KPS Reactor Vessel Internals Inspection Plan Review Request Supplement

Diunggah oleh

Andres_Pastor1987Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

KPS Reactor Vessel Internals Inspection Plan Review Request Supplement

Diunggah oleh

Andres_Pastor1987Hak Cipta:

Format Tersedia

Dominion Energy Kewaunee, Inc.

5000 Dominion Boulevard, Glen Allen, VA 23060

ATTN: Document Control Desk U. S. Nuclear Regulatory Commission Washington, DC 20555-0001

AUG 30 2H1?

Serial No. 12-508 LIC/JG/RO Docket No.: 50-305 License No.: DPR-43

DOMINION ENERGY KEWAUNEE. INC. KEWAUNEE POWER STATION REACTOR VESSEL INTERNALS INSPECTION PLAN REVIEW REQUEST SUPPLEMENT AND RESPONSE TO REQUEST FOR ADDITIONAL INFORMATION

By application dated December 12, 2011 (Reference 1), Dominion Energy Kewaunee, Inc. (DEK), requested approval, pursuant to the provisions of Renewed Operating License DPR-43, of the inspection plan for reactor vessel internal (RVI) components at Kewaunee Power Station (KPS). This inspection plan submittal was to fulfill certain requirements of Renewed Operating License DPR-43, Section 2.C(1 5)(b); specifically, Commitment Items 1 and 2 of Appendix A of NUREG-1958, "Safety Evaluation Report Related to the Kewaunee Power Station," dated January 2011. The inspection plan was supplemented on June 28, 2012 (Reference 2). Subsequently, the Nuclear Regulatory Commission (NRC) transmitted a request for additional information (RAI) regarding the inspection plan (Reference 3). The NRC questions were discussed with NRC staff to obtain clarification, during a telephone conference on July 23, 2012. The DEK response is provided in Attachment 1 to this letter. Attachment 2 provides revised RVI components inspection plan tables. If you have questions or require additional information, please feel free to contact Mr. Jack Gadzala at 920-388-8604. Very truly yours,

J. AI

rice

Vice President - Nuclear Engineering Attachments: 1. Response to Request for Additional Inspection Plan Review Request Information Reactor Vessel Internals

2. Supplement to Reactor Vessel Internals Inspection Plan Review Request, Table 3 (Revision 1)

/A07

Serial No. 12-508 Page 2 of 2

References: 1. Letter from J. Alan Price (DEK) to Document Control Desk (NRC), "Reactor Vessel Internals Inspection Plan Review Request," dated December 12, 2011. 2. Letter from J. Alan Price (DEK) to Document Control Desk (NRC), "Reactor Vessel Internals Inspection Plan Review Request, Supplement and Response to Request for Additional Information," dated June 28, 2012. 3. Email from Karl D. Feintuch (NRC) to Jack Gadzala (DEK) et al, "ME7727 Kewaunee - Request for Additional Information Re: RVI components Inspection Plan - Follow-up RAI to response provided for RAI item Cher-006," dated July 17, 2012.

Commitments made by this letter: NONE

cc:

Regional Administrator, Region III U. S. Nuclear Regulatory Commission 2443 Warrenville Road Suite 210 Lisle, IL 60532-4352 Mr. Karl D. Feintuch Project Manager U.S. Nuclear Regulatory Commission One White Flint North, Mail Stop 08-H4A 11555 Rockville Pike Rockville, MD 20852-2738 NRC Senior Resident Inspector Kewaunee Power Station

Serial No. 12-508

ATTACHMENT 1

RESPONSE TO REQUEST FOR ADDITIONAL INFORMATION REACTOR VESSEL INTERNALS INSPECTION PLAN REVIEW REQUEST

KEWAUNEE POWER STATION DOMINION ENERGY KEWAUNEE, INC.

