Nondestructive Testing

Diunggah oleh

yokeshfea100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

199 tayangan2 halamanNondestructive testing (NDT) is an assessment without doing harm, stress or destroying the test object. The mainstream applications are in aerospace, power generation, automotive, railway, petrochemical and pipeline markets. It is very difficult to weld or mold a solid object that has no risk of breaking in service, so testing at manufacture and during use is often essential.

Deskripsi Asli:

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniNondestructive testing (NDT) is an assessment without doing harm, stress or destroying the test object. The mainstream applications are in aerospace, power generation, automotive, railway, petrochemical and pipeline markets. It is very difficult to weld or mold a solid object that has no risk of breaking in service, so testing at manufacture and during use is often essential.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

199 tayangan2 halamanNondestructive Testing

Diunggah oleh

yokeshfeaNondestructive testing (NDT) is an assessment without doing harm, stress or destroying the test object. The mainstream applications are in aerospace, power generation, automotive, railway, petrochemical and pipeline markets. It is very difficult to weld or mold a solid object that has no risk of breaking in service, so testing at manufacture and during use is often essential.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

Nondestructive testing (NDT) are noninvasive techniques to determine the integrity of a material,

component or structure or quantitatively measure some characteristic of an object. In contrast to

destructive testing, NDT is an assessment without doing harm, stress or destroying the test object.

The destruction of the test object usually makes destructive testing more costly and it is also

inappropriate in many circumstances.

NDT plays a crucial role in ensuring cost effective operation, safety and reliability of plant, with

resultant benefit to the community. NDT is used in a wide range of industrial areas and is used at

almost any stage in the production or life cycle of many components. The mainstream

applications are in aerospace, power generation, automotive, railway, petrochemical and pipeline

markets. NDT of welds is one of the most used applications. It is very difficult to weld or mold a

solid object that has no risk of breaking in service, so testing at manufacture and during use is

often essential.

NDT Applications and Limitations

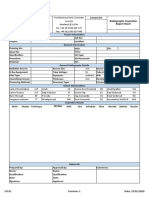

NDT Method Applications Limitations

Liquid Penetrant used on nonporous materials need access to test surface

can be applied to welds, tubing, defects must be surface breaking

brazing, castings, billets, forgings, decontamination & precleaning of

aluminium parts, turbine blades test surface may be needed

and disks, gears vapour hazard

very tight and shallow defects

difficult to find

depth of flaw not indicated

Magnetic Particle ferromagnetic materials detection of flaws limited by field

surface and slightly subsurface strength and direction

flaws can be detected needs clean and relatively smooth

can be applied to welds, tubing, surface

bars, castings, billets, forgings, some holding fixtures required for

extrusions, engine components, some magnetizing techniques

shafts and gears test piece may need

demagnetization which can be

difficult for some shapes and

magetizations

depth of flaw not indicated

Eddy Current metals, alloys and requires customized probe

electroconductors although non-contacting it requires

sorting materials close proximity of probe to part

surface and slightly subsurface low penetration (typically 5mm)

flaws can be detected false indications due to

used on tubing, wire, bearings, uncontrolled parametric variables

rails, nonmetal coatings, aircraft

components, turbine blades and

disks, automotive transmission

shafts

Ultrasonics metals, nonmetals and compositesusually contacting, either direct or

surface and slightly subsurface with intervening medium required

flaws can be detected (e.g. immersion testing)

can be applied to welds, tubing,special probes are required for

joints, castings, billets, forgings,

applications

shafts, structural components, sensitivity limited by frequency

concrete, pressure vessels, aircraft

used and some materials cause

and engine components significant scattering

used to determine thickness and scattering by test material structure

mechanical properties can cause false indications

monitoring service wear and not easily applied to very thin

deterioration materials

Radiography metals, nonmetals, composites and

access for placing test piece

Neutron mixed materials between source and detectors

used on pyrotechnics, resins, size of neutron source housing is

plastics, organic material, very large (reactors) for reasonable

honeycomb structures, radioactive

source strengths

material, high density materials,

collimating, filtering or otherwise

and materials containing hydrogen

modifying beam is difficult

radiation hazards

cracks must be oriented parallel to

beam for detection

sensitivity decreases with

increasing thickness

Radiography X- metals, nonmetals, composites and access to both sides of test piece

ray mixed materials needed

used on all shapes and forms; voltage, focal spot size and

castings, welds, electronic exposure time critical

assemblies, aerospace, marine and radiation hazards

automotive components cracks must be oriented parallel to

beam for detection

sensitivity decreases with

increasing thickness

Radiography usually used on dense or thick radiation hazards

Gamma material cracks must be oriented parallel to

used on all shapes and forms; beam for detection

castings, welds, electronic sensitivity decreases with

assemblies, aerospace, marine and increasing thickness

automotive components access to both sides of test piece

used where thickness or access needed

limits X-ray generators not as sensitive as X-rays

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- IQI (Penetrameter) Selection in Industrial Radiography TestingDokumen3 halamanIQI (Penetrameter) Selection in Industrial Radiography TestingGomathyselviBelum ada peringkat

