Structural Analysis and Design Project of Ls

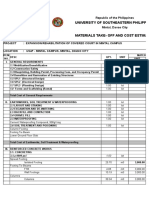

Diunggah oleh

kvranapratapHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Structural Analysis and Design Project of Ls

Diunggah oleh

kvranapratapHak Cipta:

Format Tersedia

GUILLERMO, Lou Stalin Dominique D.J.

- 2007101109 Page 1

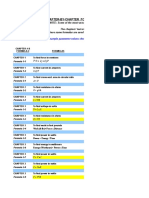

1 STRUCTURAL STEEL DESIGN

PLANS AND DRAWINGS

A. VICINITY MAP 12 356565333

LOCATION: PUERTO PRINSESA, PALAWAN, PHILIPPINES

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 2

2 STRUCTURAL STEEL DESIGN

B. DETAILS OF FLOOR PLAN/ FRAMING PLAN

5.375m.

5.375m.

1.5m.

10.75m. 10.75m. 10.75m. 10.75m.

B1

B2

B3

B9

B4

B5 B6

B7

B8

S1 S2

S3 S4

S5 S6

S7 S8

S9 S10 S11 S12

C1 C2 C3

C4

C5

C6

C7

C8

C13

C9

C14

C10

C15

C11

C16

C12

C17

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 3

3 STRUCTURAL STEEL DESIGN

GROUND FLOOR PLAN

SECOND FLOOR PLAN

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 4

4 STRUCTURAL STEEL DESIGN

C. ELEVATIONS

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 5

5 STRUCTURAL STEEL DESIGN

D. STRUCTURAL DETAILS AND SPECIFICATIONS

Design code: NSCP ASD 200123223 2322

Strength: LC channel purlins: Fy= 170 Mpa

Columns, Beams and Girders (A36 wide flanges and A36 angle bars): Fy= 248 MPa

Tierods and Sagrods: Fy=248 Mpa

E60xx: Fu= 415Mpa

A325 fasterners: Fv= 145Mpa qeqeq qqe

A36 gusset plate: Fy= 248 Mpa

Concrete pedestal: Fc= 21 Mpa

Square Base plate: Fy= 248 Mpa

Computation of Forces, Moments (Criticals): use of STAAD PRO 2007 and by manual

Roofing: corrugated galvanized iron (g.i.): gage 22

Slab Weight Concrete 150 mm thick

Frame Partitions

Wood or steel studs, 13 mm.

gypsum board each side

0.38 kPa

Ceiling Load

Gypsum board + mechanical duct

allowance

1.2 + 0.2 = 1.4 kPa

Flooring

Concrete fill finish + hardwood

flooring

0.345 + 0.19 = 0.535 kPa

Frame walls

Window, glass, frames and sash +

wood sheating

0.38+ 0.855 = 1.235 kPa

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 6

6 STRUCTURAL STEEL DESIGN

STRUCTURAL ANALYSIS AND DESIGN

A. BASIS OF DESIGN

Student Number: 2007101109

Code: 101109

Z=1

Y=0

X=2

W=6

V=0

U=2

Type of Occupancy: Commercial Building (Office)

Location of the Project: Puerto Prinsesa, Palawan, Philippines

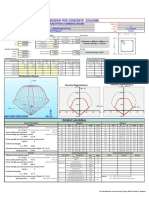

Type of Truss: Pratt Truss

Span of Truss, ST = 10.75 meters

Angle of Inclination (Truss), = 22.10

Bay Distance, L = 10.75 meters

Concrete slab thickness = 150mm.

Beams and columns are made of wide-flange sections

1.5

L L L L

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 7

7 STRUCTURAL STEEL DESIGN

`

ROOF FRAMING PLAN

LC (channel) purlins with sagrads and tierods

Roofing: corrugated galvanized iron (g.i.): gage 22

HEIGHT OF COLUMN, H

H1= 3.0m

H2= 2.75m.

1.5m

.

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 8

8 STRUCTURAL STEEL DESIGN

LEFT SIDE ELEVATION

Roof

height

H2

0.6

H1

0.6

c = -0.01

A

B

D

F

H

J

L

C E G I K

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 9

9 STRUCTURAL STEEL DESIGN

B. LOADING COMPUTATIONS

Galvanized iron roofing gage 22 (w = 2.4 lbs/ft

2

)

x = ST / division of truss = 10.75 / 6 = 1.792 m.

S = x / cos = 1.792 / cos(22.1) = 1.934 m.

h = (tan)*(ST/2) = 2.183 m.

a. Dead Loads, DL

Galvanized iron roofing gage 22 (w = 2.4 lbs/ft

2

)

RL= (2.4

)(

)(9.81 )(

)

2

(0.895m) = 102.86 N/m

b. Live Loads, LL

- Tributary Area, A

T

= 10.75 x 10.75 = 115.5625 mm

2

-

RLL= (0.6) (0.895) = 0.537 KN/m = 537 N/m

c. Wind Loads, WL

WL= (c) (q)

H= 0.6+ 3.0 + 0.6 + 2.7 +2.183 = 9.133 meters

Height Zone = (9.133 m) (

) = 29.962 ft

C=

( )

1.3sin 0.5 1.3sin 22.10 0.5 0.010908 u = =

q= 20 lb/ft ( zone III )

2.7

5

0.6

3.0

0.6

2.183

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 10

10 STRUCTURAL STEEL DESIGN

WL

WINDWARD

= 0.010908 (

) (

) (9.81 m/s

2

) (

)

2

(0.967m) = 9.26 N/m

WL

LEEWARD

= 0.5 (

) (

) (9.81 m/s

2

) (

)

2

(0.967m) = 463.08 N/m

C. DESIGN OF PURLINS, SAGRODS AND TIERODS

Design of Purlins

Critical load = (Suction is not included)

[Getting the data from Association of Structural Engineers of the Philippines (ASEP) Steel Manual]

Data Given:

Fy = 170 Mpa

LC 225 x 90 x 25 x 4.5

Weight, w (kg/m) 15.81

Area, A (mm

2

) 2015

Section Modulus about X, S

x

(x 10

3

mm

3

)

150.8

Section Modulus about Y, S

y

(x 10

3

mm

3

)

30.3

c = -0.01

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 11

11 STRUCTURAL STEEL DESIGN

According on what we learn in the previous topic of this subject,

1.00

by

bx

bx by

f

f

F F

+ s

This is the formula in computing the adequacy of purlins

Where:

f

bx

& f

by

= actual bending stress along X and Y axis respectively

F

bx

& F

by

= allowable bending stress along X and Y axis respectively

The section is said to economical if the interaction expression falls under the range

0.8 0.9

by

bx

bx by

f

f

F F

s + s .

