E 464023

Diunggah oleh

mapasabcDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

E 464023

Diunggah oleh

mapasabcHak Cipta:

Format Tersedia

Mitsubishi Heavy Industries Technical Review Vol. 46 No. 4 (Dec.

2009) 23

Study on Seismic Safety of the Small-bore Piping and Support System

KUNIHIKO SATO *1

MASATSUGU MONDE *2

DAISAKU HIRAYAMA *3

TAKUYA OGO *4

In Japan, according to the revised Regulatory Guide for Aseismic Design of Nuclear Power Reactor Facilities, September 2006, criteria of design basis earthquakes of Nuclear Power Reactor Facilities become more severe. Electric power companies were requested by the government to recheck (back-check) the seismic design of their nuclear power plants. Since seismic safety is one of the major key issues of nuclear power plant safety, it has been demonstrated that the nuclear piping and support system possesses large safety margins by various durability test reports for piping in ultimate conditions. Though knowledge of the safety margin has been accumulated from these reports, there are few seismic margin tests that both the piping and support structures show inelastic behavior in extremely high seismic excitation levels. In order to obtain the influences of inelastic behavior of the support structures to the whole piping system response when both piping and support structures show inelastic behavior, we examined seismic proving tests using E-Defense, which is the largest shaking table in the world and owned by the National Research Institute for Earth Science and Disaster Prevention. This paper introduces major results of the seismic shaking tests of the piping and support system.

|1. Introduction

Since the seismic design of the pipes and supports in nuclear power plants is based on the design yielding points, it has been considered that the piping and support system capacity has a large margin that has been demonstrated by old studies. Yet, still some technical uncertainties remain concerning the phenomenon when both piping and support structures show inelastic behavior in extremely high seismic excitation levels. The study is to comprehend the vibration characteristics (including inelastic properties) of the complete piping and support system under immense earthquake conditions, and verify the seismic margin. In addition it is part of the recheck (back-check) process for nuclear plant pipes. Pipes with a bore size of 4 and 2 inches, which are commonly used in nuclear power plants, and their corresponding supports were used in the tests. This article reports the vibration test results of the 4-inch pipes using E-Defense. Vibration tests of 2-inch pipes were executed using the shaking table in our Takasago Research Laboratory1, and it has been verified that they have sufficient seismic margin against design-basis earthquakes.

|2. Test

The support element test was conducted to obtain load-displacement characteristics, and seismic proving tests to obtain the inelastic response of the piping and support system vibration test aiming at examining the vibration characteristics of the relevant system by using a full-scale test model containing all elements such as pipes, supports, and fixtures.

*1 Deputy General Manager, Nuclear Energy Systems Engineering Center, Nuclear Energy Systems Headquarters *2 Takasago Research & Development Center, Technical Headquarters *3 Nuclear Plant Maintenance Engineering Department, Kobe Shipyard & Machinery Works *4 Nuclear Energy Systems Engineering Center, Nuclear Energy Systems Headquarters

Mitsubishi Heavy Industries Technical Review Vol. 46 No. 4 (Dec. 2009) 24

2.1

Support element test

The support element tests were designed to obtain the relationship between force and displacement at piping, when the seismic force loaded on piping support equipment consists of a U-bolt, support element, base plate and anchorage on a concrete base by confirming the behavior of the equipment until failure is attained. Figure 1 shows the outline drawing of a typical test specimen used in the element test. Figure 2 shows the simulation analysis model. Figure 3 shows load-displacement characteristics of support element test and simulation analysis. With respect to linear and second rigidities, the simulation analysis results are similar to the test results. The analysis model does not include concrete fixtures, but the end of anchor bolt is fixed.

Figure 1 support test model

Figure 2 FEM model of piping support The model imitates the welding part.