- Sample RT Report PipelineDokumen1 halamanSample RT Report Pipelinekhalid hidayatullahBelum ada peringkat

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDokumen13 halamanJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaBelum ada peringkat

- Radiographic Inspection Report SheetDokumen1 halamanRadiographic Inspection Report SheetMike BoyesBelum ada peringkat

- Audi Ioneers For Pecialized Ervices (SPSS) : S P S SDokumen8 halamanAudi Ioneers For Pecialized Ervices (SPSS) : S P S SHany Moustafa Gazar0% (1)

- RT ProcedureDokumen18 halamanRT ProcedureLuong Ho VuBelum ada peringkat

- RT Procedure Rev.0Dokumen19 halamanRT Procedure Rev.0Goutam Kumar DebBelum ada peringkat

- Industrial Radiography Image Forming Techniques English 4 PDFDokumen114 halamanIndustrial Radiography Image Forming Techniques English 4 PDFPana SilviuBelum ada peringkat

- SMS-602-RT-003 Radiographic API 1104 - B31.8 - Rev 3Dokumen27 halamanSMS-602-RT-003 Radiographic API 1104 - B31.8 - Rev 3Cak Nhass100% (1)

- Radiography Test ProcedureDokumen12 halamanRadiography Test Procedurehasan_676489616100% (4)

- 880 Manual Man 027 September 2015Dokumen91 halaman880 Manual Man 027 September 2015Pilar Medrano MenaBelum ada peringkat

- Ind Radiography GuideDokumen40 halamanInd Radiography GuidephanthanhhungBelum ada peringkat

- Non-Destructive Radiographic Testing ProcedureDokumen8 halamanNon-Destructive Radiographic Testing ProcedureJhean Bernadeth ChavezBelum ada peringkat

- 013 NDT-UT TSE API 1104 - Rev 00-2-21Dokumen21 halaman013 NDT-UT TSE API 1104 - Rev 00-2-21zainalBelum ada peringkat

- Storage & Transportation of Radioactive SourcesDokumen10 halamanStorage & Transportation of Radioactive SourcesVarunSharmaBelum ada peringkat

- Hs-Hoo-Tp-120017-Hse-Pl-04 Project Risk RegisterDokumen13 halamanHs-Hoo-Tp-120017-Hse-Pl-04 Project Risk RegisterMoaatazz NouisriBelum ada peringkat

- Radiography TrainingDokumen3 halamanRadiography Traininga769Belum ada peringkat

- NDT FOR Remaining Life Assessment PDFDokumen59 halamanNDT FOR Remaining Life Assessment PDFAnonymous ioNuZrgBelum ada peringkat

- Steel - Lack of FusionDokumen6 halamanSteel - Lack of FusionJose ContrerasBelum ada peringkat

- Project Management PlanDokumen53 halamanProject Management Planvictor egharevbaBelum ada peringkat

- Industrial Radiografi OverviewDokumen50 halamanIndustrial Radiografi OverviewЕвгений ПолещукBelum ada peringkat

- Sidd HandbookDokumen363 halamanSidd HandbookkalspriteBelum ada peringkat

- Petronas Technical Standards: Radiographic TestingDokumen22 halamanPetronas Technical Standards: Radiographic Testingradzi100% (4)

- Schedule NDE2023 Rev2-1Dokumen19 halamanSchedule NDE2023 Rev2-1AltafAliBelum ada peringkat

- Radiographic Examination Procedure: Document No. KIE - TP - R297 Revision No. 0Dokumen35 halamanRadiographic Examination Procedure: Document No. KIE - TP - R297 Revision No. 0EdAlmBelum ada peringkat

- Epri - Ut in Lieu of RTDokumen319 halamanEpri - Ut in Lieu of RTRamakrishnan AmbiSubbiah100% (1)

- Procedure For Radiography TestingDokumen9 halamanProcedure For Radiography Testinghaharamesh100% (1)

- 30-99-90-1650 Tie-In ProcedureDokumen11 halaman30-99-90-1650 Tie-In ProcedureEswar ReddyBelum ada peringkat

- Maintenance Engg.Dokumen27 halamanMaintenance Engg.Rehan SharmaBelum ada peringkat

- CEDO QuestionsDokumen25 halamanCEDO QuestionsJoshnewfound50% (2)