Inspection and Test Plan

Diunggah oleh

mfvallegaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Inspection and Test Plan

Diunggah oleh

mfvallegaHak Cipta:

Format Tersedia

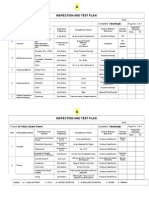

INSPECTION AND TESTING PLAN ( ITP )

2/28

ITP FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

CONTRACTOR'S VERIFICATION STAMP

PURSUANT TO SPECIAL CONDITION 6, WE SKY ORYX JOINT VENTURE, VERIFY THAT THIS SUBMITTAL SATISFIES ALL REQUIREMENTS OF THE CONTRACT, WITH THE EXCEPTION OF THE FOLLOWING CLARIFICATIONS/ PROPOSALS ACCEPTED BY THE ENGINEER; CONTRACTOR'S PROJECT MANAGER;

M. HORIKAWA PRINT NAME SIGNATURE DATE DOCUMENT REVIEW STATUS STATUS 1: WORK MAY PROCEED. STATUS 2: REVISE & RESUBMIT.WORK MAY PROCEED SUBJECT TO INCORPORATION OF COMMENTS INDICATED . STATUS 3: REVISE & RESUBMIT. WORK MAY PROCEED. STATUS 4: REVIEW NOT REQUIRED. WORK MAY PROCEED. PERMISSION TO PROCEED SHALL NOT CONSTITUTE ACCEPTANCE OR APPROVAL OF DESIGN DETAILS, CALCULATIONS, ANALYSES, TEST METHODS, OR MATERIALS DEVELOPED OR SELECTED BY CONTRACTOR AND SHALL NOT RELIEVE CONTRACTOR FROM FULL COMPLIANCE WITH THE CONTRACT TECHNICAL SPECIFICATIONS AND DRAWINGS.

Overseas Bechtel, Inc.

Date

Document No:25045-A1126-18-ITP-S-027

Rev.No 02

Prepared Date Description QA/QC Syed Kausar

Checked QA/QC Struct Engg Cond.Mgr. Mgr.

FET Mgr.

Approved Project Manager

3/29

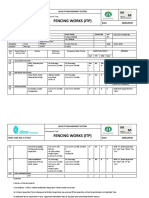

NDIA New Doha International Airpoet Project

INSPECTION AND TEST PLAN FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

Contract No.:

25045-000FC1-maht-00018

Discipline: Structural Steel Activity No.: 1.0 1.1 Document Review Activity Description

Contract Title: Passenger Terminal Complex CCP-18 Reference Procedure/Method Statements/Specs. : Spec. 05120, 05060. Controlling Document Frequency

ITP No.

25045-A1126-18-ITP-S-027

Issue date:09-02-2009

Rev. no : 2 Page: 1 of 6 Inspection*

QAP No.25145-A1000-18-GQA-S-001 Rev.2, Verifying Documents

SSI/C

Acceptance Criteria

TPIA (NDT)

SOJV

OBI

TPIA (BOI)

Project Quality Assurance Plan (PQP) Method Statement Inspection and TestMethod Statement Plan (ITP) Shop drawings Material Submittals WPS, PQR&WQT NDT (TPIA) Procedures

Project Specifications Exhibit-F Exhibit-B

Before Work Commencement

As oer OBI Status code 1, 2 and 4

SOJV-QP-10-02/X-01

1.2

Fabrication Drawings

Project Specifications

Before Work Commencement

Fabrication Drawing acceptance to SOJV

SOJV-QP-10-02/X-01 H H H R

2 2.1

Meterials-Steel Framing (ASTM A572, ASTM A36)

Paint Material Inspection

Primer Paint

Spec-05120/Clause 2.1 Spec-05120 Each Supplier submittal Delivery Manufacturer product data, Safety Data & application procedure

ASTM, drawings, 05120

MRR, Drawings D.O. (SOJVMRR-014-01 rev 1 & x-004)

SR

Inspection H-Hold Point : Written notification required. Contractor may not proceed beyond this point without written confirmation of the Engineer

W - Witness : Written notification required but Contractor may not proceed if OBI do not attend

S - Surveillance : No notification required but activity may be subjected to OBI Surveillance/ Monitoring

R - Review : Record/ Document review

4/29

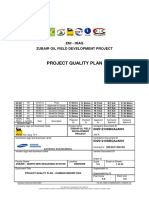

NDIA New Doha International Airpoet Project

INSPECTION AND TEST PLAN FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

Contract No.:

25045-000FC1-maht-00018

Discipline: Structural Activity No.: 2.2

Welding Consumables

Contract Title: Passenger Terminal Complex CCP-18 Reference Procedure/Method Statements/Specs. : Spec 05120, 05060. Activity Description Controlling Document Spec-05120 Part2.1, 05060, part 2.1 Supplier submittal Calibration Procedure Each Delivery Frequency

ITP No.

25045-A1126-18-ITP-S-027

Issue date ;

Rev. no : 2 Page: 2 of 6 Inspection*

SSI/C TPIA (NDT) SOJV OBI TPIA (BOI)

QAP No.25145-A1000-18-GQA-S-001 Rev.0, Verifying Documents ASME Section ll, Part C/ AWS D 1.1, Section 5.3 D.O & Batch Certificate / Electrode log Register Calibration certificates Equipments Calibrationlog

Acceptance Criteria

3 3.1

SMAN FCAW SAW Calibration Equipments Calibration Measuring Instrument NDT Testing Equipments

SR

As per manufacturer/ calibration agency recommendations.

ISO10012-1:1992, Part 1 - Metrological conformation system for measuring equipment. For NDT Awa D1.1 & ASME BPVC Section V Dimensions tolerance shall be as per AISC Specification for Structural steel Building Part 16, Chapter M,M2,2 Fabrication Tolerances 6 mm. for AESS. Fabrication Tolerances are as per AISC for Non- AESS.

