Ashrae-Si f09 Ch22 9

Diunggah oleh

yasmenn2010Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ashrae-Si f09 Ch22 9

Diunggah oleh

yasmenn2010Hak Cipta:

Format Tersedia

Pipe Sizing

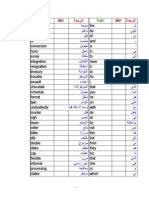

Table 11 Iron and Copper Elbow Equivalentsa

Fitting Elbow, 90 Elbow, 45 Elbow, 90 long-radius Elbow, welded, 90 Reduced coupling Open return bend Angle radiator valve Radiator or convector Boiler or heater Open gate valve Open globe valve Iron Pipe 1.0 0.7 0.5 0.5 0.4 1.0 2.0 3.0 3.0 0.5 12.0 Copper Tubing 1.0 0.7 0.5 0.5 0.4 1.0 3.0 4.0 4.0 0.7 17.0 Fixture or Groupb Occupancy Public Public Public Public Public Public Public Public Office, etc. Hotel or restaurant Private Private Private Private Private Private Private Private Private Private Private Type of Supply Control Flush valve Flush tank Flush valve Flush valve Flush tank Faucet Faucet Mixing valve Faucet Faucet Flush valve Flush tank Faucet Faucet Mixing valve Flush valve for closet Flush tank for closet Mixing valve Faucet Faucet Faucet

22.9

Table 13 Demand Weights of Fixtures in Fixture Unitsa

Weight in Fixture Unitsc 10 5 10 5 3 2 4 4 3 4 6 3 1 2 2 8 6 2 2 3 3

Water closet Water closet Pedestal urinal Stall or wall urinal Stall or wall urinal Lavatory Bathtub Shower head Service sink Kitchen sink Water closet Water closet Lavatory Bathtub Shower head Bathroom group Bathroom group Separate shower Kitchen sink Laundry trays (1 to 3) Combination fixture

Source: Giesecke (1926) and Giesecke and Badgett (1931, 1932a). aSee Table 10 for equivalent length of one elbow.

Table 12 Proper Flow and Pressure Required During Flow for Different Fixtures

Fixture Ordinary basin faucet Self-closing basin faucet Sink faucet10 mm Sink faucet15 mm Dishwasher Bathtub faucet Laundry tube cock8 mm Shower Ball cock for closet Flush valve for closet Flush valve for urinal Garden hose, 15 m, and sill cock

a Flow

Flow Pressure, kPa (gage) a Flow, L/s 55 85 70 35 105 to 175 35 35 85 105 70 to 140 105 210 0.2 0.2 0.3 0.3 b 0.4 0.3 0.2 to 0.6 0.2 1.0 to 2.5c 1.0 0.3

Licensed for single user. 2009 ASHRAE, Inc.

pressure is the pressure in the pipe at the entrance to the particular fixture considered. b Varies; see manufacturers data. c Wide range due to variation in design and type of flush valve closets.

Source: Hunter (1941). a For supply outlets likely to impose continuous demands, estimate continuous supply separately, and add to total demand for fixtures. b For fixtures not listed, weights may be assumed by comparing the fixture to a listed one using water in similar quantities and at similar rates. c The given weights are for total demand. For fixtures with both hot and cold water supplies, the weights for maximum separate demands can be assumed to be 75% of the listed demand for the supply.

all load devices simultaneously would be seriously oversized. Thus, a major issue in sizing service water piping is to determine the diversity of the loads. The procedure shown in this chapter uses the work of R.B. Hunter for estimating diversity (Hunter 1940, 1941). The present-day plumbing designer is usually constrained by building or plumbing codes, which specify the individual and collective loads to be used for pipe sizing. Frequently used codes (including the BOCA National Plumbing Code, Standard Plumbing Code, Uniform Plumbing Code, and National Standard Plumbing Code) contain procedures quite similar to those shown here. The designer must be aware of the applicable code for the location being considered. Federal mandates are forcing plumbing fixture manufacturers to reduce design flows to many types of fixtures, but these may not yet be included in locally adopted codes. Also, the designer must be aware of special considerations; for example, toilet usage at sports arenas will probably have much less diversity than the codes allow and thus may require larger supply piping than the minimum specified by the codes. Table 12 gives the rate of flow desirable for many common fixtures and the average pressure necessary to give this rate of flow. The pressure varies with fixture design. In estimating the load, the rate of flow is frequently computed in fixture units, which are relative indicators of flow. Table 13 gives the demand weights in terms of fixture units for different plumbing fixtures under several conditions of service, and Figure 8 gives the estimated demand corresponding to any total number of fixture units. Figures 9 and 10 provide more accurate estimates at the lower end of the scale. The estimated demand load for fixtures used intermittently on any supply pipe can be obtained by multiplying the number of

Fig. 5 Demand Versus Fixture Units, Mixed System, High Part of Curve

Fig. 8

Demand Versus Fixture Units, Mixed System, High Part of Curve

(Hunter 1941)

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- 040 X52-62-72 UNIC-flex V1Dokumen63 halaman040 X52-62-72 UNIC-flex V1Антон Сорока100% (2)

- Applications: For The Steam and Condensate LoopDokumen8 halamanApplications: For The Steam and Condensate Loopyasmenn2010Belum ada peringkat

