AD590

Diunggah oleh

Alvaro Mompi RuizDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

AD590

Diunggah oleh

Alvaro Mompi RuizHak Cipta:

Format Tersedia

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper I.C. Handling Procedures.

Copyright Harris Corporation 1993

14-3

S E M I C O N D U C T O R AD590

2 Wire Current Output

Temperature Transducer

Description

The AD590 is an integrated-circuit temperature transducer which pro-

duces an output current proportional to absolute temperature. The

device acts as a high impedance constant current regulator, passing

1A/

K for supply voltages between +4V and +30V. Laser trimming of

the chip's thin lm resistors is used to calibrate the device to 298.2A

output at 298.2

K (+25

C).

The AD590 should be used in any temperature-sensing application

between -55

o

C to +150

o

C in which conventional electrical tempera-

ture sensors are currently employed. The inherent low cost of a

monolithic integrated circuit combined with the elimination of support

circuitry makes the AD590 an attractive alternative for many tempera-

ture measurement situations. Linearization circuitry, precision voltage

ampliers, resistance measuring circuitry and cold junction compen-

sation are not needed in applying the AD590. In the simplest applica-

tion, a resistor, a power source and any voltmeter can be used to

measure temperature.

In addition to temperature measurement, applications include temper-

ature compensation or correction of discrete components, and biasing

proportional to absolute temperature.

The AD590 is particularly useful in remote sensing applications. The

device is insensitive to voltage drops over long lines due to its high-

impedance current output. Any well insulated twisted pair is sufcient

for operation hundreds of feet from the receiving circuitry. The output

characteristics also make the AD590 easy to multiplex: the current

can be switched by a CMOS multiplexer or the supply voltage can be

switched by a logic gate output.

Features

Linear Current Output 1A/

o

K

Wide Temperature Range -55

o

C to + 150

o

C

Two-Terminal Device Voltage In/Current Out

Wide Power Supply Range +4V to +30V

Sensor Isolation From Case

Low Cost

Ordering Information

PART

NUMBER

NON-

LINEAR-

ITY (

o

C)

TEMPERATURE

RANGE PACKAGE

AD590IH 3.0 -55

o

C to +

150

o

C

TO-52

AD590JH 1.5 -55

o

C to +

150

o

C

TO-52

File Number 3171

December 1993

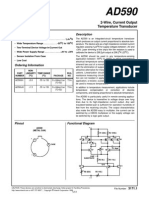

Pinout

AD590

(TO-52 CAN)

CASE

-

1

2

3

+

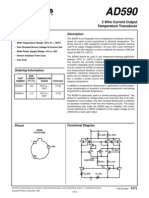

Functional Diagram

Q

1

Q

2

Q

3

Q

4

Q

5

Q

6

Q

7

Q

8

Q

9

Q

10

Q

11

Q

12

R

1

260 R

2

1040

C

1

26pF

R

3

5K R

4

11K

R

6

820 R

5

146

1 1 8

-

+

CHIP

SUBSTRATE

14-4

Specications AD590

Absolute Maximum Ratings (T

A

+ 25

o

C) Thermal Information

Supply Forward Voltage (V+ to V-) . . . . . . . . . . . . . . . . . . . . . . +44V

Supply Reverse Voltage (V+ to V-). . . . . . . . . . . . . . . . . . . . . . .-20V

Breakdown Voltage (Case to V+ to V-) . . . . . . . . . . . . . . . . . . . . 200V

Rated Performance Temperature Range TO-52 . . -55

o

C to + 150

o

C

Lead Temperature (Soldering, 10s) . . . . . . . . . . . . . . . . . . . +300

o

C

Storage Temperature Range . . . . . . . . . . . . . . . . . -65

o

C to +150

o

C

Maximum Package Power Dissipation

TO-52 Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15mW

Operating Temperature Range . . . . . . . . . . . . . . . . -55

o

C to +150

o

C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +175

o

C

CAUTION: Stresses above those listed in Absolute Maximum Ratings may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specication is not implied.

