Equalizer Ring

Diunggah oleh

Ton PhichitJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Equalizer Ring

Diunggah oleh

Ton PhichitHak Cipta:

Format Tersedia

Exp. Jt. ConfiguratorMetal Exp JointsFabric Exp JointsHVAC ProductsRect. Metal Exp.

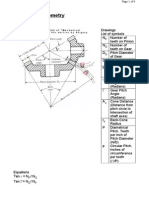

JointsOn-Site ServicesDampersProduct Downloads Equalizing Rings and Root RingsDesign Philosophy on When to Use Rings to Reinforce a BellowsSenior Flexonics Pathways philosophy is to design bellows without reinforcing rings, root rings or equalizing rings if at all possible to minimize cost. With proper use of the design equations from the Expansion Joint Manufacturers Association (EJMA) standards and state-of-the-art bellows forming equipment (roll forming and expanding mandrel forming), ring type bellows reinforcement can usually be avoided by adjusting the bellows wall thickness and convolution height.When the design conditions require that a bellows be reinforced with ring elements, Senior Flexonics Pathway engineers choose the type of reinforcement on the basis of cost from the options at right. The lowest cost reinforcement is a bar stock root ring or pipe style root ring. When more cross sectional area is required to withstand the stated design conditions, reinforcement can be added by using a 2 piece ring or by going to the more costly machined bar stock root ring.The term equalizing ring refers to bellows ring shapes similar to the details at the right. The word equalizing implies that the movement of each individual convolution is to be controlled by the equalizing rings (the word control rings is also used occasionally). The equalizing rings do limit the amount of compressive movement per convolution because the rings bottom out against one another when the convolutions have collapsed the amount that is allowed by the initial space between the rings. The benefi t from this is questionable because the rings bottom out only after the bellows have moved the maximum amount possible. This is generally more than the design movement. If the expansion joint undergoes lateral offset or angular motion, the convolutions tilt with respect to one another in service. This means that the equalizing rings would only equalize movement in one spot at best. For expansion joints that extend in service, it is diffi cult to determine any benefi t from equalizing rings.Equalizing rings also have some disadvantages. The exterior ring that defi nes the space between the convolutions covers up the bellows from view. It is nearly impossible to visually inspect this style of bellows in service. Dye penetrant examination of the exterior of the bellows is out of the question. Also, rings of any sort create crevices on the bellows outside surface which can accelerate corrosion. Hard foreign materials can also collect in the crevices and indent the bellows.The early manufacturers of expansion joints in the U.S. (Zallea Brothers for example) were limited to hydraulic forming techniques. The forming process required the use of reinforcement rings to satisfy the bellows design conditions for nearly al I steam service expansion joints and most expansion joints that would be used for FCC process lines. For steam service expansion joints, the rings were usually castings. It was convenient and low cost to provide a cast shape that looked like the equalizing ring profi le. Since the rings were a manufacturing necessity for companies limited to hydraulic forming techniques, the need for the rings was often sold as a benefi t. For example, an ad might read ask for equalizing rings to insure uniform bellows movements and conservative design.The term equalizing rings has been in use for a long time and there are many specifi ers that still ask for equalizing rings whether or not the design conditions require any sort of reinforcement. Senior Flexonics Pathways design philosophy is to propose the use of equalizing rings if they are required by the specifi cation, regard less of real need. As an alternate, Senior Flexonics Pathway engineers will generally recommend the use of bar type or pipe style root rings because of the substantial cost savings. When equalizing rings are specifi ed but the design conditions and applicable codes do not require that the Senior Flexonics Pathway design contain any reinforcement, it is

Senior Flexonics Pathways philosophy to recommend against the use of rings altogether in the interest of offering the most effi cient and cost effective design.For certain services, such as FCC process lines, it may be benefi cial to include root rings regardless of design requirements to provide additional pressure containment in case of an upset. However, any added benefi t that may be achieved by the use of equalizing rings for the same condition comes at a high cost. Rings, Equalizing A Tee shaped reinforcing ring that limits the axial compression of each convolution to the gap that exists between each reinforcing ring.