Figure 3 Load-displacement characteristics

2.2

Piping and support system vibration test

(1) Test model The model is a piping and support system with a piping bore of full-scale 100A, Sch40, which has elbows, a tee. Table 1 shows specification of test model. Figure 4 shows the piping and support system model. (2) Seismic wave Since the input excitation wave should cover the major mode of typical buildings of nuclear power plants in Japan. It was difficult to create the seismic wave of the wide-band target spectrum. So, we designed three successive waves. Input level of the seismic wave was controlled according to the purpose of test cases. Figures 5 and 6 show the basic excitation waves and response spectra, respectively.

Mitsubishi Heavy Industries Technical Review Vol. 46 No. 4 (Dec. 2009) 25

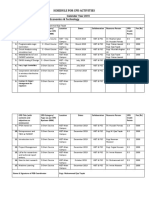

(3) Test cases Major test cases for each piping and support system are presented in Table 2. Test case 3, weights were added to the pipes to input a big seismic force that exceeds the vibration capacity of the shaking table. Test case 4, weights were added to the pipes and removal of five main supports to make the pipes and support system more sensitive to vibration, and applied vibration at the level to damage the pipes.

Table 1 specification of test model

Element Quantity Material Remarks Total length: Approx. 24 m Pipe 1 set 4B carbon steel Elbow: 9 ea. Tee: 1 ea. Nozzle: 3 places Internal fluid Support Total weight 16 ea. Approx. 80 t Water Internal pressure: 1.4 MPa

Cantilever type Expansion Anchor (with U-bolts) (including embedded type) Base mat size (10.4 m 6.4 m)

Figure 4 schematic view of test model

Figure 5 excitation waves

Figure 6 Response spectra of the excitation waves (horizontal direction)

Table 2 test case for piping and support system

Test case Case 1 Case 2 Case 3 Input level 2 2 2 Test model Test model A Test model A Test model B Remarks Applied vibration at the design earthquake level of the test model Amplified the acceleration of the S2 wave by 9 times. Amplified the response of the piping and support system with additional weights. The shaking waveform was adjusted (with the time axis) to the natural frequency of the piping system. Removed five main supports (supports 4,5,7,8,9) to make the pipes and Case 4 2 Test model C support system more sensitive to vibration, and applied vibration at a level to damage the pipes. *2: Design seismic wave of the test model

|3. Vibration Test Results for the Piping and Support System

(1) Outline of test results Table 3 lists the natural frequencies of the each test model sets. Figure 7 shows the vibration modes of these test model sets. The tee-branch portion is excited exclusively in the shaking direction on the first mode. The upper location (support 15) is dominant in the vertical direction on the second mode.

Mitsubishi Heavy Industries Technical Review Vol. 46 No. 4 (Dec. 2009) 26

Test case 1 is adjusted to the design acceleration (target: 1.47 m/s ) which is input. Test case 2 is adjusted to a level about 9 times as large as the design acceleration (target: 13.8 m/s2), which substantially exceeds the response acceleration (maximum: 6.8 m/s2) observed at the upper end of the foundations of TEPCOs Kashiwazaki-kariwa Nuclear Power Station during the Niigata Chuetsu-Oki Earthquake. Test case 3 has the additional weights to enlarge pipe displacement. Test case 4 has additional weights and support removal to generate larger pipe displacement. These test cases did not leak internal liquid from the piping, and the piping and the support system held the seismic margin more than 9 times as large as the design seismic wave.

Table 3 Natural frequencies of respective piping and support system

Natural frequency(Hz)

1st 2nd 3rd 4th

Remarks

Test model A 13.7 Test model B Test model C 6.3 3.5

16.6 10.9 9.6

25.8 15.6 13.5

28.1 Original test model Amplified the response of the 18.2 piping and support system with additional weights. 15.2 Five supports were removed.