Serial No. 12-508 Attachment 1 Page 1 of 6 RESPONSE TO REQUEST FOR ADDITIONAL INFORMATION INSPECTION PLAN FOR THE AUGMENTED INSERVICE INSPECTION PROGRAM FOR EXAMINATION OF REACTOR VESSEL INTERNALS On July 17, 2012, the NRC transmitted to Dominion Energy Kewaunee, (DEK) a request for additional information (RAI) (Reference 1) concerning the inspection plan for reactor vessel internal (RVI) components at Kewaunee Power Station (KPS). This inspection plan submittal was to fulfill certain requirements of Renewed Operating License DPR43, Section 2.C(1 5)(b); specifically, Commitment Items 1 and 2 of Appendix A of NUREG-1958, "Safety Evaluation Report Related to the Kewaunee Power Station," dated January 2011. The inspection plan was supplemented on June 28, 2012 (Reference 2). The NRC staff reviewed DEK's June 28, 2012 supplement (Reference 2), specifically as it responds to NRC question ME7727-RAII-EVIB-CHER-006-2012-05-09, and has some concerns regarding the aging degradation in Alloy X-750 clevis insert bolts. Consequently, the NRC staff developed a follow-up question (below) on the issue. This question was discussed with NRC staff to obtain clarification during a telephone conference on July 23, 2012. During the conference, NRC staff requested that DEK state whether a VT-3 inspection is required by ASME Section XI (because the clevis insert bolts are a reactor vessel internals structure). The staff also requested a qualitative analysis regarding the minimum number of clevis insert bolts (and the dowel pin) that must be functional. The RAI question is provided below, followed by the DEK response. NRC Question ME7727-RAII-EVIB-Cher-017-2012-07-17 According to Section A.1.4 in MRP-175, "Materials Reliability Program: PWR Internal Aging Degradation Mechanism Screening Threshold Values," susceptibility to stress corrosion cracking (SCC) in Nickel Base Alloy X-750 depends on the type of heat treatment that is performed on the alloy. The high temperature heat treatment (HTH) process that is used on Alloy X-750 offers better resistance to SCC than the other age hardened heat treatment processes. Previous operating experience in a US PWR unit indicates that the Alloy X-750 clevis insert bolts experienced cracking. In Table 4-9 of the MRP-227-A report, the MRP identified only wear as an aging mechanism for the clevis insert bolts. A - Based on the operating experience as stated above, the staff believes that cracking should also be included as an active aging degradation in the clevis insert bolts. Therefore, the staff requests that the licensee confirm that Alloy X-750 material in HTH condition was used for clevis insert bolts at KPS.

Serial No. 12-508 Attachment 1 Page 2 of 6

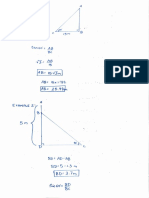

B - If the Alloy X-750 material is not in HTH condition, the staff requests that the licensee include verification of aging degradation due to cracking in its inspection and evaluation guidelines for these bolts at KPS. C -VT-3 examination of the bolts every 10 years would detect completely failed or missing bolts but not partially cracked bolts. Therefore, the staff requests the licensee to provide: (1) Justification that VT-3 technique would be adequate for monitoring the cracking issue in the clevis insert bolts before it fails; (2) Information on the number of clevis insert bolts that are necessary for maintaining their function during the extended period of operation; and, (3) Information on the number of clevis insert bolts that are currently present at KPS. Response: The primary function of the core barrel is to support the core. Lateral support for the core is provided at the upper and lower core plate locations and at intermediate positions during a seismic and LOCA event. During a seismic and LOCA event, the core may impact the baffle/former assembly that is supported by the core barrel (Reference 3). The core rests directly on the lower core plate that is ultimately supported by the core barrel. The lower core plate is attached at its periphery to the core barrel inside diameter and supported by lower support columns that are attached to the lower support forging. The lower support forging is welded at its edge to the bottom end of the core barrel. Four alignment pins located at 900 intervals are welded to the core barrel and engage the upper core plate. These pins restrain the lateral motion of the upper core plate. The baffle/former assembly is bolted to the core barrel and forms an outer envelope for the core. Four radial keys located at 900 intervals are attached to the core barrel at the lower support forging level. The radial keys restrain large transverse motions of the core barrel, but at the same time allow unrestricted radial and axial thermal expansions. Each radial key fits into the keyway of its corresponding clevis, which is welded to the reactor vessel (Figure 1). The lower core barrel is restrained laterally and torsionally by these uniformly spaced radial keys. The radial keys, along with the matching clevis inserts, are designed to limit the tangential motion between the lower end of the core barrel and the vessel. At

Serial No. 12-508 Attachment 1 Page 3 of 6 assembly, as the internals are lowered into the vessel, the keys engage the keyways of the inserts in the axial direction. With this design, the core barrel is provided with a support at the farthest extremity and may be viewed as a beam fixed at the top and guided at the bottom. With the radial key and inserts, the radial and axial expansions of the core barrel are accommodated, but circumferential movement (i.e., rotation) of the core barrel is restricted. The thickness of the clevis inserts is customized to have the optimum gap sizes. Each clevis is welded to the inside wall of the reactor vessel at 900 intervals to align with the four radial keys. The clevis inserts are attached to the clevis with eight bolts and one dowel pin. Each bolt is restrained by a bolt-head locking bar that prevents it from vibrating out of its threaded receptacle. The locking bar is attached with a tack weld on each end. The clevis inserts are retained within the clevis by friction (interference fit). Therefore, the clevis bolting is a designed redundancy to the friction fit (Figure 2). The function of the dowel pin is to offload any shear from the bolts for a case where a load is acting vertically upward on the clevis insert. A loose parts evaluation of a clevis insert bolt that experienced cracking at another utility (performed by Westinghouse Electric Company) determined that the separated heads will remain captured in the clevis insert counter-bores and will not impact operation. No safety or operability concerns were identified during this evaluation (Reference 4). The core barrel and its radial support keys are classified as core support structures. The clevis inserts are classified as reactor vessel internals structures and are also one of the components that form the interface between core supports and internals structures. CLM IS INSERT