Electrical Specications Typical Values at T

A

= +25

C, V+ = 5V, Unless Otherwise Specied

PARAMETERS

TEST

CONDITIONS AD590I AD590J UNITS

Nominal Output Current at +25

C (+298.2

o

K) 298.2 298.2 A

Nominal Temperature Coefficient 1.0 1.0 A/

o

K

Calibration Error at +25

o

C Notes 1, 5 10.0 Max 5.0 Max

o

C

Absolute Error -55

o

C to + 150

o

C, Note 7

Without External Calibration Adjustment 20.0 Max 10.0 Max

o

C

With External Calibration Adjustment 5.8 Max 3.0 Max

o

C

Non-Linearity Note 6 3.0 Max 1.5 Max

o

C

Repeatability Notes 2, 6 0.1 Max 0.1 Max

o

C

Long Term Drift Notes 3, 6 0.1 Max 0.1 Max

o

C/Month

Current Noise 40 40 pA/Hz

Power Supply Rejection

+4V < V+ < +5V 0.5 0.5 A/V

+5V < V+ < +15V 0.2 0.2 A/V

+15V < V+ < +30V 0.1 0.1 A/V

Case Isolation to Either Lead 10

10

10

10

Effective Shunt Capacitance 100 100 pF

Electrical Turn-On Time Note1 20 20 s

Reverse Bias Leakage Current Note 4 10 10 pA

Power Supply Range +4 to +30 +4 to +30 V

NOTE:

1. Does not include self heating effects.

2. Maximum deviation between +25

o

C reading after temperature cycling between -55

o

C and +150

o

C.

3. Conditions constant +5V, constant +125

o

C.

4. Leakage current doubles every +10

o

C.

5. Mechanical strain on package may disturb calibration of device.

6. Guaranteed but not tested.

7. -55

o

C Guaranteed by testing at +25

o

C and +150

o

C.

14-5

AD590

Trimming Out Errors

The ideal graph of current versus temperature for the AD590

is a straight line, but as Figure 1 shows, the actual shape is

slightly different. Since the sensor is limited to the range of

-55

o

C to +150

o

C, it is possible to optimize the accuracy by

trimming. Trimming also permits extracting maximum perfor-

mance from the lower-cost sensors.

The circuit of Figure 2 trims the slope of the AD590 output.

The effect of this is shown in Figure 3.

The circuit of Figure 4 trims both the slope and the offset.

This is shown in Figure 5. The diagrams are exaggerated to

show effects, but it should be clear that these trims can be

used to minimize errors over the whole range, or over any

selected part of the range. In fact, it is possible to adjust the I-

grade device to give less than 0.1

o

C error over the range 0

o

C

to +90

o

C and less than 0.05C error from +25

o

C to +60

o

C.

FIGURE 1. TRIMMING OUT ERRORS

FIGURE 2. SLOPE TRIMMING

FIGURE 3. EFFECT OF SLOPE TRIM

I

(

A

)

T (

o

K)

IDEAL

ACTUAL

(GREATLY

EXAGGERATED)

+5V

R 100

+

AD590

-

R = SLOPE

+

+

950

V

OUT

= 1mV/

o

K

I

(

A

)

T

(o

K)

IDEAL

ACTUAL

TRIMMED

FIGURE 5A. UNTRIMMED

FIGURE 5B. TRIM ONE: OFFSET

FIGURE 5C. TRIM TWO: SLOPE

FIGURE 5D. TRIM THREE: OFFSET AGAIN

FIGURE 5. EFFECT OF SLOPE AND OFFSET TRIMMING

14-6

AD590

Accuracy

Maximum errors over limited temperature spans, with V

S

=

+5V, are listed by device grade in the following tables. The

tables reect the worst-case linearities, which invariably

occur at the extremities of the specied temperature range.

The trimming conditions for the data in the tables are shown

in Figure 2 and Figure 4.

All errors listed in the tables are

o

C. For example, if 1

o

C

maximum error is required over the +25

o

C to +75

o

C range

(i.e., lowest temperature of +25

o

C and span of 50

o

C), then

the trimming of a J-grade device, using the single-trim circuit

(Figure 2), will result in output having the required accuracy

over the stated range. An I-grade device with two trims

(Figure 4) will have less than 0.2

o

C error. If the requirement

is for less than 1.4

o

C maximum error, from -25

o

C to +75

o

C

(100

o

span from -25

o

C), it can be satised by an I-grade

device with two trims.