S/R

4 4.1

Fabrication Marking and Cutting Spec-05120 Part2.1,2.5c, 2.5.A.2, 2.5 I Approved shop Drawings 100% Material identification and tracesbility / Inspection Request (25045-A1000-18-ITRS-002& 001)

SR

Inspection H-Hold Point : Written notification required. Contractor may not proceed beyond this point without written confirmation of the Engineer

W - Witness : Written notification required but Contractor may not proceed if OBI do not attend

S - Surveillance : No notification required but activity may be subjected to OBI Surveillance/ Monitoring

R - Review : Record/ Document review

5/28

NDIA New Doha International Airpoet Project

INSPECTION AND TEST PLAN FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

Contract No.:

25045-000FC1-maht-00018

Discipline: Structural Activity No.: Activity Description

Contract Title: Passenger Terminal Complex CCP-18 Reference Procedure/Method Statements/Specs. : Spec 05120, 05060. Controlling Document Frequency

ITP No.

25045-A1126-18-ITP-S-027

Issue date ;

Rev. no : 2 Page: 3 of 6

QAP No.25145-A1000-18-GQA-S-001 Rev.0, Verifying Documents AWS code for Weld joint preparation Marking the high strength steel as per ASTM A/A6 M. Camber if requied by IFC AWS D1.1 Complicance to production Drawing

SSI/C

Acceptance Criteria

Inspection*

TPIA (NDT)

SOJV

OBI

TPIA (BOI)

4.2

Fit-up

Spec -05120, Part 2.6.B Approved shop Drawings

100%

4.3

Welding Process

Spec-05120, Part 2.6 & 05060 Part 3.5 Production Drawings

100%

4.4

Welding Repair

Production Drawings

Repairs local surface imperfection depth below 1/16 inch or less Repair by welding where required Test on repair portion

Approved WPS & PQR AWS D1.1 APProved TPIA to review and certify weld procedures and all welder qualifications By grinding to smooth contour with a curvature of less than 1/2 inch (13 mm) in either direction. To ensure that defects have been temoved prior to depositing any weld metal, examine prepared areas by DPT.

Weld Visual Inspection Report / Inspection Request (25045-A1000-18ITR-S-003&001) Weld Visual Inspection Report / Inspection Request (25045-A1000-18-ITRS-003&001) Report/ Inspection Report (25045-A1000-18ITR-S-003&001) (NDT TPIA- Reports)

SR

SR

SR

Inspection H-Hold Point : Written notification required. Contractor may not proceed beyond this point without written confirmation of the Engineer

W - Witness : Written notification required but Contractor may not proceed if OBI do not attend

S - Surveillance : No notification required but activity may be subjected to OBI Surveillance/ Monitoring

R - Review : Record/ Document review

6/29

NDIA New Doha International Airpoet Project

INSPECTION AND TEST PLAN FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

Contract No.:

25045-000FC1-maht-00018

Discipline: Structural Activity No.: 5 5.1 WELDING TESTING Visual inspection of Welding Activity Description

Contract Title: Passenger Terminal Complex CCP-18 Reference Procedure/Method Statements/Specs. : Spec 05120, 05060. Controlling Document Frequency

ITP No.

25045-A1126-18-ITP-S-027

Issue date ;

Rev. no : 2 Page: 4 of 6 Inspection*

SSI/C

TPIA (NDT)

QAP No.25145-A1000-18-GQA-S-001 Rev.0, Verifying Documents

Acceptance Criteria

SOJV

OBI

TPIA (BOI)

Spec -05060 Part 3.2 C Drawings

100%

Weld Visual for Surface holes, cracks, Undercut, Confirming to AWS D 1.1 2004 Section (6.9), Table 6.1

Weld Visual Inspection Report (25045-A1000-18ITR-S-004) (ITPA Endorsement on Report) Visual

SR

5.2

Liquid Penetration test for Back gauging of CP Welds UT on CP Welds UT on 38 mm and thicker plate subject throung thickness weld shrinkage strain. MPI on Fillet Welds MPI on Partial penetration Welds

Spec -05120, Part 2.9

As needed

AWS D1.1 - 2004 Section (6.10) AWS D1.1 - 2004 Section (6.13) ASTM E 164

H UT Report (TPIA -Report) & Weld map

SR

5.3

Spec-05060, Part 3.2,3.5 & 05120 part 2.9 Drawings

100%

SR

5.4

Spec-05060, Part 3.5J Drawings

Web- Flange AWS D1.1 - 2004 connection 10%,ii) 10% Section (6.10) Beam and Girder ASTM E 709 connection where they connection using a clip angle, otherwise 100% All other connection s-100%

MPI Report (TPIA-Report) & Weld map

SR

Inspection H-Hold Point : Written notification required. Contractor may not proceed beyond this point without written confirmation of the Engineer

W - Witness : Written notification required but Contractor may not proceed if OBI do not attend

S - Surveillance : No notification required but activity may be subjected to OBI Surveillance/ Monitoring

R - Review : Record/ Document review

7/28

NDIA New Doha International Airpoet Project

INSPECTION AND TEST PLAN FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

Contract No.:

25045-000FC1-maht-00018

Discipline: Structural Activity No.: 5.5 RT on CP Welds Activity Description

Contract Title: Passenger Terminal Complex CCP-18 Reference Procedure/Method Statements/Specs. : Spec 05120, 05060. Controlling Document Spec-05120 part 2.9 E Drawings NDT Procedure Spec-05060 Part 3.2 & 3.2, 05120 Part 2.5, 2.6.B Approved shop Drawings 25% Frequency

ITP No.