Top view of

expanded section Expanded view at right FORGING

Figure 1

Serial No. 12-508 Attachment I Page 4 of 6

Locking Mechanism (tab across bolt head) Clevis Insert Bolt Head 0 Dowel Pin Clevis Clevis Insert

Clevis Insert

(Section A-A Figure 1 above) View towards reactor vessel interior wall

Figure 2

Basis for VT-3 Examination of Clevis Bolts Since the clevis insert bolts are a reactor vessel internals structure (and a component that forms the interface between core supports and internals structures), a VT-3 inspection is required by ASME Code, Section XI. These inspections are covered under an existing ASME Xl program and not under MRP-227 (Existing Program Items, Item B13.70 (formerly identified as Item B13.10), VT-3 examination of the clevis bolting). Based on the staff's concern, DEK has revised this item to include "loss of material (wear) and cracking" (in Table 3, Reactor Vessel Internals Inspection Plan (Reference 5)). The Alloy X-750 clevis insert bolts at KPS did not undergo the HTH treatment process. Based upon time of manufacturing and shipping, Westinghouse Electric Company indicates that the X-750 clevis insert bolts are supplied as Condition BH: * Hot worked, " Solution treatment at 980'C for 1 hour, air cooled, then, " Aged at 704'C for 20 hours, air cooled; or, 7300 C for 8 hours with a furnace cool followed by 620 0 C for 8 hours with an air cool. The proposed inspection and evaluation guidelines for these components are adequate to ensure that degradation would be indentified prior to loss of the redundant restraining function of the bolts. Because the bolts are restrained, the potential for loose parts from

Serial No. 12-508 Attachment 1 Page 5 of 6 a bolt failure is not significant. Therefore, the planned VT-3 inspection of these bolts every 10 years, as required by ASME Code, Section XI, is adequate for verification of their condition. Three previous VT-3 inspections have verified that the clevis bolts are installed and that the locking bar and tack welds are in place. Degradation of the clevis insert bolts would not result in a loss of intended function due to the nature of the design. A significant change in this support would be recognized by comparing changes from baseline neutron noise data from the excore detectors, thus providing a means for observing core barrel motion and the frequencies and mode shapes governing such motion. Moreover, to reach this stage, two additional components would have to fail. Therefore, the effects of primary water stress corrosion cracking (PWSCC) of the clevis insert bolts are not considered significant (Reference

3).

As discussed above, each of the four clevis inserts is secured to its support via eight bolts and one dowel pin. Therefore, a total of 32 clevis insert bolts and four dowel pins are in place to provide their restraining function. Since the clevis inserts are retained in place by means of an interference fit and dowel pin, the bolting is a designed redundancy. The function could reasonably be expected to be maintained (and reactor operation could safely continue) even with failure of multiple clevis bolts, since failed bolting would remain in place due the locking mechanism. Additionally, the close fit of the radial key (when the core barrel is in place) would prevent any bolt (and any dowel pin) from backing out of its housing. Even if a bolt completely cracked and its associated locking bar concurrently failed, the cracked bolt would not actually be released until the core barrel was subsequently removed. The primary consequence of a clevis bolt failure (should it occur) would be potentially to increase local wear between the radial keyways and clevis inserts. Failure of multiple bolts would likely lead to an increase in that wear potential. The presence of the dowel pin will provide some support to shear loads, thereby limiting the potential wear. In an extreme postulated case, if a loose clevis insert would be able to dislodge from the clevis (e.g., during a refueling outage when lifting the core barrel for the 10-year ISI), this could create a concern for loose parts and excessive motion of the lower internals. Multiple physical constraints exist to prevent this from occurring, even in the case of failed bolts. In the basic installation of the clevis insert, the insert is captured on each side by the clevis, such that it cannot become dislodged by moving in the right or left direction. Due to the close proximity of the radial key, lower internals, and vessel, the clevis insert is unable to become dislodged in the radial direction. Additionally, the clevis insert has a flange on the top that rests on the top side of the clevis. This ledge will prevent the clevis insert from becoming dislodged vertically downward. The only potential direction not constrained by significant lower internals and vessel structures is in the vertically upward direction (which is constrained by gravity). For the clevis insert to become dislodged upward, the bolts and dowel pins would all have to fail flush at the bolting surface between the clevis insert and vessel lug, which is unlikely. Based on the lock bar wear identified at another utility, it is more likely that the bolts would fail at the

Serial No. 12-508 Attachment 1 Page 6 of 6 head to shank radius. If failure did occur at the head to shank radius, the remaining shank provides an additional defense against the clevis insert dislodging vertically upward. As such, no additional inspections to assure the function of the clevis insert bolts are needed during the period of extended operation. As stated above, DEK has revised the KPS Reactor Vessel Internals Inspection Plan, Existing Program Items, Item B13.70, VT-3 examination of the clevis insert bolting, to include "loss of material (wear) and cracking". The revised Reactor Vessel Internals Inspection Plan Table 3 showing this change is provided in Attachment 2 to the letter transmitting this response.

