Biodiesel Plant PDF

Diunggah oleh

Junaid MalikJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Biodiesel Plant PDF

Diunggah oleh

Junaid MalikHak Cipta:

Format Tersedia

POWER PLANT EQUIPMENT PRODUCTION LINES CONSULTING SERVICES

Sonnenberger Str.16 65193 Wiesbaden - Germany

Tel. +49 (0) 611-701888 Fax +49 (0) 611-701895

www.lohrmann.com info@lohrmann.com

Budgetary Proposal Standardized Modular BioDiesel Plant with a Capacity of 3600 tons p.a.

So far, it was only possible to cover the costs for transesterification of vegetable oils and natural fats to produce BioDiesel by production on a large industrial scale. Thanks to the intelligent design of the Lohrmann BioDiesel Plant, it has now become possible to eliminate cost-intensive parts without affecting from the quality of the produced fuel. Therefore decentralised plants with lower capacities of BioDiesel can for now be operated very profitably. Lohrmann International provides a standardized technology for the efficient and safe production of BioDiesel.

POWER PLANT EQUIPMENT PRODUCTION LINES CONSULTING SERVICES

Esterification Plant (BioDiesel Container)

The whole process runs in a single tank and is completed after six to eight hours, depending on the quality of the input material. The plant technology is controlled automatically by means of a programmable logic controller (PLC). The process is visualised on a touchscreen monitor. The operator thus has the plant status in his sight at all times. Continuous data recording ensures the process control and reproducible process parameters, consequently minimising the labour and monitoring work. The process can also be telemonitored by means of a data teletransmission system.

1. A defined mass of vegetable oil (triglyceride) or fat is drawn into the central stainless steel process tank where it is heated. 2. Methanol and a catalyst are added to the heated product. The transesterification process can then start. 3. The glycerine formed settles compactly at the bottom of the tank and will be drawn off. 4. The raw biodiesel is washed with water in order to remove impurities. 5. The water settles at the bottom of the tank within a short period and is drawn off. 6. The process tank is heated for distillation, completely removing the water and methanol that have not settled in the tank under a vacuum. 7. The finished biodiesel is drawn off and pumped into the storage tank. The cycle can start again from the beginning.

POWER PLANT EQUIPMENT PRODUCTION LINES CONSULTING SERVICES

Input Output Balance Example for running time of 24 h

Depending of the quality of the insert oil / fat quality.

Advantages of Lohrmann BioDiesel Packages

+ Complete Automation + Turnkey Technology + Batch Process + Separation by Gravity + Water Flushing + Certified Plant Safety

Module Price ex works:

on request

--------------------------------------------------------------------------------------------------------------------Est. Cost of Transportation CIF Destination Port: on request Est. Cost of erection supervision and commissioning : on request Delivery time: 4 to 5 months

Anda mungkin juga menyukai

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDari EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryBelum ada peringkat

- Section 5.3: Code, Standard, and RegulationDokumen7 halamanSection 5.3: Code, Standard, and Regulationandrieysyah2525Belum ada peringkat

- BiodieselDokumen59 halamanBiodieselhugoBelum ada peringkat

- Characterization of Crude and Purified Glycerol From Biodiesel Production and Purification TechniquesDokumen5 halamanCharacterization of Crude and Purified Glycerol From Biodiesel Production and Purification TechniquesBaek Ho KimBelum ada peringkat

- Pentacool Soft Drink Manufcatruing Project ReportDokumen36 halamanPentacool Soft Drink Manufcatruing Project ReportMangal DevBelum ada peringkat

- Tyre Pyrolysis Plant CalculationsDokumen2 halamanTyre Pyrolysis Plant CalculationsTarun GuptaBelum ada peringkat

- BiodieselDokumen26 halamanBiodieseljdkiranBelum ada peringkat

- Water Hyacinth and Biogas ProductionDokumen8 halamanWater Hyacinth and Biogas ProductiongiulioBelum ada peringkat

- GHee EssenceDokumen9 halamanGHee EssencemuralismatBelum ada peringkat

- Algae Base BiorefineryDokumen13 halamanAlgae Base BiorefinerydeysiBelum ada peringkat

- Cornstarch ProjectDokumen44 halamanCornstarch ProjectpadhaiBelum ada peringkat

- Butanal PDFDokumen10 halamanButanal PDFRana Afrasyab SaeedBelum ada peringkat

- Biotech New Normal Agribusiness Final v2Dokumen36 halamanBiotech New Normal Agribusiness Final v2Bidur Prasad ChaulagainBelum ada peringkat