Figure 7 Vibration modes of piping systems (test model A)

(2) Analysis and evaluation The test model did not break as a result of the test, because of the damping ratio generated higher than design damping ratio. The damping ratio of the piping and support system increases at the shaking level because of the increase mainly due to the wear of the U-bolt and the plastic deformation of support members. These vibration tests proved that the magnitude of the damping effect was an important element in assuming the ultimate state of pipes and supports and therefore, we conducted analyses on the relationship between response displacement and damping of the pipes based on test results. For test case 4 where the maximum response displacement was measured, we evaluated the inelastic behaviors of the pipe elbow based on the simulation analysis. (a) Response displacement and damping of pipes Table 4 shows the maximum response displacements summarized for each test case. Figure 8 shows the relationship between maximum displacement and damping. It has been proved that the damping ratio is enlarged with an increase in the vibration level, and a maximum damping ratio of about 9% is observed in test model A. The damping ratio is estimated by the half power method from the transmission function, which is derived from the horizontal acceleration to the vibration table, by the Auto Regression method with the duration of the largest response level.

Table 4 Maximum response displacement of the piping system (tee and elbow A are those shown in Figure 9)

Test case Max. displacement of Max. acceleration of piping and support system (at tee) the wave 1.46 m/s2 15.3 m/s2 7.96 m/s2 13.6 m/s2 1.7 mm 16.2 mm 51.7 mm 239.8 mm Support displacement (ductility ratio) Maximum Strain Notes No. 7 No. 8 No. 9 range of elbow A support support support 1.6 mm 1.3 mm 1.6 mm 0.01% Elastic range (0.12) (0.1) (0.12) 15.9 mm 9.1 mm 15.4 mm 0.04% (1.2) (0.68) (1.16) 50.3 mm 31.8 mm 46.6 mm 0.17% (3.78) (2.39) (3.5) 1.37%

1 2 3 4

Mitsubishi Heavy Industries Technical Review Vol. 46 No. 4 (Dec. 2009) 27

Figure 8 maximum response displacement and the damping ratio

(b) Inelastic behavior of the elbow The relations between the strain amplitude at the flank of the elbow outer surface and displacement amplitude of the piping system are obtained in Figure 9 for Elbow A by the analysis. The maximum displacement of the tee at the test case 4 is about 240 mm, which was measured by displacement sensor. Figure 10 show the maximum circumferential strain range of Elbow A is about 1.3 %. Figures 11 show the simulation result. The circumferential strain of the elbow generated under 240-mm displacement of the tee agrees with the test result of 1.3%. This means that we have succeeded in accurately obtaining the status of fatigue of the pipe elbow.

Figure 10 Local strain waveform at elbow A (test case 4)

Figure 9 Pipe elbow simulation analysis model

Figure 11 Relation between tee displacement and local strain of elbow A

Mitsubishi Heavy Industries Technical Review Vol. 46 No. 4 (Dec. 2009) 28

|4. Conclusion

The results of the study are summarized as follows: (1) By loading a repetitive force to the support element, we succeeded in verifying the behaviors and actual yield strength of the piping and support system during the period until the system lost the support function. (2) In the vibration test in which immense earthquake conditions were simulated, we succeeded in verifying the seismic safety of the small-bore piping and support system. (3) In the post-test simulation analysis and a later comparison between the test and simulation results, the simulation model excellently reproduced the inelastic behaviors actually observed. This result proves that the analytical method used is valid for simulating inelastic behaviors.

Acknowledgment

This study was entrusted to us by the Kansai Electric Power Co., Inc., Kyushu Electric Power Co., Inc., Shikoku Electric Power Co., Inc., Hokkaido Electric Power Co., Inc., and Japan Atomic Power Company. We received various advice and assistance from these companies, for which we would like to express our appreciation.