25045-A1126-18-ITP-S-027

Issue date ;

Rev. no : 2 Page: 5 of 6 Inspection*

SSI/C

TPIA (NDT) TPIA (BOI)

QAP No.25145-A1000-18-GQA-S-001 Rev.0, Verifying Documents Rt Re[prt (TPIA-Report & Weld) map

Acceptance Criteria

SOJV

OBI

SR

6.0 6.1

Final Inspection (Fabrication) Final Inspection Visual Inspection Dimensional check

Before Painting

Check for dimension, tolerance, orientation, depth, camber, holes positions, distortion, straightness, Erection marks, etc & confirming to AISC "Code of Standards Practice for steel Buildings Section 6,6.4. Weld visual for surface holes, cracks, Undercut, Confirming to AWS D 1.12004 Section 6.9, Table 6.1 As per SSpc-sp 14/ NACE No.8 For AESS confirming with SSPC SP-6

Dimension Reports (25045-A1000-18ITR-S-005) (TPIA Endorsement on all fabrication Records)

SR

7.0 7.1

Sand blasting and Primer Painting Surface Preparation by Shot / Grit Blasting

Spec-05120, part 2.7 For AESS-Spec-09805 part 3.2.A.1

Each Fabricated component inspection

Paint Report (25045-A1000-18ITR-S-006)

SR

Inspection H-Hold Point : Written notification required. Contractor may not proceed beyond this point without written confirmation of the Engineer

W - Witness : Written notification required but Contractor may not proceed if OBI do not attend

S - Surveillance : No notification required but activity may be subjected to OBI Surveillance/ Monitoring

R - Review : Record/ Document review

8/28

NDIA New Doha International Airpoet Project

INSPECTION AND TEST PLAN FOR FABRICATION OF MISCELLANEOUS STRUCTURAL STEEL WORKS

Contract No.:

25045-000FC1-maht-00018

Discipline: Structural Activity No.: 7.2 Primer Paint Application & Inspection Activity Description

Contract Title: Passenger Terminal Complex CCP-18 Reference Procedure/Method Statements/Specs. : Spec 05120, 05060. Controlling Document Spec-05120, part 2.3,2.7 For AESS-Spec-09805 part 2.3 Each Batch random inspection Frequency

ITP No.

25045-A1126-18-ITP-S-027

Issue date ;

Rev. no : 2 Page: 6 of 6 Inspection*

QAP No.25145-A1000-18-GQA-S-001 Rev.0, Verifying Documents Check for Surface cleaning, Atmosphere conditions (Temperatures & Humidity), recommended maerials, Dry Film Thickness (DFT not less than 38) and confirming with Manufacturer's recommendations. For AESS primer DFT (76 12.7 ) Keep steel members off ground and spaced using pallets, dunnage, or other supports and spacers. Paint report (DFT) (25045-A1000-18ITR-S-006)

SSI/C

Acceptance Criteria

TPIA (NDT)

SOJV

OBI

TPIA (BOI)

SR

8.0

Final Inspection (Before Packing )

Inspection H-Hold Point : Written notification required. Contractor may not proceed beyond this point without written confirmation of the Engineer

W - Witness : Written notification required but Contractor may not proceed if OBI do not attend

S - Surveillance : No notification required but activity may be subjected to OBI Surveillance/ Monitoring

R - Review : Record/ Document review

9/28

INSPECTION REQUEST INSPECTION REQUEST NUMBER: CONTRACT NO: DRAWING NO: CONTRACTOR NAME: DATE: REPORT NO:

AREA / LOCATION / SUBJECT :

TYPE OF INSPECTION MATERIAL PAINTING FIT UP SURVEY WELDING FINAL INSPECTION NDT OTHER

DATE & TIME INSPECTION REQUIRED: CONTRATOR : RECEVIED BY : REPLY Approved DATE & TIME : DATE & TIME : Approved as noted Not Approved

SUB CON QC REP:

( PRINT NAME AND SIGN )

DATE:

SUB CONTRACTOR QC REP:

( PRINT NAME AND SIGN )

DATE:

OBI REP:

WITNESS & REVIEW ( PRINT NAME AND SIGN ) ONLY REVIEW

DATE:

Document No: 25045-A1126-18-ITR-S-001

10/28

Material Receiving Report

11/28

MATERIAL RECEIVING REPORT (RAW STEEL MATERIALS)

CONTRACT NO. CP - 18 CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. PROJECT : NEW DOHA INTERNATIONAL AIRPORT AREA : LOCATION : SIAM STEEL BANGNA FACTORY STORAGE AREA : SIAM STEEL BANGNA FACTORY YARD Weight Material Item No. Qty. Manufacturer Heat No. (kgs.) Specification Description DATE : REPORT NO. : SHEET NO. : Mill Test Date Certificate No. Received

Delivery Order No.

REMARKS : CONTRACTOR QC REPRESENTATIVE : DATE :

________________________________________________________________

(PRINT NAME AND SIGN)

SOJV QC REPRESENTATIVE :

DATE :

________________________________________________________________

(PRINT NAME AND SIGN)

OBI REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

__________________________________________________

WITHNESS & REVIEW ONLY REVIEW

Document No. : 25045-A1126-18-ITR-S-001,ForM a

12/28

Marking, Cutting and Drilling (Material Identification and Traceability)

13/28

MATERIAL IDENTIFICATION AND TRACEABILITY REPORT

INSPECTION REQUEST NO.: CONTRACT NO. CP - 18 PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : Item Part No./Mark No. AREA : STRUCTURE TYPE : Material Specification DRAWING NO.: Heat No. Mill Test Certificate No. Marking/ Cutting DATE : CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. REPORT NO. : SHEET NO. : LOCATION : SIAM STEEL BANGNA FACTORY

Description

Qty.

