Non Destructive Concrete Testing

Diunggah oleh

Vivek GosaviJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Non Destructive Concrete Testing

Diunggah oleh

Vivek GosaviHak Cipta:

Format Tersedia

Non Destructive Concrete Testing - Aaryan Engineers, Mumbai www.aaryanengineers.com 1.UPV TEST IS Codes applicable: As per IS 13311.

(Part 1): 1992 Applications of the test: The test is performed on structural elements. Homogeneity of Concrete. Presence of Cracks, Voids & Other Imperfections. Changes in Concrete Structure with time. Velocity co-related to strength. Equipment Used: Electric Pulse Generator. Transducer: One Pair. Amplifier. Electronic Timing Device. Test basis: Ultrasonic pulses travel faster in denser material. Each material has typical ultrasonic pulse velocities. E.g. steel, Concrete etc. using benchmarks over a period of time and conducting extensive laboratory and in-situ tests, we have co-related ultrasonic pulse velocity and estimated strength. Methodology: Assess access, Single sided, double sided etc on the structural element Clean the concrete surface thoroughly (on plaster or without plaster). Apply grease on the concrete surface where test is to be conducted. Press probes on the surface of the structural element to remove air gaps. Note down the distance between the 2 probes. Read time taken for the ultrasonic pulse from the instrument. Calculate Velocity = distance / time Repeat the test on multiple areas of the element if necessary. Test at different members of the structure.

Influencing factors for readings: Readings taken on plaster or directly taken. New/old construction in elements. New + old material (e.g. jacketed columns where new and old concrete coexist). Single sided or double sided access. (indirect or direct) Grade of Concrete. Understanding results: The estimated strength may vary from actual strength upto about +/- 15%. or so. In order to confirm the findings of the tests, core tests may be conducted on a select sample of elements, if necessary. The interpretation of strength of concrete from the UPV is based on our experience, judgment & to the best of our knowledge. The IS code 13311 (Part 1) 1992 (Indian Standard Code of Practice) gives velocity. Criterion for concrete quality grading, part of which is reproduced below: Sr. No Pulse velocity be cross probing (direct method) Concrete Quality Grading 1. Above 4.5 km/s Excellent 2. 3.5 km/s to 4.5 km/s Good 3. 3.0 km/s to 3.5 km/s Medium 4. Below 3.0 km/s Doubtful However the code does not give any interpretation of UPV in terms of strength. Hence the IS code gradings should be taken only as guidelines. However our experience shows that for M20 grade concrete a velocity of 3.5 km/s may be good but for high strength concretes like M40 or M60, the velocities for both may be above 4.5 km/s, however M40 cannot be used in place of M60, hence the IS code gradings should be taken only as guidelines. For new construction, for concrete grades higher than M30, the customer must provide reference cubes, crushing results and mix design in order to correctly arrive at the estimated strength. 2.REBOUND HAMMER This test measures the surface hardness of concrete. For new structures, the hardness reading is used to co-relate the strength of concrete. The hammer has to be used normal to the test surface, vertically (up or down) or horizontally depending on the structural element. IS Codes applicable: IS 13311, (Part 2): 1992. References: IS 516: 1959 Test for strength of concrete IS 8900: 1978 Criteria for rejection of outlying observations. Applications of the test: Assessing the Compressive Strength of Concrete Assessing the Uniformity of Concrete. Applicable for new concrete. Applicable for old concrete only with special techniques. Equipment Used: Rebound Hammer

