Monorail

Diunggah oleh

Marly ReyesHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Monorail

Diunggah oleh

Marly ReyesHak Cipta:

Format Tersedia

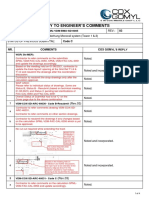

"MONORAIL" --- MONORAIL BEAM ANALYSIS

Program Description:

"MONORAIL" is a spreadsheet program written in MS-Excel for the purpose of analysis of either S-shape or W-shape underhung monorail beams analyzed as simple-spans with or without overhangs (cantilevers). Specifically, the x-axis and y-axis bending moments as well as any torsion effects are calculated. The actual and allowable stresses are determined, and the effect of lower flange bending is also addressed by two different approaches. This program is a workbook consisting of three (3) worksheets, described as follows:

Worksheet Name

Doc S-shaped Monorail Beam W-shaped Monorail Beam

Description

This documentation sheet Monorail beam analysis for S-shaped beams Monorail beam analysis for W-shaped beams

Program Assumptions and Limitations:

1. The following references were used in the development of this program: a. Fluor Enterprises, Inc. - Guideline 000.215.1257 - "Hoisting Facilities" (August 22, 2005) b. Dupont Engineering Design Standard: DB1X - "Design and Installation of Monorail Beams" (May 2000) c. American National Standards Institute (ANSI): MH27.1 - "Underhung Cranes and Monorail Syatems" d. American Institute of Steel Construction (AISC) 9th Edition Allowable Stress Design (ASD) Manual (1989) e. "Allowable Bending Stresses for Overhanging Monorails" - by N. Stephen Tanner AISC Engineering Journal (3rd Quarter, 1985) f. Crane Manufacturers Association of America, Inc. (CMAA) - Publication No. 74 "Specifications for Top Running & Under Running Single Girder Electric Traveling Cranes Utilizing Under Running Trolley Hoist" (2004) g. "Design of Monorail Systems" - by Thomas H. Orihuela Jr., PE (www.pdhengineer.com) h. British Steel Code B.S. 449, pages 42-44 (1959) i. USS Steel Design Manual - Chapter 7 "Torsion" - by R. L. Brockenbrough and B.G. Johnston (1981) j. AISC Steel Design Guide Series No. 9 - "Torsional Analysis of Structural Steel Members" by Paul A. Seaburg, PhD, PE and Charlie J. Carter, PE (1997) k. "Technical Note: Torsion Analysis of Steel Sections" - by William E. Moore II and Keith M. Mueller AISC Engineering Journal (4th Quarter, 2002) 2. The unbraced length for the overhang (cantilever) portion, 'Lbo', of an underhung monorail beam is often debated. The following are some recommendations from the references cited above: a. Fluor Guideline 000.215.1257: Lbo = Lo+L/2 b. Dupont Standard DB1X: Lbo = 3*Lo c. ANSI Standard MH27.1: Lbo = 2*Lo d. British Steel Code B.S. 449: Lbo = 2*Lo (for top flange of monorail beam restrained at support) British Steel Code B.S. 449: Lbo = 3*Lo (for top flange of monorail beam unrestrained at support) e. AISC Eng. Journal Article by Tanner: Lbo = Lo+L (used with a computed value of 'Cbo' from article) 3. This program also determines the calculated value of the bending coefficient, 'Cbo', for the overhang (cantilever) portion of the monorail beam from reference "e" in note #1 above. This is located off of the main calculation page. Note: if this computed value of 'Cbo' is used and input, then per this reference the total value of Lo+L should be used for the unbraced length, 'Lbo', for the overhang portion of the monorail beam. 4. This program ignores effects of axial compressive stress produced by any longitudinal (traction) force which is usually considered minimal for underhung, hand-operated monorail systems. 5. This program contains comment boxes which contain a wide variety of information including explanations of input or output items, equations used, data tables, etc. (Note: presence of a comment box is denoted by a red triangle in the upper right-hand corner of a cell. Merely move the mouse pointer to the desired cell to view the contents of that particular "comment box".)

SIS

on

on sheet r S-shaped beams W-shaped beams

"MONORAIL.xls" Program Version 1.3

MONORAIL BEAM ANALYSIS

Job Name: Job Number: Input:

RL(min)=-0,73

For S-shaped Underhung Monorails Analyzed as Simple-Spans with / without Overhang Per AISC 9th Edition ASD Manual and CMAA Specification No. 74 (2004) Subject: Originator:

Monorail Size: Select: Design Parameters: Beam Fy = Beam Simple-Span, L = Unbraced Length, Lb = Bending Coef., Cb = Overhang Length, Lo = Unbraced Length, Lbo = Bending Coef., Cbo = Lifted Load, P = Trolley Weight, Wt = Hoist Weight, Wh = Vert. Impact Factor, Vi = Horz. Load Factor, HLF = Total No. Wheels, Nw = Wheel Spacing, S = Distance on Flange, a = Results: Parameters and Coefficients: Pv = 7.400 kips Pw = 1.850 kips/wheel Ph = 0.600 kips ta = 0.493 in. l= 0.156 Cxo = -0.850 Cx1 = 0.600 Czo = 0.165 Cz1 = 1.948 Bending Moments for Simple-Span: x= 8.313 ft. Mx = 30.08 ft-kips My = 2.44 ft-kips S12x50 36 17.0000 17.0000 1.00 3.0000 11.5000 1.00 6.000 0.400 0.100 15 10 4 0.7500 0.3750

ksi ft. ft.