REFERENCES 1. Email from Karl D. Feintuch (NRC) to Jack Gadzala (DEK) et al, "ME7727 Kewaunee - Request for Additional Information Re: RVI components Inspection Plan - Follow-up RAI to response provided for RAI item Cher-006," dated July 17, 2012. 2. Letter from J. Alan Price (DEK) to Document Control Desk (NRC), "Reactor Vessel Internals Inspection Plan Review Request, Supplement and Response to Request for Additional Information," dated June 28, 2012. 3. Letter from Christopher I. Grimes (NRC) to Roger A. Newton (Westinghouse Owners Group), "Acceptance for Referencing of Generic License Renewal Program Topical Report Entitled, 'License Renewal Evaluation: Aging Management for Reactor Internals', WCAP-14577, Revision 1, October 2000," dated February 10, 2001. 4. Westinghouse InfoGram IG-10-1, "Reactor Internals Lower Radial Support Clevis Insert Cap Screw Degradation," dated March 31, 2010. 5. Letter from J. Alan Price (DEK) to Document Control Desk (NRC), "Reactor Vessel Internals Inspection Plan Review Request," dated December 12, 2011.

Serial No. 12-508

ATTACHMENT 2

SUPPLEMENT TO REACTOR VESSEL INTERNALS INSPECTION PLAN REVIEW REQUEST

TABLE 3 (REVISION 1)

KEWAUNEE POWER STATION DOMINION ENERGY KEWAUNEE, INC.

Serial No. 12-508

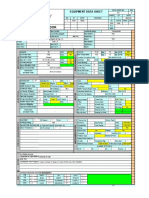

Table 3 (Revision 1) Reactor Vessel Internals Inspection Plan MRP-227 Westinghouse Plants Existing Programs Components (3 pages)

KEWAUNEE POWER STATION DOMINION ENERGY KEWAUNEE, INC.

Serial No. 12-508

Reactor Vessel Internals

B13,70 Core Barrel Assembly Core Barrel Flange Attachment Figure 4 XK-67866 B13.70 Upper Internals Assembly Upper Support Ring or Skirt Attachment Figure 4 and Figure 5 XK-67866 B13.70 Lower Internals Assembly Lower Core Plate Attachment Figure 4 and Figure 5 XK-67866 B13.70 Lower Internals Assembly Lower Core Plate Attachment Figure 4 and Figure 5 XK-67866 B13.70 Alignment and Interfacing Components Upper Core Plate Alignment Pins Attachment Figure 2 XK-67866 Reactor Vessel Upper Internals Assembly Upper Support Ring or Skirt Reactor Vessel Lower Internals Assembly Lower Core Plate Reactor Vessel Lower Internals Assembly Lower Core Plate Reactor Vessel Upper Internals Upper Core Plate Alignment Pins Y X X Y X X X X VT-3 examination. Cracking (IASCC, Fatigue) Reactor Vessel Core Barrel Y X

x2

VT-3 examination. Loss of material (wear).

VT-3 examination of the lower core plate to detect evidence of distortion and/or loss of bolt integrity. Cracking (IASCC, Fatigue) VT-3 examination. Loss of material (wear).

VT-3 examination. Loss of material (wear).

Category Notes: 1. 2. End of Original License is December 21, 2013. Examinations are performed when the core barrel is removed typically once per interval.

Table 3, Page 1 of 3

Serial No. 12-508

Reactor Vessel Internals

B13.70 Alignment and Interfacing Components Clevis Insert Bolts Attachment Figure 4 Reactor Vessel Internals Y X VT-3 examination once per interval when the lower internals are removed. Loss of material (wear) and cracking (Note 4). Eight bolts per clevis; four clevis at 900

Iintervals.

Category Notes: 1. 2. 3. 4. End of Original License is December 21, 2013. The clevis insert bolts are located on the reactor vessel below the lower internals. Per B-N-3, the structure shall be removed from the reactor for examination. Clevis insert bolts were screened in because of stress relaxation and associated potential for cracking; however, wear of the clevis/insert is the primary reason for the inspection.

Table 3, Page 2 of 3

Serial No. 12-508

Reactor Vessel Internals IEB 88-09 Reactor Vessel Bottom Mounted Instrumentation System Flux Thimble Tubes Flux Thimble Tubes (36) Y X Eddy Current Examination of the Flux Thimble Tubes Once Every Five Years

Category Notes: 1. End of Original License is December 21, 2013.