Assume that the purlins have compact sections.

If it is compact, F

bx

= 0.66F

y

and F

by

= 0.75F

y

where F

y

= 170 MPa

Computing for the total weight, w

T

Self weight= (15.81

) (9.81 m/s

2

) = 155.0961 N/m

T

w DL LL = +

W

T

= [(155.0961+537+102.86)= 794.9561 N/m

After solving the total weight, solve for the total weight components, W

x

and W

y

W

x

= W

T

cos22.1 = 794.9561 N/m (cos22.1)

W

x

= 736.5496 N/m

W

y

= W

T

sin22.1 = 794.0561 N/m (sin22.1)

W

y

= 299.0818 N/m

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 12

12 STRUCTURAL STEEL DESIGN

Solving for moment about X and Y, M

x

and M

y

Mx =

My =

Mx =

My=

Mx = 10.64 kN-m My = 1.08 kN-m

Solving actual stress along X and Y, f

bx

and f

by

f

bx =

f

by =

f

bx =

f

by =

f

bx

=70.56 MPa f

by

=40 MPa

Solving allowable stress about X and Y, F

bx

and F

by

F

bx

= 0.66 F

y

F

by

= 0.75 F

y

F

bx

= 0.66 (170)

F

by

= 0.75 (170)

F

bx

= 112.2 MPa

F

by

= 127.5 MPa

Solving for the interaction expression,

by

bx

bx by

f

f

F F

+ <1.0

by

bx

bx by

f

f

F F

+ =

=0.909< 1.0 OK!

.: the purlins is adequate and economical.

Design of Sagrods

T

SAGRODS =

W

y

L

T

SAGRODS =

(299.08) (10.75)

T

SAGRODS =

2.01 KN

T = F

T

A

g

2.01 x 10^3 = 0.6 (248) [

d

sagrods

2

] x7

d

sagrods

= 10.97mm, use d

sagrods

= 12 mm

Design og Tierods

0

H

F =

T

Tierods

= T

sagrods

cos22.1

T

Tierods

= N

2.17 x 10^3 = 0.6 (248) [

d

tierods

2

]

d

Tierods

= 4.31 mm

use d

Tierods

= 5mm

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 13

13 STRUCTURAL STEEL DESIGN

D. LOADINGS AND ANALYSIS OF TRUSS

Considering one purlin:

x

=

2

=

(10.75)

2

= 3958.97

y

=

16

=

(299.08)(10.75)

16

=200.94

Types of Truss R

x

R

y

Middle Full Truss

Side Full Truss

Half Truss

2R

x

= 2(3.95897)

= 7.91794 KN

2R

y

= 2(200.94)

= 401.88 KN

Ceiling Load, CL

Using suspended metal lath and gypsum plaster as ceiling (From NSCP Vol. 1,

Section 2-6, Table 204-2)

C = (0.02+0.008)(14.75)(7.25)=22.243 or 22243

The Section to Be Used For Each Type of Truss Members

Type of Truss Members The Section & Its Properties

Top Chords and Bottom

Chords

L 100 x 100 x14

Orientation

Weight, w (kg/m) 44.28

Area, A (mm

2

) 5238

Radius of Gyration about X, r

x

(mm)

29.95

Radius of Gyration about Y, r

y

(mm)

29.95

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 14

14 STRUCTURAL STEEL DESIGN

Web Members

(Both Tension &

Compression)

L 100 x 100 x 14

Orientation

Weight, w (kg/m) 20.56

Area, A (mm

2

) 2.619

Radius of Gyration about X, r

x

(mm)

29.95

Radius of Gyration about Y, r

y

(mm)

29.95

Self Weight

3Rx= 11876.91 N

4Rx= 15835.88 N

14Ry= 2813.16 N

CL= 0.48 kpa (10.75 m)

CL= 5.16 KN/m = 5160 N/m

1154.18 N/m

UL= CL+SW

UL= 5160 + 1154.18

UL= 6314.18 N/m

SOLVING FOR THE FORCES OF THE MEMBERS OF THE TRUSS

3Rx

6@1.79m

..

3Rx 3Rx

3Rx

4Rx

4Rx

4Rx

3@ 1.93m.

4Rx

=22.1

2.18m.

14Ry

14Ry

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 15

15 STRUCTURAL STEEL DESIGN

SAMPLE COMPUTATION OF FORCES IN CRITICAL MEMBERS

JOINT A

TABLE OF ANALSYSIS

TOP CHORD T/C FORCE (KN) LENGTH (m)

AB=JL C -420.172 1.934

BD=HJ C -420.172 1.934

DF=FH C -394.593 1.934

BOTTOM CHORD T/C FORCE 9KN) LENGTH (m)

AC=KL T 389.302 1.792

CE=IK T 365.602 1.792

EG=GI T 420.059 1.792

WEB MEMBER T/C FORCE (KN) LENGTH (m)

BC=JK C -7.934 0.728

CD=HK T 30.531 2.308

DE=HI T 77.651 1.455

EF=FI C -85.828 2.824

FG T 146.314 2.183

A

AC

AB

22.1

O

22.1

O

171.67 KN

3R

X

14R

y

AB sin22.1

o

+ 171669.621 3R

x

cos22.1

o

14R

y

sin22.1 = 0

AB = -420.172 kN (T)

AB = 420.172 kN (C)

AC + AB cos22.1

o

+ 3R

x

sin22.1

o

14R

y

cos22.1

o

= 0

AC = 389.302 kN (T)

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 16

16 STRUCTURAL STEEL DESIGN

DESIGN OF TOP AND BOTTOM CHORD

E. DESIGN FOR TOP CHORD

L= 1.934 m.

r= 29.955

Test for buckling: Solving for FS:

64.555 < 200 OK FS= 1.842

Cc= 126.169 Fa= 117.026 Mpa

kL/r < Cc

Therefore: Intermediate column

Solving for Required Area:

A=

= 3590.412 MPa

A= 3590.412 mm

2

look for the manual for most efficient section

A/2 = 1795.206 mm

2

for single angle bar

Adopt the equal angle bar section L 100 x 100 x 14

F. DESIGN FOR BOTTOM CHORD

Pcritical= 420.059 KN

L= 1.792 m

Ft= 148.8 MPa

Solving for Required Area

A=

= 2822.980 mm^2

200 <

r

kL

3

3

) ( 8

) / (

) ( 8

) / ( 3

3

5

Cc

r kl

Cc

r kl

FS + =

Fy

E

Cc

2

2t

= |

.