FIGURE 4. SLOPE AND OFFSET TRIMMING

+10V

35.7k

R

1

2k

+

AD590

-

V-

R

1

= OFFSET

R

2

= SLOPE

V

OUT

= 100mV/

o

C

97.6k R

2

5k

I Grade Maximum Errors,

o

C

NUMBER OF

TRIMS

TEMPERATURE

SPAN (

C)

LOWEST TEMPERATURE IN SPAN (

o

C)

-55 -25 0 +25 +50 +75 +100 +125

None 10 8.4 9.2 10.0 10.8 11.6 12.4 13.2 14.4

None 25 10.0 10.4 11.0 11.8 12.0 13.8 15.0 16.0

None 50 13.0 13.0 12.8 13.8 14.6 16.4 18.0 -

None 100 15.2 16.0 16.6 17.4 18.8 - - -

None 150 18.4 19.0 19.2 - - - - -

None 205 20.0 - - - - - - -

One 10 0.6 0.4 0.4 0.4 0.4 0.4 0.4 0.6

One 25 1.8 1.2 1.0 1.0 1.0 1.2 1.6 1.8

One 50 3.8 3.0 2.0 2.0 2.0 3.0 3.8 -

One 100 4.8 4.5 4.2 4.2 5.0 - - -

One 150 5.5 4.8 5.5 - - - - -

One 205 5.8 - - - - - - -

Two 10 0.3 0.2 0.1 (Note 1) (Note 1) 0.1 0.2 0.3

Two 25 0.5 0.3 0.2 (Note 1) 0.1 0.2 0.3 0.5

Two 50 1.2 0.6 0.4 0.2 0.2 0.3 0.7 -

Two 100 1.8 1.4 1.0 2.0 2.5 - - -

Two 150 2.6 2.0 2.8 - - - - -

Two 205 3.0 - - - - - - -

NOTE:

1. 1. Less than 0.05

o

C.

14-7

AD590

J Grade Maximum Errors,

o

C

NUMBER OF

TRIMS

TEMPERATURE

SPAN (

C)

LOWEST TEMPERATURE IN SPAN (

o

C)

-55 -25 0 +25 +50 +75 +100 +125

None 10 4.2 4.6 5.0 5.4 5.8 6.2 6.6 7.2

None 25 5.0 5.2 5.5 5.9 6.0 6.9 7.5 8.0

None 50 6.5 6.5 6.4 6.9 7.3 8.2 9.0 -

None 100 7.7 8.0 8.3 8.7 9.4 - - -

None 150 9.2 9.5 9.6 - - - - -

None 205 10.0 - - - - - - -

One 10 0.3 0.2 0.2 0.2 0.2 0.2 0.2 0.3

One 25 0.9 0.6 0.5 0.5 0.5 0.6 0.8 0.9

One 50 1.9 1.5 1.0 1.0 1.0 1.5 1.9 -

One 100 2.3 2.2 2.0 2.0 2.3 - - -

One 150 2.5 2.4 2.5 - - - - -

One 205 3.0 - - - - - - -

Two 10 0.1 (Note 1) (Note 1) (Note 1) (Note 1) (Note 1) (Note 1) 0.1

Two 25 0.2 0.1 (Note 1) (Note 1) (Note 1) (Note 1) 0.1 0.2

Two 50 0.4 0.2 0.1 (Note 1) (Note 1) 0.1 0.2 (Note 1)

Two 100 0.7 0.5 0.3 0.7 1.0 - - -

Two 150 1.0 0.7 1.2 - - - - -

Two 205 1.6 - - - - - - -

NOTE:

1. Less than 0.05

o

C.

Notes

1. Maximum errors over all ranges are guaranteed based on

the known behavior characteristic of the AD590.

2. For one-trim accuracy specifications, the 205

o

C span is

assumed to be trimmed at +25

o

C; for all other spans, it is

assumed that the device is trimmed at the midpoint.

3. For the 205

o

C span, it is assumed that the two-trim tem-

peratures are in the vicinity of +0

o

C and +140

o

C; for all

other spans, the specified trims are at the endpoints.

4. In precision applications, the actual errors encountered

are usually dependent upon sources of error which are

often overlooked in error budgets. These typically

include:

a. Trim error in the calibration technique used

b. Repeatability error

c. Long term drift errors

Trim Error is usually the largest error source. This error

arises from such causes as poor thermal coupling between

the device to be calibrated and the reference sensor; refer-

ence sensor errors; lack of adequate time for the device

being calibrated to settle to the nal temperature; radically

different thermal resistances between the case and the sur-

roundings (R

CA

) when trimming and when applying the

device.

