Steel Spotlight-3 PDF

Diunggah oleh

Marshall BravestarDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Steel Spotlight-3 PDF

Diunggah oleh

Marshall BravestarHak Cipta:

Format Tersedia

Steel Spotlight

Produced in association with

Steel raises the game

Exposed steelwork is the star player above the indoor pitch at the National Football Centre in Staffordshire, which is due to open soon

PROJECT REPORT

RUBY KITCHING

Project St Georges Park, National Football Centre, Burton Upon Trent Main client The Football Association Architect Redbox Design Group Main contractor Bowmer & Kirkland Structural engineer Arup Steelwork contractor Billington Structures

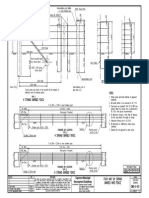

The Football Associations main aim when it rst came up with the idea of a National Football Centre was to create a place where players and coaches would feel inspired to train and improve their game. Now just months away from opening, the 73 million centre, also known as St Georges Park, is a dazzling spectacle in the Staffordshire countryside. The centre is made up of a sports block to the south and hotel and conference facilities to the north, as well as 11 outdoor pitches, including one replica Wembley stadium pitch. A 75 m-wide by 120 m-long structure houses the full-sized indoor articial pitch. Its roof is made up of curved steel trusses and clad in a gleaming white tensile PVC fabric. All the steelwork is exposed, so the highest quality nish has been specied. Many of the columns are tapered for architectural reasons and the glazed side walls slope outward at the eaves to add to the appeal of the building. This was clearly the most challenging part of the job, says Arup associate structural engineer David Bloomeld. He explains

26 | 23 February 2012

that the structure is a portalised truss, xed at either end and supported on columns made from beams tapering from 800 mm at the base to 1 m at the top. Each portal frame is spaced at 7.3 m centres and diagonal bracing is applied on all perimeter walls. The main columns sit on 3 m by 10 m by 2 m deep pad foundations supported off vibro-compacted ground. So much of the structure is visible the trusses, columns, connections that we spent a lot of time with the architect making sure everything was visually appealing, says Mr Bloomeld. Arup and architect Redbox Design Group worked closely together on the visual appearance of the building, developing the scheme to include curved trusses at rafter level which taper at each end as they meet the tapered columns. The philosophy behind the design was to create a sense of lightness natural light through the PVC tensile roof, and lightness in terms of the visual impact of the structure. Steel became the obvious material choice to achieve this.

Clever concealment We initially looked at circular hollow sections and square hollow sections for the trusses, but the architect decided a column section turned on its side would be better for the bottom boom.This allowed the upper channel of the H section to be used as a cradle to carry pipes and cables, conveniently concealed by the steel section when viewed from below, Mr Bloomeld says. During the design stage, every steel section was scrutinised to check how its position, geometry

Large steel trusses create the open column space for an indoor football pitch

is 13 m in the and section type centre while contributed to tonnes of steel columns at the creating an elegant, used for the perimeter are light steel frame. only 9 m tall. Meanwhile,Arup project Main contractor used in-house Bowmer & Kirkland, software to model and with steelwork contractor analyse the structure. Billington Structures erected the Steel cables were considered for roof. Columns were initially the diagonals in the trusses, but the complexity of designing them connected via baseplates to pile caps before the roof was erected. for a reversal of wind loads ruled The trusses came in quarters, them out, so square or hollow sections were preferred.The upper recalls Bowmer and Kirkland project manager Ian Woodall. boom of the truss is a circular Two 100-tonne mobile cranes hollow section. Keeping the roof trusses as slim lifted up the central two sections and a further two 50-tonne mobile as possible was a major design cranes put up the end sections. criterion and resulted in them All four sections were supported being 4.5 m deep in the centre of by crane until bolted together the span and 2.5 m deep at the and connected to columns. Mr ends. Purlins on the top boom Woodall adds:We were able to which support the tensile roof install three trusses a week and also had to be curved to follow the the whole structure was up in prole of the trusses.The maximum height of the structure just six weeks.

www.cnplus.co.uk

3,500

The main truss structure continues past the translucent Kallwall cladding to form a canopy frame around the perimeter of the building and a covered walkway. Propping this canopy are circular hollow section columns which are cigar-shaped, tapered at their ends. The indoor pitch building is connected at its northern edge to the sports science block. This is a composite steel structure with cellular steel beams allowing services to run through the openings, metal decking and concrete slabs. The three-storey building will include hydrotherapy pools at ground level, offices, and a human performance laboratory which will monitor players performance in different conditions. Integrating services around the hydrotherapy rooms at ground oor was challenging due to the

www.cnplus.co.uk

different types of services required, including specialist heating and cooling equipment to support the pools, pumps and backwash tanks as well as more regular mechanical and electrical equipment for offices and laboratories. The pool area also had to be sealed so that chlorine gas did not escape to other parts of the building. For this reason, above the pools, the steelwork had to be polyester powder-coated to make it more resilient to chlorine and a gas capture tank is located in the ceiling void.

Long spans A 50 m by 80 m multi-purpose sports hall nishes off the sports block. This steel-framed hall is made up of 50 m-long spliced trusses spaced at 7.3 m centres that support the roof and northlights glazing. Trusses are more conventional here, being

We spent a lot of time with the architect making sure everything was visually appealing

DAVID BLOOMFIELD, ARUP

straight and of constant depth. The roof is clad with metal decking. The truth is, when you have to design long spans, steel is the best option because its very rare that you reach a span which cannot be achieved, says Mr Bloomeld. While the indoor pitch, sports science and multi-sports hall are physically connected, the hotel complex is located 50 m to the north of the multi-purpose sports

hall and will offer more than 200 rooms, conference and banqueting facilities, restaurants and an 18 m long swimming pool. The hotel complex is made up of two bedroom wings, a recreational wing and a dining and conference wing, radiating from a central reception area. Precast concrete has been used for the structure on all the bedroom oors and steel used where longer spans are required. This is typically at rst oor level over long-span areas such as conference and banqueting suites, the reception and swimming pool. The roof is also steel-framed to accommodate plant. Currently on budget and programme, the project has involved careful coordination between the design team and contractors to ensure it is delivered to such a high standard in a short space of time.