|

\

|

(

=

Fs

Fy

Cc

r kl

Fa

2

2

) ( 2

) / (

1

A

P

Fa =

Fy Ft 6 . 0 =

A

P

Fa =

P critical = -420.172 KN

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 17

17 STRUCTURAL STEEL DESIGN

A= 2822.98 mm

2

look for the manual for most efficient section

A/2= 1411.49 mm

2

for sngle angle bar

Adopt the Equal angle bar section L 100 x 100 x 14

G. DESIGN FOR WEB MEMBER

For compression:

Pcrit= -85.828 KN

L= 2.824m

test for buckling Solve for FS

94.267 < 152.390 OK! FS = 1.895

Cc = 126.169 Fa= 94.357 MPa

kL/r < Cc

Therefore: Intermediate Column

solving for Required Area:

A

A=

= 909.604 mm

2

A = 909.604 mm

2

look for the manual for most efficient section

A/2 = 454.802 mm

2

for single angle bar

Adopt the Equal angle bar section L100 x 100 x 14

For Tension:

Pcritical= 146.314 KN

L= 2.824m

Ft=148.8 MPa

390 . 152 <

r

kL

3

3

) ( 8

) / (

) ( 8

) / ( 3

3

5

Cc

r kl

Cc

r kl

FS + =

Fy

E

Cc

2

2t

= |

.

|

\

|

(

=

Fs

Fy

Cc

r kl

Fa

2

2

) ( 2

) / (

1

A

P

Fa =

Fy Ft 6 . 0 =

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 18

18 STRUCTURAL STEEL DESIGN

P= 171669.621

N

P= 171669.621

N

H=3m.

solving for Required Area:

A=

= 1550.639 mm

2

A= 1550.639 mm

2

look for the manual for most efficient section

A/2= 775.319 mm

2

for single angle bar

Adopt the Equal angle bar section L100 x 100 x 14

DESIGN FOR SECOND FLOOR COLUMN

Consider the most critical column due to axial load alone and note that the height of the second

floor column H

2

= 2.75 m = 2,750mm. Assume that 0

kL

r

= that is less that C

c

making it an

intermediate column and that the column is hinged at both ends.

0

c

kL

C IntermediateColumn

r

= <

Knowing 0

kL

r

= ,

5

3

FS =

Then,

( )

248

1

5

3

148.8

a

a

MPa

F

F MPa

| |

|

=

|

|

\ .

=

A

P

Ft =

H=3m.

H=3m.

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 19

19 STRUCTURAL STEEL DESIGN

P= 171669.621

N

Fs= 1.764 Fa= 135.58 MPa

Assume 0.6 Fa

60% of Fa= 81.348 MPa

Solving for required Area

A =

A= 2110.319 mm

2

look in the manual for most efficient section

Adopt wide flange section W 8 x 10

3.0 m

3

3

) ( 8

) / (

) ( 8

) / ( 3

3

5

Cc

r kl

Cc

r kl

Fs + =

Fs

Fy

Cc

r kl

Fa *

) ( 2

) / (

1

2

2

(

=

A

P

Fa = % 60

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 20

20 STRUCTURAL STEEL DESIGN

ORIENTATION W 8 x 10

Weight, W (kg/m) 15

Area, A (m

2

) 1910

S

x

( x10

3

mm ) 128

S

Y

( x10

3

mm ) 17

R

x

(mm) 81.79

R

y

(mm) 21.36

Reference: Fundamentals of Structural Steel Design by DIT Gillesania

Check for the Adequacy of the section

K = 1.000

solving

for kl/r

kl/r < 200.000

33.623 < 200.000

Solving for

sovling for Cc

=33.623 < Cc E = 200000

.:intermediate column Cc= 126.169

Fs= 1.764

Fa= 135.58 MPa

=

=89.879 MPa

Therefore adequate!

Fy

E

Cc

2

2t

=

3

3

) ( 8

) / (

) ( 8

) / ( 3

3

5

Cc

r kl

Cc

r kl

Fs + =

Fs

Fy

Cc

r kl

Fa *

) ( 2

) / (

1

2

2

(

=

A

P

f a =

Fa fa<

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 21

21 STRUCTURAL STEEL DESIGN

H. DESIGN OF BEAM & GIRDER

Beam Design

Dead Loads, DL

The following dead loads are to be considered:

Type of Dead Load Component of Dead Load Required Amount

Slab Weight Concrete 150 mm thick

Frame Partitions

Wood or steel studs, 13 mm.

gypsum board each side

0.38 kPa

Ceiling Load

Gypsum board + mechanical duct

allowance

1.2 + 0.2 = 1.4 kPa

Flooring

Concrete fill finish + hardwood

flooring

0.345 + 0.19 = 0.535 kPa

Frame walls

Window, glass, frames and sash +

wood sheating

0.38+ 0.855 = 1.235 kPa

Reference: National Structural Code of the Philippines (NSCP) Volume 1, Section 204 DEAD LOADS

Live Loads, LL

According to NSCP Vol. 1 Section 205 Table 205-1, the minimum uniform live load for

commercial building (office) is 2.4 kPa.

Assume section of wide flange:

Using W 12 x 230 whose properties are

W12 x 230

Orientation

Weight, w (kg/m)

342

Area, A (mm

2

)

43677

Section Modulus about X, S

X

(x10

3

mm

3

) 5260

Section Modulus about Y, S

Y

(x10

3

mm

3

) 1885

Radius of Gyration about X, r

x

(mm) 151.64

Radius of Gyration about Y, r

y

(mm) 84.07

Depth , d 382.27

Thickness of web , tw 32.64

Base of flange, bf 327.53

Thickness of flange, tf 52.580

Moment of Inertia, Ix 1007

Moment of Inertia, Iy 309

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 22

22 STRUCTURAL STEEL DESIGN

w = total dead loads + live load + self weight of section

Dead loads = partitions + ceilings + floor finishes + floor framing

DL= 3.55 kPa

LL= 2.4 kPa

DL + LL= 5.95 kPa

conc= 23.50

weight of slab= conc * thickness

= 3525 N/m

2

= 3525 KN/m

2

DL+LL+weight of slab= 9.475 KN/m

2

Tributary area= 57.781 m

2

(DL+LL+wt. slab)(TA)/L = 50.928 KN/m

(self weight of section)(9.81)/1000 = 4.905 KN/m

total w= 55.833 KN/m

ANALYSIS OF BEAM

w = 55.833

L= 10.75 m.