- Biodiesel ReportDokumen57 halamanBiodiesel ReportsirlancelotksaBelum ada peringkat

- PAckaging Industry Exhibitors ListDokumen3 halamanPAckaging Industry Exhibitors Listbhushandanani100% (1)

- Praj Industries 180817Dokumen12 halamanPraj Industries 180817Deep Run WatersBelum ada peringkat

- Feasibility Study of Hexane ProductionDokumen3 halamanFeasibility Study of Hexane ProductionIntratec SolutionsBelum ada peringkat

- Biodiesel - Feedstocks and Processing Technologies, 2nd Edition (2016)Dokumen469 halamanBiodiesel - Feedstocks and Processing Technologies, 2nd Edition (2016)jimmy100% (1)

- Fumed Silica MarketDokumen13 halamanFumed Silica Marketvicky_coolguyBelum ada peringkat

- Bio-Solvents Galactic 2014Dokumen84 halamanBio-Solvents Galactic 2014Σταύρος ΒουγιουκλίδηςBelum ada peringkat

- Techno-Economic Assessment About Vinyl AcetateDokumen3 halamanTechno-Economic Assessment About Vinyl AcetateIntratec SolutionsBelum ada peringkat

- Soya Milk, Paneer, CurdDokumen11 halamanSoya Milk, Paneer, Curdpankaj_kalita100Belum ada peringkat

- (Specialty Chemicals Division) Specializes in Manufacturing CHIRAL Products - Up To 99.9% Chiral PurityDokumen6 halaman(Specialty Chemicals Division) Specializes in Manufacturing CHIRAL Products - Up To 99.9% Chiral Purityagexpharma chemicalBelum ada peringkat

- FARMNEWS - Pcaarrd - Department of Science and TechnologyDokumen39 halamanFARMNEWS - Pcaarrd - Department of Science and TechnologyimlaphiBelum ada peringkat

- Understanding Biodiesel Technologies From Concept To Clarity PDFDokumen21 halamanUnderstanding Biodiesel Technologies From Concept To Clarity PDFKPBelum ada peringkat

- HP ScrubberDokumen16 halamanHP Scrubbers1308bBelum ada peringkat

- Glycerin Market Analysis - FinalDokumen35 halamanGlycerin Market Analysis - Finalnitishm1711100% (1)

- SOP - Quenching Pyrophoric MaterialsDokumen5 halamanSOP - Quenching Pyrophoric Materialsdhavalesh1Belum ada peringkat

- Liquid Biofuels Bioethanol - Soccol 1st EditionDokumen516 halamanLiquid Biofuels Bioethanol - Soccol 1st Editionamandafulan10Belum ada peringkat

- 1 - Presentation Genencor 2011 05 25Dokumen120 halaman1 - Presentation Genencor 2011 05 25Kannan RanganathanBelum ada peringkat

- Industrial Production of Ethanol From Sugar CaneDokumen4 halamanIndustrial Production of Ethanol From Sugar CanequixoticepiphanyBelum ada peringkat

- The Chemistry of EthanolDokumen21 halamanThe Chemistry of EthanolHarvey Obispo AceritBelum ada peringkat

- Continuous IndustriesDokumen3 halamanContinuous IndustriesjithmavelyBelum ada peringkat

- International Project References: Thyssenkrupp Industrial Solutions (India)Dokumen8 halamanInternational Project References: Thyssenkrupp Industrial Solutions (India)Divyesh PatelBelum ada peringkat

- Mother Dairy Fruit and Vegetable PVTDokumen49 halamanMother Dairy Fruit and Vegetable PVTAadietya SinhaBelum ada peringkat

- Project Report On Onion Dehydration-Powder, Flakes / Kibbled and Minced (Onion Products Garlic Powder)Dokumen10 halamanProject Report On Onion Dehydration-Powder, Flakes / Kibbled and Minced (Onion Products Garlic Powder)Sachin SharmaBelum ada peringkat

- Styrene Butadiene Rubber Production PlantDokumen6 halamanStyrene Butadiene Rubber Production PlantHarold AldayBelum ada peringkat

- Project Profile On Petroleum JellyDokumen10 halamanProject Profile On Petroleum JellymahahajBelum ada peringkat

- Bio-Ethanol ProductionDokumen11 halamanBio-Ethanol ProductionRavi ShankarBelum ada peringkat

- Fuel From FarmDokumen168 halamanFuel From FarmKUKU100% (1)

- Polylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherDokumen4 halamanPolylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherAxis ResearchMindBelum ada peringkat