Repeatability Errors arise from a strain hysteresis of the

package. The magnitude of this error is solely a function of

the magnitude of the temperature span over which the

device is used. For example, thermal shocks between +0

o

C

and +100

o

C involve extremely low hysteresis and result in

repeatability errors of less than 0.05

o

C. When the thermal-

shock excursion is widened to -55

o

C to +150

o

C, the device

will typIcally exhibit a repeatability error of 0.05

o

C (0.10

guaranteed maximum).

Long Term Drift Errors are related to the average operating

temperature and the magnitude of the thermal-shocks expe-

rienced by the device. Extended use of the AD590 at tem-

peratures above +100

o

C typically results in long-term drift of

0.03

o

C per month; the guaranteed maximum is 0.10

o

C

per month. Continuous operation at temperatures below

+100

o

C induces no measurable drifts in the device. Besides

the effects of operating temperature, the severity of thermal

shocks incurred will also affect absolute stability. For ther-

mal-shock excursions less than +100

o

C, the drift is difcult

to measure (<0.03

o

C). However, for +200

o

C excursions, the

device may drift by as much as 0.10

o

C after twenty such

shocks. If severe, quick shocks are necessary in the applica-

tion of the device, realistic simulated life tests are recom-

mended for a thorough evaluation of the error introduced by

such shocks.

14-8

AD590

Typical Applications

FIGURE 6A.

FIGURE 6B.

FIGURE6. SIMPLE CONNECTION. OUTPUT IS PROPORTIONAL

TO ABSOLUTE TEMPERATURE

FIGURE 7. LOWEST TEMPERATURE SENSING SCHEME.

AVAILABLE CURRENT IS THAT OF THE

COLDEST SENSOR

+

-

AD590

1k

+5V

V

OUT

= 1mV/

o

K

423

298.2

218

O

U

T

P

U

T

C

U

R

R

E

N

T

(

A

)

TEMPERATURE

423

o

K 298.2

o

K 218

o

K

(-55

o

C) (+25

o

C) (+150

o

C)

+15V

10K

+

AD590 (AS MANY AS DESIRED)

-

V

OUT

(MIN)

+

-

+

-

0.1%

FIGURE 8. AVERAGE TEMPERATURE SENSING SCHEME

The sum of the AD590 currents appears across R, which is

chosen by the formula:

n being the number of sensors. See Figure 8.

FIGURE 9. SINGLE SETPOINT TEMPERATURE CONTROLLER

The AD590 produces a temperature-dependent voltage

across R (C is for ltering noise). Setting R

2

produces a

scale-zero voltage. For the celsius scale, make R = 1k and

V

ZERO

= 0.273V. For Fahrenheit, R = 1.8k and V

ZERO

=

0.460V. See Figure 9.

FIGURE 10. SIMPLEST THERMOMETER.

Meter displays current output directly in degrees Kelvin.

using the AD590J, sensor output is within 10 degrees over

the entire range. See Figure 10.

+15V

+

-

+

-

+

-

(ADDITIONAL SENSORS)

333.3

V

OUT

(AVG) = (R)

i

0.1%

n

(FOR 3 SENSORS)

R

10k

n

=

+15V

R

+

AD590

-

C

3

2

4

1

7

R

1

R

B

R

2

R

3

LM311

ICL8069

1.23V

V

ZERO

HEATER

ELEMENT

0.1%

+

-

AD590

4V < V

BATT

+

-

M

<30V

+-

500A

14-9

AD590

FIGURE 11. BASIC DIGITAL THERMOMETER, CELSIUS AND

FAHRENHEIT SCALES

ALL values in k

The ICL7106 has a V

IN

span of 2.0V and a V

CM

range of

(V+ -0.5) volts to (V- +1) volts. R is scaled to bring each

range within V

CM

while not exceeding V

IN

. V

REF

for both

scales is 500mV maximum rending on the celsius range

+199.9

o

C limited by the (short-term) maximum allowable

sensor temperature. Maximum reading on the fahrenheit

range is +199.9

o

F (+93.3

o

C) limited by the number of dis-

play digits. See Figure 11 and notes below.