Table 3, Page 3 of 3

Anda mungkin juga menyukai

- Clevis Bolts Material 3Dokumen5 halamanClevis Bolts Material 3Andres_Pastor1987Belum ada peringkat

- Electrically Insulating Plastic Guard Equipment For Protection of WorkersDokumen5 halamanElectrically Insulating Plastic Guard Equipment For Protection of WorkersOSCAR MAURICIO GUTIERREZ GOMEZBelum ada peringkat

- Hazards of Pneumatic Test Feb11 - DLDokumen6 halamanHazards of Pneumatic Test Feb11 - DLMike MavrosBelum ada peringkat

- Endurance Regression Testing Method To Obtain A Hydrostatic Design Basis For Fiberglass PipeDokumen15 halamanEndurance Regression Testing Method To Obtain A Hydrostatic Design Basis For Fiberglass PipeAvik Kundu100% (1)

- Fracture Mechanics Approach To Pressure Vessel Failures PDFDokumen8 halamanFracture Mechanics Approach To Pressure Vessel Failures PDFsandeeppandey0789Belum ada peringkat

- How To (Maybe) Measure Laser Beam QualityDokumen16 halamanHow To (Maybe) Measure Laser Beam QualityLuming ZhaoBelum ada peringkat

- Ipc2022-86922 Progress of Assessment Model Development For DeterminingDokumen14 halamanIpc2022-86922 Progress of Assessment Model Development For DeterminingOswaldo MontenegroBelum ada peringkat

- API 650 Manhole Torque ValuesDokumen2 halamanAPI 650 Manhole Torque ValuesJadon TheophilusBelum ada peringkat

- Different Material STD ComparisionDokumen15 halamanDifferent Material STD ComparisionKamal RajuBelum ada peringkat

- Iec 61400-25-6-2010Dokumen36 halamanIec 61400-25-6-2010Yassine BecharBelum ada peringkat

- Jis 2275 1989 PDFDokumen35 halamanJis 2275 1989 PDFsud1313100% (1)

- WindSonic GPA Manual 1405-PS-0019 Issue 25Dokumen35 halamanWindSonic GPA Manual 1405-PS-0019 Issue 25eduardo ayalaBelum ada peringkat

- Link Engineering Dearborn Cert Scope V 008Dokumen8 halamanLink Engineering Dearborn Cert Scope V 008karthegreBelum ada peringkat

- F1472Dokumen5 halamanF1472Antonio JBelum ada peringkat

- Formulas For Torsional Properties and Stresses in Thin-Walled Closed and Open Cross SectionsDokumen10 halamanFormulas For Torsional Properties and Stresses in Thin-Walled Closed and Open Cross SectionsAnonymous JEe6LWPBelum ada peringkat

- AME 204 Spring 2012 Midterm Exam I SolutionDokumen6 halamanAME 204 Spring 2012 Midterm Exam I SolutionJack ZhaoBelum ada peringkat

- Elastic Properties of PotatoDokumen5 halamanElastic Properties of Potatopriya07rajBelum ada peringkat

- BS 8503-1Dokumen17 halamanBS 8503-1HaiBelum ada peringkat

- MPS 08122022 121826Dokumen2 halamanMPS 08122022 121826Sanjay Kumar BarikBelum ada peringkat

- PTC 10 1997Dokumen202 halamanPTC 10 1997Joel CieltoBelum ada peringkat

- J79 195 Rev H AMPCO SDS Rod WireDokumen10 halamanJ79 195 Rev H AMPCO SDS Rod WireNair R RakeshBelum ada peringkat

- Sample Vessel 3 96 Horizontal Vessel PreDokumen24 halamanSample Vessel 3 96 Horizontal Vessel PresoloBelum ada peringkat

- Single Hoist Crane Inspection Report 02-1006877 - J1604751 - NQ5728 - PDFDokumen3 halamanSingle Hoist Crane Inspection Report 02-1006877 - J1604751 - NQ5728 - PDFAnonymous N2Se0bYBelum ada peringkat

- Installation Practices FOR Cable Raceway Systems: The Okonite CompanyDokumen56 halamanInstallation Practices FOR Cable Raceway Systems: The Okonite Companymohsin shaikhBelum ada peringkat

- 106M5801K Diagramas de Conexionado 2300Dokumen11 halaman106M5801K Diagramas de Conexionado 2300Leinner RamirezBelum ada peringkat

- BIOBASE Vertical Laminar Flow Cabinet BBS-DDC'SDC User Manual 202109Dokumen25 halamanBIOBASE Vertical Laminar Flow Cabinet BBS-DDC'SDC User Manual 202109SACO QCBelum ada peringkat

- Iec 332-3Dokumen31 halamanIec 332-3Muhammad Adrianto LubisBelum ada peringkat

- 505xt 1 en PDFDokumen242 halaman505xt 1 en PDFSyed Mohammad NaveedBelum ada peringkat

- 13-Mechanical Testing of Ceramics PDF 2022Dokumen9 halaman13-Mechanical Testing of Ceramics PDF 2022aryan mike minzBelum ada peringkat

- OceanEng ResumesDokumen84 halamanOceanEng ResumesChristoper NavaBelum ada peringkat

- SECTION 1 OVERVIEWDokumen263 halamanSECTION 1 OVERVIEWCharbel Ghanem100% (1)

- Procedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterDokumen12 halamanProcedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterVitor100% (1)

- Control Noise PollutionDokumen18 halamanControl Noise PollutionDarshhhBelum ada peringkat