L=17 x=8,313 S=0,75

RR(max)=9,13 Lo=3

S12x50 Pv=7,4

ft. ft. kips kips kips

Nomenclature S12x50 Member Properties: 14.60 in.^2 d/Af = 12.000 in. Ix = 0.687 in. Sx = 5.480 in. Iy = 0.659 in. Sy = 1.438 in. J= 1.250 in. Cw = (with overhang)

= Pv*(L+(Lo-S/2))/L+w/1000/(2*L)*(L+Lo)^2 = -Pv*(Lo-S/2)/L+w/1000/(2*L)*(L^2-Lo^2)

% %

ft. in.

A= d= tw = bf = tf = k= rt =

Support Reactions: RR(max) = 9.13 RL(min) = -0.73 Pv = P*(1+Vi/100)+Wt+Wh (vertical load) Pw = Pv/Nw (load per trolley wheel) Ph = HLF*P (horizontal load) ta = tf-bf/24+a/6 (for S-shape) l = 2*a/(bf-tw) Cxo = -1.096+1.095*l+0.192*e^(-6.0*l) Cx1 = 3.965-4.835*l-3.965*e^(-2.675*l) Czo = -0.981-1.479*l+1.120*e^(1.322*l) Cz1 = 1.810-1.150*l+1.060*e^(-7.70*l)

x = 1/2*(L-S/2) (location of max. moments from left end of simple-span) Mx = (Pv/2)/(2*L)*(L-S/2)^2+w/1000*x/2*(L-x) My = (Ph/2)/(2*L)*(L-S/2)^2

Lateral Flange Bending Moment from Torsion for Simple-Span: (per USS Steel Design Manual, 1981) e= 6.000 in. e = d/2 (assume horiz. load taken at bot. flange) at = 21.662 at = SQRT(E*Cw/(J*G)) , E=29000 ksi and G=11200 ksi Mt = 0.29 ft-kips Mt = Ph*e*at/(2*(d-tf))*TANH(L*12/(2*at))/12 X-axis Stresses for Simple-Span: fbx = 7.13 ksi Lb/rt = 163.20 Fbx = 17.72 ksi

fbx = Mx/Sx Lb/rt = Lb*12/rt Fbx = 12000*Cb/(Lb*12/(d/Af)) <= 0.60*Fy

3 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

Y-axis Stresses for Simple-Span: fby = 5.14 ksi fwns = 1.21 ksi fby(total) = 6.35 ksi Fby = 27.00 ksi

fby = My/Sy fwns = Mt*12/(Sy/2) (warping normal stress) fby(total) = fby+fwns Fby = 0.75*Fy

Combined Stress Ratio for Simple-Span: S.R. = 0.638 S.R. = fbx/Fbx+fby(total)/Fby Vertical Deflection for Simple-Span: Pv = 6.500 kips D(max) = 0.1412 in. D(ratio) = L/1445 D(allow) = 0.4533 in. Bending Moments for Overhang: Mx = 19.65 ft-kips My = 1.58 ft-kips

Pv = P+Wh+Wt (without vertical impact) D(max) = Pv/2*(L-S)/2/(24*E*I)*(3*L^2-4*((L-S)/2)^2)+5*w/12000*L^4/(384*E*I) D(ratio) = L*12/D(max) D(allow) = L*12/450 Defl.(max) <= Defl.(allow),

Mx = (Pv/2)*(Lo+(Lo-S))+w/1000*Lo^2/2 My = (Ph/2)*(Lo+(Lo-S))

Lateral Flange Bending Moment from Torsion for Overhang: (per USS Steel Design Manual, 1981) e= 6.000 in. e = d/2 (assume horiz. load taken at bot. flange) at = 21.662 at = SQRT(E*Cw/(J*G)) , E=29000 ksi and G=11200 ksi Mt = 0.57 ft-kips Mt = Ph*e*at/(d-tf)*TANH(Lo*12/at)/12 X-axis Stresses for Overhang: fbx = 4.66 ksi Lbo/rt = 110.40 Fbx = 21.60 ksi Y-axis Stresses for Overhang: fby = 3.32 ksi fwns = 2.42 ksi fby(total) = 5.74 ksi Fby = 27.00 ksi Combined Stress Ratio for Overhang: S.R. = 0.428 Vertical Deflection for Overhang: Pv = 6.500 kips D(max) = 0.0715 in. D(ratio) = L/503 D(allow) = 0.0800 in. Bottom Flange Bending (simplified): be = 7.908 in. tf2 = 0.859 in. am = 1.818 in. Mf = 3.363 in.-kips Sf = 0.572 in.^3 fb = 5.88 ksi Fb = 27.00 ksi

fbx = Mx/Sx Lbo/rt = Lbo*12/rt Fbx = 12000*Cbo/(Lbo*12/(d/Af)) <= 0.60*Fy

fby = My/Sy fwns = Mt*12/(Sy/2) (warping normal stress) fby(total) = fby+fwns Fby = 0.75*Fy

