Vanzetti Cryogenic Pumps & Technology Guide

Diunggah oleh

kanchanabalaji0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

682 tayangan0 halamanThis document provides information on cryogenic pumps and engineered systems produced by Vanzetti Engineering s.r.l. for air gases. It describes their line of reciprocating pumps in various sizes that can transfer liquids such as LIN, LOX, LAR, and LN2 at high pressures and flow rates. It also mentions their centrifugal submerged pumps and engineered pump skid systems for cryogenic applications.

Deskripsi Asli:

dd

Judul Asli

Cryo pump.pdf

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document provides information on cryogenic pumps and engineered systems produced by Vanzetti Engineering s.r.l. for air gases. It describes their line of reciprocating pumps in various sizes that can transfer liquids such as LIN, LOX, LAR, and LN2 at high pressures and flow rates. It also mentions their centrifugal submerged pumps and engineered pump skid systems for cryogenic applications.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

682 tayangan0 halamanVanzetti Cryogenic Pumps & Technology Guide

Diunggah oleh

kanchanabalajiThis document provides information on cryogenic pumps and engineered systems produced by Vanzetti Engineering s.r.l. for air gases. It describes their line of reciprocating pumps in various sizes that can transfer liquids such as LIN, LOX, LAR, and LN2 at high pressures and flow rates. It also mentions their centrifugal submerged pumps and engineered pump skid systems for cryogenic applications.

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 0

Vanzetti Engineering s.r.l.

Via Avv. Giovanni Agnelli, 10

12033 MORETTA (CN) ITALY

Tel. (+39) 0172 915811

Fax (+39) 0172 915822

www.vanzettiengineering.com

info@vanzettiengineering.com

www.vanzettiengineering.com

CRYOGENIC PUMPS

& ENGINEERED SYSTEMS

FOR AIR GASES

LIN LOX LAR LCO

2

LN

2

O

[

H

I

G

H

E

S

T

C

R

Y

O

G

E

N

I

C

P

E

R

F

O

R

M

A

N

C

E

]

[ HIGHEST CRYOGENIC PERFORMANCE ]

Vanzetti is the only Italian manufacturer of cryogenic components

such as reciprocating, centrifugal and submerged pumps speci-

cally designed for air gases industry.

Thanks to 20-years experience acquired in cryogenic and gas ap-

plications, the company has develop a cutting-edge, safe and ef-

cient range of components, which are appreciated and estemeed

world-wide.

Cryogenic pumps represent Vanzetti core production.

They are designed to assure highest exibility and easiest

employment. Tested with LIN prior to delivery, Vanzetti pumps are

offered also as engineered solutions, with pre-assembled skid ready

to be installed.

Air gases industry is denitely Vanzetti key business.

The Italian brand has been elected and appreciated for 20 years by

gas companies, international and local organisations thanks to the

high-quality components and successful installations developed

world-wide.

CRYOGENIC PUMPS

& TECHNOLOGY

FOR AIR GASES

SIAD - AUSTRIA RIVOIRA PRAXAIR - ITALY

AHG - SAUDI ARABIA

AIR LIQUIDE CZECH REP.

AIR LIQUIDE - FINLAND

WESTFALEN - GERMANY

AIR LIQUIDE - FINLAND

2 3

CRYOGENIC

RECIPROCATING PUMPS

CRYOGENIC

RECIPROCATING PUMPS

High pressure/Medium fow-rate High pressure/High fow-rate

MAIN FEATURES

Available MONO and DUPLEX

Oil crankdrive lubricated

Foot-mounted or skid-assembled congurations

Compatible either with Cold Converter and Thermosyphon storage

tanks

Quick maintenance thanks to a seal system integrated in the cartridge

Easy installation due to the 360 swinging gas inlets and outlets

Modular assembly

Low operating noise < 80 dBA

Customized electric control panel available on demand

Fully automated systems available on demand.

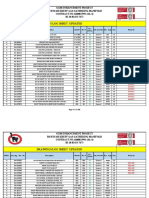

VT-1 PERFORMANCE

* at max delivery pressure

VT-55 PERFORMANCE

VT-1 VT-55

APPLICATIONS

Heavy-duty operations.

High pressure/high ow-rate cylinder and

buffer lling.

TRANSFERRED FLUIDS

LIN LOX LAR LCO

2

LN

2

O

APPLICATIONS

Cylinder and buffer lling

at high pressure.

TRANSFERRED FLUIDS

LIN LOX LAR LCO

2

LN

2

O

* at max delivery pressure

MAIN FEATURES

Available MONO to QUINTUPLEX

Oil crankdrive lubricated

Foot-mounted or skid-assembled

congurations

Compatible either with Cold Converter

and Thermosyphon storage tanks

Quick maintenance thanks to a seal

system integrated in the cartridge

Modular assembly

Low operating noise < 80 dBA

Customized electric control panel

available on demand

Fully automated systems available on

demand.