23 February 2012 | 27

Steel Spotlight

Produced in association with

A focus on quality

The new director general of the British Constructional Steelwork Association is determined to promote the high standards of work of its members

INTERVIEW

RUBY KITCHING

MAKING HER mARK

Born to a British mother and Australian father, Sarah McCannBartlett grew up in Australia and studied international politics and economics at Melbourne University. Her first job was with the forerunner to the Woolmark Company her initial role was to analyse and forecast the demand for Australian wool from China and India. After three years, she was posted to Ilkley, West Yorkshire. The picturesque Victorian spa town had been the centre of the wool trading industry, so the predecessors of the Woolmark Company had set up an office there. Here, her focus was on global marketing and research. Following a three-year posting to New York with Woolmark, she retuned to Melbourne and began working for the Building & Plumbing Commissions, latterly as deputy commissioner. She worked on programmes to get all professionals in the building and plumbing industries registered for quality assurance purposes and helped introduce the first sustainable building regulations into house building in Victoria. In 2010, she returned to the UK to settle with her husband, four-yearold son and three dogs. In September 2011, she became director general of the BCSA, spending her time between London and Yorkshire, as well as visiting members around the country.

DELIVERING VALUE

The steel construction sector is looking forward to helping deliver the governments ambitious infrastructure growth plan, which includes a number of major structures and steel is likely to be the choice for many of them. But the optimism is tinged with a worry that some clients may look further afield for a solution and squander the opportunity to kickstart the UK economy. The money is being invested by the government for a specific reason, so we are hoping that authorities remember that during project procurement, research shows that for every 1 spent on construction, 2.84 is created in wider economic impact, says Sarah McCann-Bartlett. The UK steel construction industry is a world benchmark, with nothing to fear from competition on a level playing field. Our members have a modern business outlook and have invested a tremendous amount to ensure that we deliver the highest standards of quality, health and safety and sustainability. Clients must appreciate that lowest cost is unlikely to deliver best value. The association is committed to quality and competence and it is a requirement of BCSA membership that all steelwork contractors are audited and classified by the types of work and project size that they are able to undertake. The Register of Qualified Steelwork Contractors for Bridgeworks Scheme was developed by the BCSA. For many years, the Highways Agency has required its steelwork contractors for all its bridge contracts to be on the register. All the new infrastructure projects should adopt the RQSC scheme for bridges and BCSA membership for other structures, says Ms McCann-Bartlett. Both take the guesswork out of procurement and give the client assurance that the steelwork contractor they employ is properly equipped to carry out the work. The RQSC scheme is open to all steelwork contractors with a fabrication facility in the EU, subject to their successful completion of the assessment process.

With the country in recession and private and public sector projects thin on the ground, the BCSA is having to work harder to ensure its members are rst in line to win work when projects eventually get going.The BCSAs new director general Sarah McCann-Bartlett joins the organisation at a tough time, but says she looks forward to the challenges that lie ahead. The BCSA is the national organisation for the steel construction industry. Its members are companies that undertake design, fabrication and erection of steelwork, or are companies associated with these activities. Id like to see BCSA members widely acknowledged as the best steelwork contractors in the world, enthuses Ms McCann-Bartlett. Id also like to see contracts awarded across the public and private sector on a level playing eld, based on high standards of quality assurance, health and safety and sustainability. It is not the rst time the international executive has been involved with supporting an industry that needed to remind its supply chain and clients of the importance of using native highquality contractors. She spent nearly ten years with the Woolmark Company, an Australian organisation that developed the widely recognised mark of wool quality found on textiles and clothing. Woolmarks objective was to increase the amount of Australian wool consumed against cotton and synthetic products, says Ms McCann-Bartlett. We achieved this by providing technical support

28 | 23 February 2012

to wool processers, spinners, weavers and garment manufacturers, undertaking global marketing of wool as a bre, and forming strategic partnerships with other stakeholders. We also explained to fashion houses, such as Hugo Boss, the importance of using the Woolmark to guarantee quality of product.

Constructive choices Similarities between the wool industry and constructional steel can easily be drawn. While at the Woolmark Company she was all too aware of eastern manufacturing: Its lack of focus on human rights, particularly health and safety, undercut local rms which were focused on doing the right thing. For the constructional steelwork industry, she believes being a BCSA member is the equivalent of being branded with the Woolmark logo and the association is working to inuence public sector procurement requirements to state that only quality-assured, audited steelwork contractors should win work. Clearly we aim to put across that being a BCSA member is the differentiator between a great steelwork contractor and a not-sogreat one, she says, adding that The Highways Agency procures its steelwork contractors for bridge contracts only from the Register of Qualied Steelwork Contractors for Bridgeworks Scheme, which is administered by the BCSA. We want to see Network Rail, local government authorities and other public sector clients also choosing from the RQSC for bridges and coming to the BCSA for building work, she says. BCSA is also hearing reports that

We aim to put across that being a BCSA member is the differentiator between being a great steelwork contractor and a not-so-great one

contractual conditions are becoming more onerous. Alongside its Specialist Engineering Contractors Group colleagues, BCSA is monitoring the uptake of the recent amendments to the Construction Act and the governments fair payment initiative, both of which should have a real impact on payment across the whole construction industry. BCSA is also one of the

groups supporting the introduction of the Construction Contracts Bill in the Republic of Ireland, which will improve contract conditions for its Irish members.

Popularity points While steels market share in construction is already high, staying ahead of the game relies on constantly developing the

www.cnplus.co.uk

product to suit market needs and marketing its successes. Steel has inherent advantages which help its popularity its high strength-to-weight ratio lends itself to efficient lightweight construction, it is aesthetically pleasing in bridges and buildings it can take your breath away and its sustainable, recyclable and reusable in its existing form. You dont have to do anything with it

www.cnplus.co.uk

to reuse it, says Ms McCannBartlett. Through a joint marketing initiative with Tata Steel, the BCSA continues to work towards maintaining and, where possible, increasing steels healthy market share. The single-storey, shed market is almost 100 per cent and the multistorey market averages 70 per cent with some variation across different building types. We want to promote the efficiency of steel and that because you use less of it, the selfweight of a building is less, so the foundations are cheaper. For constructional steel to stay at the top of its game, barriers to its uptake have to be addressed. For some, the sustainability of steel is its stumbling block, particularly around the energy of manufacture. This needs to be weighed up with the fact that the material has a long life and is endlessly recyclable, says Ms McCannBartlett. Were now looking at whole lifecycle analysis of steel as a structural material and this is where steel comes into its own.