S.R. = fbx/Fbx+fby(total)/Fby (assuming full design load, Pv without impact, at end of overhang) Pv = P+Wh+Wt (without vertical impact) D(max) = Pv*Lo^2*(L+Lo)/(3*E*I)+w/12000*Lo*(4*Lo^2*L-L^3+3*Lo^3)/(24*E*I) D(ratio) = Lo*12/D(max) D(allow) = Lo*12/450 Defl.(max) <= Defl.(allow),

Min. of: be = 12*tf or S*12 (effective flange bending length) tf2 = tf+(bf/2-tw/2)/2*(1/6) (flange thk. at web based on 1:6 slope of flange) am = (bf/2-tw/2)-(k-tf2) (where: k-tf2 = radius of fillet) Mf = Pw*am Sf = be*tf^2/6 fb = Mf/Sf Fb = 0.75*Fy

4 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

Bottom Flange Bending per CMAA Specification No. 74 (2004): Local Flange Bending Stress @ Point 0: sxo = sxo = Cxo*Pw/ta^2 -6.46 ksi szo = szo = Czo*Pw/ta^2 1.25 ksi Local Flange Bending Stress @ Point 1: sx1 = sx1 = Cx1*Pw/ta^2 4.56 ksi sz1 = sz1 = Cz1*Pw/ta^2 14.82 ksi Local Flange Bending Stress @ Point 2: sx2 = sx2 = -sxo 6.46 ksi sz2 = sz2 = -szo -1.25 ksi Resultant Biaxial Stress @ Point 0: sz = 13.22 ksi sx = -4.85 ksi txz = 0.00 ksi sto = 16.19 ksi Resultant Biaxial Stress @ Point 1: sz = 23.39 ksi sx = 3.42 ksi txz = 0.00 ksi st1 = 21.88 ksi Resultant Biaxial Stress @ Point 2: sz = 11.34 ksi sx = 4.85 ksi txz = 0.00 ksi st2 = 9.85 ksi sz = fbx+fby+0.75*szo sx = 0.75*sxo txz = 0 (assumed negligible) sto = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

(Note: torsion is neglected)

(Sign convention: + = tension, - = compre

Pw

Pw

<= Fb = 0.66*Fy = 23,76 ksi

sy = fbx+fby+0.75*sz1 sx = 0.75*sx1 txz = 0 (assumed negligible) st1 = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

<= Fb = 0.66*Fy = 23,76 ksi

sz = fbx+fby+0.75*sz2 sx = 0.75*sx2 txz = 0 (assumed negligible) st2 = SQRT(sx^2+sz^2-sx*sz+3*txz^2) Y

<= Fb = 0.66*Fy = 23,76 ksi

tw X Pw Z Pw

tf

Point 2 Point 0 tw/2

Point 1

bf/4

bf

5 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

/ without Overhang No. 74 (2004) Checker:

RR(max)=9,13 Lo=3

ature

mber Properties: 3.32 303.00 50.60 15.60 5.69 2.770 502.0

in.^4 in.^3 in.^4 in.^3 in.^4 in.^6

+(Lo-S/2))/L+w/1000/(2*L)*(L+Lo)^2 Lo-S/2)/L+w/1000/(2*L)*(L^2-Lo^2)

t end of simple-span)

SS Steel Design Manual, 1981)

fbx <= Fbx, O.K.

(continued)

6 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

fby <= Fby, O.K.

S.R. <= 1.0, O.K.

^2)+5*w/12000*L^4/(384*E*I)

Defl.(max) <= Defl.(allow), O.K.

SS Steel Design Manual, 1981)

fbx <= Fbx, O.K.

fby <= Fby, O.K.

S.R. <= 1.0, O.K.

2*L-L^3+3*Lo^3)/(24*E*I)

Defl.(max) <= Defl.(allow), O.K.

ed on 1:6 slope of flange)

fb <= Fb, O.K.

(continued)

7 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

torsion is neglected) convention: + = tension, - = compression)

S-shape Trolley Wheel

Pw

<= Fb = 0.66*Fy = 23,76 ksi, O.K.

<= Fb = 0.66*Fy = 23,76 ksi, O.K.