CONTRACTOR QC REPRESENTATIVE :

DATE :

_________________________________________________________________________

(PRINT NAME AND SIGN)

SOJV QC REPRESENTATIVE :

DATE :

_________________________________________________________________________

(PRINT NAME AND SIGN)

OBI REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

_________________________________________________________

WITHNESS & REVIEW ONLY REVIEW

Document No. : 25045-18-ITR-S-002

14/28

Fit-Up Inspection

15/28

FIT- UP INSPECTION REPORT (WELD GROOVE)

INSPECTION REQUESTNO.: CONTRACT NO. CP - 18 CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : STRUCTURE TYPE : WELD JOINT KEYPLAN : DATE : REPORT NO. : SHEET NO. : AREA : LOCATION : SIAM STEEL BANGNA FACTORY DRAWING NO. :

(SEE ATTACHED SHEETS)

LEGEND: F = FILLTE WELD

P = PARTIAL PENETRATION WELD

C = COMPLETE PENETRATION WELD

Joint No. Root Gap

Root Face

Groove Angle

Remark

Joint No.

Root Gap

Root Face

Groove Angle

Remark

CONTRACTOR QC REPRESENTATIVE :

DATE :

__________________________________________________________

(PRINT NAME AND SIGN)

SOJV QC REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

OBI REPRESENTATIVE : DATE : WITNESS &REVIEW ONLY REVIEW

Document No. :25045-A1126-18-ITR-S-003

______________________________

(PRINT NAME AND SIGN)

16/28

FIT- UP INSPECTION REPORT (WELD GROOVE)

INSPECTION REQUESTNO.: CONTRACT NO. CP - 18 CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : STRUCTURE TYPE : WELD JOINT KEYPLAN : DATE : REPORT NO. : SHEET NO. : AREA : LOCATION : SIAM STEEL BANGNA FACTORY DRAWING NO.

(SEE ATTACHED SHEETS)

LEGEND: F = FILLTE WELD

P = PARTIAL PENETRATION WELD

C = COMPLETE PENETRATION WELD

PIECE MARK

DRAWING NO.

REV.

Joint No.

Root Gap

Root Face

Groove Angle

Remark

CONTRACTOR QC REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

SOJV QC REPRESENTATIVE : DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

OBI REPRESENTATIVE : DATE : WITNESS &REVIEW ONLY REVIEW

Document No. :25045-A1126-18-ITR-S-003,Form b

______________________________

(PRINT NAME AND SIGN)

17/28

Weld Visual Inspection (VT)

18/28

19/28

20/28

WELD VISUAL INSPECTION REPORT

INSPECTION REQUESTNO.: CONTRACT NO. CP - 18 CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : STRUCTURE TYPE : DRAWING NO. : Joint No. WPS No. Welding Process Welder Id No. Marking / Cutting Report No. Fit-Up Report No. Visual DATE : REPORT NO. : SHEET NO. : AREA : LOCATION : SIAM STEEL BANGNA FACTORY MATERIAL SPECIFICATION:

VASUAL INSPECTION SUMMARY (As per AWS D1.1/D1.1M:2006 Sectuib 6.9, Tavle 6.1): Item No. Inspection Category Result Item No. Inspection Category Result

OTHER REMARKS (IF ANY): Refer to attached weld joint keyplan

CONTRACTOR QC REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

SOJV QC REPRESENTATIVE : DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

OBI REPRESENTATIVE : DATE : WITNESS &REVIEW ONLY REVIEW

Document No. : 25045-A1126-18-ITR-S-004

______________________________

(PRINT NAME AND SIGN)

21/28

Final Inspection

22/28

FINAL INSPECTION REPORT

(VISUAL INSPECTION & SUMMARY OF INSPECTION REPORTS)

INSPECTION REQUEST NO.: CONTRACT NO.: CP-18 CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : STRUCTURE TYPE: MATERIAL SPECIFICATION: ASTM A572 Grade 50 DATE : REPORT NO. : SHEET NO. : AREA : LOCATION : SIAM STEEL BANGNA FACTORY DRAWING No.:

INSPECTION REPORTS SUMMARY

Description

ITP Activity No.

Inspection Report No.

INSPECTION RESULT:

OTHER REMARKS (IF ANY):

CONTRACTOR QC REPRESENTATIVE :

DATE :

__________________________________________________________

(PRINT NAME AND SIGN)

TPIA REPRESENTATIVE

DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

SOJV QC REPRESENTATIVE : DATE :

(PRINT NAME AND SIGN)

__________________________________________________________

OBI REPRESENTATIVE : DATE : WITNESS &REVIEW ONLY REVIEW

Document No. : 25045-A1126-18-ITR-S-005

______________________________

(PRINT NAME AND SIGN)

23/28

FINAL INSPECTION REPORT

(VISUAL INSPECTION & SUMMARY OF INSPECTION REPORTS)

INSPECTION REQUEST NO.: CONTRACT NO.: CP-18 CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : STRUCTURE TYPE: MATERIAL SPECIFICATION: ASTM A572 Grade 50 DATE : REPORT NO. : SHEET NO. : AREA : LOCATION : SIAM STEEL BANGNA FACTORY DRAWING No.:

Non-Destructive Examination (NDE) Report Summary Ultrasonic Testing (UT) Radiographic Testing (RT) Magnetic Particle Testing (MT)

Document No. : 25045-A1126-18-ITR-S-005, form b

24/28

Dimensional Inspection (Pre-Fit up)

25/28

DIMENSIONAL INSPECTION REPORT (SINGLE PRODUCT)

INSPECTION REQUEST NO.: CONTRACT NO. CP - 18 PROJECT : NEW DOHA INTERNATIONAL AIRPORT STRUCTURE TYPE: L1 PIEXE MARK DD (mm) e2 DD (mm) 4-6ARCH1 DD (mm) E

(mm)