The whole picture Simplied lifecycle analyses look at the carbon footprint of a material from cradle to gate that is, from its point of manufacture to when it leaves the factory. In

this situation, natural materials such as timber score well. But if a whole-life cradle-to-grave scenario is considered the carbon footprint from manufacture until the material must be disposed of other materials may score better. Were now talking about cradle-to-cradle timescales and are working in partnership with Tata Steel to understand this better, she says. Steel can be reused if a building is carefully dismantled rather than demolished. This sustainability story is explored in the report Target Zero, which considers the factors affecting zero-carbon construction. While the debate continues as to how a zero-carbon building should be assessed, the pace of building itself in the public and private sector has slowed down considerably. Ms McCannBartlett argues that the way out lies in public infrastructure spending. We strongly support the governments infrastructure spending plan as well as the nuclear programme. However, we are pressing government to ensure projects get started quicker and that a forward programme of projects be published so that the industry can feel bold enough to plan ahead.

23 February 2012 | 29

Steel Spotlight

Produced in association with

Steel is the premier solution for the inn

The steel frame of a new budget hotel in central Liverpool has been able to connect a complex faade of masonry, cladding and glazing

HOTEL

LOCATION OF NEW PREMIER INN

Liverpool Central Loop Line

GRAND ENTRANCE

The specification was very high on the [foyer] steelwork because the architect wanted to make the steel members part of the feature, explains EvadX project manager Steve Morris. Connections are mostly hidden, requiring onsite welding and grinding, removal of weld spatter and craters to be filled in for aesthetic reasons or are highly expressed bolted connections. Curtins project engineer Dave Jones recalls that full-scale prototypes were produced with EvadX during the design development period to provide high quality, visually aesthetic exposed steelwork connections. EvadX used computer software, Strucad, to help the design team understand the details which were then agreed upon by the architect. He adds: The result is that connections are bespoke, discrete and create a very elegant frame. The foyer steelwork also includes a 22 m-long and a 19 m tubular column which were both too long to be lifted in whole pieces by the tower crane. Instead, both columns arrived on site in halves and were site-welded. Pre-welded connections on the end of each tube helped locate the two halves. The foyer steelwork is being lifted into position using the tower crane, with operatives assisting on mobile elevated working platforms. Since this corner is located in a pedestrianised area, the hoarding has been extended around the extra plant to allow safe erection.

RUBY KITCHING

Project Premier Inn, Liverpool Main client Whitbread Hotels & Restaurants Architect Allison Pike Main contractor Watkin Jones Structural engineer Curtins Consulting Steelwork contractor EvadX

Albert Dock Liverpool James Street Rail Site slopes down in this direction New Premier Inn

t rS ve no a H

Duk e St

Fle et St Se el St

er Li v

St

Gil be rt St

0 M 200

hotel related to the area this is Liverpool One is a 153,000 sq m provided in the nautical and ropeshopping and leisure district just making-themed artwork which is east of Albert Dock. It opened for applied onto 18 panes of glazing in business in 2008, providing a 1 the foyer (see box). billion investment for the city. Steelwork for the main hotel With more visitors, more and retail units has already been accommodation is required and budget hotel operator Premier Inn erected, with the trickier elements supporting the foyer glazing going is now building its third hotel in up in the next few weeks. A single the city, on the edge of Liverpool tower crane and mobile cranes One. Costing 12 million, it is the erect the steelwork, cladding and largest self-build project parent masonry elements of the project. company Whitbread Hotels & Restaurants has undertaken in the UK. The steel-framed structure Hotel location will also include three retail units The development is situated on a and four restaurants at ground diamond-shaped plot of land oor level. surrounded by Hanover Street to Setting this hotel apart from the north-west, Fleet Street to the others in the area is the attention north-east, Seel Street to the to detail put into the design and south-west and a car park to the construction of the glazed corner south east. A new service road entrance foyer, which rises from called David Lewis Road will be rst oor level to above built between the car park the roof parapet. The and new hotel, linking prism-shaped Seel Street with Fleet structure Street. The site cantilevers over naturally slopes the pavement and down to its lowest tapers out with edge along Hanover months of height. Planning Street. programme officials were keen Retail units and to ensure that it stores occupy oors up expressed how the to level two and four

15

storeys of hotel accommodation sit on the streetside retail units.The development takes the shape of something like a squared doughnut from second oor level,with plant and drainage located at the centre on the second oor at roof. Liverpool was bombed extensively during World War II, so an unexploded ordnance specialist had been appointed to advise on specic project risks prior to site investigation, excavation and groundwork. Through investigation of the site, consultant Curtins identied poor ground conditions that meant the ground oor would need to be suspended and piled foundations installed. But excavating, screening, crushing and re-compacting 12,000 sq m of made ground as part of the demolition contract improved its properties so that pad foundations onto sandstone bedrock and a ground-bearing slab need only be built. Crushed and screened demolition rubble from a 1960s multistorey carpark on the site also helped provide material to create two levelled areas on a site, half of which Hanover Street side

The elevation along one street incorporates a step in the ground oor level to take-in the sites slope

We arrived at this solution as the best from a cost and programme point of view

JOHN KELLY, CURTINS CONSULTING

is about one storey lower. Excavation to about 2 m to 2.5 m below ground level ensured obstructions in the ground were also removed at this stage and a retaining wall was built halfway across the site to support the change in ground level.

Level best Ground level is assumed to be along Hanover Street, with the lowest oor on the opposite side of the site starting at level one. Since the hotel oors all begin at level two on the streetside elevations, double-height units can be

www.cnplus.co.uk

accommodated on the Hanover Street side, while only singlestorey height units can be accommodated on the other half of the site. With a tight 15-month programme, steel framed construction with composite metal oors was deemed both the quickest and most cost-effective way to build the hotel. We looked at timber-framed solutions and modular forms of construction, but we arrived at this solution as the best from a cost and programme point of view, says Curtins Consulting associate John Kelly. The faade is quite complex incorporating a mixture of masonry, cladding and glazing. Some framing systems, particularly modular, would not be able to accommodate all the different sorts of connections required, but steel was more than capable of doing so.

www.cnplus.co.uk

Street-facing elevations are acoustically drylined to ensure hotel residents are not disturbed by street noise and fresh air for ventilation is drawn from the hollow in the centre of the doughnut-shaped building, rather than from the street. The project also includes traditionally built bathrooms, rather than pods, giving the client exibility in design. The majority of the steel frame is based around a regular column grid pattern of 7.2 m by 7.7 m. With a central corridor and equal-sized rooms either side, the design required three lines of columns including the perimeter members, with a central row positioned in the corridor. Transfer beams at second oor level helped distribute the more dense hotel structure on to fewer columns in the retail units. This has meant that the columns at ground oor are fairly

heavily loaded. Coupled with the fact that the buildings footprint covers most of the site, there are some locations next to the boundary where a full perimeter baseplate cannot be accommodated. Here, the baseplates have had to be tied to adjacent column baseplates using steel struts. The solution meant that load is shared between columns and that deep foundations are not required. Structural stability is derived from extra bracing in lift shafts, stairways and partition walls. Each side of the building has had to be designed discretely with its own stability system due to lack of continuity across the depth of the building.