FIGURE 12. BASIC DIGITAL THERMOMETER, KELVIN SCALE

R R

1

R

2

R

3

R

4

R

5

o

F 9.00 4.02 2.0 12.4 10.0 0

o

C 5.00 4.02 2.0 5.11 5.0 11.8

V+

REF HI

REF LO

ICL7106

IN HI

COMMON

IN LO

R

1

R

+

-

V-

R

2

R

3

R

4

R

5

AD590

R

n

n 1 =

5

28k = nominal

V+

7.5k

2.26k

+

-

V-

5k

15k

1.00k

AD590

SCALE

ADJ

REF HI

REF LO

ICL7106

IN HI

COMMON

IN LO

The Kelvin scale version reads from 0 to +1999

o

K theoreti-

cally, and from +223

o

K to +473

o

K actually. The 2.26k resis-

tor brings the input within the ICL7106 V

CM

range: 2 qeneral-

purpose silicon diodes or an LED may be substituted. See

Figure 12 and notes below.

FIGURE 13. BASIC DIGITAL THERMOMETER, KELVIN SCALE

WITH ZERO ADJUST

This circuit allows zero adjustment as well as slope adjust-

ment. the ICL8069 brings the input within the common-mode

range, while the 5k pots trim any offset at +218

K (-55

o

C),

and set the scale factor. See Figure 13 and notes below.

Notes for Figure 11, Figure 12 and Figure 13

Since all 3 scales have narrow V

lN

spans, some optimization

of ICL7106 components can be made to lower noise and

preserve CMR. The table below shows the suggested val-

ues. Similar scaling can be used with the ICL7126 and

ICL7136.

SCALE V

lN

RANGE (V) R

lNT

(k) C

AZ

(F)

K 0.223 to 0.473 220 0.47

C -0.25 to +1.0 220 0.1

F -0.29 to +0.996 220 0.1

For all:

C

REF

= 0.1F

C

lNT

= 0.22F

C

OSC

=100pF

R

OSC

= 100k

V+

7.5k

1k

+

-

V-

5k

15k

AD590

SCALE

ADJ

0.1%

1.000V

12k

ZERO

ADJ

26.1k

5k

402

ICL8069

1.235V

REF HI

REF LO

ICL7106

IN HI

COMMON

IN LO

14-10

AD590

FIGURE 14. CENTIGRADE THERMOMETER (0

o

C - +100

o

C)

The ultra-low bias current of the ICL7611 allows the use of

large value gain resistors, keeping meter current error under

1

/

2

%, and therefore saving the expense of an extra meter

driving amplier. See Figure 14.

+15V

10k

1k

+

AD590

-

10mV/

o

C

20k

44.2k

0.1%

ZERO SET

115k

118k

FULL-SCALE

ADJUST

100

10k 2.7315V

M +100A

+

-

-

ICL7611

FIGURE 15. DIFFERENTIAL THERMOMETER

The 50k pot trims offsets in the devices whether internal or

external, so it can be used to set the size of the difference

interval. this also makes it useful for liquid level detection

(where there will be a measurable temperature difference).

See Figure 15.

10k

+

NO. 1

-

V

OUT

= (T

2

- T

1

) x

V+

50k

5M

10k

+

-

+

-

(10mV/

o

C)

741

V-

(8V MIN)

NO. 2

FIGURE 16. COLD JUNCTION COMPENSATION FOR TYPE K THERMOCOUPLE

The reference junction(s) should be in close thermal contact

with the AD590 case. V+ must be at least 4V, while ICL8069

current should be set at 1mA - 2mA. Calibration does not

require shorting or removal of the thermocouple: set R

1

for

V

2

= 10.98mV. If very precise measurements are needed,

adjust R

2

to the exact Seebeck coefcient for the thermo-

couple used (measured or from table) note V

1

, and set R

1

to

buck out this voltage (i.e., set V

2

= V

1

). For other thermocou-

ple types, adjust values to the appropriate Seebeck coef-

cient. See Figure 16.

V+

1A/

o

K

R

2

40.2

SEEBECK

COEFFICIENT = 40V/

o

K

TYPE K

V

OUT

+

-

ICL8069

1.235V

4.7F

R

1

4521

40.2

V+

+

-

T

C

= 40V/

o

K V

1

= 10.98mV

V

2

= 10.98mV

+

-

14-11

AD590

FIGURE 17. MULTIPLEXING SENSORS

If shorted sensors are possible, a series resistor in series

with the D line will limit the current (shown as R, above: only

one is needed). A six-bit digital word will select one of 64

sensors.

