Spief Spiocef Manual PDF

Diunggah oleh

Razvan MaresJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Spief Spiocef Manual PDF

Diunggah oleh

Razvan MaresHak Cipta:

Format Tersedia

SPi-EF

and

SPi-OCEF

Fault Passage Indicators

USER MANUAL

Nortech Management Ltd. Tadcaster House, Keytec 7 Business Park, Kempton Road, PERSHORE WR10 2TA Untied Kingdom tel: +44 (0) 8700 111 992 fax: +44 (0) 8700 111 992 e-mail: info@nortechonline.co.uk web site: http://www.nortechonline.co.uk

E&OE

Nortech Management Ltd

Revised November 2002 D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 1

OVERVIEW

This document describes the Operation, Installation and Maintenance for two fault passage indicators: SPi-EF (Self Powered Earth Fault indicator) SPi-OCEF (Self Powered Over Current and Earth Fault indicator) The SPi unit is connected to a local AC supply which is used to maintain operational readiness. On removal of this local supply an internal power source supports the operation and any indications of the SPi. When the local AC supply is restored after a period of self powered operation the SPi replenishes the standby internal power source. Indication for faults is by flashing Hyper-Bright LED for and additional electrical indication from auxiliary contacts. THERE IS NO BATTERY IN EITHER THE SPi-EF OR THE SPi-OCEF. Also in the range is the SPi-OCEF Programmable which provides additional functionality.

CONTENTS

Section 1. 2. General Description Operation Fault Definition Fault Indications Fault Scenarios Current Transformers Switchgear Earthing Specification Installation Physical Wiring Enclosure Bracket 7. Operational Checks SPi-EF SPi-OCEF SPi-OCEF Injection Test Appendix 16 Page 2 3

3. 4. 5. 6.

8 10 11 13

18

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 2

1.

GENERAL DESCRIPTION

The SPi range of fault passage indicators is designed for application to distribution networks where manually operated or automated switchgear is installed. When current above a threshold level is detected the indicator operates alarm contacts for remote indication and illuminates an integral high brightness Light Emitting Diode (LED). Indicators strategically placed in the distribution network aid identification of a faulty section of network as shown in fig.1A where a fault occurs at position A.

SOURCE

NO

TRIP

Fault past these points NO

Fig.1A

The SPi-EF and SPi-OCEF indicators are compact units contained within a high strength polycarbonate case and sealed within a waterproof compound. The SPi-EF indicator, fig.1B, is used with a core balance current transformer (CT) mounted around a distribution cable at the switchgear end. When earth current is detected in any phase conductor, the SPi-EF unit measures the current and if a fault is calculated, an ultra bright LED is flashed. For a permanent fault the indicating period is 3 hours. For a transient fault the indicating period is 24 hours. In each case contacts are operated for remote alarms. The power supply to the indicator is taken from the local distribution network under normal system conditions. When supply is detected the indicator charges over a short time and is available for fault detection and indication during and after a fault occurrence for a period of up to 6 hours for a permanent fault.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 3

Fig.1B SPi indicator (SPi-EF shown) In practice the measurement of true fault current by use of a core balance CT requires consideration to the following: - Any external earth wire connections used with distribution switchgear must be routed carefully such that the cable core current can be accurately measured During the fault clearance period when the device is measuring, capacitive currents can flow into the fault location from both ends of the feeder. The indicator must discriminate between true fault current and short time capacitive discharge current. - Strong magnetic fields produced by external current flowing in earthwire connections in close proximity to the indicator or core balance CT must not cause operation of the indicator. - Core balance current transformers used must be unaffected by external fault currents. The SPi range of indicators has been designed to operate under these most onerous conditions and give reliable indications. The SPi-OCEF indicator, is used with either 3 phase mounted CT s or alternatively, 2 phase mounted and one core balance CT. The indicator monitors for phase to phase and earth faults and operates to give remote alarms and local indications as for the SPi-EF indicator. -

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 4

2.