<= Fb = 0.66*Fy = 23,76 ksi, O.K.

ta

8 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

MONORAIL BEAM ANALYSIS

Job Name: Job Number: Input:

RL(min)=-0,73

For W-shaped Underhung Monorails Analyzed as Simple-Spans with / without Overhang Per AISC 9th Edition ASD Manual and CMAA Specification No. 74 (2004) Subject: Originator:

Monorail Size: Select: Design Parameters: Beam Fy = Beam Simple-Span, L = Unbraced Length, Lb = Bending Coef., Cb = Overhang Length, Lo = Unbraced Length, Lbo = Bending Coef., Cbo = Lifted Load, P = Trolley Weight, Wt = Hoist Weight, Wh = Vert. Impact Factor, Vi = Horz. Load Factor, HLF = Total No. Wheels, Nw = Wheel Spacing, S = Distance on Flange, a = Results: Parameters and Coefficients: Pv = 7.400 kips Pw = 1.850 kips/wheel Ph = 0.600 kips ta = 0.640 in. l= 0.097 Cxo = -1.903 Cx1 = 0.535 Czo = 0.192 Cz1 = 2.319 Bending Moments for Simple-Span: x= 8.313 ft. Mx = 30.08 ft-kips My = 2.44 ft-kips W12x50 36 17.0000 17.0000 1.00 3.0000 11.5000 1.00 6.000 0.400 0.100 15 10 4 0.7500 0.3750

ksi ft. ft.

L=17 x=8,313 S=0,75

RR(max)=9,13 Lo=3

W12x50 Pv=7,4

ft. ft. kips kips kips

Nomenclature W12x50 Member Properties: 14.60 in.^2 d/Af = 12.200 in. Ix = 0.370 in. Sx = 8.080 in. Iy = 0.640 in. Sy = 1.140 in. J= 2.170 in. Cw = (with overhang)

= Pv*(L+(Lo-S/2))/L+w/1000/(2*L)*(L+Lo)^2 = -Pv*(Lo-S/2)/L+w/1000/(2*L)*(L^2-Lo^2)

% %

ft. in.

A= d= tw = bf = tf = k= rt =

Support Reactions: RR(max) = 9.13 RL(min) = -0.73 Pv = P*(1+Vi/100)+Wt+Wh (vertical load) Pw = Pv/Nw (load per trolley wheel) Ph = HLF*P (horizontal load) ta = tf (for W-shape) l = 2*a/(bf-tw) Cxo = -2.110+1.977*l+0.0076*e^(6.53*l) Cx1 = 10.108-7.408*l-10.108*e^(-1.364*l) Czo = 0.050-0.580*l+0.148*e^(3.015*l) Cz1 = 2.230-1.490*l+1.390*e^(-18.33*l)

x = 1/2*(L-S/2) (location of max. moments from left end of simple-span) Mx = (Pv/2)/(2*L)*(L-S/2)^2+w/1000*x/2*(L-x) My = (Ph/2)/(2*L)*(L-S/2)^2

Lateral Flange Bending Moment from Torsion for Simple-Span: (per USS Steel Design Manual, 1981) e= 6.100 in. e = d/2 (assume horiz. load taken at bot. flange) at = 53.354 at = SQRT(E*Cw/(J*G)) , E=29000 ksi and G=11200 ksi Mt = 0.67 ft-kips Mt = Ph*e*at/(2*(d-tf))*TANH(L*12/(2*at))/12 X-axis Stresses for Simple-Span: fbx = 5.62 ksi Lb/rt = 94.01 Fbx = 21.60 ksi

fbx = Mx/Sx Lb/rt = Lb*12/rt Fbx = 12000*Cb/(Lb*12/(d/Af)) <= 0.60*Fy

9 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

Y-axis Stresses for Simple-Span: fby = 2.11 ksi fwns = 1.16 ksi fby(total) = 3.27 ksi Fby = 27.00 ksi

fby = My/Sy fwns = Mt*12/(Sy/2) (warping normal stress) fby(total) = fby+fwns Fby = 0.75*Fy

Combined Stress Ratio for Simple-Span: S.R. = 0.381 S.R. = fbx/Fbx+fby(total)/Fby Vertical Deflection for Simple-Span: Pv = 6.500 kips D(max) = 0.1094 in. D(ratio) = L/1865 D(allow) = 0.4533 in. Bending Moments for Overhang: Mx = 19.65 ft-kips My = 1.58 ft-kips

Pv = P+Wh+Wt (without vertical impact) D(max) = Pv/2*(L-S)/2/(24*E*I)*(3*L^2-4*((L-S)/2)^2)+5*w/12000*L^4/(384*E*I) D(ratio) = L*12/D(max) D(allow) = L*12/450 Defl.(max) <= Defl.(allow),

Mx = (Pv/2)*(Lo+(Lo-S))+w/1000*Lo^2/2 My = (Ph/2)*(Lo+(Lo-S))

Lateral Flange Bending Moment from Torsion for Overhang: (per USS Steel Design Manual, 1981) e= 6.100 in. e = d/2 (assume horiz. load taken at bot. flange) at = 53.354 at = SQRT(E*Cw/(J*G)) , E=29000 ksi and G=11200 ksi Mt = 1.41 ft-kips Mt = Ph*e*at/(d-tf)*TANH(Lo*12/at)/12 X-axis Stresses for Overhang: fbx = 3.67 ksi Lbo/rt = 63.59 Fbx = 21.60 ksi Y-axis Stresses for Overhang: fby = 1.36 ksi fwns = 2.43 ksi fby(total) = 3.79 ksi Fby = 27.00 ksi Combined Stress Ratio for Overhang: S.R. = 0.310 Vertical Deflection for Overhang: Pv = 6.500 kips D(max) = 0.0554 in. D(ratio) = L/650 D(allow) = 0.0800 in. Bottom Flange Bending (simplified): be = 7.680 in. am = 3.355 in. Mf = 6.207 in.-kips Sf = 0.524 in.^3 fb = 11.84 ksi Fb = 27.00 ksi

fbx = Mx/Sx Lbo/rt = Lbo*12/rt Fbx = 12000*Cbo/(Lbo*12/(d/Af)) <= 0.60*Fy

fby = My/Sy fwns = Mt*12/(Sy/2) (warping normal stress) fby(total) = fby+fwns Fby = 0.75*Fy