AD590 (64)

+15V

(OPTIONAL)

R

8

13

D

GND V-

7

6

5

14

3

2

1

0

15 16 1 2

COLUMN

SELECT

ENABLE +15V

ROW

SELECT

ENABLE

HI-0548

8 CHANNEL

MUX

V-

GND

3

14

HI-0548

8 CHANNEL

MUX

4

7 6 5 3 2 1 0 4

3

9

10

11

12

7

6

5

4

10k 0.1% V

OUT

15 16 1

2

(OPTION-

R

9 10 11 12 7 6 4 5

AL) 8 13

0 1 2

D

14-12

AD590

Die Characteristics

DIE DIMENSIONS:

37 x 58 x 14 1mils

METALLIZATION:

Type: Aluminum 100%

Thickness: 15k 1k

GLASSIVATION:

Type: PSG/Nitride

PSG Thickness: 7k 1.4k

Nitride Thickness: 8k 1.2k

Metallization Mask Layout

AD590

Anda mungkin juga menyukai

- Somatic Symptom DisorderDokumen26 halamanSomatic Symptom DisorderGAYATHRI NARAYANAN100% (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDari EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsPenilaian: 3.5 dari 5 bintang3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Assignment On Diesel Engine OverhaulingDokumen19 halamanAssignment On Diesel Engine OverhaulingRuwan Susantha100% (3)

- 110 Waveform Generator Projects for the Home ConstructorDari Everand110 Waveform Generator Projects for the Home ConstructorPenilaian: 4 dari 5 bintang4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- 1.6.-How To Teach Reported Speech - Review - Practice & Lesson PlanDokumen8 halaman1.6.-How To Teach Reported Speech - Review - Practice & Lesson Planspatel1972100% (2)

- Hedge Fund Strategies, Mutual Fund Comparison & Fund of FundsDokumen46 halamanHedge Fund Strategies, Mutual Fund Comparison & Fund of Fundsbboyvn100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- MOH Formulary Drug List 2014Dokumen115 halamanMOH Formulary Drug List 2014mahmud000Belum ada peringkat

- A Course in KettlebellsDokumen40 halamanA Course in KettlebellsMagoots100% (1)

- 1956 11 15 Saucerian Bulletin Vol-1#5Dokumen6 halaman1956 11 15 Saucerian Bulletin Vol-1#5Keith S.Belum ada peringkat

- AD590Dokumen11 halamanAD590Timmy Neil SixxBelum ada peringkat

- lm35 PDFDokumen15 halamanlm35 PDFRogers Ferreras BenitezBelum ada peringkat

- 2N6027Dokumen9 halaman2N6027mariogizziBelum ada peringkat

- High Voltage, Current Shunt Monitor AD8215: Features Functional Block DiagramDokumen16 halamanHigh Voltage, Current Shunt Monitor AD8215: Features Functional Block Diagramarjun_ramanathan_2Belum ada peringkat

- Datasheet Lm35anDokumen21 halamanDatasheet Lm35anDaniiel GuerreroBelum ada peringkat

- TMP 35 GDokumen16 halamanTMP 35 GWeslley FariaBelum ada peringkat

- LM61 SensorDokumen9 halamanLM61 SensorTalles VianaBelum ada peringkat

- Datasheet PDFDokumen13 halamanDatasheet PDFclaudiu72Belum ada peringkat

- LM101A/LH2101A: General Purpose Operational AmplifierDokumen12 halamanLM101A/LH2101A: General Purpose Operational AmplifierAlexandre S. CorrêaBelum ada peringkat

- ACPL312TDokumen18 halamanACPL312Tcms_saBelum ada peringkat

- AD590Dokumen16 halamanAD590Trantan CdtBelum ada peringkat

- Ad 22105Dokumen8 halamanAd 22105nevdullBelum ada peringkat

- Differential/Cascode Amplifier For Commercial and Industrial Equipment From DC To 120Mhz FeaturesDokumen10 halamanDifferential/Cascode Amplifier For Commercial and Industrial Equipment From DC To 120Mhz FeaturessunantoBelum ada peringkat

- ADP3338 Data SheetsDokumen16 halamanADP3338 Data SheetstarpinoBelum ada peringkat

- DT92xx MultimeterDokumen5 halamanDT92xx Multimeterhammouche_soufianeBelum ada peringkat

- Tle2426 High Precision Virtual GroundDokumen29 halamanTle2426 High Precision Virtual GroundgofuckingdieBelum ada peringkat