References

1. 2. E. Shirai et al., Inelastic test of the small bore piping and support system : Part 1, ASME PVP, 2008 E. Shirai et al., Inelastic test of the small bore piping and support system : Part 2, ASME PVP, 2008

Anda mungkin juga menyukai

- Models and Finite Elements For Thin-WalledDokumen25 halamanModels and Finite Elements For Thin-WalledmapasabcBelum ada peringkat

- Catalogue Pipe Hangers SupportsDokumen1 halamanCatalogue Pipe Hangers SupportsmapasabcBelum ada peringkat

- Tutorial MathCadDokumen12 halamanTutorial MathCadmapasabc0% (1)

- Reported Speech RulesDokumen4 halamanReported Speech RulesBenjamin StaffordBelum ada peringkat

- Stress Analysis of Piping SystemsDokumen108 halamanStress Analysis of Piping SystemsShijumon KpBelum ada peringkat

- M11PC00038 Final ReportDokumen63 halamanM11PC00038 Final ReportmapasabcBelum ada peringkat

- Fluid Estructure Interaction VerDokumen56 halamanFluid Estructure Interaction VermapasabcBelum ada peringkat

- 577AADokumen231 halaman577AAmapasabcBelum ada peringkat

- 5.0 Modeling For Analysis 5.1 Structural Boundaries: Seismic Design and Retrofit of Piping SystemsDokumen5 halaman5.0 Modeling For Analysis 5.1 Structural Boundaries: Seismic Design and Retrofit of Piping SystemsmapasabcBelum ada peringkat

- Iso 3183-3 1999Dokumen60 halamanIso 3183-3 1999mapasabcBelum ada peringkat

- IPENZ PN19-SeismicResistancePressureEquipmentFinalDokumen138 halamanIPENZ PN19-SeismicResistancePressureEquipmentFinalnikhil0104Belum ada peringkat

- Ocean Bottom Seismometer - Estimate of Costs: ConsumablesDokumen2 halamanOcean Bottom Seismometer - Estimate of Costs: ConsumablesmapasabcBelum ada peringkat

- 6907Dokumen7 halaman6907Won JangBelum ada peringkat

- Chapter 5 - Momentum Equation and Its ApplicationsDokumen33 halamanChapter 5 - Momentum Equation and Its ApplicationsmapasabcBelum ada peringkat

- c2TR Version 5.10 CAESAR II Technical Reference ManualDokumen634 halamanc2TR Version 5.10 CAESAR II Technical Reference Manualmapasabc100% (1)

- Slug Flow AnalysisDokumen32 halamanSlug Flow AnalysisSachin Chavan100% (3)

- Transfer piping loads from AutoPIPE to STAAD.ProDokumen21 halamanTransfer piping loads from AutoPIPE to STAAD.Promapasabc100% (1)

- Sensors 12 03693 Tabla ResumenDokumen27 halamanSensors 12 03693 Tabla ResumenmapasabcBelum ada peringkat

- Cable - Pulling Edsa ManualDokumen48 halamanCable - Pulling Edsa Manualmapasabc100% (3)

- Recommendations For Maritime Works: SE IE S 0Dokumen2 halamanRecommendations For Maritime Works: SE IE S 0mapasabcBelum ada peringkat

- BestPracticesGuide 10 EDokumen6 halamanBestPracticesGuide 10 EmapasabcBelum ada peringkat

- AutoCAD MEP Piping EssentialsDokumen2 halamanAutoCAD MEP Piping EssentialsmapasabcBelum ada peringkat

- GrooveDokumen10 halamanGroovemapasabcBelum ada peringkat

- Ch17 SectionI-R3Dokumen119 halamanCh17 SectionI-R3mapasabcBelum ada peringkat

- I JR Te 0106030035Dokumen6 halamanI JR Te 0106030035mapasabcBelum ada peringkat

- I JR Te 0105001004Dokumen4 halamanI JR Te 0105001004mapasabcBelum ada peringkat

- Ch17 SectionI-R3Dokumen119 halamanCh17 SectionI-R3mapasabcBelum ada peringkat

- Buckling Strength of Shells: Recommended Practice DNV-RP-C202Dokumen21 halamanBuckling Strength of Shells: Recommended Practice DNV-RP-C202Rodrigo SouzaBelum ada peringkat

- Design and Installation of Buried PipesDokumen2 halamanDesign and Installation of Buried PipesmapasabcBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Full ThesisDokumen145 halamanFull ThesisMd. Shofiul IslamBelum ada peringkat