Clear thinking Clear spans were required for the retail units, with mezzanine levels hung from the underside of the second oor steelwork so that columns did not break up the space at ground oor. The ground oor retail areas needed to be large and open, so steel worked well, but it also suited the more regular and repetitive frame which was needed above level two, explains Curtins project engineer Dave Jones. He adds that the scheme was modelled using 3D modelling software, which helped visualise the structure, particularly its level changes. The model was also useful when it came to coordinating interfaces with cladding, glazing, internal blockwork and external brickwork as well as services and

ra St

nd

St

re e

tA

502

construction issues on site. 3D modelling gave us the ability to check and cross-check the structure. It took time and resources to build, but when the project started on site, it really helped with coordination issues and meant the building could y up, adds Mr Jones. Steelwork contractor EvadX has also installed the precast stairs using the onsite tower crane, which has a 2.8-t capacity. Despite high winds and snow, the project remains on target for completion in autumn.

23 February 2012 | 31

30 | 23 February 2012

Steel Spotlight

Produced in association with

Selection process key to success

Choosing the right steelwork contractor for the job could make the difference between a really successful project and one that is not so good

CHOOSING A CONTRACTOR

RUBY KITCHING

SUSTAINABILITY CHARTER

The BCSA was one of the first organisations to establish a Sustainability Charter for its members. The Steel Construction Sustainability Charter scheme has been running since 2005 and helps identify companies which practise sustainable steel construction. Members are assessed against 12 criteria and can apply for different levels of recognition. To become a member six of the criteria need to be satisfied, silver membership needs nine, and gold needs all 12.

Its well known that changes made to a building or bridges design when it is onsite have huge implications on the success of a project. Many sorry tales have been told about jobs which should be remembered as technically exciting and visually stunning, but became entrenched in bad feeling because of changes that

resulted in claims. According to BCSA president Ivor Roberts, Building Information Modelling (BIM) could be the thing that irons out the details of a design before it gets onsite, while ridding the industry of the claims culture. Assurance of design would also make fabricating a much more straightforward operation, he adds. Good steelwork contractors are very exible and quick to respond

BCSA Gets reaDy FOr CE MarKinG

The BCSA is preparing for CE marking (CEM) of structural steelwork to be mandatory acrossall member EU states in July2014 (including the UK and Republic of Ireland). CEM is a way of ensuring a product meets the minimum requirement for health and safety. All steel sections and structural bolts are assessed against a harmonised standard. This standard is the same across all member states. The standards list the performance characteristics for the product, the values for which are declared by the manufacturer on CEmarking, says BCSA director of engineering David Moore. It is really about health and safety because the performance characteristics identify how the product performs in fires, how strong and durable it is and how the product is made, amongst others. For non-standard or proprietary products, which fall outside the scope of the harmonised standard, a European Technical Assessment may be developed and used to assess and CE mark the product. The main harmonised standards for the constructional steel industry are as follows: n BS EN 10025-1 Steel open sections, I , H channels n BS EN 10210-1 hot finished tubesections n BS EN 10219 cold formed tubes n BS EN 1090-1 fabricated steel n BS EN 14399-1 preloadable bolts n BS EN 15048-1 non-preloadable bolts To satisfy the requirements on CEM for fabricated steel, steelwork contractors need to have in place a certified Factory Production Control (FPA) system. This may require them to put in place a Welding Quality Management (WQM) system that is in line with BS EN ISO3834. The most difficult and challenging aspect related to the introduction of CEM is the requirement for a knowledgeable and competent responsible welding co-ordinator, adds Moore. The BCSA provides members with the necessary technical support and guidance to setup and implement CEM, FPC and WQM systems.

to challenges. They work efficiently and have a quick turnaround between jobs. But if a client says, can you change this? or can you add that?, it becomes very complicated particularly when the nish date of a project is difficult to shift. We back BIM because there is so much information up front, which means that changes are less likely to happen further down the line. Everything should have been thought through even down to where lighting brackets should be located. With BIM, there is a level of condence that the information is nal and correct. On receiving a design, a good steelwork contractor can cut down the fabrication programme. With construction programmes already tight, it pays to have a good or competent steelwork contractor on board. BCSA members are steelwork contractors involved in building and bridge work, who are regularly audited for the type and size of job they can undertake.The BCSA also assesses rms quality assurance, technical capabilities, health and safety and sustainability practices (see box, far right). Crucially, track records and details of referees are also included on the register, so formerclients such as local authorities, consultants and main contractors may be contacted for an unbiased recommendation, adds Mr Roberts. He advises clients to visit the workshop to get a better feel for a contractors capabilities because there is a huge range from a single building workshop with limited handling facilities, to ones with multiple large buildings

The 12 criteria for sustainability charter membership

1 A published sustainability policy (mandatory). 2 Progress towards sustainability monitored using specific management targets. 3 Involvement with the local community on social issues and with the steel construction community generally. 4 An accredited health and safety management system to BS OHSAS 18001, or health and safety management as an integral part of a quality management system accredited to BS EN ISO 9001. 5 Investors in People accreditation or a structured programme for personnel training, development and communication. 6 A published equal opportunitiespolicy. 7 A published ethical trading policy. 8 An accredited environmental management system to BS EN ISO14001. 9 Use of environmental impact assessment for process improvement. 10 A policy to manage energy and vehicle fuel usage in the business. 11 A policy to question whether suppliers have published sustainability policies. 12 An accredited quality management system to BS EN ISO9001.