- Def Stan 61-12 Part 18Dokumen43 halamanDef Stan 61-12 Part 18Deepto BanerjeeBelum ada peringkat

- NEMA GFCI 2012 Field Representative PresentationDokumen37 halamanNEMA GFCI 2012 Field Representative PresentationGerver RodriguezBelum ada peringkat

- Role of Trade Unions: A Case Study in Indian Railways (With Special Reference To Northern Central Railways)Dokumen7 halamanRole of Trade Unions: A Case Study in Indian Railways (With Special Reference To Northern Central Railways)Divya RaghuvanshiBelum ada peringkat

- What Is 30c8 SteelDokumen3 halamanWhat Is 30c8 SteelSanjay MehtaBelum ada peringkat

- Advanced PropulsionDokumen17 halamanAdvanced PropulsionSuman PalBelum ada peringkat

- Providing Standards To The Aerospace and Defense Industries Since 1941Dokumen2 halamanProviding Standards To The Aerospace and Defense Industries Since 1941sriyan vBelum ada peringkat

- Sae As 5202a 2005-05-25Dokumen3 halamanSae As 5202a 2005-05-25Andr EkmeBelum ada peringkat

- Nas1921 AiaDokumen4 halamanNas1921 AiaGrandiosBelum ada peringkat

- 2022 23 WarwickRacing SESDokumen162 halaman2022 23 WarwickRacing SESPrem SinghBelum ada peringkat

- PTC 2021 Lam-ThanhDokumen13 halamanPTC 2021 Lam-ThanhSaumitra Shankar GuptaBelum ada peringkat

- I-Et-3010.00-5140-700-P4x-002 - K - Specification For Electrical Material An...Dokumen208 halamanI-Et-3010.00-5140-700-P4x-002 - K - Specification For Electrical Material An...everton maldonadoBelum ada peringkat

- Stainless Steel Behavior in PWR CircuitsDokumen14 halamanStainless Steel Behavior in PWR CircuitsMac NeryBelum ada peringkat

- Mitre Gate UsaceDokumen118 halamanMitre Gate UsaceVishal KumarBelum ada peringkat

- Silicone Rubber PropertiesDokumen15 halamanSilicone Rubber PropertiesSh.nasirpurBelum ada peringkat

- Some Applications of TrigonometryDokumen6 halamanSome Applications of TrigonometryCHHATRESH P LBelum ada peringkat

- JW1782BDokumen13 halamanJW1782BGustavo AlonsoBelum ada peringkat

- Radc TR 85 91 - May1985Dokumen441 halamanRadc TR 85 91 - May1985sezgin bayramBelum ada peringkat

- Oshkosh Product Overview 10-1-13 PDFDokumen32 halamanOshkosh Product Overview 10-1-13 PDFAbdelkader DraïBelum ada peringkat

- Codes and Standards for Battery Management Systems PerformanceDokumen6 halamanCodes and Standards for Battery Management Systems PerformanceGjbBelum ada peringkat

- Chase Testing PresentationDokumen18 halamanChase Testing PresentationDiego Chavez0% (1)

- Susana Santoyo, Miguel Herrero, Javier Senorans F., Alejandro CifuentesDokumen7 halamanSusana Santoyo, Miguel Herrero, Javier Senorans F., Alejandro CifuentesKiệt LêBelum ada peringkat

- Estimating Loss-of-Coolant Accident (LOCA) Frequencies Through The Elicitation ProcessDokumen448 halamanEstimating Loss-of-Coolant Accident (LOCA) Frequencies Through The Elicitation ProcessEnformableBelum ada peringkat

- Student's Report on Solar Energy Installation and Arduino ProjectsDokumen51 halamanStudent's Report on Solar Energy Installation and Arduino ProjectsJohn EsiebomaBelum ada peringkat

- Ieee STD Ansi-Ieee STD 743-1984Dokumen52 halamanIeee STD Ansi-Ieee STD 743-1984abdou samiBelum ada peringkat

- Vaporizador: Equipment Data SheetDokumen1 halamanVaporizador: Equipment Data SheetAlonso DIAZBelum ada peringkat

- Kral Bem 2uDokumen10 halamanKral Bem 2ukhadanghoangBelum ada peringkat

- Distribution Code: A001S Copies Received:Ltri Encl SIZE . .Dokumen18 halamanDistribution Code: A001S Copies Received:Ltri Encl SIZE . .Pria BudiBelum ada peringkat

- Leak in Control Rod Drive Mechanism HousingDokumen17 halamanLeak in Control Rod Drive Mechanism HousingAndres_Pastor1987Belum ada peringkat

- Fatigue Testing in Socket WeldsDokumen31 halamanFatigue Testing in Socket WeldsAndres_Pastor1987100% (1)

- Weld TheoryDokumen47 halamanWeld TheoryAndres_Pastor1987Belum ada peringkat

- Experimental Elastic Stress Analysis of Partial Penetration Welded NozzleDokumen14 halamanExperimental Elastic Stress Analysis of Partial Penetration Welded NozzleAndres_Pastor1987Belum ada peringkat