- Advanced Monolithic Systems: Rohs CompliantDokumen8 halamanAdvanced Monolithic Systems: Rohs CompliantWilliam BlackBelum ada peringkat

- Ad 536 ADokumen8 halamanAd 536 AlamikkBelum ada peringkat

- LM35 Precision Centigrade Temperature Sensors: Features DescriptionDokumen25 halamanLM35 Precision Centigrade Temperature Sensors: Features DescriptionMary RamiireezBelum ada peringkat

- LM723 Voltage RegulatorDokumen14 halamanLM723 Voltage Regulatorvanminh91bkBelum ada peringkat

- D D D D D D D: MOC3009 THRU MOC3012 Optocouplers/OptoisolatorsDokumen7 halamanD D D D D D D: MOC3009 THRU MOC3012 Optocouplers/OptoisolatorsFer TgBelum ada peringkat

- 1A Low Dropout Voltage Regulator DatasheetDokumen8 halaman1A Low Dropout Voltage Regulator DatasheetMauricio Raul RotmanBelum ada peringkat

- LM35Dokumen15 halamanLM35filipecampospereiraBelum ada peringkat

- ADXL210Dokumen11 halamanADXL210JaehyupKimBelum ada peringkat

- ICL8069 - Low Voltage Reference - Intersil CorporationDokumen6 halamanICL8069 - Low Voltage Reference - Intersil Corporationwlen2012Belum ada peringkat

- CA3059, CA3079: Description FeaturesDokumen12 halamanCA3059, CA3079: Description FeaturesMiltongrimi GrimilBelum ada peringkat

- LM19 2.4V, 10 A, TO-92 Temperature Sensor: Features DescriptionDokumen14 halamanLM19 2.4V, 10 A, TO-92 Temperature Sensor: Features DescriptionalvarezsilvaBelum ada peringkat

- 1.225V Micropower Shunt Voltage Reference: DescriptionDokumen9 halaman1.225V Micropower Shunt Voltage Reference: DescriptionRicardo MosqueiraBelum ada peringkat

- CA3161EDokumen4 halamanCA3161EAlejandro Borrego DominguezBelum ada peringkat

- Datasheet For LM45Dokumen9 halamanDatasheet For LM45Bhimsen BudhathokiBelum ada peringkat

- Yokogawa Temperature Transmitergs01c50b01-00eDokumen9 halamanYokogawa Temperature Transmitergs01c50b01-00eLuis Eduardo Díaz LópezBelum ada peringkat

- LM 19Dokumen14 halamanLM 19hindukusc80Belum ada peringkat

- LM35 Precision Centigrade Temperature Sensors: General DescriptionDokumen13 halamanLM35 Precision Centigrade Temperature Sensors: General Descriptionpartidopartido7890Belum ada peringkat

- Features Description: 12-Bit, Multiplying D/A ConverterDokumen9 halamanFeatures Description: 12-Bit, Multiplying D/A Convertershobhitmittal7Belum ada peringkat

- Ua723cn PDFDokumen18 halamanUa723cn PDFOsman KoçakBelum ada peringkat

- Ua 723Dokumen21 halamanUa 723roozbehxox0% (1)

- Sensor de Temperatura LM50Dokumen8 halamanSensor de Temperatura LM50Erick Dos SantosBelum ada peringkat

- Ad8421 PDFDokumen28 halamanAd8421 PDFsoft4gsmBelum ada peringkat

- Dac 0800Dokumen16 halamanDac 0800Ali A-cBelum ada peringkat

- Distributed byDokumen13 halamanDistributed byleoval253232Belum ada peringkat

- 42pt330-Ub 42pt350-Ud 42pt350c-Ud Chassis Pu14kDokumen56 halaman42pt330-Ub 42pt350-Ud 42pt350c-Ud Chassis Pu14kAngel GarciaBelum ada peringkat

- Chip Ca3098eDokumen12 halamanChip Ca3098etopogigio240Belum ada peringkat

- PM4018MUDokumen11 halamanPM4018MUaldo_suviBelum ada peringkat

- GS01C50B01-00EN 021 YTA110.unlockedDokumen9 halamanGS01C50B01-00EN 021 YTA110.unlockedxi_felBelum ada peringkat

- NCV2931Dokumen23 halamanNCV2931Vijai PrabhuBelum ada peringkat

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDari EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesBelum ada peringkat

- Standard Engine Exhause Silencer and Accessories Catalog PDFDokumen32 halamanStandard Engine Exhause Silencer and Accessories Catalog PDFslow_bbBelum ada peringkat