Quality steelwork is assured from BCSA members workshops

with state-of-the-art technology for sawing and drilling. He believes contractors which are BCSA members are also better placed to understand the impact of new trends, such as BIM, or new legislation which can impose different ways of working. Under European Union legislation for example, CE marking will become mandatory in July 2014 (see box, left). The legislation requires manufacturers to make an explicit declaration that their products are safe, always requiring another organisation to validate it. In contrast, if you choose a steelwork contractor which is not a BCSA member or on the Register of Qualied Steelwork Contractors Scheme for Bridgeworks, then you risk not knowing whether they are technically and nancially sound, adds Mr Roberts.

www.cnplus.co.uk

usinG the BCSA tO FinD a cOMPetent steelWOrK cOntractOr

Prequalifying steelwork contractors for tenders can be easily done usingthe membership list of the BCSA, or the Register of Qualified Steelwork Contractors Scheme for Bridgeworks (RQSC). Approximately 100 steelwork contractors are BCSA members. Each are assessed by the BCSA against their capabilities in 14 categories of building steelwork and eight sub-categories of bridge construction. The categories give guidance on what type of steelwork activities the company is competent to undertake, which relates to the companys work facilities, its track record and its technical and management experience. Crosschecking these categories against specific project requirements is an easy way of shortlisting contractors. found specifically on the RQSC for bridges, which is administered by the BCSA and is open to any competent steelwork contractor with a fabrication facility in the EU. It was developed to fulfil the needs of the Highways Agency. All the agencys contracts involving structural steelwork require a contractor to be on this register. To select a suitable steelwork contractor for type and scale of work; visit www.steelconstruction. org/directories or use the new Find a steelwork contractor App for smartphones which will shortly be available for download at www.steelconstruction.org. Both of these options have search functions where various criteria, such as sustainability, can be selected.

The listing also classifies each company by suggesting the size of steelwork contract that the company has the financial and management resources to undertake. Bridgework contractors can be

32 | 23 February 2012

www.cnplus.co.uk

23 February 2012 | 33

Steel Spotlight

Produced in association with

Steel to the rescue

Gloucestershires four new re stations are being built using steel frames to ensure they are ready for action as soon as possible

PROJECT REPORT

RUBY KITCHING

Project Cheltenham East Fire Station, Keynsham Road, Cheltenham, Gloucestershire Main client Gloucestershire Fire and Rescue Service Architect CalderPeel Main contractor Kier Moss Structural engineer WYG Steelwork contractor Adstone Construction

Cheltenham East Fire Station: steel frame construction gave the client condence that the design could be adapted for future needs

Gloucestershire Fire & Rescue Service is overseeing construction of four new re stations to replace two older stations which date back to the 1950s and 60s. The project has been procured under a 25-year, 40 million PFI contract with consortium Blue 3, which includes contractor Kier Moss. The new stations have been located strategically around Gloucestershire to ensure that incident response times in the county can be reduced to eight minutes, in line with the ambulance service. All four are of steel-framed construction, with composite steel oors. The steelwork contractor is Adstone Construction. One, Cheltenham East re station, will be located on the site of the former Cheltenham re station at the junction of Keynsham Road and College Bath Road. During construction, re service operations have been temporarily shifted to a nearby factory building. Since the new stations are required to serve the community as soon as possible, a cost-effective and speedy form of construction was required. The [Cheltenham] re service is working from a temporary facility, so they want to be in the new station as soon as possible, says consultant WYG technical director Jim Seagar. It was a no-brainer, really, using steel-framed construction, because it meant that the structure could be up quickly in

34 | 23 February 2012

NEW tRaINING FaCILItIEs

The modern fire station is very different to the buildings which were erected in the 1950s and 60s. Gone are the firemans pole and drill towers, to be replaced by a lift and more sophisticated and appropriate training facilities. Emergency scenarios which can be recreated by the Gloucestershire fire and rescue teams at Gloucester South stations life skills centre include pulling a car out of a ditch or rescuing people from road traffic or rail incidents. The centre is equipped with vehicles and railway track, street furniture and traffic lights, and even a four-bedroomed house. This is housed under a 23 m spanning monopitch roof made up of 610 mm-deep beam sections. The centre is used to train fire fighters, but also to educate the public on fire risks and other emergency situations which can arise, such as flooding. The new stations recognise the fact the fire service deals with many emergency situations, other than fires. Gloucester North station will also include a state-of-the-art road traffic collision training area for fire fighters to test their operational skills. Cheltenham West will have a purpose-built training building that will provide a range of practical scenarios, such as ladder work, breathing apparatus search and rescue, basement firefighting and flooding to test firefighters operational skills.

less than six weeks. Each re station, including the Cheltenham East station, is made up of a single-storey appliance bay that houses the re engines, and a three-storey main office block.

Flexibility rst The 30 m-long by 15 m-deep appliance bay structure at Cheltenham East is formed from steel portal frames spanning 15 m and spaced at 5 m centres to accommodate six re engines. There is also a 15m-deep cantilevering canopy attached to the appliance bay which is supported along its length by a 30 m-long steel truss. Again, with future exibility in mind, these canopies can later be used as part of a permanent roof, should the appliance bay need to be extended to accommodate more re engines. Clear spans were also essential in this building to provide the engines with room to manoeuvre. The main office block is of steelframed construction with composite oors. At ground oor, rooms are used to store re-

ghting equipment and provide cleaning and drying areas, changing rooms and offices for the station manager and other personnel. Accommodation, including dining and recreational areas, is located on the rst oor and plant is located on the second. The new buildings are also steel-framed for future exibility, explains Mr Seagar. The structure is built off a primary grid, but partition walls can be moved about to suit future needs.

We dont know what a modern re service will look like in the future, so exibility and robustness had to be built in at the outset. For example, there is no longer a remans pole connecting the living accommodation and appliance bay. Instead, stairs and a lift do the job. The few internal columns which remain within the depth of the building in the main block have been carefully positioned

www.cnplus.co.uk

within internal walls, so that they services through openings in deeper section beams, would do not encroach on clear spans. make it easier to carry out Stability will be provided to each alterations in the future. structure through horizontal and The curved community block is vertical bracing systems also a steel-framed structure and incorporated into the structural has function rooms at ground frame. The location of posts and column bracing were agreed with oor level, which can be hired out by the public. A tness suite the architect to avoid conicts occupies the rst oor. Its curved with windows and doors. Most elevation allows the adjacent internal walls are non-loadbearing so they can be removed or listed building to be viewed more prominently and was a key part of repositioned to accommodate the buildings planning consent, future modications. since the previous station The rst-oor steel beams of obscured this view. the main block and community Steel lent itself to the curved block have been designed two-storey building, because it compositely, with the metal could form the curve effortlessly, decking and reinforced concrete says Mr Seagar. He adds that the slab using shear studs. This has community buildings on the ensured that beam depths and other two sites use glulam therefore oor depths beams, but have are kept to a orthogonal elevations minimum, allowing and are only singleroom for a storey. Connecting suspended ceiling the main and that will steel truss community blocks accommodate supports feature is a covered services in the walkway, created ceiling void. The canopy using glulam rafters design team felt this, and glazing. as opposed to feeding

We dont know what a modern re service will look like in the future, so exibility and robustness had to be built in at the outset

JIM SEAGAR, WYG

The stations were modelled using three-dimensional software to help designers understand the interaction between the three main blocks that make up the new station.