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Bs 302-Part2-1987 (Steel Wire Ropes-Specification For Ropes FDokumen13 halamanBs 302-Part2-1987 (Steel Wire Ropes-Specification For Ropes Fcelsocarvalh100% (1)

- Calculate Heat Loss from Insulated PipeDokumen8 halamanCalculate Heat Loss from Insulated PipeTon PhichitBelum ada peringkat

- Apex Status - Issue 2 (2-01-2008)Dokumen22 halamanApex Status - Issue 2 (2-01-2008)BorisLundbergBelum ada peringkat

- Bevel ExplanationDokumen4 halamanBevel ExplanationVarun VaidyaBelum ada peringkat

- Common Causes of Piping VibrationDokumen2 halamanCommon Causes of Piping VibrationTg TarroBelum ada peringkat

- Physics Question Bank Kvpy PDFDokumen97 halamanPhysics Question Bank Kvpy PDFaswin sivakumarBelum ada peringkat

- Parts Manual Parts Manual Service Manual: Reach TrucksDokumen22 halamanParts Manual Parts Manual Service Manual: Reach TrucksChristian Bedoya10% (10)

- Kramer Steven PDFDokumen32 halamanKramer Steven PDFFurkan YılmazBelum ada peringkat

- Despiese Bomba de Direccion D8TDokumen3 halamanDespiese Bomba de Direccion D8TEliecer godoyBelum ada peringkat

- Pump Clinic - Centrifugal Troubleshooting Chapters 1 - 43Dokumen295 halamanPump Clinic - Centrifugal Troubleshooting Chapters 1 - 43Noel Dunn75% (4)

- Finite Element Analysis of Stress Factors in Pipe BendsDokumen7 halamanFinite Element Analysis of Stress Factors in Pipe BendsSteve IpBelum ada peringkat

- 0387 1301 FINAL CEPA Surface Loading Calculator User ManualDokumen43 halaman0387 1301 FINAL CEPA Surface Loading Calculator User ManualTon Phichit100% (2)

- LPG Carbon Dioxide Fire Suppression System Installation Manual .Dokumen50 halamanLPG Carbon Dioxide Fire Suppression System Installation Manual .hrhgk100% (1)

- Pipe NoiseDokumen10 halamanPipe NoiseRoshin99Belum ada peringkat

- PSV Back PressureDokumen2 halamanPSV Back PressureTon PhichitBelum ada peringkat

- Operation and Maintenance Manual FOR Winch TYPE: 07.02.08: (Acc. To MSC.1/Circ.1206)Dokumen12 halamanOperation and Maintenance Manual FOR Winch TYPE: 07.02.08: (Acc. To MSC.1/Circ.1206)GogaBelum ada peringkat

- Pipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Dokumen8 halamanPipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Ton PhichitBelum ada peringkat

- LP Bypass SystemDokumen25 halamanLP Bypass SystemTon Phichit100% (1)

- Abb Review 2000Dokumen9 halamanAbb Review 2000Ton PhichitBelum ada peringkat

- Control TechnologyDokumen104 halamanControl TechnologyTon PhichitBelum ada peringkat

- Insert Flanges For Jacketed PipingDokumen4 halamanInsert Flanges For Jacketed PipingTon PhichitBelum ada peringkat

- 66 Lateral PDFDokumen7 halaman66 Lateral PDFGerman ToledoBelum ada peringkat

- Steam TurbinesDokumen24 halamanSteam Turbinesrt_sendhilBelum ada peringkat

- Aquarium PumpsDokumen1 halamanAquarium PumpsTon PhichitBelum ada peringkat

- Tracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsDokumen4 halamanTracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsTon PhichitBelum ada peringkat

- VibrationDokumen10 halamanVibrationAHMEDSAEED013Belum ada peringkat

- 390Dokumen9 halaman390Ton PhichitBelum ada peringkat

- Engineering Standard for Piping Material Selection (On Plot PipingDokumen431 halamanEngineering Standard for Piping Material Selection (On Plot PipingpradeepBelum ada peringkat

- 21 5 1710Dokumen31 halaman21 5 1710Ton PhichitBelum ada peringkat

- ML 070260376Dokumen25 halamanML 070260376Ton PhichitBelum ada peringkat

- Tracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsDokumen4 halamanTracking Down Vibrations: Modal and Operating Deflection Shape Analysis As Damage-Analysis ToolsTon PhichitBelum ada peringkat

- 12 Ernie Sturtz Pumping Facility Design StandardsDokumen41 halaman12 Ernie Sturtz Pumping Facility Design StandardsTon PhichitBelum ada peringkat