OPERATION

The SPi is powered from the local mains supply under system normal conditions. When first energised the indicator is ready for fault indication after 60 seconds. If supply is lost and then restored within 30 minutes the indicator is ready for fault indication after 10 seconds. Measurement of earth current is made every 1mSec. When current above the threshold setting of the indicator is measured a fault calculation is initiated. The algorithm used for fault measurement allows the indicator to grade with the minimum settings likely to be used by the source protection relays and at the same time avoid possible mis-measurement due to capacitive charge currents. The indicator characteristic is shown in App.A against typical source protection minimum settings.

2.1 Fault Definition

The indicator determines a fault as follows: IF supply was on 500mS before the current exceeds the threshold set point AND the current exceeds the characteristic criteria (app. A) AND the supply is off within 500mS after the current dropping below the threshold set point THEN a fault is set

Fault Definition indeterminate

Supply

Current

500msec maximum

Curve Time achieved

500msec maximum

2.2

Fault Indication

A fault is indicated on the SPi by an ultra-bright LED, flashing at an interval of approximately 1.5 seconds. For remote alarms, volt free contacts are closed at the start of the indicating period. The alarm contacts can be specified fleeting (2 seconds), or permanently closed until the end of the indicating period. The device will indicate for both transient and permanent faults. The indications are as follows: - Transient Fault, if fault current is measured and the mains supply is restored in less than 3 hours the high intensity red LED will flash repeatedly for 24 hours unless reset - Permanent Fault, if fault current is measured and the mains supply is still off after 3 hours the high intensity red LED will flash repeatedly for 3 hours unless reset - Trigger level, the fault LED will indicate when the threshold operating current is reached and until the curve time is achieved If a transient fault is being indicated and a new fault is detected, all indicators will update and indicate for the new fault situation. A test/reset button located on the front of the SPi can be used to test the functionality of the indicator or to reset a fault indication.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 5

2.3

Fault Scenarios

The action of the indicator under various fault situations is shown in more detail below: -

Transient Fault Supply

Fault Current Fault Sensing Indication

24 hr

3 min

Relay

Fleeting or latched option

On fault detection the indicator will flash to indicate fault passage. After a valid fault has been set and providing supply is restored, no fault measurements are taken for 3 minutes. If the line voltage is restored within 3 hours the unit will indicate for a total of 24 hours and at the same time monitor the circuit for further faults. Permanent Fault supply restored before 3 hour time out period Supply

Up to 3 hours

Fault Current Fault Sensing Indication

24 hr

Relay

Fleeting or latched option

If, following the fault, supply is not restored the unit will indicate for 3 hours. If supply is restored during this period the unit will indicate for 24 hours and monitor and update for further faults.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 6

Permanent Fault supply restored after 3 hour time out period Supply

More than 3 hours

Fault Current Fault Sensing Indication

3 hours

Relay

Fleeting or latched option

If, following a fault, supply is not restored within 3 hours, the unit will reset.

Trasnsient Fault followed by a Permanent Fault past SPi Supply

Fault Current Fault Sensing Indication

3 mins

3 hours

Relay

Fleeting or latched option

If, when indicating for a transient fault, fault current is measured, the unit will fully update for the new fault.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 7

Trasnsient Fault followed by a Transient Fault past SPi Supply

Fault Current Fault Sensing Indication

3 mins

3 mins

24 hours

Relay

Fleeting or latched option

If, when indicating for a transient fault, fault current is measured and the line voltage is immediately restored, the will indicate for a further 24 hours and fully update for any further faults.

Trasnsient Fault followed by a Permanent Fault BEFORE SPi Supply

Source CB open

Fault Current Fault Sensing Indication

3 mins

Relay

Fleeting or latched option

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 8

3.