VT1 SERIES

32-36-40-45

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 80 rpm Max 450 rpm

[l/min] [gal/min] [l/min] [gal/min] [bar] [psi] [kW]

VT1 32 35 2,0 0,5 11,3 3,0 420 6090 4 - 22 TW 6,5

VT1 36 35 2,6 0,7 14,3 3,8 420 6090 5,5 - 30 TW 6,5

VT1 40 35 3,2 0,8 17,7 4,7 420 6090 5,5 - 30 TW 6,5

VT1 45 35 4,0 1,1 22,4 5,9 300 4350 7,5 - 30 TW 6,5

VT1-D 45 35 8,0 2,2 44,8 11,8 300 4350 15 - 60 TW 6,5

VT55 SERIES

58-62

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 80 rpm Max 450 rpm

[l/min] [gal/min] [l/min] [gal/min] [bar] [psi] [kW]

VT55 55 58 9,9 2,6 55,8 14,7 420 6090 18,5 - 110 TW10

VT55 55 62 10,6 2,8 59,7 15,8 420 6090 18,5 - 110 TW10

VT55-D 55 58 19,9 5,3 111,6 29,5 420 6090 30 - 160 TW10

VT55-D 55 62 21,2 5,6 119,3 31,5 420 6090 30 - 160 TW10

VT55-T 55 58 29,8 7,9 167,5 44,2 420 6090 45 - 250 TW10

VT55-T 55 62 31,9 8,4 179,0 47,3 420 6090 45 - 250 TW10

VT55-Q 55 58 49,6 13,1 279,0 73,7 420 6090 73 - 350 TW10

VT55-Q 55 62 53,0 14,0 299,0 79,0 420 6090 75 - 400 TW10

4 5

CRYOGENIC

RECIPROCATING PUMPS

CRYOGENIC

RECIPROCATING PUMPS

Medium pressure/High fow-rate High pressure/Medium fow-rate

MAIN FEATURES

Foot-mounted or skid-assembled

congurations

Compatible either with Cold Converter and

Thermosyphon storage tanks

Quick maintenance thanks to a seal system

integrated in the cartridge

Modular assembly

Low operating noise < 80 dBA

Customized electric control panel available on

demand

Fully automated systems available on demand.

VT-100 PERFORMANCE

VT-100

SERIES

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 80 rpm Max 350 rpm

[l/min] [gal/min] [l/min] [gal/min] [bar] [psi] [kW]

VT100 100 58 32,8 8,7 143,4 37,9 120 1740 18,5 - 73 TW10

VT100 100 62 35,1 9,3 153,5 40,5 120 1740 18,5 - 75 TW10

VT100-D 100 58 65,6 17,3 286,9 75,8 120 1740 30 - 132 TW10

VT100-D 100 62 70,1 18,5 306,7 81,0 120 1740 30 - 132 TW10

VT100-T 100 58 98,4 26,0 430,3 113,7 120 1740 45 - 200 TW10

VT100-T 100 62 105,2 27,8 460,0 121,5 120 1740 45 - 200 TW10

VT100-Q 100 58 164,0 43,3 717,2 189,5 120 1740 73 - 315 TW10

VT100-Q 100 62 175,3 46,3 766,7 202,5 120 1740 73 - 315 TW10

HP

APPLICATIONS

Cylinder and buffer lling at high

pressure.

TRANSFERRED FLUIDS

LIN LOX LAR

APPLICATIONS

Process and back-up

TRANSFERRED FLUIDS

LIN LOX LAR LCO

2

LN

2

O

HP

22-25-30-36-40

SERIES

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 150 rpm Max 420 rpm

[l/min] [gal/min] [l/min] [gal/min] [bar] [psi] [kW]

HP 22 20 1,0 0,3 2,9 0,8 420 6090 2,2 - 5,5 TW3

HP 25 20 1,3 0,4 3,7 1,0 420 6090 3 - 7,5 TW3

HP 25 32 2,0 0,5 6,1 1,6 420 6090 4 - 11 TW3

HP 30 20 1,8 0,5 5,3 1,4 300 4350 3 - 7,5 TW3

HP 30 32 2,9 0,8 8,8 2,3 300 4350 4 - 15 TW3

HP 36 20 2,6 0,7 7,9 2,1 300 4350 4 - 11 TW3

HP 36 32 4,2 1,1 13,5 3,6 300 4350 5,5 - 18,5 TW3

Min 120 rpm Max 450 rpm

HP 40 32 4,1 1,1 15,6 4,1 300 4350 5,5 22 TW6

HP 40 40 5,1 1,4 19,5 5,2 300 4350 7,5 30 TW6

HP 40 35 4,5 1,2 17,1 4,5 420 6090 11 30 TW6,5 (oil)

HP PERFORMANCE

* at max delivery pressure

MAIN FEATURES

Foot-mounted or skid-assembled congurations

Grease crankdrive lubricated (except from HP 40/35)

Compatible either with Cold Converter and Thermosyphon storage tanks

Low operating noise < 80 dBA

Customized electric control panel available on demand

Fully automated systems available on demand.