S.R. = fbx/Fbx+fby(total)/Fby (assuming full design load, Pv without impact, at end of overhang) Pv = P+Wh+Wt (without vertical impact) D(max) = Pv*Lo^2*(L+Lo)/(3*E*I)+w/12000*Lo*(4*Lo^2*L-L^3+3*Lo^3)/(24*E*I) D(ratio) = Lo*12/D(max) D(allow) = Lo*12/450 Defl.(max) <= Defl.(allow),

Min. of: be = 12*tf or S*12 (effective flange bending length) am = (bf/2-tw/2)-(k-tf) (where: k-tf = radius of fillet) Mf = Pw*am Sf = be*tf^2/6 fb = Mf/Sf Fb = 0.75*Fy

10 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

Bottom Flange Bending per CMAA Specification No. 74 (2004): Local Flange Bending Stress @ Point 0: sxo = sxo = Cxo*Pw/ta^2 -8.60 ksi szo = szo = Czo*Pw/ta^2 0.87 ksi Local Flange Bending Stress @ Point 1: sx1 = sx1 = Cx1*Pw/ta^2 2.42 ksi sz1 = sz1 = Cz1*Pw/ta^2 10.47 ksi Local Flange Bending Stress @ Point 2: sx2 = sx2 = -sxo 8.60 ksi sz2 = sz2 = -szo -0.87 ksi Resultant Biaxial Stress @ Point 0: sz = 8.38 ksi sx = -6.45 ksi txz = 0.00 ksi sto = 12.88 ksi Resultant Biaxial Stress @ Point 1: sz = 15.58 ksi sx = 1.81 ksi txz = 0.00 ksi st1 = 14.76 ksi Resultant Biaxial Stress @ Point 2: sz = 7.08 ksi sx = 6.45 ksi txz = 0.00 ksi st2 = 6.78 ksi sz = fbx+fby+0.75*szo sx = 0.75*sxo txz = 0 (assumed negligible) sto = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

(Note: torsion is neglected)

(Sign convention: + = tension, - = compre

<= Fb = 0.66*Fy = 23,76 ksi

sy = fbx+fby+0.75*sz1 sx = 0.75*sx1 txz = 0 (assumed negligible) st1 = SQRT(sx^2+sz^2-sx*sz+3*txz^2)

<= Fb = 0.66*Fy = 23,76 ksi

sz = fbx+fby+0.75*sz2 sx = 0.75*sx2 txz = 0 (assumed negligible) st2 = SQRT(sx^2+sz^2-sx*sz+3*txz^2) Y

<= Fb = 0.66*Fy = 23,76 ksi

tw Pw Z Point 2 X Pw

Point 0 Point 1 bf

tf

11 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

h / without Overhang No. 74 (2004) Checker:

RR(max)=9,13 Lo=3

ature

ember Properties: 2.36 391.00 64.20 56.30 13.90 1.710 1880.0

in.^4 in.^3 in.^4 in.^3 in.^4 in.^6

+(Lo-S/2))/L+w/1000/(2*L)*(L+Lo)^2 Lo-S/2)/L+w/1000/(2*L)*(L^2-Lo^2)

t end of simple-span)

SS Steel Design Manual, 1981)

fbx <= Fbx, O.K.

(continued)

12 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

fby <= Fby, O.K.

S.R. <= 1.0, O.K.

^2)+5*w/12000*L^4/(384*E*I)

Defl.(max) <= Defl.(allow), O.K.

SS Steel Design Manual, 1981)

fbx <= Fbx, O.K.

fby <= Fby, O.K.

S.R. <= 1.0, O.K.

2*L-L^3+3*Lo^3)/(24*E*I)

Defl.(max) <= Defl.(allow), O.K.

fb <= Fb, O.K.

(continued)

13 of 14

11/8/2013 8:35 PM

"MONORAIL.xls" Program Version 1.3

torsion is neglected) convention: + = tension, - = compression)

<= Fb = 0.66*Fy = 23,76 ksi, O.K.

<= Fb = 0.66*Fy = 23,76 ksi, O.K.

<= Fb = 0.66*Fy = 23,76 ksi, O.K.