- KU-11-6 FinalDokumen208 halamanKU-11-6 FinalTon PhichitBelum ada peringkat

- Viibratiion DiiagnostiicsDokumen113 halamanViibratiion DiiagnostiicsDanielAvellanedaBelum ada peringkat

- Load SequencingDokumen7 halamanLoad SequencingTon PhichitBelum ada peringkat

- System DesignDokumen16 halamanSystem DesignTon PhichitBelum ada peringkat

- Thermal Considerations in Pipe FlowsDokumen11 halamanThermal Considerations in Pipe FlowsWaqas AhmadBelum ada peringkat

- Hurricane-2006 12 46-53Dokumen8 halamanHurricane-2006 12 46-53Ton PhichitBelum ada peringkat

- Tension and Sag 07-25-06Dokumen7 halamanTension and Sag 07-25-06Ton PhichitBelum ada peringkat

- TD302REC: Specifications Standard EquipmentDokumen2 halamanTD302REC: Specifications Standard EquipmentfuffinoBelum ada peringkat

- Power Screw ReportDokumen15 halamanPower Screw ReportTanvesh PatilBelum ada peringkat

- 2-Theory of SedimentationDokumen11 halaman2-Theory of SedimentationSheeraz AhmedBelum ada peringkat

- Sebp4195 76 02 Allcd - 010 PDFDokumen957 halamanSebp4195 76 02 Allcd - 010 PDFJusaNada100% (1)

- Government of India Ministry of Railways: DraftDokumen26 halamanGovernment of India Ministry of Railways: DraftraveenBelum ada peringkat

- DE-18 Fuel Oil Injection Pump and Device Parts ListsDokumen6 halamanDE-18 Fuel Oil Injection Pump and Device Parts ListsK.l. DhanaBelum ada peringkat

- CCMC Canadian Code Compliance Evaluation - National Research Council CanadaDokumen14 halamanCCMC Canadian Code Compliance Evaluation - National Research Council CanadaMark AdamsBelum ada peringkat

- Racor Oil Filtration Hydraulic Filter Cart 7768Dokumen2 halamanRacor Oil Filtration Hydraulic Filter Cart 7768sinter-musicBelum ada peringkat

- Keperluan Document Sebagai Dasar Penerbitan SLODokumen4 halamanKeperluan Document Sebagai Dasar Penerbitan SLOFaturrakhman KhairanBelum ada peringkat

- EJOT ASYST Component System Flyer 10.17Dokumen5 halamanEJOT ASYST Component System Flyer 10.17Eren GülayBelum ada peringkat

- Electric Pumps Cat 2006 ScreenDokumen258 halamanElectric Pumps Cat 2006 ScreenNicolasBelum ada peringkat

- Autoscan P12 04 16 enDokumen12 halamanAutoscan P12 04 16 enCouscoussiere GrandgazBelum ada peringkat

- Sachin Solanki CNC/IPC/13 Summary SupportDokumen61 halamanSachin Solanki CNC/IPC/13 Summary Supportshivam modanwalBelum ada peringkat

- Figure R4-1: Vacuum Column FlowsheetDokumen18 halamanFigure R4-1: Vacuum Column Flowsheetnico123456789Belum ada peringkat

- Check Valves: Check Valve and Pre - LL Valve Type FDokumen2 halamanCheck Valves: Check Valve and Pre - LL Valve Type FSaeid MirBelum ada peringkat

- Curvilinear Motion and ProjectilesDokumen15 halamanCurvilinear Motion and ProjectilesAltammar1367% (3)

- Engineering Plastic Properties and Processing GuidelinesDokumen28 halamanEngineering Plastic Properties and Processing GuidelinesSamuel Berger VeltenBelum ada peringkat

- Wire Wizard Catalogue AUDokumen28 halamanWire Wizard Catalogue AUpotblakBelum ada peringkat

- CMT Capitolul 4 - Transmisii Curele DintateDokumen19 halamanCMT Capitolul 4 - Transmisii Curele DintateANABelum ada peringkat

- Assingment 2Dokumen1 halamanAssingment 2Aliaa TarekBelum ada peringkat

- S Emi Rotary Hand Wing Pumps: A Plication PDokumen2 halamanS Emi Rotary Hand Wing Pumps: A Plication PMarketing CTNBelum ada peringkat