HP 65/80 PERFORMANCE

HP 65/80

SERIES

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 80 rpm Max 380 rpm

[l/min] [gal/min] [l/min] [gal/min] [bar] [psi] [kW]

HP 65 32 7,6 2,0 36,3 9,6 120 1740 4 - 18,5 TW6

HP 65 40 9,6 2,5 45,4 12,0 120 1740 5,5 - 22 TW6

HP 65 35 8,4 2,2 39,7 10,5 120 1740 4 - 22 TW6,5 (oil)

HP 80 32 11,6 3,1 55,0 14,5 120 1740 5,5 - 30 TW6

HP 80 40 14,5 3,8 68,7 18,2 120 1740 7,5 - 37 TW6

HP 80 35 12,7 3,3 60,2 15,9 120 1740 7,5 - 30 TW6,5 (oil)

* at max delivery pressure

VT-100

HP 65/80

6 7

CRYOGENIC

RECIPROCATING PUMPS

For CO

2

and N

2

O

MAIN FEATURES

Foot-mounted or skid-assembled congurations

Grease crankdrive lubricated

Modular assembly

Low operating noise < 80 dBA

Customized electric control panel available on demand

Fully automated systems available on demand.

HPH 40

SERIES

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 100 rpm Max 500 rpm

[l/min] [kg/h] [l/min] [kg/h] [bar] [psi] [kW]

HPH 40 20 2,1 134,8 10,7 637,5 120 1740 1,1 - 5,5 TW3A

HPH 40 32 3,4 215,5 17,1 1077,3 120 1740 2,2 - 9 TW3A

HPL 35/40

SERIES

PISTON

DIAMETER

STROKE

FLOW-RATE

DESIGN

PRESSURE

E.M. NOMINAL

POWER*

DRIVE TYPE Min 100 rpm Max 400 rpm

[l/min] [kg/h] [l/min] [kg/h] [bar] [psi] [kW]

HPL 35 13 1,1 66,8 4,4 278,5 120 1740 0,55 - 3 TW1,4

HPL 35 26 2,1 134,2 8,5 536,1 120 1740 1,1 - 5,5 TW1,4

HPL 40 13 1,4 87,6 5,8 363,5 120 1740 0,75 - 3 TW1,4

HPL 40 26 2,8 175,1 11,1 699,9 120 1740 1,5 - 7,5 TW1,4

* at max delivery pressure

APPLICATIONS

Cylinder lling

TRANSFERRED FLUIDS

LCO

2

LN

2

O

CENTRIFUGAL

SUbMERGEd PUMPS

ARTIKA SERIES

MAIN FEATURES

Available with 1, 2 or 4 stages

Cryostat vacuum insulated

FLOW-RATE: 30 to 1.300 l/min

H min/max: see attached

datasheet

MAX SUCTION PRESSURE: 20 bar

LOW MAINTENANCE due to the

seal-less pump concept.

MODEL

ARTIKA

160 - II

ARTIKA

160 - IV

ARTIKA

200 - II

ARTIKA

200-IV

ARTIKA

230-I

ARTIKA

230-II

N of stages 2 4 2 4 1 2

Transmission Direct with high frequency motor - VFD drive

Min - Max ow-rate Q (l/min) 30 430 30 430 60 640 60 640 100 1300 100 1300

Min - Max total differential head H (m) 53 280 106 560 96 445 192 890 46 99 91 198

Max suction pressure (bar) 20

ARTIKA PERFORMANCE

APPLICATIONS

Liquid storage transfer.

Truck, trailer and ISO container

loading/unloading.

Transfer boost-pump, back-up

and peak-shaving.

Suitable for continuous service or wherever

you need to frequently start and stop the

pump.

TRANSFERRED FLUIDS

LIN LAR

HPH HPL

HPH PERFORMANCE

HPL PERFORMANCE

8 9

CRYOGENIC

CENTRIFUGAL PUMPS

To transfer cryogenic fuids Pumps on-board

APPLICATIONS

Transfer of cryogenic uids between

storages.

Truck/trailer loading/unloading.

Vanzetti centrifugal pumps can be

supplied foot-mounted or on-skid

including all the required components

and accessories for the pump safe and

reliable running.

TRANSFERRED FLUIDS

LIN LOX LAR LCO

2

LN

2

O

SGM 185

SGM 185

[ Electric motor and gearbox ]

HGM 185

[ Hydraulic motor and gearbox ]

dSM 160 dSM 230

dSM 185

[ Electric motor and direct coupled ]

SGM185/dSM230

ON SKId

PERFORMANCE

MODEL SGM 160 SGM 185

TRANSMISSION GEARBOX

LUBRICATION MINERAL OIL

MIN MAX FLOW-RATE Q (l/min) 45 540 85 910

MIN MAX TOTAL

DIFFERENTIAL HEAD H (m)

29 225 110 420

MAX SUCTION PRESSURE (bar/g) 5

MODEL DSM 230 DSM 185 DSM 160

TRANSMISSION DIRECT

MIN MAX FLOW-RATE Q (l/min) 85 1250 23 315 19 217

MIN MAX TOTAL

DIFFERENTIAL HEAD H (m)

8,5 74 7,6 50 5,4 37

MAX SUCTION PRESSURE (bar/g) 5

MODEL SGM 185 HGM 185 DSM 185

TRANSMISSION GEARBOX GEARBOX DIRECT COUPLED

MIN MAX FLOW-RATE Q (l/min) 85 910 85 910 23 315

MIN MAX TOTAL

DIFFERENTIAL HEAD H (m)

110 420 110 420 7,6 50

MAX SUCTION PRESSURE (bar/g) 5 5 5

PERFORMANCE

APPLICATIONS

Transfer of cryogenic uids from mobile trailers to

stationary storage tanks (or iso-containers).