CURRENT TRANSFORMERS

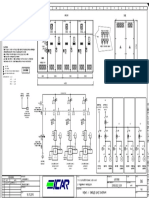

The SPi-EF is designed for use with a 60/1 core balance CT having a minimum rating of 1.5VA and an accuracy of 10% up to 4 times primary current (10P4). With this CT the threshold current is 50Amps. If other ratio CT s are used the operating threshold is: 0.833 x P/S Where P is CT primary current rating and S is CT secondary rating. The SPi-OCEF is designed for use with 3 phase mounted 400/1 CT s, fig.3A, or alternately 2 phase mounted 400/1 CT s and a single 60/1 core balance CT as used with the SPi-EF indicator, fig.3B. Note that when a core balance CT is used, the phase mounted CT s must always be connected to terminals 1 and 3 on the SPi indicator. At the rear of the indicator two switches allow the overcurrent threshold level to be set to 600A or 250A and the CT arrangement to be set (3 phase mounted CT s or 2 phase mounted and 1 core balance CT. The earth-fault threshold level is a nominal 50A. If an existing core balance CT is used the earth-fault threshold level will be dependent on the CT primary rating.

OC1

OC2

EF

1 3 5 E 7 SPi-OCEF

3 x Phase mounted CT s

Switchgear

C11 C31 C51

C70 C90 Alternative earthing arrangement

Fig.3A Connections using 3 phase mounted current transformers

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 9

OC1

OC2

EF

1 3 5 E 7 SPi-OCEF

2 x Phase mounted CT s

Switchgear

C11 C31 C70

C71 C90 Core Balanced CT Alternative earthing arrangement

Fig.3B Connections using 2 phase mounted CT s and one core balance CT

Important note: Phase mounted current transformers must be securely mounted around the cable cores at a point where the core earthed screen passes through and beyond the CT. The jointing procedure for the cable termination should specify the method to be adopted in order to ensure electrical stress control. The secondary wiring must be earthed, as shown by figure 3A and 3B.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 10

4. SWITCHGEAR EARTHING Earth fault current is returned to source through the path of least resistance. When the fault occurs in a cable system, the majority of return current will flow through the cable sheath, thus resulting in a null output from a core balance CT, as shown in figure 4A. Fault Current

SPi

Return Fault Current

MINIMAL OUTPUT

Fig.4A This effect can be prevented if the cable earthing connection between the cable and adjacent switch is routed through the core balance CT, figure 4B.

Fault Current

Fault Current

SPi

Return Fault Current

SPi

Return Fault Current

Correct output

Correct output

Fig.4B Where single core cables are used, each sheath earth-wire must be routed through the single core balance CT.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 11

5.

SPECIFICATION

Case Power Supply options Charge/Rearm time Threshold fault current Polycarbonate 122mm (H) x 120mm (W) x 105mm (D) 1. 110- 250V 2. 40- 65V From loss of supply: 10 seconds for first 30 minutes and then 60 seconds SPi-EF SPi-OCEF Earth fault only as formula (section 3 above) Phase fault 600A or 250A selectable Earth fault 50A nominal Following a fault detection the indicator will not sense a further fault for a period of 3 minutes Indicator Ultra bright LED 1.5 second flash rate 24 hours duration for transient fault 3 hours duration for permanent fault if supply is restored during this period the unit will update if a new fault is detected Remote Alarm options 1. Fleeting normally open volt free contacts (2.0 Sec) standard 2. Latched normally open volt free contacts (option) Alarm is actively biased to the non-operated position during the normal supply-on period and during the fault-measuring period. The SPi indicators have been tested for compliance with the following standards: ENVIRONMENTAL WITHSTAND Insulation Between any terminal and earth Between independent circuits Across normally open contacts 2kV RMS for 1 minute 2kV RMS for 1 minute 1kV RMS for 1 minute

Transient Over-voltage Between all terminals and earth or between any two terminals High Frequency Disturbance 2.5kV Common mode (longitudinal) 1kV Series mode (transverse) Electrostatic Discharge 8kV contact Fast Transient 2kV 5/50nSec. 2.5kHz repetitive No mal-operation, steady state, operated or during fault measurement No mal-operation No mal-operation No mal-operation 5kV 1.2/50Sec.