R

R

) 2 (

4

) (L ST

TA=

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 23

23 STRUCTURAL STEEL DESIGN

use the assume wide flange, W 12 X 230

fb= 163.68 Mpa

solving for Sx to determine the most economical section

Sx= 4790.671 x10

3

mm

3

Note: look for the manual for the most efficient section

Adopt the wide flange section W 12 x 230

Check for the Adequacy:

Test for compactness:

3.115< 13.038

Compact!

11.712 < 128.85

Compact!

Fb= 163.68 MPa

fb = 149.075 MPa

149.075 < 163.8

.: the section is adequate

=

Ra = 291.772 KN

Fy fb 66 . 0 =

Sx

Mx

f b=

Fy tf

bf 170

2

s

Fy tw

d 1680

=

Fy Fb 66 . 0 =

Sx

Mx

f b=

Fb fb<

L

L wL

Ra

) 2 / (

=

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 24

24 STRUCTURAL STEEL DESIGN

ANALYSIS OF GIRDER

assume section of wide flange W 21 x 402

W 21 x 402

Orientation

Weight, w (kg/m)

598

Area, A (mm

2

)

76129

Section Modulus about X, S

X

(x10

3

mm

3

) 15355

Section Modulus about Y, S

Y

(x10

3

mm

3

) 3097

Radius of Gyration about X, r

x

(mm) 259.08

Radius of Gyration about Y, r

y

(mm) 83.06

Depth , d 660.91

Thickness of web , tw 43.94

Base of flange, bf 340.49

Thickness of flange, tf 79.5

Moment of Inertia, Ix 5078

Moment of Inertia, Iy 529

Use the same loadings

DL+LL+weight of slab = 9.475 Kn/m

2

Tributary area = 57.781 m

2

(DL+LL+wt. slab)(TA)/ST = 50.928 Kn/m

(self weight of section)(9.81)/1000 = 5.866 KN/m

total w= 56.795 KN/m

solving for Sx to determine the most economical section

Sx= 14593.648 x 10^3 mm

3

Adopt the wide flange section W 14 x 500

Sx

Mx

f b=

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 25

25 STRUCTURAL STEEL DESIGN

Check for the Adequacy:

Test for compactness:

2.141<10.795 Compact!

15.041 < 106.680

Compact!

Fb= 163.680 MPa

fb = 155.564 MPa

155.564 < 163.680

.:the section is adequate

=

Ra = 597.042 KN

ANALYSIS FOR CONTINUOUS BEAM

Self Weight, SW

W 14 x 61

Orientation

Weight, w (kg/m)

90.83

Area, A (mm

2

)

11548

Section Modulus about X, S

X

(x10

3

mm

3

) 1510

Section Modulus about Y, S

Y

(x10

3

mm

3

) 351

Radius of Gyration about X, r

x

(mm) 151.88

Radius of Gyration about Y, r

y

(mm) 62.1

Depth , d 352.8

Thickness of web , tw 9.5

Base of flange, bf 253.9

Thickness of flange, tf 16.4

Moment of Inertia, Ix 266.388

Moment of Inertia, Iy 44.537

Fy tw

d 1680

s

Fy Fb 66 . 0 =

Fb fb<

L

L wL

Ra

) 2 / (

=

Sx

PL wST

fb

|

|

.

|

\

|

+

=

4 8

2

Fy tf

bf 170

2

s

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 26

26 STRUCTURAL STEEL DESIGN

self weight of section = (89)(9.81)(1/1000) = 0.87 kN/m

Dead loads = 3.55 kPa

Live load = 2.4 KPa

eight of slab =

conc

x thk

Weight of slab = 23.5 x 150 mm = 3.525 KN/m

2

W =

+ LL + weight of slab = 3.55 + 2.4+ 3.525 = 9.475 KN/m

2

Tributary Area,

T

=

0.25ST(4)

4

+1.5(4)()=

0.25(10.75)(4)(10.75)

4

+1.5(4)(10.75)= 93.91 km

( + + eight of slab)(

T

)

4

=

9.475(93.91)

4(10.75)

= 20.693 km

(+eight of slab)(

T

)

4

=

3.55+3.525(93.91)

4(10.75)

= 15.4515 km

Assume the section is compact.

Solving for the reactions

1

+ 2

1

+

2

+

c

2

+

6

1

a

1

1

+

6

2

b

2

= 6(

h

1

1

+

h

2

2

)

Consider that there is no settlement in the reactions, M

a

= M

e

= 0, and

6

1

a

1

1

=

6

3

a

3

6

3

b

w

3

4

=

15.4515(10.75)

3

4

=4798.8375N-m

2

6

2

a

2

2

=

6

2

b

2

=

6

4

b

w

3

4

=

20.693(10.75)

3

4

=6426.7123N-m

2

Where L

1

= L

2

= L

3

= 10. 75m

A

B C D E L

1

L

2

L

3

L

4

15.4515 KN/m 15.4515 KN/m 20.693 KN/m

20.693 KN/m

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 27

27 STRUCTURAL STEEL DESIGN

Considering the first and second span

2

1

+

2

+

c

2

+

6

1

a

1

1

+

6

2

b

2

=

2

21.5 +

c

(10.75) + 4798.8375+6426.7123 = 0

43

10.75

= 11225.2498

Considering the second and third span

2

+ 2

c

2

+

3

+

3

+

6

2

a

2

2

+

6

3

b

3

= 0

10.75 + 2

c

(21.5) +

(10.75) + 4798.8375+6426.7123 = 0

10.75

43

10.75

= 11225.2498

Considering the third and fourth span

c

3

+ 2

3

+

4

+

6

3

a

3

3

+

6

4

b

4

= 0

c

10.75 + 2

(21.5) + 4798.8375+6426.7123 = 0

10.75

43

= 11225.2498

Solving for the internal moments simultaneously.

M

B

=

-223.76kN-m

M

C

=

-149.17 kN-m

M

D

=

-223.76 kN-m

Checking for adequacy:

Solving the actual bending stress, f

b

f

b

=

max

S

x

=

223.76 x 10

6

= 148.19

Solving the allowable bending stress, F

b

F

b

= 0.66Fy

F

b

= 0.66 (248) = 163.68 MPa

Since f

b

<F

b

, the section is adequate as long girder.