Direct coupled or with gearbox, Vanzetti on-board

centrifugal pumps can be equipped with electric or

hydraulic motor

TRANSFERRED FLUIDS: LIN LOX LAR LCO

2

LN

2

O

10 11

ENGINEEREd

SYSTEMS

Besides single cryogenic components, Vanzetti offer also

includes advanced engineered systems suitably tailored to

full specic customers needs.

They are true assembled equipment, including all the safety

and process devices and the control panel.

These package systems are transportable into 20 40

containers, ready to be installed on-site and fully complying

with clients needs.

With them, Vanzetti intends to meet particular requirements

from customers in need of package customized systems,

pre-assembled on skid and ready to be installed on-site.

MObILE CYLINdER

FILLING SKId

CRYOGENIC

CENTRIFUGAL

PUMP

on skid suitable for liquid

transfer from low pressure

stationary/mobile tanker to

higher pressure stationary

cryogenic tank.

AUTOMATIC

MObILE

TANKER

FILLING SKId

equipped with centrifugal

pumps, suitable for LIN LOX

LAR.

MObILE FILLING

SKId

equipped with reciprocating pump

and ambient vaporizer.

RECIPROCATING PUMP ON SKId

for high pressure cylinder flling.

Engineered systems for high

pressure cylinder flling with

LIN LOX LAR up to 400 bar

Engineered systems

for LIN LOX LAR transfer,

flling and back-up

LIN LOX LAR

bACK-UP SKId

PUMPING ANd

VAPORISING SYSTEM

for big capacity buffer flling.

12 13

MAIN FEATURES

HIGH PRESSURE: 300 and 420 bar

LOW PRESSURE: 40 bar

FLOW-RATE OF EACH MODULE: 102 to 956 Nm

3

/h (HP), 60 to 2111 Nm

3

/h (LP).

HIGH PRESSURE VAP internal pipe made of stainless steel.

LOW PRESSURE VAP made of aluminium (EN AW6060).

Modular assembly in order to assure the required ow-rate.

For continuous service, double vaporizing lines are installed equipped with change-over system.

SALES

& SERVICES

SALES PROPOSAL

Vanzetti offers an extensive range of cryogenic pumps

for the air gases industry, suitable to be employed in

a variety of applications in the cryogenics (LIN, LOX,

LAR, LCO

2

, LN

2

O).

We also provide customized engineered systems in

order to full specic customers needs, by means of

pre-assembled components on-skid, ready to be in-

stalled on-site.

Air gases pumps and cryogenic systems are fully de-

signed by Vanzetti technical staff and manufactures at

its production plant.

sales@vanzettiengineering.com

SERVICES

MAINTENANCE

Several Vanzetti high pressure pumps are equipped

with a cutting-edge seal system integrated in the

cartridge, aiding the maintenance and a fast and easy

replacement.

Possible interventions:

cold end replacement

cartridge and seals revision

precautionary and corrective maintenance

exchange-program.

SPARE PARTS

Available at Vanzetti a complete spare parts stock for

the whole range of cryogenic components produced

by the company.

customercare@vanzettiengineering.com

TRAINING

At its internal conference hall, Vanzetti regularly arrang-

es free programs of technical and practical guidance

aimed at training technicians and professionals in the

air gases/cryogenics industry.

The sessions include technical programs mainly about

pumps maintenance, correct working of components

and systems, applications of each product and others.

training@vanzettiengineering.com

QUALITY & CERTIFICATIONS

The company operates thoroughly in accordance with

Quality Management System assuring the perfect

traceability of design, building, control and testing

phases of each component for the industrial reliability

of the company.

Vanzetti works in compliance with the following Na-

tional and European certications:

QUALITY MANAGEMENT SYSTEM

UNI EN ISO 9001: 2008

PED CERTIFICATION - EU Directive 97/23/EC

MACHINERY EUROPEAN DIRECTIVE 2006/42/EC

RUSSIAN/BALTIC AREA CERTIFICATIONS:

GOST-R, ROSTECHNADZOR, GAZPROM

EIGA/IGC/CGA GUIDELINES

Vanzetti production plant is provided with an ad-

vanced test station for strictly checking the compo-

nents thanks to the following accurate operations:

dimensional control of mechanical components

before assembly

functional test of each pump

with Liquid Nitrogen (LIN)

before delivery.

AMbIENT

VAPORIzERS

High & low pressure

APPLICATIONS: cryogenic uids vaporization.