- Effect of Commercial Cladding On The Fracture BehaviorDokumen9 halamanEffect of Commercial Cladding On The Fracture BehaviorAndres_Pastor1987Belum ada peringkat

- Investigations On Partial Penetration Welded NozzleDokumen15 halamanInvestigations On Partial Penetration Welded NozzleAndres_Pastor1987Belum ada peringkat

- Thermal and Mechanical Analysis of WeldDokumen11 halamanThermal and Mechanical Analysis of WeldAndres_Pastor1987Belum ada peringkat

- Assessment of Socket Weld Integrity in PipingsDokumen30 halamanAssessment of Socket Weld Integrity in PipingsAndres_Pastor1987100% (1)

- Weld TheoryDokumen47 halamanWeld TheoryAndres_Pastor1987Belum ada peringkat

- A Review of Fatigue Failures in LWR Plants in JapanDokumen16 halamanA Review of Fatigue Failures in LWR Plants in JapanAndres_Pastor1987Belum ada peringkat

- WeldingDokumen752 halamanWeldingAndres_Pastor1987100% (3)

- Reactor Vessel CladdingDokumen23 halamanReactor Vessel CladdingAndres_Pastor1987Belum ada peringkat

- Assessment of Socket Weld Integrity in PipingsDokumen30 halamanAssessment of Socket Weld Integrity in PipingsAndres_Pastor1987100% (1)

- ASME Code Calculation BMI RepairDokumen22 halamanASME Code Calculation BMI RepairAndres_Pastor1987Belum ada peringkat

- Weld DesignDokumen2 halamanWeld DesignAndres_Pastor1987Belum ada peringkat

- Effect of Commercial Cladding On The Fracture BehaviorDokumen9 halamanEffect of Commercial Cladding On The Fracture BehaviorAndres_Pastor1987Belum ada peringkat

- BWR Pressure Vessel Cladding Cracking InvestigationDokumen18 halamanBWR Pressure Vessel Cladding Cracking InvestigationAndres_Pastor1987Belum ada peringkat

- Experimental Elastic Stress Analysis of Partial Penetration Welded NozzleDokumen14 halamanExperimental Elastic Stress Analysis of Partial Penetration Welded NozzleAndres_Pastor1987Belum ada peringkat

- BWR Pressure Vessel Cladding Cracking InvestigationDokumen18 halamanBWR Pressure Vessel Cladding Cracking InvestigationAndres_Pastor1987Belum ada peringkat

- IAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFDokumen215 halamanIAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFAndres_Pastor1987100% (1)

- BWR Reactor Vessel Bottom Head Failure ModesDokumen11 halamanBWR Reactor Vessel Bottom Head Failure ModesAndres_Pastor1987Belum ada peringkat

- A Review of Fatigue Failures in LWR Plants in JapanDokumen16 halamanA Review of Fatigue Failures in LWR Plants in JapanAndres_Pastor1987Belum ada peringkat

- Manganese EffectsDokumen4 halamanManganese EffectsAndres_Pastor1987Belum ada peringkat

- IAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFDokumen215 halamanIAEA 1556 Assessment and Management of Ageing of Major Nuclear Power Plant Components Important To Safety PWR Pressure Vessels 2007 Update PDFAndres_Pastor1987100% (1)

- Phase Transformation in MetalDokumen492 halamanPhase Transformation in MetalAndres_Pastor1987Belum ada peringkat

- Manganese Effects 2Dokumen8 halamanManganese Effects 2Andres_Pastor1987Belum ada peringkat

- Effects of Manganese in Weld MetalDokumen9 halamanEffects of Manganese in Weld MetalAndres_Pastor1987Belum ada peringkat

- A Flow-Partitioned Deformation Zone Model For Defect Formation During Friction Stir WeldingDokumen5 halamanA Flow-Partitioned Deformation Zone Model For Defect Formation During Friction Stir WeldingAndres_Pastor1987Belum ada peringkat

- Weld Op IDokumen110 halamanWeld Op IAndres_Pastor1987Belum ada peringkat

- Welding Inspection - Multiple ChoiseDokumen15 halamanWelding Inspection - Multiple ChoiseAndres_Pastor1987Belum ada peringkat

- Worzakowska2016 Article ThermalBehaviorDecompositionMeDokumen10 halamanWorzakowska2016 Article ThermalBehaviorDecompositionMeJavier Andres Munoz ChavesBelum ada peringkat

- Numerical Investigation of Heat Transfer Coefficient in Ribbed Rectangular Duct With Various Shaped Ribs and Different CoolantsDokumen4 halamanNumerical Investigation of Heat Transfer Coefficient in Ribbed Rectangular Duct With Various Shaped Ribs and Different CoolantsedBelum ada peringkat