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 12

EMC Susceptibility Emissions Current Injection Operation Mechanical General Temperature range Case construction to IP65. Processor circuitry in lid protected in epoxy resin moulding. -25C to +70C ambient 50A threshold 10% up to at least 20,000A primary current for 3 Sec. through 60/1 current transformer 100kHz to 1gHz, 3V/ metre on all planes, no maloperation No significant emissions

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 13

6.

INSTALLATION

6.1 Physical

The SPi-EF is constructed in a fully weatherproof polycarbonate enclosure. The indicator is encapsulated into the casing lid with a reset /test button in a central position under the information nameplate. Connections are made from the indicator to a terminal strip mounted to the rear of the casing. Fig.6A shows the connections for the SPi-EF and fig.6B for the SPiOCEF indicator. Three 20mm cable gland entry holes are provided (one with blanking plug) for mains supply, CT s and alarm output, fig 6C. The indicator should be mounted for good visibility and as close as practical to the CT. One core of the CT should be connected to earth for safety. Any external earth wires should be routed to maintain a minimum clearance of 100mm from the SPi-EF.

6.2

Wiring Connections

* L N E

*

CT

ALRM

REMOVE LINK IF EARTH CONNECTED AT CT

Fig.6A SPi-EF connections

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 14

OVERCURRENT 600A 250A SETTING SWITCH 1 2

CT TYPE 3x400A 2x400A+CORE

L N 1

3 5 E

7 ALRM

3xPHASE CT - LINK 7-E 2xPHASE CT 1xCORE CT LINK 5-E REFER TO MANUAL FOR CONNECTIONS REMOVE LINK IF EARTH CONNECTED AT CT

Fig.6B SPi-OCEF connections The connections are as follows: Power Supply L - N The power, which is also used for supply sensing, can be from 100V 250VAC. Current Transformers CT 1A nominal input from core balance CT (SPi-EF). ABCD 1A nominal inputs from either 3 phase mounted CT s or 2 phase mounted CT s and 1 core balance CT (SPi-OCEF). Alarms Normally open, isolated contacts are provided for remote signalling fault. The operation of the alarm contacts is fleeting (2 seconds duration).

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 15

6.3

Enclosure Detail

Fig.6C SPi case detail

6.4 Optional Mounting Bracket Detail

20 mm 20 mm

2 holes, M6 clearance

6 holes, M6 clearance

177

Side view

Front view

Top view

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 16

7.

OPERATIONAL CHECKS

When powered up the test/reset button located on the front of the SPi can be used in two ways to confirm the operational readiness, and functionality of the indicator. 1. When operated the LED will flash for a short time and then steady until the test/reset button is released, the remote alarm relay contacts will not be operated. 2. If the power supply to the SPi is removed within 15 seconds of test 1, the remote alarm contacts will close, allowing confirmation of the remote fault indication circuitry. The unit will indicate until supply is restored. A full check for operation can be carried out by current injection across the CT secondary terminals of the indicator. The test procedure is as follows: -

7.1

1. 2. 3. 4. 5.

SPi-EF

Confirm power supply on Inject 0.7 A into SPi-EF and note LED and note LED does not flash Inject 1 Amp into SPi-EF and note LED flashes briefly Switch supply AND fault current OFF at the same time Confirm correct indications and alarms

7.2

SPi-OCEF

When installed and with the indicator powered up, primary current injection should be carried out to confirm that the CT s are of the correct ratio and polarity. When the current setting of the indicator is reached the appropriate LED will illuminate. As the current is increased above the fault level threshold the LED will switch off as the fault curve time is reached (see app. A). A full operational check of the indicator is achieved as follows: 1. Confirm power supply on 2. Inject current below threshold level (OC or EF) and note LED does not flash 3. Inject current above threshold level (OC or EF) and note LED does not flash 4. Switch supply AND fault current OFF at the same time 5. Confirm correct indications and alarms

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 17

7.3

SPi-OCEF Injection Tests

It is important that CT polarities are correct, the table below shows the minimum primary injection tests that should be carried out to confirm correct secondary CT wiring connections. CT A P in Test 1 Injection Link Test 2 Injection Link Test 3 Injection Link Test 4 Injection Link Test 5 Test 6 Test 7 Inject Inject Inject X X X X X X X X X X X X X X EF EF EF None X X X X X X None X EF P out P in CT B P out X P in CT C P out SPi-OCEF indication EF