BIM win Drawings were easier and quicker to reproduce for construction, explains Mr Seagar, because design changes only had to be made once on the model, and all the drawings would be automatically updated. This is part of the move towards Building Information Modelling and a way

30 m

of making us work more efficiently, he adds. Demolition of the existing re station at Keynsham Road was carried out last April, followed by site clearance and construction of pad foundations. The main block was the rst to be erected. The Cheltenham East site is almost entirely occupied by the buildings footprint, so there is limited space for materials storage during construction. This meant steel sections were delivered in relatively small bundles, so could be erected almost immediately Everything is delivered just in time, and weve put a lot of effort into going through the build programme and understanding the structural requirements ahead of ordering deliveries, explains Kier Moss senior site agent Paul Ingram. This saw steel erection carried out using mobile lifting plant rather than a static tower crane, due to the lack of space. But, even with a tight programme and a tight site, Cheltenham East re station is still due to open in April.

23 February 2012 | 35

www.cnplus.co.uk

Anda mungkin juga menyukai

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDari EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesBelum ada peringkat

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenDari EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenPenilaian: 5 dari 5 bintang5/5 (1)

- Charlotte RD, Ec2Dokumen2 halamanCharlotte RD, Ec2kurtrobbinsBelum ada peringkat

- Case Studies-Residential BuildingsDokumen28 halamanCase Studies-Residential BuildingsSaurav Saini100% (2)

- Fastest High Rise BuildingDokumen1 halamanFastest High Rise Buildingdenise aviBelum ada peringkat

- 3 Recent Innovations For Steel and Composite Steel-Concrete Structures in AustraliaDokumen72 halaman3 Recent Innovations For Steel and Composite Steel-Concrete Structures in AustraliaMREFAATBelum ada peringkat

- Urban Hospital Build in Good Health: Steel SpotlightDokumen5 halamanUrban Hospital Build in Good Health: Steel SpotlightMarshall BravestarBelum ada peringkat

- Building Technology 5: Membrane Structures & Steel Structures in ArchitectureDokumen17 halamanBuilding Technology 5: Membrane Structures & Steel Structures in ArchitectureGabriel RoaBelum ada peringkat

- College of Architecture Universtiy of Santo Tomas Espaìa, ManilaDokumen6 halamanCollege of Architecture Universtiy of Santo Tomas Espaìa, ManilaKaizer Khamomill T. MacatiagBelum ada peringkat

- Burj Khalifa, Dubai - Currently The World's Tallest Man Made Structure, The Burj Khalifa Stands at 829.8m. Using ADokumen5 halamanBurj Khalifa, Dubai - Currently The World's Tallest Man Made Structure, The Burj Khalifa Stands at 829.8m. Using AClaire EngbinoBelum ada peringkat

- Benz StadiumDokumen18 halamanBenz StadiumHARI NIVETHAN K G 20BAR0026Belum ada peringkat

- Dongkuk Steel: Leading Global Steel Development with Innovative TechnologiesDokumen18 halamanDongkuk Steel: Leading Global Steel Development with Innovative TechnologiesdcdecastrojrBelum ada peringkat

- Steel As A Structural MaterialDokumen10 halamanSteel As A Structural MaterialFaisal ShahzadBelum ada peringkat

- Dhruv Bansal - 10110014 Madhav Singh - 10110031Dokumen18 halamanDhruv Bansal - 10110014 Madhav Singh - 10110031Sarthi KatyalBelum ada peringkat

- Steel FrameDokumen5 halamanSteel FrameDanielle Ann Joyce ValenciaBelum ada peringkat

- Delhi Parliament LibraryDokumen4 halamanDelhi Parliament LibraryChenna ManikanteswaraBelum ada peringkat

- PAPER IASS Geodesic Dome Cottonera Sports Hall MaltaDokumen9 halamanPAPER IASS Geodesic Dome Cottonera Sports Hall MaltaistructeBelum ada peringkat

- London Olympic StadiumDokumen3 halamanLondon Olympic StadiumPranav SamdadiyaBelum ada peringkat

- London Olympic StadiumDokumen3 halamanLondon Olympic StadiumPranav SamdadiyaBelum ada peringkat

- London aquatics center wave-like roofDokumen15 halamanLondon aquatics center wave-like roofMADHU MITHABelum ada peringkat

- Manuscript Ipd 2Dokumen87 halamanManuscript Ipd 2John Louie PimentelBelum ada peringkat

- Construction of Cold Formed Steel StructuresDokumen6 halamanConstruction of Cold Formed Steel Structureseksi_hasanBelum ada peringkat

- Architectural and StructuralDokumen2 halamanArchitectural and StructuralBledoreBelum ada peringkat

- Design of Steel and Timber Report For Hangula Peter P. 219376049Dokumen12 halamanDesign of Steel and Timber Report For Hangula Peter P. 219376049LinusBelum ada peringkat

- The Development of The Light Gauge Steel Framing Industry in AustraliaDokumen7 halamanThe Development of The Light Gauge Steel Framing Industry in AustraliaMurthy GunaBelum ada peringkat

- SPA Summer 2002 Newsletter - Structural Precast Concrete Developments/TITLEDokumen4 halamanSPA Summer 2002 Newsletter - Structural Precast Concrete Developments/TITLEmagdyamdbBelum ada peringkat

- Iare SSDD LN PDFDokumen94 halamanIare SSDD LN PDFNi MeshBelum ada peringkat

- Hollow Sections For Multi Storey ColumnsDokumen37 halamanHollow Sections For Multi Storey ColumnsVimut SuttipongBelum ada peringkat