TRANSFERRED FLUIDS: LIN LOX LAR LCO

2

LN

2

O

Standard

Models

Dimensions

Nominal Capacity

Nm

3

/h

Model

Extrusion

number

Extrusion

conguration

Extrusion

Length

[mm]

Width

[mm]

Length

[mm]

Height

[mm]

Weight

[kg]

Volume

[l]

Heat

Exchange

Surface [m

2

]

LOX LIN LAR

VAP406/VAP306 6 3 x 2 4600 833 720 5572 162 3,0 40 120 133 164

VAP412/VAP312 12 4 x 3 4600 1180 890 5572 315 5,9 80 240 267 328

VAP416/VAP316 16 4 x 4 4600 1180 1180 5572 417 7,9 107 320 355 437

VAP420/VAP320 20 5 x 4 4600 1240 1470 5572 537 9,9 133 400 444 546

VAP424/VAP324 24 6 x 4 4600 1240 1760 5572 635 11,9 160 480 533 656

VAP430/VAP330 30 6 x 5 4600 1530 1760 5572 785 14,8 200 600 666 820

VAP436/VAP336 36 6 x 6 4600 1760 1820 5572 930 17,8 240 720 800 984

VAP442/VAP 342 42 7 x 6 4600 2110 1760 5572 1076 20,8 280 840 933 1147

VAP448/VAP348 48 8 x 6 4600 2340 1880 5572 1222 23,7 320 960 1066 1311

VAP456/VAP356 56 8 x 7 4600 2340 2170 5572 1410 27,7 374 1119 1244 1530

Standard

Models

Dimensions

Nominal Capacity

Nm

3

/h

Model

Extrusion

conguration

Extrusion

Length

[mm]

Width

[mm]

Length

[mm]

Height

[mm]

Weight

[kg]

Volume

[l]

Heat

Exchange

Surface [m

2

]

LOX LIN LAR

VAPAl-44 2 x 2 4000 550 550 5200 90 7,0 22,6 69 74 92

VAPAl-64 3 x 2 4000 550 800 5200 130 10,5 33,8 104 112 137

VAPAl-124 4 x 3 4000 800 1100 5200 234 21,0 67,7 208 223 275

VAPAl-164 4 x 4 4000 1300 1300 5200 300 28,1 90,2 277 298 366

VAPAl-204 5 x 4 4000 1300 1600 5200 417 35,1 112,8 346 372 458

VAPAl-244 6 x 4 4000 1300 1880 5200 490 42,1 135,4 415 447 549

VAPAl-304 6 x 5 4000 1570 1880 5200 620 52,6 169,2 519 558 687

VAPAl-364 6 x 6 4000 1900 1900 5200 750 63,1 203,0 623 670 824

VAPAl-306 6 x 5 6000 1650 1940 7200 920 76,5 253,8 779 838 1030

VAPAl-366 6 x 6 6000 1940 1940 7200 1100 125,0 304,6 935 1005 1236

VAPAl-426 7 x 6 6000 1960 2250 7200 1270 145,0 355,3 1090 1173 1442

VAPAl-486 8 x 6 6000 1950 2440 7200 1450 160,0 406,1 1246 1340 1648

VAPAl-566 8 x 7 6000 2150 2440 7200 1650 142,9 473,8 1454 1563 1923

VAPAl-568 8 x 7 8000 2150 2440 9200 2200 187,6 631,7 1939 2085 2564

VAPAl-569 8 x 7 9000 2150 2440 10200 2450 209,9 710,6 2181 2345 2884

VAPA1-5610 8 x 7 10000 2800 2440 11200 2850 232,3 789,6 2423 2606 3205

HIGH PRESSURE AMBIENT VAPORIZERS PERFORMANCE - 300 and 420 bar

LOW PRESSURE AMBIENT VAPORIZERS PERFORMANCE - up to 40 bar

AIR LIQUIDE - FINLAND

14 15

Vanzetti Engineering s.r.l.

Via Avv. Giovanni Agnelli, 10

12033 MORETTA (CN) ITALY

Tel. (+39) 0172 915811

Fax (+39) 0172 915822

www.vanzettiengineering.com

info@vanzettiengineering.com

www.vanzettiengineering.com

CRYOGENIC PUMPS

& ENGINEERED SYSTEMS

FOR AIR GASES

LIN LOX LAR LCO

2

LN

2

O

[

H

I

G

H

E

S

T

C

R

Y

O

G

E

N

I

C

P

E

R

F

O

R

M

A

N

C

E

]

[ HIGHEST CRYOGENIC PERFORMANCE ]

Anda mungkin juga menyukai

- Sihi Pompa LPG API 610Dokumen1 halamanSihi Pompa LPG API 610Andry RimanovBelum ada peringkat

- Joule Thomson ExpansionDokumen2 halamanJoule Thomson ExpansiondndudcBelum ada peringkat

- Technical PaperDokumen6 halamanTechnical PaperCJ CHBelum ada peringkat

- Corken Gas CompressorsDokumen16 halamanCorken Gas CompressorssamvendanBelum ada peringkat

- Compressor & TheoryDokumen41 halamanCompressor & TheoryJaveed A. KhanBelum ada peringkat

- NGL PumpsDokumen4 halamanNGL Pumpsamol patkiBelum ada peringkat

- 30M - ConocoPhillips Optimized CascadeDokumen11 halaman30M - ConocoPhillips Optimized CascadeX-Titan Wan de Pirates100% (1)

- NSB Liquid Ring CompressorDokumen8 halamanNSB Liquid Ring Compressorboom10100% (1)

- Design and Fabrication of Direct Evaporative Modified CoolerDokumen14 halamanDesign and Fabrication of Direct Evaporative Modified CoolerPraful RajputBelum ada peringkat

- Reciprocating Pumps - NDPDDokumen2 halamanReciprocating Pumps - NDPDDhanny MiharjaBelum ada peringkat