DATE : CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. AREA : DRAWING NO.: L2 E (mm) B1 DD (mm) E (mm) B13 DD (mm) DD (mm) E (mm) B2 E (mm) B14 E (mm) DD (mm) E (mm) DD (mm) DD (mm) DD (mm) B3 E (mm) B15 E (mm) DD (mm) DD (mm) L3 E (mm) DD (mm) B4 E (mm) B16 E (mm) DD (mm) DD (mm) L4 E (mm) DD (mm) B5 E (mm) B17 E (mm) DD (mm) DD (mm) L5 E (mm) B6 E (mm) B18 E (mm) DD (mm) DD (mm) DD (mm) H1 E (mm) B7 E (mm) B19 E (mm) DD (mm) DD (mm) DD (mm) B8 E (mm) B20 E (mm) DD (mm) DD (mm) H2 E (mm) DD (mm) B9 E (mm) B21 E (mm) DD (mm) REPORT NO. : SHEET NO. : LOCATION : SIAM STEEL BANGNA FACTORY H3 E (mm) DD (mm) H4 E (mm) DD (mm) e1 E (mm)

B10 E (mm) B22 DD E DD DD

B11 E (mm) (mm)

B12 E (mm) DD

B23 E (mm)

(mm)

(mm) (mm) (mm) B34

B24 DD (mm) LEGEND: E (mm) DD

B25 E (mm) DD (mm)

B26 E (mm) DD (mm)

B27 E (mm) DD (mm)

B28 E (mm) DD (mm)

B29 E (mm) DD (mm)

B30 E (mm) DD (mm)

B31 E (mm) DD (mm)

B32 E (mm) DD (mm)

B33 E (mm) (mm)

B35 E DD E (mm)

DD

(mm) (mm) (mm)

SUBCONTRACTOR QC REPRESENTATIVE

DATE :

(PRINT NAME AND SIGN)

_________________________________________________________________________

SOJV QC REPRESENTATIVE : DATE :

_________________________________________________________________________

(PRINT NAME AND SIGN)

OBI REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

________________________________________________________________

WITHNESS & REVIEW ONLY REVIEW

Document No. : 25045-A1126-18-ITR-S-005,Form C

26/28

Painting Inspection

27/28

PAINTING INSPECTION REPORT

INSPECTION REQUEST NO.: CONTRACT NO. CP - 18 PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : Surface Preparation: Sa 2.5 Paint Specification: 25045-a1100-18-ssd-s-xxxx Paint Material: Primer Coat DFT (microns) Gage Readings Average 1st 2nd 3rd AREA : STRUCTURE TYPE : No. of Coats: Required DFT: 76 microns DRAWING NO.: Blasting & Painting Date: Ambient Te,perature ( C) Weather : Steel Temperature ( C) Dew Point (C) Primer Coat DFT (microns) Gage Readings 2nd 3rd DATE : CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. REPORT NO.: SHEET NO.: LOCATION : SIAM STEEL BANGNA FACTORY

Spot No.

Spot No.

Relative Humidity (%): Primer Coat DFT (microns) Gage Readings Average 1st 2nd 3rd

Spot No.

1st

Average

OTHER REMARKS (IF ANY): Note: Refer to Sheet 3 of 3 for DFT Spot Measuring Keyplan.

CONTRACTOR QC REPRESENTATIVE :

DATE :

____________________________________________________________________________

(PRINT NAME AND SIGN)

SOJV QC REPRESENTATIVE :

DATE :

_____________________________________________________________________________

(PRINT NAME AND SIGN)

OBI REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

________________________________________________________________ WITHNESS &

REVIEW ONLY REVIEW

Document No. : 25045-A1126-18-ITR-S-006

28/28

PAINTING INSPECTION REPORT

INSPECTION REQUEST NO.: CONTRACT NO. CP - 18 PROJECT : NEW DOHA INTERNATIONAL AIRPORT PIECE MARK : Surface Preparation: Sa 2.5 Paint Specification: 25045-a1100-18-ssd-s-xxx Paint Material: AREA : STRUCTURE TYPE : No. of Coats: One (1) Required DFT: 76 microns DRAWING NO.: Blasting & Painting Date: Ambient Te,perature (C) Relative Humidity (%): Primer Coat DFT (microns) Gage Readings Spot No. Average 1st 2nd 3rd Weather : Steel Temperature (C) Dew Point (C) Average DFT (microns) Inspection Result DATE : CONTRACTOR NAME : SIAM STEEL INTERNATIONAL PLC. REPORT NO.: SHEET NO.: LOCATION : SIAM STEEL BANGNA FACTORY

Item No.

Piece Mark

Drawing No.

Rev.

CONTRACTOR QC REPRESENTATIVE :

DATE :

____________________________________________________________________________

(PRINT NAME AND SIGN)

SOJV QC REPRESENTATIVE :

DATE :

_____________________________________________________________________________

(PRINT NAME AND SIGN)

OBI REPRESENTATIVE :

DATE :

(PRINT NAME AND SIGN)

________________________________________________________________

WITHNESS & REVIEW ONLY REVIEW

Document No. : 25045-A1126-18-ITR-S-006,form b

Anda mungkin juga menyukai

- 026-Itp For Structural Steel PDFDokumen18 halaman026-Itp For Structural Steel PDFKöksal Patan100% (11)

- Inspection Test Plan For Fabrication & Erection 2016Dokumen14 halamanInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Dokumen10 halamanQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- Inspection and Testing PlanDokumen7 halamanInspection and Testing PlanStephen David Gozun50% (2)

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDokumen7 halamanINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- 3.0 Inspection & Test PlanDokumen10 halaman3.0 Inspection & Test PlanAbdul Hakam Mohamed Yusof80% (5)

- Inspection Test Plan - SampleDokumen12 halamanInspection Test Plan - SampleZaheedManooBelum ada peringkat