Nortech Management Limited

document reference D_061_0279 issue 2.02

SPi-EF and SPi-OCEF - USER MANUAL

PAGE 18

Appendix A

SPi-EF Response against Normal Inverse & Very Inverse curves using 0.1TM

10.00

1.00 Seconds @ 0.1TM 0.10 0.01 1 10 PSM Standard Very SPi-EF 100

Nortech Management Limited

document reference D_061_0279 issue 2.02

Anda mungkin juga menyukai

- Bulletin 857 Protection System For Feeder and Motor Protection, Series ADokumen516 halamanBulletin 857 Protection System For Feeder and Motor Protection, Series ARazvan MaresBelum ada peringkat

- Product Data Sheet 3RH1440-1BM40: Contactor Relay, Latched, 4-Pole, 4 NO, SIZE S00, DC 220VDokumen5 halamanProduct Data Sheet 3RH1440-1BM40: Contactor Relay, Latched, 4-Pole, 4 NO, SIZE S00, DC 220VRazvan MaresBelum ada peringkat

- Best Overhead Line Software - Power Line PDFDokumen1 halamanBest Overhead Line Software - Power Line PDFRazvan MaresBelum ada peringkat

- Day-Ahead Hourly Forecasting of Power Generation From Photovoltaic PlantsDokumen14 halamanDay-Ahead Hourly Forecasting of Power Generation From Photovoltaic PlantsRazvan MaresBelum ada peringkat

- AN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150Dokumen144 halamanAN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150Razvan MaresBelum ada peringkat

- AN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150 PDFDokumen2 halamanAN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150 PDFRazvan MaresBelum ada peringkat

- NT00381-02 - T300-OVR Installation Guide PDFDokumen48 halamanNT00381-02 - T300-OVR Installation Guide PDFRazvan MaresBelum ada peringkat

- Tcs 7PA26 - 27 - 30 - Catalog - SIP-2008 - en PDFDokumen7 halamanTcs 7PA26 - 27 - 30 - Catalog - SIP-2008 - en PDFBagus Permadi100% (1)

- Catalogue - Control Relays and TimersDokumen196 halamanCatalogue - Control Relays and TimersRazvan MaresBelum ada peringkat

- CBCT PDFDokumen1 halamanCBCT PDFRazvan MaresBelum ada peringkat

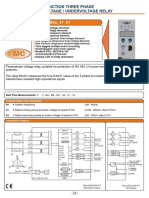

- MC MC: Multifunction Three Phase Overvoltage / Undervoltage RelayDokumen4 halamanMC MC: Multifunction Three Phase Overvoltage / Undervoltage RelayRazvan Mares100% (1)

- Graphical Symbols For Electrical Circuit Diagrams 20003 HQ enDokumen4 halamanGraphical Symbols For Electrical Circuit Diagrams 20003 HQ enMohammed Mushtaha100% (1)

- SG30KTL M Quick User ManualDokumen34 halamanSG30KTL M Quick User ManualRazvan MaresBelum ada peringkat

- Circuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsDokumen8 halamanCircuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsRazvan Mares50% (2)

- Batreii Cond ICARDokumen1 halamanBatreii Cond ICARRazvan MaresBelum ada peringkat

- Structural Design of Steel Latticed TowersDokumen13 halamanStructural Design of Steel Latticed Towersskumaran1100% (11)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Toolbox Talks Working at Elevations English 1Dokumen1 halamanToolbox Talks Working at Elevations English 1AshpakBelum ada peringkat

- HorticultureDokumen168 halamanHorticultureagni sahanaBelum ada peringkat

- Elements or Appurtenances of The Stilling BasinsDokumen21 halamanElements or Appurtenances of The Stilling BasinsAhmad PshtiwanBelum ada peringkat