- API Std 618 vs 680 for Critical Nitrogen CompressorDokumen3 halamanAPI Std 618 vs 680 for Critical Nitrogen CompressorShantanuBelum ada peringkat

- Multiphase - Pumps - Axel CalgaryDokumen45 halamanMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáBelum ada peringkat

- Valve Sizing Calculations: Proper Selection Requires Understanding FlowDokumen17 halamanValve Sizing Calculations: Proper Selection Requires Understanding Flowarianto32Belum ada peringkat

- Centrifugal Compressor System InteractionDokumen6 halamanCentrifugal Compressor System Interactionshivajireturns100% (1)

- 1 1Dokumen9 halaman1 1Ankush SehgalBelum ada peringkat

- TEWI AnalysisDokumen63 halamanTEWI Analysismirali74Belum ada peringkat

- Session 5 - Linde Hampson Process.Dokumen7 halamanSession 5 - Linde Hampson Process.SHOBHIT KUMARBelum ada peringkat

- 2013 LNG FSRU FPSO Pump Considerations For Ship Motion AIChE Spring G.woodDokumen15 halaman2013 LNG FSRU FPSO Pump Considerations For Ship Motion AIChE Spring G.woodjbloggs2007Belum ada peringkat

- Choosing the Right Vane Pump for Your ProcessDokumen25 halamanChoosing the Right Vane Pump for Your ProcessGirlish JackieBelum ada peringkat

- Buffer & Barrier Fluids Plan 52Dokumen4 halamanBuffer & Barrier Fluids Plan 52gatita_salemBelum ada peringkat

- Compressor Systems Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDokumen25 halamanCompressor Systems Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignJBelum ada peringkat

- 11 Compressor Terms Acronyms Units of MeasureDokumen8 halaman11 Compressor Terms Acronyms Units of MeasureLe Anh DangBelum ada peringkat

- Technical Specifications Mechanical Seal ComparisonDokumen3 halamanTechnical Specifications Mechanical Seal Comparisonsushant_jhawerBelum ada peringkat

- Medium Capacity Air Separation Plants for Oxygen Nitrogen and Argon ProductionDokumen8 halamanMedium Capacity Air Separation Plants for Oxygen Nitrogen and Argon Productionkalyanm203515100% (1)

- How to Size Liquid Ring Vacuum PumpsDokumen3 halamanHow to Size Liquid Ring Vacuum PumpsdayrogBelum ada peringkat

- Presentation ExpandersDokumen17 halamanPresentation ExpandersMohamed Balbaa100% (3)

- The Definitive Guide To Cryogenic EngineeringDokumen21 halamanThe Definitive Guide To Cryogenic EngineeringSamanthaPereraBelum ada peringkat

- Porta-Test Whirlyscrub VDokumen2 halamanPorta-Test Whirlyscrub VJagadeesh UnnamBelum ada peringkat

- NOTES 5 - RefrigerationDokumen20 halamanNOTES 5 - RefrigerationMakoya_malumeBelum ada peringkat

- LNG Pumps, CMDokumen11 halamanLNG Pumps, CMRachitBelum ada peringkat

- Ge Small Scale Liquefied Natural Gas Plants GuideDokumen8 halamanGe Small Scale Liquefied Natural Gas Plants GuideMuhamad Apriyudi Syafputra100% (1)

- Multiphase BoostingDokumen31 halamanMultiphase BoostingjoreliBelum ada peringkat

- Guidance On The Safe Operation of Vacuum Insulated Storage Tank-BOCDokumen26 halamanGuidance On The Safe Operation of Vacuum Insulated Storage Tank-BOCchem_taBelum ada peringkat

- Cryogenics & LNG Application GuideDokumen16 halamanCryogenics & LNG Application GuidesusantoBelum ada peringkat

- Pulsation DampnerDokumen2 halamanPulsation DampnerEliezer Mendez Gonzalez0% (1)

- Datasheet Selenoid ValveDokumen31 halamanDatasheet Selenoid ValveIccank NdutBelum ada peringkat

- Pocket API 682 4th Edition Piping Plans - EN Burgmann PDFDokumen131 halamanPocket API 682 4th Edition Piping Plans - EN Burgmann PDFPoncho RmzBelum ada peringkat

- LAT4Dokumen6 halamanLAT4Said FerdjallahBelum ada peringkat

- Thermal Design of Coil-Wound LNG Heat ExchangersDokumen168 halamanThermal Design of Coil-Wound LNG Heat ExchangersMuhammad Rozi100% (1)

- Robatherm Medical EngDokumen11 halamanRobatherm Medical EngSamiYousifBelum ada peringkat

- Turbo Machines Lab: Centrifugal and Reciprocating CompressorsDokumen38 halamanTurbo Machines Lab: Centrifugal and Reciprocating CompressorsUpendra SravanBelum ada peringkat

- Driving Centrifugal Compressor TechnologyDokumen52 halamanDriving Centrifugal Compressor TechnologySHRIKANT GADEBelum ada peringkat

- Leistritz Multiphase Pumping SystemDokumen30 halamanLeistritz Multiphase Pumping SystempsycopaulBelum ada peringkat

- Alfa LavalDokumen24 halamanAlfa Lavaldroid11Belum ada peringkat

- Nitrogen Production SystemsDokumen9 halamanNitrogen Production Systemscmar64Belum ada peringkat