14 of 14

11/8/2013 8:35 PM

Anda mungkin juga menyukai

- Reinforced Concrete Design to Eurocode 2Dokumen420 halamanReinforced Concrete Design to Eurocode 2Mustafa Hyali97% (71)

- European Standards and Markings For Fall ArrestDokumen7 halamanEuropean Standards and Markings For Fall ArrestBatepola BacBelum ada peringkat

- BS 5500 Appendix K and DDokumen14 halamanBS 5500 Appendix K and DCRISTIAN SILVIU IANUCBelum ada peringkat

- Life Lines RequirementsDokumen2 halamanLife Lines RequirementsAnsarMahmoodBelum ada peringkat

- Shell-Bottom Joint Strength CheckDokumen3 halamanShell-Bottom Joint Strength CheckKP SahuBelum ada peringkat

- Weldable Clips: Weldlok 15 & 24 Suggested Weld and Installation InstructionsDokumen2 halamanWeldable Clips: Weldlok 15 & 24 Suggested Weld and Installation InstructionsBrajham Felix Alberto Garay100% (1)

- MONORAIL BEAM ANALYSISDokumen7 halamanMONORAIL BEAM ANALYSISDiego Andres RamosBelum ada peringkat

- AD 1-Cantilever Slab ExtensionDokumen4 halamanAD 1-Cantilever Slab ExtensionMalith De Silva100% (4)

- Equilibrium of Beam Experiment (EAT102Dokumen3 halamanEquilibrium of Beam Experiment (EAT102Nur DiniBelum ada peringkat

- Surface Area Structural SteelDokumen6 halamanSurface Area Structural Steelnaveen_8667% (3)

- Calculation For Wall Anchor Bracket Project Phase 1A &1B: Data - 08 11 2020 REV 00Dokumen9 halamanCalculation For Wall Anchor Bracket Project Phase 1A &1B: Data - 08 11 2020 REV 00Antonysamy SanthanamBelum ada peringkat

- API 650 Tank Nozzle Stand OutDokumen5 halamanAPI 650 Tank Nozzle Stand OutJunaid MateenBelum ada peringkat

- Engineer's Comments ReplyDokumen4 halamanEngineer's Comments ReplyfrancisbautistaBelum ada peringkat

- 2276 1Dokumen2 halaman2276 1hogoyoBelum ada peringkat

- Bleed & Flushing Ring GuideDokumen1 halamanBleed & Flushing Ring GuideRatna Giridhar KavaliBelum ada peringkat

- Autodesk 3D Design Software Suite FeaturesDokumen14 halamanAutodesk 3D Design Software Suite Featuressplaw9484Belum ada peringkat

- Flange Ansi B 16.5 - 150 LbsDokumen6 halamanFlange Ansi B 16.5 - 150 LbsZdenko Mahacek0% (1)

- Simple joint design in steel structuresDokumen8 halamanSimple joint design in steel structuresNikola PejatovicBelum ada peringkat

- Chibro Press Fit Piping Data SheetDokumen5 halamanChibro Press Fit Piping Data SheetBoyd JohnstonBelum ada peringkat

- Facilities On Offshore Installations: Guide For Building and ClassingDokumen209 halamanFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyBelum ada peringkat

- t4759 Bmu PlusDokumen6 halamant4759 Bmu PlusDraganaBelum ada peringkat

- Bolt Length Check ISO 4014Dokumen30 halamanBolt Length Check ISO 4014ValentinBelum ada peringkat

- Hydraulic Emergency Shut-Off System For Pressurised Liquefied Gas Storage TanksDokumen4 halamanHydraulic Emergency Shut-Off System For Pressurised Liquefied Gas Storage TanksLindsey PatrickBelum ada peringkat

- Rangkuman PDFDokumen1 halamanRangkuman PDFsaskia100% (1)

- Universal Beams To BS4 Part 1 - 2005Dokumen2 halamanUniversal Beams To BS4 Part 1 - 2005Jeebers CrrebersBelum ada peringkat

- CLC - KPR007399 01 37a 101 - REV 01Dokumen60 halamanCLC - KPR007399 01 37a 101 - REV 01yassir dafallaBelum ada peringkat

- A Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Dokumen5 halamanA Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Bimal DeyBelum ada peringkat

- Jis g3456 Grade STPT 410 Pipes PDFDokumen1 halamanJis g3456 Grade STPT 410 Pipes PDFMitul MehtaBelum ada peringkat

- Knife Gate Valve - AVKCMSDokumen2 halamanKnife Gate Valve - AVKCMSjuantamad02Belum ada peringkat

- Calculation - Loading PlatformDokumen7 halamanCalculation - Loading PlatformDaniel SarmientoBelum ada peringkat

- Columns DesignDokumen60 halamanColumns DesignifsrebraBelum ada peringkat

- Hempel Galvosil 1570019840Dokumen2 halamanHempel Galvosil 1570019840Jj OredinaBelum ada peringkat

- Pin StressesDokumen5 halamanPin Stressesprajakt_pieBelum ada peringkat

- Galvanized Scaffold Tubes & Couplers Product SpecsDokumen2 halamanGalvanized Scaffold Tubes & Couplers Product SpecssalmanBelum ada peringkat

- Final 175T Crane Spec DT 11.1.16 PDFDokumen57 halamanFinal 175T Crane Spec DT 11.1.16 PDFRohan KulkarniBelum ada peringkat

