximum cylinder pressure occurring owing to the high specific density of the cold air. This can be achieved by applying a waste gate (blow-off valve) for either scavenge air or exhaust gas. Although an exhaust waste gate offers certain thermodynamic advantages, the best choice is a scavenge air waste gate because it offers a much higher reliability by avoiding contact with high-temperature exhaust gas. The valve operates on a simple on/off function. If the ambient air temperature drops below 5C, the waste gate opens and scavenge air is diverted to the air inlet pipe.

overall fuel consumption by reducing the main engine power required for a given ship speed, or it can be used to boost the propulsion power for a higher ship speed or to provide extra sea margin. It can also be used as a generator to supply electrical power for ship services while the ship is at sea if the WHR plant is not operational.

RT-flex COMMON-RAIL ENGINES

Wrtsil RT-flex common-rail engines are ideal partners for high-efficiency WHR plants. The precision and flexibility available in engine setting given by the fully electronically controlled RT-flex common-rail system deliver clear benefits such as smokeless operation at all engine speeds, lower stable running speeds, lower fuel consumption, lower exhaust emissions and consistent engine settings for reduced maintenance. SHAFT MOTOR/ALTERNATOR SYSTEM The RT-flex system also has the option The shaft motor/alternator is of the low-speed of Delta Tuning that provides lower fuel type, directly mounted in the propeller shaft consumption at part loads compared with line. It operates on variable electrical supply conventional camshaft-type engines. This frequency. A frequency control system controls tuning option takes advantage of the complete the frequency to and from the electrical flexibility in fuel injection and valve operation supply. The system operates on 6600V. It is allowed by the common-rail system. arranged to operate as either a motor or an In both the versions with original tuning alternator. and Delta Tuning, the RT-flex engines comply The shaft motor/alternator gives the fully with the NOX regulation of Annex VI of the additional benefit of operational flexibility. The MARPOL 73/78 convention. shaft motor can be employed to reduce the The cleaner combustion achieved by

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Paradigm Shift Essay 2Dokumen17 halamanParadigm Shift Essay 2api-607732716Belum ada peringkat

- Key formulas for introductory statisticsDokumen8 halamanKey formulas for introductory statisticsimam awaluddinBelum ada peringkat

- Domingo V People (Estafa)Dokumen16 halamanDomingo V People (Estafa)Kim EscosiaBelum ada peringkat

- FALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFDokumen3 halamanFALL PROTECTION ON SCISSOR LIFTS PDF 2 PDFJISHNU TKBelum ada peringkat

- All Associates Warning Against ChangesDokumen67 halamanAll Associates Warning Against Changesramesh0% (1)

- Doe v. Myspace, Inc. Et Al - Document No. 37Dokumen2 halamanDoe v. Myspace, Inc. Et Al - Document No. 37Justia.comBelum ada peringkat

- Guide to Fair Value Measurement under IFRS 13Dokumen3 halamanGuide to Fair Value Measurement under IFRS 13Annie JuliaBelum ada peringkat

- EE290 Practice 3Dokumen4 halamanEE290 Practice 3olgaBelum ada peringkat

- Artificial IseminationDokumen6 halamanArtificial IseminationHafiz Muhammad Zain-Ul AbedinBelum ada peringkat

- WassiDokumen12 halamanWassiwaseem0808Belum ada peringkat

- Emerson Park Master Plan 2015 DraftDokumen93 halamanEmerson Park Master Plan 2015 DraftRyan DeffenbaughBelum ada peringkat

- Tatoo Java Themes PDFDokumen5 halamanTatoo Java Themes PDFMk DirBelum ada peringkat

- Tygon S3 E-3603: The Only Choice For Phthalate-Free Flexible TubingDokumen4 halamanTygon S3 E-3603: The Only Choice For Phthalate-Free Flexible TubingAluizioBelum ada peringkat

- Cianura Pentru Un Suras de Rodica OjogDokumen1 halamanCianura Pentru Un Suras de Rodica OjogMaier MariaBelum ada peringkat

- Abinisio GDE HelpDokumen221 halamanAbinisio GDE HelpvenkatesanmuraliBelum ada peringkat

- 27 MARCH 2020: Assignment 5 Question PaperDokumen4 halaman27 MARCH 2020: Assignment 5 Question PaperShadreck SandweBelum ada peringkat

- PWC Global Project Management Report SmallDokumen40 halamanPWC Global Project Management Report SmallDaniel MoraBelum ada peringkat

- 14 15 XII Chem Organic ChaptDokumen2 halaman14 15 XII Chem Organic ChaptsubiBelum ada peringkat

- PA Inspection Guidelines For Single Site Acceptance: 1 © Nokia Siemens NetworksDokumen18 halamanPA Inspection Guidelines For Single Site Acceptance: 1 © Nokia Siemens NetworksDenny WijayaBelum ada peringkat

- Ca. Rajani Mathur: 09718286332, EmailDokumen2 halamanCa. Rajani Mathur: 09718286332, EmailSanket KohliBelum ada peringkat

- NOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationDokumen10 halamanNOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationNur AfiqahBelum ada peringkat

- Application D2 WS2023Dokumen11 halamanApplication D2 WS2023María Camila AlvaradoBelum ada peringkat

- Clean Agent ComparisonDokumen9 halamanClean Agent ComparisonJohn ABelum ada peringkat

- Identifying The TopicDokumen2 halamanIdentifying The TopicrioBelum ada peringkat

- Programming Manual Magic 308/616-CLI Quick ReferenceDokumen16 halamanProgramming Manual Magic 308/616-CLI Quick ReferencekrishnamarajublrBelum ada peringkat

- Janome DC6030 Sewing Machine Instruction ManualDokumen56 halamanJanome DC6030 Sewing Machine Instruction ManualiliiexpugnansBelum ada peringkat

- Cisco CMTS Feature GuideDokumen756 halamanCisco CMTS Feature GuideEzequiel Mariano DaoudBelum ada peringkat

- Conceptual FrameworkDokumen24 halamanConceptual Frameworkmarons inigoBelum ada peringkat

- (Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingDokumen17 halaman(Bio) Chemistry of Bacterial Leaching-Direct vs. Indirect BioleachingKatherine Natalia Pino Arredondo100% (1)

- IP68 Rating ExplainedDokumen12 halamanIP68 Rating ExplainedAdhi ErlanggaBelum ada peringkat