- Niir Modern Technology Confectionery Industries With Formulae Processes 2nd Revised EditionDokumen6 halamanNiir Modern Technology Confectionery Industries With Formulae Processes 2nd Revised EditionAshwin RadhakrishnanBelum ada peringkat

- 1bottles Group Production of Bisphenol-ADokumen112 halaman1bottles Group Production of Bisphenol-AJames BelciñaBelum ada peringkat

- 01 May 2019 1313296377UGIE2OXPFRDokumen66 halaman01 May 2019 1313296377UGIE2OXPFRemad hayekBelum ada peringkat

- Web RefDokumen395 halamanWeb RefUtkarsh GhateBelum ada peringkat

- Executive Summary: NACES 2015 - Plant DesignDokumen2 halamanExecutive Summary: NACES 2015 - Plant DesignVentrue LeongBelum ada peringkat

- Polylactic Acid (PLA) Production-64832 PDFDokumen63 halamanPolylactic Acid (PLA) Production-64832 PDFzackBelum ada peringkat

- DR Seema ParohaDokumen21 halamanDR Seema ParohaTEERATH RAJBelum ada peringkat

- Amish Iocl Barauni MainDokumen16 halamanAmish Iocl Barauni Mainamish umar0% (1)

- Splitting 6 6 TPH Cps Pfad Feed 150 Tons Per DayDokumen1 halamanSplitting 6 6 TPH Cps Pfad Feed 150 Tons Per Dayrizky efrinaldoBelum ada peringkat

- Reliance - Wastewater TreatmentDokumen4 halamanReliance - Wastewater Treatmentarini_aristia_sBelum ada peringkat

- Chemical Weekly Sep28Dokumen220 halamanChemical Weekly Sep28arpit garg100% (1)

- Bioplastics: Centre T Hnol M LL R D University D Lhi IndiDokumen13 halamanBioplastics: Centre T Hnol M LL R D University D Lhi IndiTino RodriguezBelum ada peringkat

- Wim de Greyt - Desmet Ballestra Group - Introduction On Glycerol As Co-Product of Biodiesel ProductionDokumen12 halamanWim de Greyt - Desmet Ballestra Group - Introduction On Glycerol As Co-Product of Biodiesel Productionsamyusekhar100% (1)

- Approved CNG KitsDokumen1 halamanApproved CNG KitsAbdullah TahirBelum ada peringkat

- AlfaLaval Corn Gluten Dewatering BrochureDokumen2 halamanAlfaLaval Corn Gluten Dewatering BrochureI. Murali KrishnaBelum ada peringkat

- Budgetary Proposal Standardized Modular System Oecosys 4000 For The Production of Biodiesel With A Capacity of 3600 Tons P.ADokumen4 halamanBudgetary Proposal Standardized Modular System Oecosys 4000 For The Production of Biodiesel With A Capacity of 3600 Tons P.AJunaid MalikBelum ada peringkat

- Maquina de Biodiesel A Partir de Aceite CaseraDokumen2 halamanMaquina de Biodiesel A Partir de Aceite CaseraAndres Echeverri CastroBelum ada peringkat

- Alphakat CY Presentation-1Dokumen20 halamanAlphakat CY Presentation-1Niko Koja0% (1)

- BiodieselDokumen2 halamanBiodieselzos1969Belum ada peringkat

- Biofuels, International Food Prices, and The Poor: Joachim Von BraunDokumen7 halamanBiofuels, International Food Prices, and The Poor: Joachim Von BraunJunaid MalikBelum ada peringkat

- Budgetary Proposal Standardized Modular System Oecosys 4000 For The Production of Biodiesel With A Capacity of 3600 Tons P.ADokumen4 halamanBudgetary Proposal Standardized Modular System Oecosys 4000 For The Production of Biodiesel With A Capacity of 3600 Tons P.AJunaid MalikBelum ada peringkat

- Conditions PDFDokumen2 halamanConditions PDFJunaid MalikBelum ada peringkat

- The Price of BiodieselDokumen17 halamanThe Price of BiodieselJunaid MalikBelum ada peringkat

- Advantages PDFDokumen35 halamanAdvantages PDFJunaid MalikBelum ada peringkat

- Biodiesel Ifo PDFDokumen18 halamanBiodiesel Ifo PDFJunaid MalikBelum ada peringkat

- Biodiesel PDFDokumen17 halamanBiodiesel PDFJunaid MalikBelum ada peringkat

- Couplings PDFDokumen30 halamanCouplings PDFJunaid MalikBelum ada peringkat

- Humidification Plant Are We Humbly UtilisingSAshokDokumen6 halamanHumidification Plant Are We Humbly UtilisingSAshokYogesh SharmaBelum ada peringkat