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 28

28 STRUCTURAL STEEL DESIGN

15.4515 KN/m

20.693 KN/m

Solving for the reactions:

SEGMENT AB:

SEGMENT BC

SEGMENT CD:

SEGMENT DE:

A B

15.4515 KN/m

B C

20.693 KN/m

C D

D E

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 29

29 STRUCTURAL STEEL DESIGN

REACTIONS:

Ay=142.504 KN Dy=313.639 KN

By=313.639 KN Ey=73.166 KN

Cy=254.897 KN

V

max

=313.639 KN

I. DESIGN OF COLUMNS

FIRST FLOOR COLUMN

Firsts Floor Exterior Column Design

The height of the first floor column H

1

= 3 m = 3000mm. Assume that kL/r= 0

that is less that C

c

making it an intermediate column and that the column is hinged at both ends.

kL/r = 0 <C

c

, intermediate column!

Therefore, FS = 5/3

Fa = 0.6(Fy) = 0.6(248) = 148.8 MPa

Assume Fa

column

= 0.60Fa

Fa

column

= 0.60 (148.8MPa)

Fa

column

= 89.28 MPa

Fa

column

=

89. 28 a =

313.639(1000)

A = 3512.98 mm

2

3.0 m

313.639 kN

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 30

30 STRUCTURAL STEEL DESIGN

Using W 8 x 21 whose properties are

W 8 x 21

Orientation

Weight, w (kg/m) 31

Area, A (mm

2

) 3974

Section Modulus about X, S

X

(x10

3

mm

3

) 298

Section Modulus about Y, S

Y

(x10

3

mm

3

) 61

Radius of Gyration about X, r

x

(mm) 88.65

Radius of Gyration about Y, r

y

(mm) 32

Depth , d 210.31

Thickness of web , tw 6.35

Base of flange, bf 133.86

Thickness of flange, tf 10.16

Moment of Inertia, Ix 31

Moment of Inertia, Iy 4

Reference: Association of Structural Engineers of the Philippines (ASEP) Steel Manual

Checking the adequacy of the section:

r

=

1.0(3000)

32

=93.75 C

c

=

2

2

Fy

=

2

2

(200000)

248

= 126.169

kL/r <C

c

, therefore, intermediate column!

Solving allowable compressive stress, F

a

FS= 1.89 Fa=94.83 MPa

Solving for actual stress, fa

f

a

=

=

313.639(1000)

3974

=78.92

Since f

a

<F

a

, the section is adequate as second floor column.

Note:

For design purposes: for other columns including those on the second floor, use the same

section from the computation with respect to the critical load.

No internal column, all columns were on the sides (exterior) of the structure.

3

3

) ( 8

) / (

) ( 8

) / ( 3

3

5

Cc

r kl

Cc

r kl

Fs + = |

.

|

\

|

(

=

Fs

Fy

Cc

r kl

Fa

2

2

) ( 2

) / (

1

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 31

31 STRUCTURAL STEEL DESIGN

J. DESIGN OF BASE PLATE

Assume the base plate is square that rests on full area of concrete pedestal whose f

c

= 21

MPa (the most common).

plate

=

c

F

p

Where P

c

= column load and F

p

= allowable bending stress of concrete

Solving column load, P

c

c

=313639 N+9.81

m

s

2

(31

g

m

)(3.0 m)

=314551.33

Solving allowable bearing stress of concrete, F

p

F

p

=0.35 (f

c) =0.35(21 a)

p

=7.35

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 32

32 STRUCTURAL STEEL DESIGN

Solving the required area of the base plate, A

plate

plate

=

c

F

p

=

314551.33 N

7.35

=42796.1 mm

2

Knowing the base plate is square,

=N=

plate

=N=42796.1

==206.872 mm Say use 210mm x 210mm

However, it is too small to support the section, thus, use 450mm x 450mm

Solving for thickness, t

t=2x

f

p

f

y

Where x is larger between m & n, and f

p

is the actual bearing stress

Solving the actual bearing stress, f

p

f

p

=

actual

=

314551.33

(450)

2

=1.55

Solving m & n

m=

N - 0.95d

2

=

450-0.95(210.31)

2

=125.103 mm

n=

- 0.8b

f

2

=

450-0.80(133.86)

2

=171.456 mm

Then, x = 171.456 mm

Hence,

t=2x

f

p

f

y

=2(171.456mm)

1.55

248

=27.11, say t=30 mm

Henceforth, use 450mm x 450mm x 30 mm A36 base plate

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 33

33 STRUCTURAL STEEL DESIGN

K. DESIGN OF CONNECTION

Truss Member Connection (Riveted Connection)

Considering the member that carries the highest value of internal force.

TYPE OF

MEMBER

MEMBER

INTERNAL

FORCE

(N)

LENGTH

(m)

CROSS

SECTIONAL

AREA

(mm

2

)

ACTUAL

STRESS

(MPa)

Top chord AB 420172 1.934 5238 80.22

Using 10mm A36 gusset plate, 25

mm A325 fasteners (whose Fv=145MPa)

Analyzing shear V failure conditions.

F

v

=

max

v

v

=

max

F

v

N [

4

(25mm)

2

] =

420.172(1000)

145

N =5.9 say 6

Analyzing bearing P failure conditions.

F

p

=

max

v

p

=

max

F

p

N [25(10)]=

420.172(1000)

0.4(400)

N =10.5 say 11

Therefore, use 11 25mm A325 fasteners to resist both shear and bearing failure

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 34

34 STRUCTURAL STEEL DESIGN

Beam and Girder Connection (Riveted Connection)

Consider the shear force V of 313.639 kN (the maximum shear that occurs in the short

girders), use 28 mm A325 fasteners (whose Fv=145MPa). Assume that the connecting angle is

10mm.

Analyzing shear V failure conditions.

F

v

=

max

v

v

=

max

F

v

N [

4

(28mm)

2

] =

313.639(1000)

145

N = 3.51 say 4

Analyzing bearing P failure conditions.

F

p

=

max

p

p

=

max

F

p

N [(28)(10)]=

313.639(1000)

0.4(400)

N = 7

Therefore, use 7 28mm A325 fasteners to resist both shear and bearing failure

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 35

35 STRUCTURAL STEEL DESIGN

Frame and Support Connection (Wielded Connection)

Using E60XX electrode whose Fu = 415MPa, we consider the shear force V of 313.639kN (the

maximum shear that occurs in the short girders). The wield thickness is assumed to be 8mm

Analyzing shear V failure conditions.