- A Review Based On The Synthesis of Carbon Quantum Dots: Top-Down, Bottom-Up Approaches and Their PropertiesDokumen12 halamanA Review Based On The Synthesis of Carbon Quantum Dots: Top-Down, Bottom-Up Approaches and Their PropertiesInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- 25-07-2021 - INCOMING JR CO-SC-N120 - Jee-Adv (2012-P2) - Q.PDokumen13 halaman25-07-2021 - INCOMING JR CO-SC-N120 - Jee-Adv (2012-P2) - Q.PAaryan KumarBelum ada peringkat

- Quick Review Is 6403Dokumen2 halamanQuick Review Is 6403Kanaiyalal N. ShethBelum ada peringkat

- Lime-metakaolin mortars properties applicationsDokumen6 halamanLime-metakaolin mortars properties applicationsTezinBelum ada peringkat

- Heat of SolutionDokumen7 halamanHeat of SolutionAbeera MalikBelum ada peringkat

- Science 7 Week 6 ModuleDokumen7 halamanScience 7 Week 6 ModuleExequiel Macalisang Ramientos Jr.Belum ada peringkat

- Marks Distribution (Section I: 50 1 50, Section II: 10 1 10, Section III: 10 4 40)Dokumen11 halamanMarks Distribution (Section I: 50 1 50, Section II: 10 1 10, Section III: 10 4 40)zakaria masud sonyBelum ada peringkat

- V LedDokumen4 halamanV LedAmandeep Singh GujralBelum ada peringkat

- Gel in SituDokumen10 halamanGel in SituNur IslamiaBelum ada peringkat

- Heavy metal accumulation in Acropora aspera coral from Pomalaa waters, Southeast SulawesiDokumen12 halamanHeavy metal accumulation in Acropora aspera coral from Pomalaa waters, Southeast SulawesiMelky AnggiBelum ada peringkat

- Is.15656.2006 - Hazard Identification and Risk AssessmentDokumen31 halamanIs.15656.2006 - Hazard Identification and Risk Assessmentjitesh26100% (3)

- Kreb's Cycle (Aka, Tricarboxylic Acid (TCA) Cycle, Citric Acid Cycle)Dokumen20 halamanKreb's Cycle (Aka, Tricarboxylic Acid (TCA) Cycle, Citric Acid Cycle)Jayadev KodikalBelum ada peringkat

- Membrane Reactor by Shivani MunishwarDokumen32 halamanMembrane Reactor by Shivani MunishwarShivani MunishwarBelum ada peringkat

- XRD Kuliah Anorganik AdvanceDokumen31 halamanXRD Kuliah Anorganik AdvanceMulyaBelum ada peringkat

- Insertion Ultrasonic Flow MeterDokumen3 halamanInsertion Ultrasonic Flow Meterbsanidhya10Belum ada peringkat

- Physical and Chemical Properties of OPC GradesDokumen2 halamanPhysical and Chemical Properties of OPC GradesPIDCL WITH SUBUDHIBelum ada peringkat

- Design of Photobioreactors For Mass Cultivation of Photosynthetic Organisms PDFDokumen12 halamanDesign of Photobioreactors For Mass Cultivation of Photosynthetic Organisms PDFBrei Parayno LaurioBelum ada peringkat

- Lab 3 Drug Analysis and DNA ExtractionDokumen12 halamanLab 3 Drug Analysis and DNA ExtractionBeaBelum ada peringkat

- IIT Kanpur Mass Transfer Course OverviewDokumen2 halamanIIT Kanpur Mass Transfer Course OverviewAnonymous rkAeZVSKBelum ada peringkat

- 80451180Dokumen2 halaman80451180aminBelum ada peringkat

- The Korean Herbal Pharmacopoeia history and revisionsDokumen13 halamanThe Korean Herbal Pharmacopoeia history and revisionsKMNB BMNKBelum ada peringkat

- Prediction of Defects in Antifriction Bearings Using Vibration Signal AnalysisDokumen5 halamanPrediction of Defects in Antifriction Bearings Using Vibration Signal AnalysisdossokyBelum ada peringkat

- 4000 Chinese Words 1-100Dokumen10 halaman4000 Chinese Words 1-100SchlermbholBelum ada peringkat

- Evaluation of Packaging MaterialDokumen26 halamanEvaluation of Packaging MaterialSadhana GhimireBelum ada peringkat

- Tablet CappingDokumen4 halamanTablet CappingSevinc TunaBelum ada peringkat

- Extraction of Caffein From Tea and Sublimation of Crude CaffeinDokumen4 halamanExtraction of Caffein From Tea and Sublimation of Crude CaffeinMargel PeconBelum ada peringkat

- Engineering 435 Lab Report: Team Members Brian Vandagriff Marc Moss James Linder Corita SuberDokumen7 halamanEngineering 435 Lab Report: Team Members Brian Vandagriff Marc Moss James Linder Corita SuberAh WenBelum ada peringkat

- PMMA Data SheetDokumen8 halamanPMMA Data SheetalonsoBelum ada peringkat