- Inspection and Test Plan For Steel StrucDokumen6 halamanInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Inspection Test Plan For Civil Works Rev 01Dokumen22 halamanInspection Test Plan For Civil Works Rev 01Eze Nonso50% (2)

- Inspection and Test PlantDokumen121 halamanInspection and Test PlantMajid Dixon89% (9)

- Inspection and Test ProcedureDokumen8 halamanInspection and Test Proceduregaehdd1100% (1)

- Inspection Test Plan - Piping FabricationDokumen5 halamanInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Inspection and Test Plan ConcreteDokumen2 halamanInspection and Test Plan ConcreteStephen Vivek100% (10)

- Inspection and Test Plan For Structure Steel Erection WorksDokumen11 halamanInspection and Test Plan For Structure Steel Erection WorksVijaya BaraniBelum ada peringkat

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDokumen5 halamanOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanBelum ada peringkat

- QC Inspection and Test PlanDokumen9 halamanQC Inspection and Test PlanGK VISWANATH100% (3)

- Inspection and Test Plan For PC Sheet PileDokumen5 halamanInspection and Test Plan For PC Sheet PileNgọc Đức Đoàn100% (2)

- Inspection Test PlanDokumen2 halamanInspection Test PlanBalaji Guru90% (10)

- Qa-Qc Quality PlanDokumen60 halamanQa-Qc Quality PlanNaveed Ahmed Get-Info94% (17)

- Inspection Test PlanDokumen3 halamanInspection Test PlanSharique Ali50% (2)

- Inspection Test PlanDokumen7 halamanInspection Test PlanWalha Wassim100% (1)

- B11 Living Quarters Quality Plan ProceduresDokumen24 halamanB11 Living Quarters Quality Plan ProceduresAbdul Hakam Mohamed Yusof100% (6)

- Sample QC Inspection and Test PlanDokumen9 halamanSample QC Inspection and Test PlanMDS Mohamed100% (3)

- Inspection and Test Plan - Fencing C-015Dokumen2 halamanInspection and Test Plan - Fencing C-015Furqan100% (1)

- QAQC Plan for Structural Steel Works at Al Maha CenterDokumen40 halamanQAQC Plan for Structural Steel Works at Al Maha Centerashraf100% (3)

- Inspection Test Plan For FabricationDokumen4 halamanInspection Test Plan For FabricationAshwani Dogra100% (9)

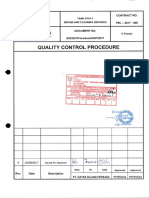

- Quality Control Procedure SampleDokumen12 halamanQuality Control Procedure Samplepocharquitecturaromania92% (50)

- Inspection & Test PlanDokumen19 halamanInspection & Test Planaszliza100% (1)

- Inspection and Testing Plan for Mechanical & Electrical WorksDokumen3 halamanInspection and Testing Plan for Mechanical & Electrical WorksAlex Deru50% (2)

- ITP Structural SteelDokumen14 halamanITP Structural SteelNavneet SinghBelum ada peringkat

- (A358) Inspection Test Plan - Rev.d - 130514Dokumen5 halaman(A358) Inspection Test Plan - Rev.d - 130514Ronny AjaBelum ada peringkat

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsDokumen5 halamanPreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Civil ItpDokumen60 halamanCivil ItpBiswas100% (1)

- Submittal ProceduresDokumen15 halamanSubmittal ProceduresAnonymous swFolM3gXBelum ada peringkat

- Typical Project Quality Plan & ITP CPCDokumen15 halamanTypical Project Quality Plan & ITP CPCnice guy100% (1)

- Project Inspection Test Plan Steel StructureDokumen47 halamanProject Inspection Test Plan Steel StructureMohammed Ady Ganjar100% (4)

- Itp For Steel Structure Erection (Content) Rev.1Dokumen3 halamanItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Dokumen34 halaman9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- Project Quality Plan - For SatropDokumen22 halamanProject Quality Plan - For Satropvinothkumar100% (3)

- X6 Structural Steel Erection Inspection Test PlanDokumen11 halamanX6 Structural Steel Erection Inspection Test PlanNoor A Qasim100% (1)

- Project Quality Assurance PlanDokumen17 halamanProject Quality Assurance PlanJOSHUA SULLEGUE100% (7)

- Drainage Work - Inspection Test Plan - ITPDokumen4 halamanDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- Inspection and Test Plan (Itp)Dokumen20 halamanInspection and Test Plan (Itp)المهندس محمد الزواهرة Eng Mohummed Al-zawhreh100% (2)

- QC-QA PlanDokumen22 halamanQC-QA Planfaisal ahmad100% (1)

- Inspection Test PlanDokumen3 halamanInspection Test PlanMathivanan Anbazhagan100% (2)

- Inspection and Test Procedure and Plan Rev 0 Commented by HDECDokumen16 halamanInspection and Test Procedure and Plan Rev 0 Commented by HDECarchalys4u100% (4)

- Understanding Inspection and Test Plan-UpDokumen15 halamanUnderstanding Inspection and Test Plan-UpAniruddha Kulkarni100% (2)

- 4.itp For Instrumentation & ControlDokumen10 halaman4.itp For Instrumentation & ControlJoel Alcantara75% (4)

- CONTRACT NO. TANK D101-1 REPAIR AND CLEANING QC PROCEDUREDokumen6 halamanCONTRACT NO. TANK D101-1 REPAIR AND CLEANING QC PROCEDUREAndreas Schlager100% (3)

- Request For InspectionDokumen1 halamanRequest For Inspection알안젤로Belum ada peringkat

- ITP For Steel Structure1Dokumen3 halamanITP For Steel Structure1吴兴泊Belum ada peringkat

- Inspection & Test Plan for Fire Fighting System Pipe FabricationDokumen7 halamanInspection & Test Plan for Fire Fighting System Pipe Fabricationjiturit33% (3)