- Iso-15667Dokumen7 halamanIso-15667Chichi Julian FlekerBelum ada peringkat

- Davit Trolley - Validation of Davit & Support BracketDokumen17 halamanDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapBelum ada peringkat

- Car Washer CatalogueDokumen24 halamanCar Washer Cataloguesra electricalsBelum ada peringkat

- Asme VDokumen1 halamanAsme VMohd AnsariBelum ada peringkat

- BS en ISO 14122 - 3 - 2001 - EN - Segurança de Máquinas - Meio de Acessos Permanentes - Parte 3Dokumen24 halamanBS en ISO 14122 - 3 - 2001 - EN - Segurança de Máquinas - Meio de Acessos Permanentes - Parte 376971495Belum ada peringkat

- Deaerators BrochureDokumen4 halamanDeaerators BrochurefahimshkBelum ada peringkat

- ET Subsea Ball ValvesDokumen9 halamanET Subsea Ball ValvesAndrew BaileyBelum ada peringkat

- Iv. Design Calculation of Rafter, Girder & ColumnDokumen5 halamanIv. Design Calculation of Rafter, Girder & ColumnFaizal Sattu100% (1)

- Advanced Heat Exchangers: Shell & Tube Marine CondensersDokumen16 halamanAdvanced Heat Exchangers: Shell & Tube Marine CondensersMarco CambeiroaBelum ada peringkat

- Technical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dokumen5 halamanTechnical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dudung SBelum ada peringkat

- E-1 Deluge ValveDokumen10 halamanE-1 Deluge ValveTracy SankarBelum ada peringkat

- API 651 Reading ChecklistDokumen1 halamanAPI 651 Reading ChecklistbacabacabacaBelum ada peringkat

- Piping Engineering All Codes and StandardDokumen17 halamanPiping Engineering All Codes and Standardomkar parabBelum ada peringkat

- Butterfly ValvesDokumen27 halamanButterfly ValvesИгорьBelum ada peringkat

- Branchtein LifelineDesign PaperDokumen18 halamanBranchtein LifelineDesign Paperital1961100% (1)

- Aluminium Alloy 3003 Data SheetDokumen1 halamanAluminium Alloy 3003 Data SheetShyamKhatriBelum ada peringkat

- ER-56-03 EN Packager Standards Skid Design and FabricationDokumen4 halamanER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoBelum ada peringkat

- TEMA Eighth Edition - ClarificationsDokumen13 halamanTEMA Eighth Edition - ClarificationsJerome100% (1)

- Dimensions and weights of stainless steel pipesDokumen1 halamanDimensions and weights of stainless steel pipesAyhan AkyüzBelum ada peringkat

- As 4553-2008 Gas Space Heating AppliancesDokumen8 halamanAs 4553-2008 Gas Space Heating AppliancesSAI Global - APACBelum ada peringkat

- Hilti-Fischer Anchor BoltDokumen2 halamanHilti-Fischer Anchor Boltpavitrakedar100% (1)

- Asme b31.3 Table A 1 Basic Allowable Stress Carbon Steel Pipe and Tube Data Table 1Dokumen1 halamanAsme b31.3 Table A 1 Basic Allowable Stress Carbon Steel Pipe and Tube Data Table 1Crazy CBelum ada peringkat

- API 650 Storage Tank HRD - SubDokumen7 halamanAPI 650 Storage Tank HRD - SubBimal DeyBelum ada peringkat

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADokumen1 halamanDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhBelum ada peringkat

- Steel Pipe Dimensions - ANSI Schedule 40Dokumen3 halamanSteel Pipe Dimensions - ANSI Schedule 40StevenAronBelum ada peringkat

- API 650 Des PDFDokumen13 halamanAPI 650 Des PDFDhakshina K100% (1)

- "Monorail" - Monorail Beam Analysis: Program DescriptionDokumen7 halaman"Monorail" - Monorail Beam Analysis: Program DescriptionvenkieeBelum ada peringkat

- Monorail Design Excel PDFDokumen7 halamanMonorail Design Excel PDFsagar1503Belum ada peringkat

- Monorail 0.5 TonDokumen9 halamanMonorail 0.5 TonAndreas HendiBelum ada peringkat

- Thermo 5th Chap01P001 PDFDokumen33 halamanThermo 5th Chap01P001 PDFHasan ÖzdemBelum ada peringkat

- Heat Exch DesignDokumen34 halamanHeat Exch DesignMarly ReyesBelum ada peringkat

- Aisc Clean Columns WorksheetDokumen5 halamanAisc Clean Columns Worksheetscrbdgharavi100% (1)

- Pipe Insulation Addendum 1Dokumen3 halamanPipe Insulation Addendum 1Rafael ReyesBelum ada peringkat

- Hofierka JaroslavDokumen19 halamanHofierka JaroslavMarly ReyesBelum ada peringkat