- SC Capacity of CablesDokumen5 halamanSC Capacity of Cablesswagata12345Belum ada peringkat

- Moc3011 PDFDokumen7 halamanMoc3011 PDFAlvaro Mompi RuizBelum ada peringkat

- An 273Dokumen6 halamanAn 273Alvaro Mompi RuizBelum ada peringkat

- AD590Dokumen0 halamanAD590Alvaro Mompi RuizBelum ada peringkat

- LP Direct & Indirect SpeechDokumen7 halamanLP Direct & Indirect SpeechJoana JoaquinBelum ada peringkat

- Optimizing Local Geoid Undulation Model Using GPS Levelling Measurements and Heuristic Regression ApproachesDokumen12 halamanOptimizing Local Geoid Undulation Model Using GPS Levelling Measurements and Heuristic Regression ApproachesLeni HelianiBelum ada peringkat

- Hbo Group AnalysisDokumen5 halamanHbo Group AnalysisAlexa Dei GalinatoBelum ada peringkat

- GEY 102-Introduction To Geology 1-Lecture Slides - Prof. M.E. NtonDokumen44 halamanGEY 102-Introduction To Geology 1-Lecture Slides - Prof. M.E. Ntonabuabdmuqseet2001Belum ada peringkat

- RUN ON SENTENCES AND FRAGMENTS GUIDEDokumen17 halamanRUN ON SENTENCES AND FRAGMENTS GUIDEWAHEED-UL -ISLAMBelum ada peringkat

- Understanding Virtue EthicsDokumen4 halamanUnderstanding Virtue EthicsMark Russel Sean LealBelum ada peringkat

- VC3 TranslationDokumen313 halamanVC3 TranslationFuyuki Maxwell ArashiBelum ada peringkat

- Aircrew Standards Manual FY2015 V1Dokumen211 halamanAircrew Standards Manual FY2015 V1Anonymous Pb39klJ100% (1)

- Logic and Its Metatheory: Instructor InformationDokumen6 halamanLogic and Its Metatheory: Instructor InformationMarco StoroniMazzolani Di MaioBelum ada peringkat

- Myasthenia Gravis Presentation and Treatment Variations: A Case Study ApproachDokumen5 halamanMyasthenia Gravis Presentation and Treatment Variations: A Case Study ApproachLiyasariBelum ada peringkat

- Grade 5 DLL SCIENCE 5 Q4 Week 9Dokumen6 halamanGrade 5 DLL SCIENCE 5 Q4 Week 9Joanna Marie Cruz FelipeBelum ada peringkat

- Berkman Classics: Lawrence Lessig'S Ilaw CourseDokumen1 halamanBerkman Classics: Lawrence Lessig'S Ilaw CourseJoe LimBelum ada peringkat

- Work Industry and Canadian Society 7th Edition Krahn Test BankDokumen7 halamanWork Industry and Canadian Society 7th Edition Krahn Test BankSamanthaRamospfozx100% (10)

- Geppetto's Wish Comes True: Pinocchio Becomes a Real BoyDokumen1 halamanGeppetto's Wish Comes True: Pinocchio Becomes a Real BoyDonzBelum ada peringkat

- The General RetiresDokumen17 halamanThe General Retiresfo100% (1)

- Crafting Your Keto Diet MindsetDokumen3 halamanCrafting Your Keto Diet MindsetoculosoakleyBelum ada peringkat

- Dr. Sun Chemistry Summary 2019 PDFDokumen75 halamanDr. Sun Chemistry Summary 2019 PDFPranav ChatiBelum ada peringkat

- HR Syl 5 Pages 2023-2024 20.09.2023Dokumen5 halamanHR Syl 5 Pages 2023-2024 20.09.2023ABLEELECTRONBelum ada peringkat

- SAP Training Program Proposal for StudentsDokumen2 halamanSAP Training Program Proposal for StudentsAjay KumarBelum ada peringkat

- Relación Entre Séneca y MaquiaveloDokumen14 halamanRelación Entre Séneca y MaquiaveloJuan Pablo TorresBelum ada peringkat

- AbstractDokumen23 halamanAbstractaashish21081986Belum ada peringkat

- Contract Costing - Practise ProblemsDokumen3 halamanContract Costing - Practise ProblemsMadhavasadasivan Pothiyil50% (2)