F

v

=

max

v

v

=

max

F

v

.707(8mm)()=

313639(1000)

0.3(415)

L =445.4 say 450 mm.

Therefore, use 450 mm long 8mm thick wield to resist shear failure.

GUILLERMO, Lou Stalin Dominique D.J. - 2007101109 Page 36

36 STRUCTURAL STEEL DESIGN

L. APPENDICES

-ASEP Steel Handbook 2004

-NSCP (National Structural Code of the Philippines)

-Steel review book (Fundamentals of Structural Steel Design)

By: DIT Gillesania

-STAAD PRO 2007

-AUTOCADD 2009

-Google Earth and Google Maps

-Progress Reports

M. ACKNOWLEDGMENTS

Im gld tht I hd finished my projet on time even though it is quite rush in

the making, I thank all those who had help me on the times of working of the project

matter. First of all, I thank God for the guidance, wisdom and knowledge he blessed

to me. Second, I thank our beloved professor in CE134P (steel and timber design),

Engr. Edgardo Cruz for all what he had taught to us regarding the subject matter

including his personal experience. Third, I thank my fellow steelmates because they

help me in times of problem regarding the project matter, they explain what is not

clear to me and they share their work, it help a lot, it acts like a reference. Fourth,

Manuel Trinidad, Jr. and his family, because they welcome us, they let us work our

project on their house, they fed us and even let us use their electricity, phone,

internet connection and other more, all that is necessary to use for the project,

special thanks to the father of Manuel for guiding us and teaching us to use STAAD, it

became handy for getting the forces on the truss, frame and beam. Fifth, I thank my

friend, Christiane Bernardo for helping me to create my floor plan using autocadd.

Our experience regarding the making of this project will be an unforgettable one due

to what we experience, it is the first time for me and some of my classmates to have

not just one day overnight of working having very less time for sleep and even almost

none but because of it we learned many lessons and we learned to budget time and

srifie our leisure time for work nd mny more. Im relly very gld nd very

thankful that I have finished my project just in time.

Anda mungkin juga menyukai

- Starlight Aluminum and Glass SupplyDokumen5 halamanStarlight Aluminum and Glass SupplyVin UbangBelum ada peringkat

- STC rating measures sound attenuation through building partitionsDokumen15 halamanSTC rating measures sound attenuation through building partitionsKenneth MarcosBelum ada peringkat

- SC Balinagay Builders Proposed Residential Building Cost BreakdownDokumen2 halamanSC Balinagay Builders Proposed Residential Building Cost BreakdownMark Christian EsguerraBelum ada peringkat

- COMBINED FOOTING DESIGNDokumen10 halamanCOMBINED FOOTING DESIGNclarkgaguiBelum ada peringkat

- 1 To 2: A To: Proposed Hostel CompexDokumen4 halaman1 To 2: A To: Proposed Hostel Compexanon_577049076Belum ada peringkat

- BOQ - Covered Court (Rev.005)Dokumen208 halamanBOQ - Covered Court (Rev.005)Kevin Marc BabateBelum ada peringkat

- Office Building Structural Load Design CriteriaDokumen4 halamanOffice Building Structural Load Design Criterianap_carinoBelum ada peringkat

- Design and Analysis of Seismic Resistant Apartment BuildingDokumen12 halamanDesign and Analysis of Seismic Resistant Apartment BuildingMunzuara AktherBelum ada peringkat

- Load Analysis 2-6Dokumen28 halamanLoad Analysis 2-6Azaina1Belum ada peringkat

- 2 M High Free Standing WallDokumen20 halaman2 M High Free Standing WallAnonymous ciKyr0tBelum ada peringkat

- Manual (Aitech) : ON Accreditation of Innovative Technologies For HousingDokumen48 halamanManual (Aitech) : ON Accreditation of Innovative Technologies For HousingJohn Ray Esmama CalasicasBelum ada peringkat

- 1way and 2way SlabsDokumen7 halaman1way and 2way Slabslance lancelottiBelum ada peringkat

- Slab Design Slab C8Dokumen1 halamanSlab Design Slab C8Mark Christian Esguerra100% (1)

- Dimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmDokumen1 halamanDimension Is 300mm X 300mm of Columns With 4pcs - Ø16mmMark Christian EsguerraBelum ada peringkat

- Guide to Stormwater Drainage DesignDokumen29 halamanGuide to Stormwater Drainage DesignGatot NugrohoBelum ada peringkat

- ASHRAE Method Air Flow: Air Temp Water TempDokumen7 halamanASHRAE Method Air Flow: Air Temp Water TempsamehBelum ada peringkat

- Design of Singly Reinforced BeamDokumen360 halamanDesign of Singly Reinforced BeamTyrone PaulinoBelum ada peringkat

- Reference: ACI 318M 2014 Chapter 11.1 Special Reinforcement Details For Seismic ZonesDokumen4 halamanReference: ACI 318M 2014 Chapter 11.1 Special Reinforcement Details For Seismic ZonesTri SetiyonoBelum ada peringkat

- Scaffolding Price: FramesDokumen5 halamanScaffolding Price: FramesRenalyn AndradeBelum ada peringkat

- Design of Column FootingDokumen5 halamanDesign of Column Footinggani100% (1)

- Concentric Column: Design of Square/Rectangular Isolated FootingDokumen21 halamanConcentric Column: Design of Square/Rectangular Isolated FootingangeladolfoBelum ada peringkat

- One Way Slab Design: Ref: Nilson-13Th Edition-418 Page ExampleDokumen4 halamanOne Way Slab Design: Ref: Nilson-13Th Edition-418 Page Examplerasedul islamBelum ada peringkat

- FINALDokumen215 halamanFINALMJ CiprianoBelum ada peringkat

- Engineering Drawings Service Proposal - 11282022Dokumen2 halamanEngineering Drawings Service Proposal - 11282022Ella SelomBelum ada peringkat

- NBC Form B-02 Excavation PermitDokumen1 halamanNBC Form B-02 Excavation PermitEngineer LeeBelum ada peringkat

- Concrete slab and beam design calculationsDokumen16 halamanConcrete slab and beam design calculationsGing LimjocoBelum ada peringkat

- Tot StationDokumen97 halamanTot Stationkkrao100% (1)

- RC Manual Calculation SheetDokumen1 halamanRC Manual Calculation SheetHeLmi HendrixBelum ada peringkat