- MD PV ASME v0.1Dokumen35 halamanMD PV ASME v0.1rizalramaBelum ada peringkat

- Reporte 2007Dokumen220 halamanReporte 2007Marly ReyesBelum ada peringkat

- Tai UtcDokumen2 halamanTai UtcMarly ReyesBelum ada peringkat

- LRFD For Steel and Composite BeamsDokumen23 halamanLRFD For Steel and Composite BeamsMunna SheikBelum ada peringkat

- Sap2000 v22 SFD-CSA-S16-14Dokumen117 halamanSap2000 v22 SFD-CSA-S16-14Mike Smith100% (1)

- SDS2 7.2-Connection GuideDokumen114 halamanSDS2 7.2-Connection Guidethe_dehumanizer100% (2)

- Liceo de Cagayan University College of Engineering Prestressed Concrete Design Take Home ExamDokumen1 halamanLiceo de Cagayan University College of Engineering Prestressed Concrete Design Take Home ExamdbircsBelum ada peringkat

- Manual Mechanics of Deformable Bodies 3Dokumen48 halamanManual Mechanics of Deformable Bodies 3Miyamura IzumiBelum ada peringkat

- LTB Part2 F14 OptDokumen15 halamanLTB Part2 F14 OptNejib GhazouaniBelum ada peringkat

- Flexistrut-8 2Dokumen167 halamanFlexistrut-8 2Lachlan RhodesBelum ada peringkat

- Notching On BeamsDokumen28 halamanNotching On BeamsElvie Rodado GubalaneBelum ada peringkat

- (B) Mechanical Properties of Matter: Hooke's LawDokumen57 halaman(B) Mechanical Properties of Matter: Hooke's LawOwani JimmyBelum ada peringkat

- Trebuchet PhysicsDokumen16 halamanTrebuchet PhysicsLeo KutsBelum ada peringkat

- Timber Structures Euro BookDokumen364 halamanTimber Structures Euro BookДаваажав ОдгийвBelum ada peringkat

- Glass Panes Acting As Shear Wall: E.M.P. Huveners, F. Van Herwijnen, F. Soetens, and H. HofmeyerDokumen26 halamanGlass Panes Acting As Shear Wall: E.M.P. Huveners, F. Van Herwijnen, F. Soetens, and H. Hofmeyer83357796Belum ada peringkat

- STAAD Technical Reference 2005Dokumen680 halamanSTAAD Technical Reference 2005Jay PatelBelum ada peringkat

- CES522 A 02 - Topic 2a - 1. Cover - EffectiveDepth - ULS AnalysisDokumen23 halamanCES522 A 02 - Topic 2a - 1. Cover - EffectiveDepth - ULS AnalysisAizuddinBelum ada peringkat

- ETABS Users Manual Frame Rigid Offset AssignmentsDokumen5 halamanETABS Users Manual Frame Rigid Offset AssignmentsvardogerBelum ada peringkat

- Release Notes ENG 14 1000Dokumen51 halamanRelease Notes ENG 14 1000Fatih AvdovicBelum ada peringkat

- CE 486 Preliminary Report - DenizyukcenDokumen28 halamanCE 486 Preliminary Report - DenizyukcenNasyrBekBelum ada peringkat

- Airplane Stress Analysis Report No. 82Dokumen72 halamanAirplane Stress Analysis Report No. 82brkappaBelum ada peringkat

- (Asce) Ae 1943-5568 0000057Dokumen7 halaman(Asce) Ae 1943-5568 0000057Alemayehu DargeBelum ada peringkat

- Analysis of Bare and Infilled Frames with Shear WallsDokumen6 halamanAnalysis of Bare and Infilled Frames with Shear WallsagustinussetBelum ada peringkat

- WCT2014-Design of 2nd CoentunnelDokumen8 halamanWCT2014-Design of 2nd CoentunnelTrong TranBelum ada peringkat

- Foynes Port Expansion for Deeper Draft VesselsDokumen7 halamanFoynes Port Expansion for Deeper Draft VesselsAdam Michael GreenBelum ada peringkat

- Raft Foundations - Design & Analysis With A Practical Approach PDFDokumen140 halamanRaft Foundations - Design & Analysis With A Practical Approach PDFemmanuel83% (6)

- Analytical Model For Beams On Elastic Foundations Considering The Coupling of HorizontalDokumen12 halamanAnalytical Model For Beams On Elastic Foundations Considering The Coupling of HorizontalPrantik Adhar SamantaBelum ada peringkat

- Chapter 1 - Introduction To RCDokumen46 halamanChapter 1 - Introduction To RCMazliah Zainal AbidinBelum ada peringkat

- Howard G. Allen, Zhengnong Feng (Auth.), A. Vautrin (Eds.) - Mechanics of Sandwich Structures_ Proceedings of the EUROMECH 360 Colloquium Held in Saint-Étienne, France, 13–15 May 1997 (1998, Springer Netherlands) - LibDokumen441 halamanHoward G. Allen, Zhengnong Feng (Auth.), A. Vautrin (Eds.) - Mechanics of Sandwich Structures_ Proceedings of the EUROMECH 360 Colloquium Held in Saint-Étienne, France, 13–15 May 1997 (1998, Springer Netherlands) - LibpqnamwBelum ada peringkat