- Business Ethics Case StudiesDokumen25 halamanBusiness Ethics Case Studiesswaggerbox100% (2)

- كتاب رائع فى BmsDokumen49 halamanكتاب رائع فى Bmsyasmenn2010Belum ada peringkat

- 7000 Words TranslatedDokumen236 halaman7000 Words Translatedyasmenn2010100% (1)

- English Communication Skills: Showing that you're listening ساهظأ فغشت غًرسذ كَأDokumen15 halamanEnglish Communication Skills: Showing that you're listening ساهظأ فغشت غًرسذ كَأyasmenn2010Belum ada peringkat

- Variable Air Volume SystemsDokumen121 halamanVariable Air Volume Systemsyasmenn2010Belum ada peringkat

- 2006 National Standard Plumbing Code ILLUSTRATED 255Dokumen1 halaman2006 National Standard Plumbing Code ILLUSTRATED 255yasmenn2010Belum ada peringkat

- Iso SpinDokumen5 halamanIso SpinjhgsgsBelum ada peringkat

- Cpu 2000 App ListDokumen11 halamanCpu 2000 App ListKaiser IqbalBelum ada peringkat

- ABB Review 2 2020 en 72 TruOne Zenith ArticleDokumen4 halamanABB Review 2 2020 en 72 TruOne Zenith ArticlePrakash KandasamyBelum ada peringkat

- Gep Primary Water Resource Aug12 NSWDokumen50 halamanGep Primary Water Resource Aug12 NSWNitin AroraBelum ada peringkat

- Bulletin: ICC International Court of ArbitrationDokumen30 halamanBulletin: ICC International Court of ArbitrationPriscila Machado MartinsBelum ada peringkat

- Karma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Dokumen37 halamanKarma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Lars JensenBelum ada peringkat

- Ludo (Sorry) - Game StrategyDokumen8 halamanLudo (Sorry) - Game Strategysuperyoopy100% (1)

- The Impact of Updating Health Benefits Plans On Health Technologies Usage and Expenditures The Case of ColombiaDokumen24 halamanThe Impact of Updating Health Benefits Plans On Health Technologies Usage and Expenditures The Case of ColombiaTeana Zapata JaramilloBelum ada peringkat

- IIT Dharwad Advt No. 012 V5 FinalDokumen8 halamanIIT Dharwad Advt No. 012 V5 FinalRitesh PaliwalBelum ada peringkat

- Conductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForDokumen6 halamanConductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForRob GridleyBelum ada peringkat

- Exam 2 ND Semester 201516Dokumen10 halamanExam 2 ND Semester 201516Samson SeiduBelum ada peringkat

- Family Tree Template With DetailsDokumen8 halamanFamily Tree Template With DetailsJude WellsBelum ada peringkat

- Eng8Quarter1Week1 2Dokumen6 halamanEng8Quarter1Week1 2Duero-Hadjilatip KayeBelum ada peringkat

- Nexys 2Dokumen12 halamanNexys 2sacramusBelum ada peringkat

- Business Statistics I: Hypothesis TestingDokumen58 halamanBusiness Statistics I: Hypothesis TestingJamesBelum ada peringkat

- ContemporaryDokumen2 halamanContemporaryAlbert PaggaoBelum ada peringkat

- Black Mirror Analysis: 15 Million Merits (Due 27/04/16)Dokumen11 halamanBlack Mirror Analysis: 15 Million Merits (Due 27/04/16)Will MunnyBelum ada peringkat

- How To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentDokumen19 halamanHow To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentClaudiu Stefan HaiduBelum ada peringkat

- Student Advisory Form: Institute of Space TechnologyDokumen6 halamanStudent Advisory Form: Institute of Space Technologyjawad khalidBelum ada peringkat

- THMT 3312: Research Methods For Tourism & Hospitality ManagementDokumen13 halamanTHMT 3312: Research Methods For Tourism & Hospitality Managementmilrosebatilo2012Belum ada peringkat

- 제8차 전력수급기본계획Dokumen51 halaman제8차 전력수급기본계획김명근Belum ada peringkat

- Json Out InvoiceDokumen2 halamanJson Out Invoicetkpatel529Belum ada peringkat

- Non-Parametric TestsDokumen1 halamanNon-Parametric TestssdvdsvBelum ada peringkat

- Revo Uninstaller Pro HelpDokumen61 halamanRevo Uninstaller Pro HelpGuy Sinclaire OmbeBelum ada peringkat

- QCBS RFP For Gweir SHPP PMC PDFDokumen125 halamanQCBS RFP For Gweir SHPP PMC PDFjayant pathakBelum ada peringkat

- 2010 Ue CDokumen7 halaman2010 Ue CLau Sze WaBelum ada peringkat

- Cambridge O Level: PHYSICS 5054/42Dokumen16 halamanCambridge O Level: PHYSICS 5054/42Lapu LapuBelum ada peringkat

- Psychology Concepts and Applications 4Th Edition Nevid Solutions Manual Full Chapter PDFDokumen49 halamanPsychology Concepts and Applications 4Th Edition Nevid Solutions Manual Full Chapter PDFfidelmanhangmhr100% (9)