- Iconn Ud DD 047047Dokumen6 halamanIconn Ud DD 047047williamjdtBelum ada peringkat

- ITP For LpseperatorDokumen2 halamanITP For LpseperatorRichard PeriyanayagamBelum ada peringkat

- Itp Non AsmeDokumen7 halamanItp Non AsmeAkhilesh Kumar100% (1)

- AGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dokumen49 halamanAGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dilshad Ahemad100% (2)

- Inspection Request Form For Post-Tensioning WorkDokumen2 halamanInspection Request Form For Post-Tensioning WorkWr ArBelum ada peringkat

- Repair Procedure ANNEXUREDokumen16 halamanRepair Procedure ANNEXUREShaikh AdilBelum ada peringkat

- ITP For Piping WorksDokumen3 halamanITP For Piping WorksOrlando1949100% (3)

- Method Statement For Cable Installation WorksDokumen40 halamanMethod Statement For Cable Installation WorksParimalazhagan Muthukaruppan94% (18)

- 7950 - W1A (FF) - W1B (SF) - Slab Loading Test - Structural Report - Rev - 1Dokumen13 halaman7950 - W1A (FF) - W1B (SF) - Slab Loading Test - Structural Report - Rev - 1mfvallegaBelum ada peringkat

- SCC - Efnarc FranceDokumen32 halamanSCC - Efnarc FrancefernandoBelum ada peringkat

- Basic Geotechnical InvestigationDokumen3 halamanBasic Geotechnical InvestigationmfvallegaBelum ada peringkat

- MSDS - Sikagard 65 WN B SpainDokumen12 halamanMSDS - Sikagard 65 WN B SpainmfvallegaBelum ada peringkat

- Section 9 Asphalt Pavement RecyclingDokumen10 halamanSection 9 Asphalt Pavement RecyclingAmritha SunnyBelum ada peringkat

- Expression of Interest: Skilled Migrant CategoryDokumen36 halamanExpression of Interest: Skilled Migrant CategorymfvallegaBelum ada peringkat

- Memo in Motion For ContemptDokumen118 halamanMemo in Motion For ContemptMark SternBelum ada peringkat

- Lesson 2 - Social Networking For BusinessDokumen41 halamanLesson 2 - Social Networking For BusinessFranco SanPedroBelum ada peringkat

- Willie Chee Keong Tan - Research Methods (2018, World Scientific Publishing Company) - Libgen - Li PDFDokumen236 halamanWillie Chee Keong Tan - Research Methods (2018, World Scientific Publishing Company) - Libgen - Li PDFakshar pandavBelum ada peringkat

- Soft SkillsDokumen117 halamanSoft Skillskiran100% (1)

- SISU Datenblatt 7-ZylDokumen2 halamanSISU Datenblatt 7-ZylMuhammad rizkiBelum ada peringkat

- Mercedes B-Class Accessories ListDokumen34 halamanMercedes B-Class Accessories ListmuskystoatBelum ada peringkat

- Fayol's Principles in McDonald's ManagementDokumen21 halamanFayol's Principles in McDonald's Managementpoo lolBelum ada peringkat

- Wyckoff e BookDokumen43 halamanWyckoff e BookIan Moncrieffe95% (22)

- SolidEdge MachineryLibrary V15.00Dokumen139 halamanSolidEdge MachineryLibrary V15.00ttBelum ada peringkat

- Make $50 A Day Autopilot MethodDokumen4 halamanMake $50 A Day Autopilot MethodJadon BoytonBelum ada peringkat

- Constitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Dokumen3 halamanConstitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Mukesh ShuklaBelum ada peringkat

- 2012 NAPTIN DocumentDokumen48 halaman2012 NAPTIN DocumentbenaikodonBelum ada peringkat

- BR18 Mechanical Engineering Robotics Semester VIDokumen2 halamanBR18 Mechanical Engineering Robotics Semester VIPRAVEeBelum ada peringkat

- JAM 2020 Information Brochure: Admission to M.Sc., Joint M.Sc.-Ph.D., M.Sc.-Ph.D. Dual Degree and Integrated Ph.D. ProgrammesDokumen51 halamanJAM 2020 Information Brochure: Admission to M.Sc., Joint M.Sc.-Ph.D., M.Sc.-Ph.D. Dual Degree and Integrated Ph.D. ProgrammesVaibhav PachauleeBelum ada peringkat

- Salesforce Platform Developer 1Dokumen15 halamanSalesforce Platform Developer 1Kosmic PowerBelum ada peringkat

- Dues+&+Bylaws+Committee+Packet ICPI John@bestadmix Com Tholyfield@Dokumen52 halamanDues+&+Bylaws+Committee+Packet ICPI John@bestadmix Com Tholyfield@Greefield JasonBelum ada peringkat

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDokumen10 halamanBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaBelum ada peringkat

- DX DiagDokumen31 halamanDX DiagJose Trix CamposBelum ada peringkat

- November 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE StudentsDokumen19 halamanNovember 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE Studentssatish gordeBelum ada peringkat

- NPTEL Web Course On Complex Analysis: A. SwaminathanDokumen19 halamanNPTEL Web Course On Complex Analysis: A. SwaminathanMohit SharmaBelum ada peringkat

- Ts 391 IltDokumen5 halamanTs 391 IltFunnypoumBelum ada peringkat

- M88A2 Recovery VehicleDokumen2 halamanM88A2 Recovery VehicleJuan CBelum ada peringkat

- FFTW Installation On WindowsDokumen6 halamanFFTW Installation On WindowsDebora SchwarzBelum ada peringkat

- Jurisdiction of The Supreme CourtDokumen1 halamanJurisdiction of The Supreme CourtAnshul Yadav100% (1)