- Shell Xl-40 BrochureDokumen2 halamanShell Xl-40 BrochureJunaid MalikBelum ada peringkat

- UntitledDokumen1 halamanUntitledJunaid MalikBelum ada peringkat

- Milling Programming ManualDokumen207 halamanMilling Programming ManualAhmad Suffian IsmailBelum ada peringkat

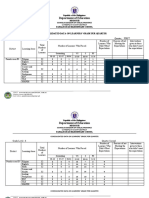

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDokumen4 halamanDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaBelum ada peringkat

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDokumen3 halamanEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunBelum ada peringkat

- Sabian Aspect OrbsDokumen8 halamanSabian Aspect Orbsellaella13100% (2)

- CPD - SampleDokumen3 halamanCPD - SampleLe Anh DungBelum ada peringkat

- 23 Ray Optics Formula Sheets Getmarks AppDokumen10 halaman23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikBelum ada peringkat

- My BaboogDokumen1 halamanMy BaboogMaral Habeshian VieiraBelum ada peringkat

- BSS Troubleshooting Manual PDFDokumen220 halamanBSS Troubleshooting Manual PDFleonardomarinBelum ada peringkat

- CSWIP-WP-19-08 Review of Welding Procedures 2nd Edition February 2017Dokumen6 halamanCSWIP-WP-19-08 Review of Welding Procedures 2nd Edition February 2017oberai100% (1)

- Unit 1 PrinciplesDokumen17 halamanUnit 1 PrinciplesRohit YadavBelum ada peringkat

- Manhole Head LossesDokumen11 halamanManhole Head Lossesjoseph_mscBelum ada peringkat

- CycleMax IntroDokumen13 halamanCycleMax IntroIslam AtefBelum ada peringkat

- CM2192 - High Performance Liquid Chromatography For Rapid Separation and Analysis of A Vitamin C TabletDokumen2 halamanCM2192 - High Performance Liquid Chromatography For Rapid Separation and Analysis of A Vitamin C TabletJames HookBelum ada peringkat

- Etag 002 PT 2 PDFDokumen13 halamanEtag 002 PT 2 PDFRui RibeiroBelum ada peringkat

- Waste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFDokumen11 halamanWaste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFdatinov100% (1)

- Gas Compressor SizingDokumen1 halamanGas Compressor SizingNohemigdeliaLucenaBelum ada peringkat

- Pyramid Type Plate Bending MachineDokumen10 halamanPyramid Type Plate Bending MachineAswin JosephBelum ada peringkat

- BDokumen28 halamanBLubaBelum ada peringkat

- Names of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: KindergartenDokumen4 halamanNames of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: Kindergartenapi-428128701Belum ada peringkat

- Principled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Dokumen24 halamanPrincipled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Jeremias GordonBelum ada peringkat

- Engineering Ethics in Practice ShorterDokumen79 halamanEngineering Ethics in Practice ShorterPrashanta NaikBelum ada peringkat

- Anker Soundcore Mini, Super-Portable Bluetooth SpeakerDokumen4 halamanAnker Soundcore Mini, Super-Portable Bluetooth SpeakerM.SaadBelum ada peringkat

- Transfert de Chaleur AngDokumen10 halamanTransfert de Chaleur Angsouhir gritliBelum ada peringkat

- Topic: Grammatical Issues: What Are Parts of Speech?Dokumen122 halamanTopic: Grammatical Issues: What Are Parts of Speech?AK AKASHBelum ada peringkat

- .IAF-GD5-2006 Guide 65 Issue 3Dokumen30 halaman.IAF-GD5-2006 Guide 65 Issue 3bg_phoenixBelum ada peringkat

- 1973 Further Discussion of Fiedler's Contingency Model of Leadership EffectivenessDokumen8 halaman1973 Further Discussion of Fiedler's Contingency Model of Leadership EffectivenesslengocthangBelum ada peringkat

- Tribes Without RulersDokumen25 halamanTribes Without Rulersgulistan.alpaslan8134100% (1)

- DLP English 10 AIRADokumen8 halamanDLP English 10 AIRAMae Mallapre100% (1)

- Load Chart Crane LiftingDokumen25 halamanLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- Technical Sheet Racloflex NTDokumen2 halamanTechnical Sheet Racloflex NTAnthony AngBelum ada peringkat

- Ultra Electronics Gunfire LocatorDokumen10 halamanUltra Electronics Gunfire LocatorPredatorBDU.comBelum ada peringkat