- Understanding STC Ratings and Their LimitationsDokumen10 halamanUnderstanding STC Ratings and Their LimitationsDavid BeggBelum ada peringkat

- Durable Precast Bleachers and Grandstands for Spans Up to 28 FeetDokumen5 halamanDurable Precast Bleachers and Grandstands for Spans Up to 28 FeetMardeOpamenBelum ada peringkat

- Leave Credit Monitoring Report 2019Dokumen10 halamanLeave Credit Monitoring Report 2019Pros Mktg Nueva EcijaBelum ada peringkat

- RCD-DeSIGN Engr. Mark ChristianDokumen9 halamanRCD-DeSIGN Engr. Mark ChristianTaki TachibanaBelum ada peringkat

- CHB Wall Reinforcement Design CalculatorDokumen1 halamanCHB Wall Reinforcement Design Calculatorgon972001Belum ada peringkat

- FM-CPM22-01 CSHP Application Form - Simplified - REV 0 - MAY 19 2020Dokumen1 halamanFM-CPM22-01 CSHP Application Form - Simplified - REV 0 - MAY 19 2020Benedict NisperosBelum ada peringkat

- Multi Deck 146Dokumen36 halamanMulti Deck 146bondar1100% (1)

- Technical Specifications-Format (For Review)Dokumen2 halamanTechnical Specifications-Format (For Review)Eduardo De Castro Cruz Jr.Belum ada peringkat

- Base Plate Anchor Bolt DesignDokumen8 halamanBase Plate Anchor Bolt DesignnoneofyourbusineesBelum ada peringkat

- INSTALL METAL DECKINGDokumen4 halamanINSTALL METAL DECKINGGeorge BryanBelum ada peringkat

- Seismic Analysis (Static Procedure)Dokumen6 halamanSeismic Analysis (Static Procedure)Sofiah Marshialyn PepitoBelum ada peringkat

- 26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Dokumen1 halaman26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Ahmad Badsha QuadriBelum ada peringkat

- Pow-Entrance Gate and Fencing 1Dokumen12 halamanPow-Entrance Gate and Fencing 1Earl Justin EnriqueBelum ada peringkat

- Base Shear SeismicDokumen16 halamanBase Shear SeismicBrandon Calvin GoBelum ada peringkat

- Unified Application For BLDG PermitDokumen3 halamanUnified Application For BLDG PermitJohn Isaac Navarro CamposBelum ada peringkat

- Weekly Progress Report: Republic of The Philippines Philippine Rural Development Project (PRDP)Dokumen73 halamanWeekly Progress Report: Republic of The Philippines Philippine Rural Development Project (PRDP)stella marizBelum ada peringkat

- Foundation Design of Lamp PostDokumen1 halamanFoundation Design of Lamp PostMayank AgrawalBelum ada peringkat

- RC ColumnsDokumen9 halamanRC ColumnsACES JEEL CENDA�A100% (1)

- ROOF TRUSS DESIGN AND MAINTENANCE GUIDEDokumen36 halamanROOF TRUSS DESIGN AND MAINTENANCE GUIDETaufiq PrihantoroBelum ada peringkat

- Chapter 3 - LoadsDokumen43 halamanChapter 3 - Loadsmorteza0% (1)

- Design of Two-Way Slab for Residential UnitDokumen235 halamanDesign of Two-Way Slab for Residential Unitramel sigueBelum ada peringkat

- Footing Design and AnalysisDokumen5 halamanFooting Design and AnalysisRichelle DandoBelum ada peringkat

- Subgrade Modulus Foundation Analysis GuideDokumen1 halamanSubgrade Modulus Foundation Analysis GuideZain SaeedBelum ada peringkat

- H D E G: Male C.R. PWD C.R. Female C.R. Pump RMDokumen1 halamanH D E G: Male C.R. PWD C.R. Female C.R. Pump RMMark Christian EsguerraBelum ada peringkat

- Structural DesignDokumen7 halamanStructural DesignDENCOBelum ada peringkat

- Structural Analysis & Design of 2 Storey Residential BuildingDokumen104 halamanStructural Analysis & Design of 2 Storey Residential BuildingForceBelum ada peringkat

- Calculation NoteDokumen10 halamanCalculation NoteJay EvansBelum ada peringkat

- Roof load capacity and design load calculationsDokumen2 halamanRoof load capacity and design load calculationstyannottiBelum ada peringkat

- Structural Steel Design Plans and DrawingsDokumen36 halamanStructural Steel Design Plans and DrawingskvranapratapBelum ada peringkat

- Jutpani SS20Dokumen23 halamanJutpani SS20Suman NakarmiBelum ada peringkat

- Payment receipt for Rs. 796.5 from Venkataramana Reddy KDokumen1 halamanPayment receipt for Rs. 796.5 from Venkataramana Reddy KkvranapratapBelum ada peringkat

- The Horse ConquerorDokumen13 halamanThe Horse ConquerorkvranapratapBelum ada peringkat

- Cricket Betting TipsterDokumen11 halamanCricket Betting TipsterkvranapratapBelum ada peringkat

- Vision RacingDokumen14 halamanVision RacingkvranapratapBelum ada peringkat

- Library AutomationDokumen15 halamanLibrary AutomationkvranapratapBelum ada peringkat

- Payment receipt for Rs. 796.5 from Venkataramana Reddy KDokumen1 halamanPayment receipt for Rs. 796.5 from Venkataramana Reddy KkvranapratapBelum ada peringkat

- ACtjan 1Dokumen1 halamanACtjan 1kvranapratapBelum ada peringkat

- Payment receipt for Rs. 767 online transactionDokumen1 halamanPayment receipt for Rs. 767 online transactionkvranapratapBelum ada peringkat

- Receipt FebDokumen1 halamanReceipt FebkvranapratapBelum ada peringkat

- Sbi 24aug2018Dokumen1 halamanSbi 24aug2018kvranapratapBelum ada peringkat

- New Text Document SDWWWDokumen1 halamanNew Text Document SDWWWkvranapratapBelum ada peringkat

- The Essence of Living Enlightenment PDFDokumen171 halamanThe Essence of Living Enlightenment PDFkckejaman100% (1)

- Payment receipt for Rs. 796.5 from Venkataramana Reddy KDokumen1 halamanPayment receipt for Rs. 796.5 from Venkataramana Reddy KkvranapratapBelum ada peringkat