- Datum Compressor Cut PDFDokumen1 halamanDatum Compressor Cut PDFJ.SIVIRABelum ada peringkat

- DEAERATORDokumen5 halamanDEAERATORMonkeysee MangkiduBelum ada peringkat

- Relief Valve Tutorial Spirax SarcoDokumen16 halamanRelief Valve Tutorial Spirax SarcoamokhtaBelum ada peringkat

- Lect 5 - Liquefaction - 2015 PDFDokumen6 halamanLect 5 - Liquefaction - 2015 PDFAnonymous oqlnO8e100% (1)

- Cryogenic ProcessDokumen25 halamanCryogenic Processmohamed100% (2)

- Hydrate and DehydrationDokumen46 halamanHydrate and DehydrationOlvis Guillen100% (1)

- Industrial Refrigeration CompressorDokumen8 halamanIndustrial Refrigeration Compressorr_sridhar20064780100% (2)

- Environmental Protection TechnologiesDokumen4 halamanEnvironmental Protection TechnologiesKostyantyn DrobotBelum ada peringkat

- Condensers Control and Reclaim VOCsDokumen3 halamanCondensers Control and Reclaim VOCsgpcshfBelum ada peringkat

- LNG Storage & Loading Systems Chapter 34Dokumen8 halamanLNG Storage & Loading Systems Chapter 34divatf07Belum ada peringkat

- Tappan Furnace FG6RK 096N 16BDokumen4 halamanTappan Furnace FG6RK 096N 16BAnubis RahlBelum ada peringkat

- Hägglunds Compact Hydraulic Motor Product ManualDokumen25 halamanHägglunds Compact Hydraulic Motor Product ManualP Venkata Suresh100% (2)

- Book LayoutDokumen8 halamanBook LayoutaamenaBelum ada peringkat

- The Institution of Engineers (India) : IntpeDokumen8 halamanThe Institution of Engineers (India) : IntpekanchanabalajiBelum ada peringkat

- Api Purchasing Guide 2015-08-29 PDFDokumen20 halamanApi Purchasing Guide 2015-08-29 PDFQaiser HafeezBelum ada peringkat

- TTD - FAQs dt.4-6-2016Dokumen6 halamanTTD - FAQs dt.4-6-2016Srinivas KrishnaBelum ada peringkat

- Seamless Api Pipes PDFDokumen14 halamanSeamless Api Pipes PDFsreeBelum ada peringkat

- PE Mech Machine Apr 2017Dokumen2 halamanPE Mech Machine Apr 2017flounder33Belum ada peringkat

- Off Shore TankDokumen1 halamanOff Shore TankkanchanabalajiBelum ada peringkat

- NEW - NCEES FE Exam Schedule For July - December 2018 PDFDokumen1 halamanNEW - NCEES FE Exam Schedule For July - December 2018 PDFkanchanabalajiBelum ada peringkat

- FE Mec CBT Specs PDFDokumen4 halamanFE Mec CBT Specs PDFVictor VerdanBelum ada peringkat

- NEW - NCEES FE Exam Schedule For July - December 2018 PDFDokumen1 halamanNEW - NCEES FE Exam Schedule For July - December 2018 PDFkanchanabalajiBelum ada peringkat

- Guide To Professional Registration With The Engineering CouncilDokumen2 halamanGuide To Professional Registration With The Engineering CouncilRonald GeorgeBelum ada peringkat

- Intro To Basic UTDokumen41 halamanIntro To Basic UTgirish310100% (1)

- Pipe 1.25 SCH - XxsDokumen5 halamanPipe 1.25 SCH - XxskanchanabalajiBelum ada peringkat

- Vehicle DrawingDokumen4 halamanVehicle DrawingkanchanabalajiBelum ada peringkat

- Reference Data - : Metric Conversion ChartDokumen29 halamanReference Data - : Metric Conversion ChartkanchanabalajiBelum ada peringkat

- Wireless Broadband Contract SME Izwi ConnectixDokumen6 halamanWireless Broadband Contract SME Izwi ConnectixkanchanabalajiBelum ada peringkat

- ASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDEDokumen11 halamanASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDEKarthik AnandanBelum ada peringkat

- Early Writing For Little Hands PDFDokumen63 halamanEarly Writing For Little Hands PDFNHIMMALAY100% (1)

- Color Green RecognitionDokumen1 halamanColor Green RecognitionkanchanabalajiBelum ada peringkat

- FS2 Learning Journey: Expressive Art & DesignDokumen2 halamanFS2 Learning Journey: Expressive Art & DesignkanchanabalajiBelum ada peringkat

- Ns Edp Mut Hoot Form 1095101137Dokumen12 halamanNs Edp Mut Hoot Form 1095101137kanchanabalajiBelum ada peringkat

- DB 200 SLDokumen2 halamanDB 200 SLkanchanabalajiBelum ada peringkat

- DIPRA DesignofDuctileIronPipeOnSupportsDokumen10 halamanDIPRA DesignofDuctileIronPipeOnSupportskanchanabalajiBelum ada peringkat

- Gems Winchester - Karama Boys PDFDokumen1 halamanGems Winchester - Karama Boys PDFkanchanabalajiBelum ada peringkat