- Market & Industry Analysis CheckDokumen2 halamanMarket & Industry Analysis CheckAndhika FarrasBelum ada peringkat

- THE MEDIUM SHAPES THE MESSAGEDokumen56 halamanTHE MEDIUM SHAPES THE MESSAGELudovica MatildeBelum ada peringkat

- StarletDokumen16 halamanStarletMohsen SirajBelum ada peringkat

- Kj1010-6804-Man604-Man205 - Chapter 7Dokumen16 halamanKj1010-6804-Man604-Man205 - Chapter 7ghalibBelum ada peringkat

- EPA - Regulatory Impact AnalysisDokumen822 halamanEPA - Regulatory Impact AnalysisSugarcaneBlogBelum ada peringkat

- Identifying Community Health ProblemsDokumen4 halamanIdentifying Community Health ProblemsEmvie Loyd Pagunsan-ItableBelum ada peringkat

- Sharpie Art Workshop: Techniques & Ideas for Transforming Your WorldDari EverandSharpie Art Workshop: Techniques & Ideas for Transforming Your WorldPenilaian: 3 dari 5 bintang3/5 (16)

- One Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunDari EverandOne Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunPenilaian: 4 dari 5 bintang4/5 (25)

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingDari EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingBelum ada peringkat

- Drawing Mandalas: How to Create Beautiful, Intricate PatternsDari EverandDrawing Mandalas: How to Create Beautiful, Intricate PatternsBelum ada peringkat

- Celtic Line Drawing - Simplified InstructionsDari EverandCeltic Line Drawing - Simplified InstructionsPenilaian: 5 dari 5 bintang5/5 (4)

- Living Color: Painting, Writing, and the Bones of SeeingDari EverandLiving Color: Painting, Writing, and the Bones of SeeingPenilaian: 4 dari 5 bintang4/5 (4)

- Beginner's Guide To Procreate: Characters: How to create characters on an iPad ®Dari EverandBeginner's Guide To Procreate: Characters: How to create characters on an iPad ®3dtotal PublishingPenilaian: 4 dari 5 bintang4/5 (1)

- Let's Draw Flowers: A Creative Workbook for Doodling and BeyondDari EverandLet's Draw Flowers: A Creative Workbook for Doodling and BeyondBelum ada peringkat

- Beginner's Guide to Fantasy DrawingDari EverandBeginner's Guide to Fantasy Drawing3dtotal PublishingBelum ada peringkat

- Art Models SarahAnn031: Figure Drawing Pose ReferenceDari EverandArt Models SarahAnn031: Figure Drawing Pose ReferencePenilaian: 3 dari 5 bintang3/5 (4)

- Portrait Painting in Oil: 10 Step by Step Guides from Old Masters: Learn to Paint Portraits via Detailed Oil Painting DemonstrationsDari EverandPortrait Painting in Oil: 10 Step by Step Guides from Old Masters: Learn to Paint Portraits via Detailed Oil Painting DemonstrationsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesDari EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesPenilaian: 2 dari 5 bintang2/5 (12)

- The Illustrator's Guide To Procreate: How to make digital art on your iPadDari EverandThe Illustrator's Guide To Procreate: How to make digital art on your iPadBelum ada peringkat

- Oil & Acrylic Workshop: Classic and Contemporary Techniques for Painting Expressive Works of ArtDari EverandOil & Acrylic Workshop: Classic and Contemporary Techniques for Painting Expressive Works of ArtPenilaian: 5 dari 5 bintang5/5 (2)

- Art Models Paris015: Figure Drawing Pose ReferenceDari EverandArt Models Paris015: Figure Drawing Pose ReferencePenilaian: 3 dari 5 bintang3/5 (3)

- The Everything Drawing Book: From Basic Shape to People and Animals, Step-by-step Instruction to get you startedDari EverandThe Everything Drawing Book: From Basic Shape to People and Animals, Step-by-step Instruction to get you startedPenilaian: 3 dari 5 bintang3/5 (5)

- Celestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesDari EverandCelestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesPenilaian: 3.5 dari 5 bintang3.5/5 (6)

- Fundamentals of Character Design: How to Create Engaging Characters for Illustration, Animation & Visual DevelopmentDari EverandFundamentals of Character Design: How to Create Engaging Characters for Illustration, Animation & Visual Development3dtotal PublishingPenilaian: 5 dari 5 bintang5/5 (2)

- Jackie Shaw's Learn to Paint Flowers: A Step-by-Step Approach to Beautiful ResultsDari EverandJackie Shaw's Learn to Paint Flowers: A Step-by-Step Approach to Beautiful ResultsPenilaian: 5 dari 5 bintang5/5 (1)

- Art Models MonikaT013: Figure Drawing Pose ReferenceDari EverandArt Models MonikaT013: Figure Drawing Pose ReferencePenilaian: 2 dari 5 bintang2/5 (1)

- Art Models Jenni001: Figure Drawing Pose ReferenceDari EverandArt Models Jenni001: Figure Drawing Pose ReferencePenilaian: 5 dari 5 bintang5/5 (1)

- Just Draw Botanicals: Beautiful Botanical Art, Contemporary Artists, Modern MaterialsDari EverandJust Draw Botanicals: Beautiful Botanical Art, Contemporary Artists, Modern MaterialsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Art Models AnaIv309: Figure Drawing Pose ReferenceDari EverandArt Models AnaIv309: Figure Drawing Pose ReferencePenilaian: 3 dari 5 bintang3/5 (2)

- Generative Art: A practical guide using ProcessingDari EverandGenerative Art: A practical guide using ProcessingPenilaian: 4 dari 5 bintang4/5 (4)

- Drawing: Flowers: Learn to Draw Step-by-StepDari EverandDrawing: Flowers: Learn to Draw Step-by-StepPenilaian: 5 dari 5 bintang5/5 (2)