- A Comparison of Concrete Steel and Timber Construction EssayDokumen4 halamanA Comparison of Concrete Steel and Timber Construction EssayJordan Kurt S. Gu100% (3)

- Structural Features of Four Different Types of BuildingsDokumen27 halamanStructural Features of Four Different Types of BuildingsaryanwickedBelum ada peringkat

- Corus Jumbo Sections 2004Dokumen20 halamanCorus Jumbo Sections 2004Collin NguBelum ada peringkat

- Structural Steel: Group IncDokumen34 halamanStructural Steel: Group IncHowo4DieBelum ada peringkat

- The Gherkin.Dokumen4 halamanThe Gherkin.Natalia MouthonBelum ada peringkat

- Ship Loader MongstadDokumen4 halamanShip Loader Mongstadbi_747555164Belum ada peringkat

- Why steel is an increasingly popular construction materialDokumen13 halamanWhy steel is an increasingly popular construction materialRajat PathakBelum ada peringkat

- Rsa 2019Dokumen58 halamanRsa 2019LordM00nBelum ada peringkat

- Macaraeg-Arc044 (RSW No. 2)Dokumen33 halamanMacaraeg-Arc044 (RSW No. 2)Kathleen Denise Doria MacaraegBelum ada peringkat

- One World Trade CenterDokumen31 halamanOne World Trade Centersakshi meherBelum ada peringkat

- Tappen Zee Bridge ReplacementDokumen19 halamanTappen Zee Bridge Replacementmkeit123Belum ada peringkat

- Aurora Place Commercial Office Tower - 88 Phillip Street, SydneyDokumen27 halamanAurora Place Commercial Office Tower - 88 Phillip Street, SydneyekaapriliawatiBelum ada peringkat

- Individual Case Study - Queen Elizabeth's Olympic ParkDokumen6 halamanIndividual Case Study - Queen Elizabeth's Olympic ParkMichael CostaBelum ada peringkat

- Sarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresDokumen17 halamanSarkisian Et Al. 2009, AlSharq Tower, Optimization Tools For The Design of StructuresMais Maher AldwaikBelum ada peringkat

- ESDEP Vol0101ADokumen64 halamanESDEP Vol0101Aaladinmf1100% (1)

- Long Span StructureDokumen13 halamanLong Span StructurePranav M0% (1)

- Concrete Construction Article PDF - Solving Reinforcement Congestion ProblemsDokumen3 halamanConcrete Construction Article PDF - Solving Reinforcement Congestion ProblemsridminjBelum ada peringkat

- MSB01 Architect S Guide 2010-08-05Dokumen75 halamanMSB01 Architect S Guide 2010-08-05Sencu Razvan100% (1)

- Building Technology Project 2 - Construction SolutionsDokumen12 halamanBuilding Technology Project 2 - Construction SolutionsYuan MingBelum ada peringkat

- Manchester City Stadium - Structural Case StudyDokumen20 halamanManchester City Stadium - Structural Case StudyYuvan SethBelum ada peringkat

- Steel Truss Bridge StructureDokumen5 halamanSteel Truss Bridge Structurearjun 2008Belum ada peringkat

- Brewery Wharf Bridge: History and LocationDokumen2 halamanBrewery Wharf Bridge: History and Locationiliescu_oana_1Belum ada peringkat

- Design and Construction of Burj Al ArabDokumen53 halamanDesign and Construction of Burj Al ArabMuhamed Munjee95% (43)

- Introduction To Steel DesignDokumen65 halamanIntroduction To Steel DesignkentsunglaoBelum ada peringkat

- Use of Steel in The Seismic Retrofit of Historic Oakland City HallDokumen12 halamanUse of Steel in The Seismic Retrofit of Historic Oakland City HallRigobertoGuerraBelum ada peringkat

- Cost Comparison Steel vs. ConcreteDokumen20 halamanCost Comparison Steel vs. ConcreteHibozo82% (17)

- Petronas Tower - Stainless Steel - G3Dokumen12 halamanPetronas Tower - Stainless Steel - G3Gayathri kalkiBelum ada peringkat

- P028 Industrial Lattice Frame BuildingDokumen100 halamanP028 Industrial Lattice Frame BuildingAnilMohanK100% (12)

- Lincoln Center Canopies - Glass Supporting Steel: January 2012Dokumen10 halamanLincoln Center Canopies - Glass Supporting Steel: January 2012rukesh104Belum ada peringkat

- Construction Methods in Industrialized BuildingsDokumen37 halamanConstruction Methods in Industrialized BuildingsJoseph EzekielBelum ada peringkat

- 01.week 1 - Part 1Dokumen26 halaman01.week 1 - Part 1regieBelum ada peringkat

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsDari EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsPenilaian: 5 dari 5 bintang5/5 (1)

- CMDG General AllDokumen9 halamanCMDG General AllMarshall BravestarBelum ada peringkat

- Evolution Magazine May 2010Dokumen20 halamanEvolution Magazine May 2010Marshall BravestarBelum ada peringkat

- Ltu Ex 07239 SeDokumen97 halamanLtu Ex 07239 SeMarshall BravestarBelum ada peringkat

- Engtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceDokumen32 halamanEngtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceMuhammad ArshadBelum ada peringkat

- Digester FrontDokumen1 halamanDigester FrontMarshall BravestarBelum ada peringkat

- 2 Design of Reinforce Concrete BeamsDokumen60 halaman2 Design of Reinforce Concrete BeamsTshepiso NthiteBelum ada peringkat

- Train Like You Mean It: The Ultimate Performance TreadmillDokumen2 halamanTrain Like You Mean It: The Ultimate Performance TreadmillMarshall BravestarBelum ada peringkat

- 5 Tests That Could Save Your Life: 30 Worst Foods in AmericaDokumen2 halaman5 Tests That Could Save Your Life: 30 Worst Foods in AmericaMarshall BravestarBelum ada peringkat

- BestPracticeGuide4 Issue3 ElectricalDokumen20 halamanBestPracticeGuide4 Issue3 ElectricalMarshall BravestarBelum ada peringkat

- 04 MomentDistribution PDFDokumen88 halaman04 MomentDistribution PDFSimran Radheshyam SoniBelum ada peringkat

- Diesel Be Stupid CatalogueDokumen15 halamanDiesel Be Stupid CatalogueSaberAYarBelum ada peringkat