- 1 s2.0 S0956713515002546 Main PDFDokumen9 halaman1 s2.0 S0956713515002546 Main PDFIfwat ThaqifBelum ada peringkat

- The Greek LettersDokumen18 halamanThe Greek LettersSupreet GuptaBelum ada peringkat

- Conduit 5Dokumen42 halamanConduit 5dediBelum ada peringkat

- EnglishDokumen18 halamanEnglishSarah SiddiquiBelum ada peringkat

- Local AnesthesiaDokumen55 halamanLocal AnesthesiaAhmed MagdyBelum ada peringkat

- AP Human Geography Review Unit 2Dokumen18 halamanAP Human Geography Review Unit 2BaselOsman50% (2)

- Sorsogon State College Engineering & ArchitectureDokumen11 halamanSorsogon State College Engineering & ArchitectureArianne Mae De Vera GallonBelum ada peringkat

- Air Cooler With Checking DoorDokumen2 halamanAir Cooler With Checking DoorSuraj KumarBelum ada peringkat

- Exact Solution Tank DrainageDokumen8 halamanExact Solution Tank DrainageFelipe CastBelum ada peringkat

- Carriages and Mounts SeriesDokumen92 halamanCarriages and Mounts Seriessudhirm16Belum ada peringkat

- Vital Judo Throwing TechniquesDokumen193 halamanVital Judo Throwing TechniquesJuan Jose Opazo Carvajal100% (1)

- 8v92ta DetroitDokumen554 halaman8v92ta Detroit10000389% (9)

- Sensors & Transducers: (Code: EI 401)Dokumen4 halamanSensors & Transducers: (Code: EI 401)Mayukh BiswasBelum ada peringkat

- Atlantis Is Discovered - Atlantis in Middle Danubian Depression (Pannonian Basin) A New Location of Atlantis IslandDokumen31 halamanAtlantis Is Discovered - Atlantis in Middle Danubian Depression (Pannonian Basin) A New Location of Atlantis Islandpaulct2004721260% (10)

- Propagare - Threshold Degradation - AbateriDokumen72 halamanPropagare - Threshold Degradation - AbateriAndrada AdaBelum ada peringkat

- Research Report 2011 Asses Water ChambalDokumen41 halamanResearch Report 2011 Asses Water Chambalsamyak sambhareBelum ada peringkat

- Reason: God Had Made The Mistake of Sending Only 70 PesosDokumen2 halamanReason: God Had Made The Mistake of Sending Only 70 PesosS Vaibhav81% (21)

- Course For Loco Inspector Initial (Diesel)Dokumen239 halamanCourse For Loco Inspector Initial (Diesel)Hanuma Reddy93% (14)

- Oplan Tumbler ProposalDokumen3 halamanOplan Tumbler ProposalKay Tuppil ManzanillaBelum ada peringkat

- School: Grade Level: Teacher: Section Teaching Dates and Time: QuarterDokumen3 halamanSchool: Grade Level: Teacher: Section Teaching Dates and Time: QuarterZeny Aquino DomingoBelum ada peringkat

- Bio-Rad D-10 Dual ProgramDokumen15 halamanBio-Rad D-10 Dual ProgramMeesam AliBelum ada peringkat

- Unit-3 DC Machines IMP QuestionsDokumen30 halamanUnit-3 DC Machines IMP Questionskrishna Sai Atla VenkataBelum ada peringkat

- EOCR 종합 EN 2015 PDFDokumen228 halamanEOCR 종합 EN 2015 PDFShubhankar KunduBelum ada peringkat

- Green Engine 2 PDFDokumen7 halamanGreen Engine 2 PDFharivardhanBelum ada peringkat

- Planning & Cost Control Engineer (Primavera & MS Project) : Aouache FaridDokumen3 halamanPlanning & Cost Control Engineer (Primavera & MS Project) : Aouache FaridFarid FaridBelum ada peringkat

- It Park Design Submission PDFDokumen20 halamanIt Park Design Submission PDFSAKET TYAGI100% (1)

- HP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessDokumen4 halamanHP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessPằngPằngChiuChiuBelum ada peringkat