- Design For Horizontal Atomization 2Dokumen1 halamanDesign For Horizontal Atomization 2kanchanabalajiBelum ada peringkat

- Catalogue KingTankDokumen5 halamanCatalogue KingTankkanchanabalajiBelum ada peringkat

- (13342) Literacy - Captions 28042016Dokumen1 halaman(13342) Literacy - Captions 28042016kanchanabalajiBelum ada peringkat

- Desalination Plant - Resilience Modelling - CSDokumen2 halamanDesalination Plant - Resilience Modelling - CSkanchanabalajiBelum ada peringkat

- Fees StructureDokumen2 halamanFees StructurekanchanabalajiBelum ada peringkat

- Questions for pictures using 'Is' or 'Can' with Yes/No answersDokumen1 halamanQuestions for pictures using 'Is' or 'Can' with Yes/No answerskanchanabalajiBelum ada peringkat

- (13630) Literacy - Writing Captions 04052016Dokumen1 halaman(13630) Literacy - Writing Captions 04052016kanchanabalajiBelum ada peringkat

- Aluminium Composite Panel - ACP Fabrication - Cladding and Glazing - Partition SheetsDokumen7 halamanAluminium Composite Panel - ACP Fabrication - Cladding and Glazing - Partition SheetsALEX PANELSBelum ada peringkat

- Cable Laying Equipment: CCC (Underwater Engineering) SalDokumen5 halamanCable Laying Equipment: CCC (Underwater Engineering) Sallaleye_olumideBelum ada peringkat

- Quotations FormatDokumen3 halamanQuotations FormatRakeshBelum ada peringkat

- CV Summary for Network EngineerDokumen2 halamanCV Summary for Network EngineerManisha PatilBelum ada peringkat

- Bartec Headed Bars Qualification File and References 2017.09.08Dokumen35 halamanBartec Headed Bars Qualification File and References 2017.09.08Andres Hermoso MeijideBelum ada peringkat

- Test ReportDokumen5 halamanTest ReportluongdunBelum ada peringkat

- Pgdca LevelDokumen82 halamanPgdca Levelbetu8137Belum ada peringkat

- Unit 5 MCQDokumen9 halamanUnit 5 MCQDhanesh PawarBelum ada peringkat

- Torneado del peón: Procesos de manufactura en el laboratorioDokumen14 halamanTorneado del peón: Procesos de manufactura en el laboratorioDanny Urtecho Ponte100% (1)

- Official Ied 1Dokumen5 halamanOfficial Ied 1api-532866093Belum ada peringkat

- Alok KadamDokumen5 halamanAlok KadamJohnathan RoweBelum ada peringkat

- Award For BestDokumen15 halamanAward For BestRohit KumarBelum ada peringkat

- 7.0 Call Back ServiceDokumen2 halaman7.0 Call Back ServiceSreenath S KallaaraBelum ada peringkat

- GGM Enhancement Project Drawings Log Sheet UpdatedDokumen198 halamanGGM Enhancement Project Drawings Log Sheet UpdatedJohn BuntalesBelum ada peringkat

- Barografo FoxboreDokumen16 halamanBarografo FoxboreojrfgmrfBelum ada peringkat

- 3 D Printing TechnologyDokumen17 halaman3 D Printing TechnologyClassic PrintersBelum ada peringkat

- 01.hazards of Trapped Pressure & Vacuum-38Dokumen2 halaman01.hazards of Trapped Pressure & Vacuum-38rahulBelum ada peringkat

- Minimum Equipment List (MEL) - SKYbrary Aviation SafetyDokumen1 halamanMinimum Equipment List (MEL) - SKYbrary Aviation SafetyhmmnksyBelum ada peringkat

- Gyrolok CatalogDokumen58 halamanGyrolok CatalogmartinvandoornBelum ada peringkat

- SKF SM 20 - CSTR SpecificationDokumen3 halamanSKF SM 20 - CSTR SpecificationPaweł HejmowskiBelum ada peringkat

- Mark11 Spare Parts Section - REV3Dokumen72 halamanMark11 Spare Parts Section - REV3Orlando MelipillanBelum ada peringkat

- Service CatalogDokumen28 halamanService CatalogUsman Hamid100% (1)

- Tesla v. Xpeng's Cao ComplaintDokumen14 halamanTesla v. Xpeng's Cao ComplaintmashablescribdBelum ada peringkat

- The Six Big Losses in Manufacturing - EvoconDokumen23 halamanThe Six Big Losses in Manufacturing - Evoconarvin john cabralBelum ada peringkat

- SCM CostsDokumen9 halamanSCM CostsArnav VatsBelum ada peringkat

- Actual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsDokumen4 halamanActual4Test: Actual4test - Actual Test Exam Dumps-Pass For IT ExamsLovis NKBelum ada peringkat

- Maruti Strike ReportDokumen37 halamanMaruti Strike ReportHyder HussainBelum ada peringkat

- Developer Feasibility StudyDokumen9 halamanDeveloper Feasibility Studysam dorilloBelum ada peringkat

- ATFMDokumen4 halamanATFMYuranan LimpananvadeeBelum ada peringkat

- Steel Industry Hand Safety ToolsDokumen24 halamanSteel Industry Hand Safety ToolsTaherBelum ada peringkat