- Welcome To TrinidadRealtor - ComkkDokumen1 halamanWelcome To TrinidadRealtor - ComkkMarshall BravestarBelum ada peringkat

- Cork Expansion Joint Filler SheetDokumen2 halamanCork Expansion Joint Filler SheetMarshall BravestarBelum ada peringkat

- 1foundationsDokumen10 halaman1foundationsMarshall BravestarBelum ada peringkat

- The Essential Guide To Eurocodes Transition Part-1Dokumen33 halamanThe Essential Guide To Eurocodes Transition Part-1limegreens100% (4)

- Foreword The Need For Land EvaluationDokumen74 halamanForeword The Need For Land EvaluationMarshall BravestarBelum ada peringkat

- Institution of Structural Engineers Exam GuideDokumen1 halamanInstitution of Structural Engineers Exam GuideMarshall BravestarBelum ada peringkat

- NMTPFDokumen19 halamanNMTPFMarshall BravestarBelum ada peringkat

- Institution of Structural Engineers Exam GuideDokumen1 halamanInstitution of Structural Engineers Exam GuideMarshall BravestarBelum ada peringkat

- Structural Engineers: The Institution ofDokumen2 halamanStructural Engineers: The Institution ofMarshall BravestarBelum ada peringkat

- Structural Engineers: The Institution ofDokumen4 halamanStructural Engineers: The Institution ofMarshall BravestarBelum ada peringkat

- Portal FramesDokumen31 halamanPortal FramesMarshall BravestarBelum ada peringkat

- ReadmeDokumen2 halamanReadmeMarshall BravestarBelum ada peringkat

- DocDokumen20 halamanDocMarshall BravestarBelum ada peringkat

- STDokumen22 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen2 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen12 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen3 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen6 halamanSTMarshall BravestarBelum ada peringkat

- STDokumen11 halamanSTMarshall BravestarBelum ada peringkat

- July 2011 Nova Scotia South Shore Real EstateDokumen176 halamanJuly 2011 Nova Scotia South Shore Real EstateNancy BainBelum ada peringkat

- Faculty of Civil Engineering and Architecture Research GuideDokumen36 halamanFaculty of Civil Engineering and Architecture Research Guidegabi_xyzBelum ada peringkat

- White Cement Prospect ICR 2008-12Dokumen3 halamanWhite Cement Prospect ICR 2008-12jsabovik33Belum ada peringkat

- Cold Chain in PakistanDokumen4 halamanCold Chain in Pakistan188arsBelum ada peringkat

- Bohler Image Brochure GBDokumen38 halamanBohler Image Brochure GBtentuBelum ada peringkat

- Case Study in Community Development of Cabanatuan CityDokumen10 halamanCase Study in Community Development of Cabanatuan CityMark Emerson Alfonso Hernandez100% (1)

- Design Basis Report FOR Cable Tray: Document No. RINFRA-KUMPP-NEE-220-R-0001-R00Dokumen6 halamanDesign Basis Report FOR Cable Tray: Document No. RINFRA-KUMPP-NEE-220-R-0001-R00pulasta109Belum ada peringkat

- Oil and Gas Translation ServicesDokumen3 halamanOil and Gas Translation Serviceshappy_tridindiaBelum ada peringkat

- TRC Staaaructural BrochureDokumen74 halamanTRC Staaaructural BrochurePriscilla Combs100% (1)

- AHMDokumen23 halamanAHMeka_dewantoBelum ada peringkat

- UNIservice Global Ecosolut 24 Supervision Tank Cleaning 02Dokumen8 halamanUNIservice Global Ecosolut 24 Supervision Tank Cleaning 02Ian RidzuanBelum ada peringkat

- INTRODUCTION TO AGRICULTURE READING COMPREHENSIONDokumen3 halamanINTRODUCTION TO AGRICULTURE READING COMPREHENSIONAnonymous Fn7Ko5riKT100% (5)

- Roller Conveyor Machines Type RRBDokumen9 halamanRoller Conveyor Machines Type RRBAnas ElhadramiBelum ada peringkat

- Structural Design of Concrete Block PavementsDokumen11 halamanStructural Design of Concrete Block PavementsOso OsoBelum ada peringkat

- Hess405 PDFDokumen16 halamanHess405 PDFVgarg GargBelum ada peringkat

- Light Rail SystemsDokumen25 halamanLight Rail Systemsapi-294562810Belum ada peringkat

- Sports ObermeyerDokumen13 halamanSports Obermeyermaulikparekh09100% (3)

- BBA - Under Floor HeatingDokumen8 halamanBBA - Under Floor HeatingPaul KwongBelum ada peringkat

- Development of Design Guidelines For Rural Low Volume Roads in MalaysiaDokumen12 halamanDevelopment of Design Guidelines For Rural Low Volume Roads in MalaysiagabemzamanBelum ada peringkat

- Visual Inspection of Seamless PipesDokumen20 halamanVisual Inspection of Seamless PipesFasil Paruvanath100% (2)

- Lease TypesDokumen1 halamanLease TypesSatish RaiBelum ada peringkat

- Advantages of Metal CastingDokumen6 halamanAdvantages of Metal CastingHarshGuptaBelum ada peringkat

- FOB & CIF BasisDokumen4 halamanFOB & CIF BasisSrikrishna DharBelum ada peringkat

- Dave PDFDokumen8 halamanDave PDFChaturvedi TanyaBelum ada peringkat

- Fire Extinguisher GuideDokumen29 halamanFire Extinguisher GuidepaulbowesBelum ada peringkat

- Manpower Planning - Final Assembly & ProcessingDokumen11 halamanManpower Planning - Final Assembly & Processingsitam_nitj4202Belum ada peringkat

- Astm A314Dokumen3 halamanAstm A314Vinicius BacellarBelum ada peringkat

- OPKCDokumen20 halamanOPKCZeeshan AsaniBelum ada peringkat

- EURONORM 130 - 77 - Cold-Rolled Non-Coated Mild Unalloyed Steel Flat Products For Cold Forming Quality StandardDokumen4 halamanEURONORM 130 - 77 - Cold-Rolled Non-Coated Mild Unalloyed Steel Flat Products For Cold Forming Quality StandardJaveed A. KhanBelum ada peringkat

- Outline Specification 7,500 m3 LNG CarrierDokumen10 halamanOutline Specification 7,500 m3 LNG CarrierKelvin Xu100% (1)