- Payment receipt for Rs. 796.5 from Venkataramana Reddy KDokumen1 halamanPayment receipt for Rs. 796.5 from Venkataramana Reddy KkvranapratapBelum ada peringkat

- ACtjan 1Dokumen1 halamanACtjan 1kvranapratapBelum ada peringkat

- Journal No 1094147193812 Date of Payment 04/07/2018 TSPSC Id TS2100503347 Amount 200.0 Status SuccessDokumen1 halamanJournal No 1094147193812 Date of Payment 04/07/2018 TSPSC Id TS2100503347 Amount 200.0 Status SuccesskvranapratapBelum ada peringkat

- Sbi 24aug2018Dokumen1 halamanSbi 24aug2018kvranapratapBelum ada peringkat

- No Data FileDokumen1 halamanNo Data FilekvranapratapBelum ada peringkat

- Rent Receipt: Employee Code: 1465Dokumen1 halamanRent Receipt: Employee Code: 1465kvranapratapBelum ada peringkat

- SssDokumen8 halamanSsskvranapratapBelum ada peringkat

- SssDokumen3 halamanSsskvranapratapBelum ada peringkat

- Color Coding Key ExpandedDokumen1 halamanColor Coding Key ExpandedkvranapratapBelum ada peringkat

- SssDokumen14 halamanSsskvranapratapBelum ada peringkat

- SssDokumen1 halamanSsskvranapratapBelum ada peringkat

- SssDokumen14 halamanSsskvranapratapBelum ada peringkat

- System Soft Technologies India PVR Tan No:-Hyds17282G Pan:-Aaicsb297E Period:Apr 2014-31St Aug 2014 231500 7,8 Empty 9 TH 231500 10Th 3900 11Th 4500Dokumen1 halamanSystem Soft Technologies India PVR Tan No:-Hyds17282G Pan:-Aaicsb297E Period:Apr 2014-31St Aug 2014 231500 7,8 Empty 9 TH 231500 10Th 3900 11Th 4500kvranapratapBelum ada peringkat

- SssDokumen1 halamanSsskvranapratapBelum ada peringkat

- WEEKLY REPORT 1-14Dokumen3 halamanWEEKLY REPORT 1-14kvranapratapBelum ada peringkat

- House Rent DeclarationDokumen1 halamanHouse Rent DeclarationkvranapratapBelum ada peringkat

- House Rent DeclarationDokumen1 halamanHouse Rent DeclarationkvranapratapBelum ada peringkat

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Dokumen5 halamanLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnBelum ada peringkat

- Tyre ManufacturingDokumen18 halamanTyre ManufacturingniteshkrisBelum ada peringkat

- CHEST Workout Structure and Training Log PREVIEWDokumen3 halamanCHEST Workout Structure and Training Log PREVIEWgaurav singhBelum ada peringkat

- E12817 GT AC5300 Manual EnglishDokumen152 halamanE12817 GT AC5300 Manual Englishlegato1984Belum ada peringkat

- 1 Project ManagementDokumen14 halaman1 Project Managementyaswanth119Belum ada peringkat

- Valve Group-Control - AuxiliaryDokumen3 halamanValve Group-Control - AuxiliarythierrylindoBelum ada peringkat

- DC Motor Direction Control ReportDokumen6 halamanDC Motor Direction Control ReportEngr Farhanullah SarkiBelum ada peringkat

- Understand Centrifugal CompressorDokumen16 halamanUnderstand Centrifugal Compressorramanathan72-1100% (2)

- Zhao PeiDokumen153 halamanZhao PeiMuhammad Haris HamayunBelum ada peringkat

- Dissertation ErsatzteilmanagementDokumen7 halamanDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFDokumen6 halamanDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- Admin Interview Questions and Answers - Robert HalfDokumen2 halamanAdmin Interview Questions and Answers - Robert HalfWaqqas AhmadBelum ada peringkat

- DPWH Standard Specifications for ShotcreteDokumen12 halamanDPWH Standard Specifications for ShotcreteDino Garzon OcinoBelum ada peringkat

- Design Rules CMOS Transistor LayoutDokumen7 halamanDesign Rules CMOS Transistor LayoututpalwxyzBelum ada peringkat

- Qcs 2010 Section 5 Part 8 Transportation and Placing of ConcreteDokumen7 halamanQcs 2010 Section 5 Part 8 Transportation and Placing of Concretebryanpastor106Belum ada peringkat

- RefrigerationDokumen11 halamanRefrigerationBroAmirBelum ada peringkat

- Prefabricated Structures ComponentsDokumen16 halamanPrefabricated Structures ComponentsKrish KrishBelum ada peringkat

- P8B WS Memory Qualified Vendors List (QVL)Dokumen3 halamanP8B WS Memory Qualified Vendors List (QVL)bolpensmaierBelum ada peringkat

- Nazneen Wahab CVDokumen5 halamanNazneen Wahab CVRavi MittalBelum ada peringkat

- Smart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsDokumen5 halamanSmart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsEko Hadi Susanto100% (1)

- AOE - FormDokumen8 halamanAOE - FormBimal GuptaBelum ada peringkat

- حل جميع المعادلات الكهربائيةDokumen60 halamanحل جميع المعادلات الكهربائيةGandhi HammoudBelum ada peringkat

- Managing ImapDokumen408 halamanManaging ImapPriya RaoBelum ada peringkat

- OceanPixel Abundo Marine Renewable Energy An Emerging OptionDokumen96 halamanOceanPixel Abundo Marine Renewable Energy An Emerging OptionjopaypagasBelum ada peringkat

- Abstract Classes and Methods in Object Oriented ProgrammingDokumen13 halamanAbstract Classes and Methods in Object Oriented Programmingkishore1201Belum ada peringkat

- Guide: Royal Lepage Estate Realty BrandDokumen17 halamanGuide: Royal Lepage Estate Realty BrandNazek Al-SaighBelum ada peringkat

- Numerical Ability - Data Interpretation 3: 25 QuestionsDokumen6 halamanNumerical Ability - Data Interpretation 3: 25 QuestionsAvishek01Belum ada peringkat

- PDF Saa6d140e 2 Seriespdf CompressDokumen8 halamanPDF Saa6d140e 2 Seriespdf CompressNathawatBelum ada peringkat

- Gypsum Ceiling PDFDokumen1 halamanGypsum Ceiling PDFAanchal Mishra100% (1)

- Milenium BypassDokumen1 halamanMilenium BypassdinotecBelum ada peringkat