- 06-2 QCS 2014Dokumen25 halaman06-2 QCS 2014Raja Ahmed Hassan100% (6)

- General Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Dokumen10 halamanGeneral Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Ryan SutherlandBelum ada peringkat

- Village Restaurant Floor PlansDokumen6 halamanVillage Restaurant Floor Planslilama45-1Belum ada peringkat

- List of Engineering CollegesDokumen6 halamanList of Engineering CollegesHarsh TiwariBelum ada peringkat

- 89TDokumen5 halaman89Tmorheno2k6594Belum ada peringkat

- Flyer Sheet MetalDokumen8 halamanFlyer Sheet MetalBG2012Belum ada peringkat

- Value Analysis and Value Engineering: by - Ravishankar K SrescoeDokumen31 halamanValue Analysis and Value Engineering: by - Ravishankar K SrescoeThiru TrishBelum ada peringkat

- Catalog BECDokumen23 halamanCatalog BECGCRIADHBelum ada peringkat

- CIVE 437 - Syllabus 2023 FallDokumen2 halamanCIVE 437 - Syllabus 2023 FallAtifBelum ada peringkat

- NICET Sprinkler ManualDokumen20 halamanNICET Sprinkler ManualTroy S. Thomas100% (2)

- 3 Holes-Uni Hydraulic Piston Pumps: Pump Type Code Pressure Max Speed WeightDokumen4 halaman3 Holes-Uni Hydraulic Piston Pumps: Pump Type Code Pressure Max Speed Weightrodolfo rodríguezBelum ada peringkat

- Conveyors and ChutesDokumen2 halamanConveyors and ChutesGanesan Balraj50% (2)

- Assessment Rubrics for ThermodynamicsDokumen16 halamanAssessment Rubrics for Thermodynamicstaufiqishak09Belum ada peringkat

- Drehgeber Übersicht - en - Web PDFDokumen44 halamanDrehgeber Übersicht - en - Web PDFRăzvan PopaBelum ada peringkat

- Maintenance Culture: Mama Cass Restaurants LimitedDokumen22 halamanMaintenance Culture: Mama Cass Restaurants LimitedOsagie AlfredBelum ada peringkat

- Practical Analysis and DesignDokumen570 halamanPractical Analysis and DesignAaron A AshBelum ada peringkat

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTDokumen7 halamanErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- Paf KietDokumen2 halamanPaf KietMaazHussainBelum ada peringkat

- Software Engineering Question BankDokumen6 halamanSoftware Engineering Question BankDr. A. Pathanjali Sastri100% (1)

- DH Series: Air Circuit BreakersDokumen4 halamanDH Series: Air Circuit BreakerskazishahBelum ada peringkat

- Design Criteria and Guidelines For Surface Infrastructure Mechanical and StructuralDokumen68 halamanDesign Criteria and Guidelines For Surface Infrastructure Mechanical and Structuraljonodo89Belum ada peringkat

- Re VistasDokumen1.236 halamanRe VistasDego MorenoBelum ada peringkat

- OOAD Lecture 3Dokumen12 halamanOOAD Lecture 3M AliBelum ada peringkat

- Analysis and Design of Shear WallDokumen30 halamanAnalysis and Design of Shear Wallteguh widayat100% (1)

- Cleanroom Software EngineeringDokumen2 halamanCleanroom Software EngineeringSameer ShahulBelum ada peringkat

- Combined Current List of Eligible Skilled OccupationsDokumen26 halamanCombined Current List of Eligible Skilled Occupationsapi-226054936Belum ada peringkat

- Customer Satisfaction Analysis in Four Wheeler Service CentreDokumen4 halamanCustomer Satisfaction Analysis in Four Wheeler Service CentreInternational Journal of Innovations in Engineering and ScienceBelum ada peringkat

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Dokumen405 halamanCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- Design of Tension MembersDokumen30 halamanDesign of Tension Memberssharer1Belum ada peringkat