Test basis: Harder the surface of the material tested, greater is the rebound. In new concrete, as it gains strength, hardness increases and as a result, the readings increase. The hammer can be used in 3 orientation, Vertical up or down (typically used for slab), horizontal (for columns). Depending on the orientation used and age of concrete, the results are interpreted for strength. Methodology: Identify test Locations. Clean the concrete surface thoroughly (remove plaster, if present ). Press hammer and release. Note down the reading. Take an average of multiple readings. Repeat the test on multiple areas of the element if necessary. Test at different members of the structure. Influencing factors for readings: Readings taken on directly concrete. New/old construction in elements. New + old material (e.g. jacketed columns where new and old concrete coexist). Carbonation of surface. Condition of the surface. Moisture content. Curing and age of concrete. Cement and aggregates ( detailed mix design) used. Understanding results: The Rebound Hammer test measures surface hardness only (upto about 50 mm depth). In order to assess continuity inside the element, UPV test is recommended. The estimated strength may very from actual strength about +/- 10%. In order to confirm the findings of tests, core tests may be conducted on a select sample of element. 3. HALF CELL POTENTIAL Half call potential test determines the probability of corrosion activity taking place at the point in the Reinforcement. A higher probability means more chances of corrosion. This test measures the probability and not the extent of corrosion. Codes Applicable: ASTM - C -876, 1991. Applications of the test: Assessment of probability of corrosion being present. Equipment Used: HCP Kit. Carbonation Measurement Kit. Test basis: Half Cell Potential The potential in millivolts decrease with the increase in probability of corrosion in the steel reinforcement. Carbonation:

Concrete, being basically a porous material, undergoes carbonation process with ageing. As the protective cover of the concrete carbonates completely, the corrosion reaches the steel reinforcement, rapidly accelerating the process of corrosion in steel.

Methodology: Half Cell Potential Identify test locations. Drill hole with a electric drill machine to reach the steel reinforcement rod. Establish electric contact to the reinformcement. Measure voltage in millivolts. on the surface of concrete at multiple locations of the member. Test at different members of the structure. Methodology: Carbonation Identify test locations. Drill hole with a electric drill machine to reach the steel reinforcement rod. Inject indicator chemical & insert steel rod. Indicator chemical determines at what depth the color changes. Influencing factors for readings : Extent of corrosion. Understanding results: The HCP test gives probability of corrosion and not the actual corrosion. For better understanding, ASTM have classified this into 3 categories as 10%, 50% and 90% probability. Carbonation test gives the depth in mm to which the carbonation has taken place in the concrete cover. 4. REINFORCEMENT MAPPING This method is used to assess reinforcement bar diameter and spacing of main bars and stirrups. For new structures it can be used to determine the exact usage of steel. In old buildings this is used to gather information on the reinforcement, not available or otherwise. This information is then used to prepare the structural drawings as constructed. 5. CORE TESTING 75mm, 100mm or 150mm diameter cores are taken on site using state of the art core cutting machines. Cover meter is used to locate the reinforcement steel before core cutting. This prevents structural damage to the RCC

member by avoiding the reinforcement. These cores are dressed in our lab and tested using standard compression testing methods to determine compressive strength and arrive at equivalent cube strength of concrete. IS Codes applicable: IS : 456 / IS : 516 / IS : 1199 Applications: Assessment of strength. Study of aggregates used in the mix design. Assessing probable causes of failures/problems. Equipment Used: Core cutter. Core compression testing machine. Test basis: A core sample is the actual representation of the material used in the structural element. When processed and subjected to load, it fails at a particular load, giving a fair idea of its compressive strength. Methodology: Step1: Reinforcement Mapping. By using a special instrument, based on eddy currents, the reinforcements are mapped in the structural member. Step 2: Core cutting. Cores are taken using special diamond cutters of 75 mm, 100 mm or 150 mm diameter. Locations are selected to avoid steel so as to minimize the damage to the structure.

Step 3: Dressing. The edges of the core are smoothend using grinding and cutting wheels and epoxy mortar is applied on both sides for capping. This ensures that the ends are approximately at 90% to the axis and are within 0.05 mm plane ness.

Step 4: Immersion in water

The core samples are immersed in water for 48 hours. The cores are weighed before and after immersion. Step 5: Compression testing. The cores are then subjected to compression forces on compression testing machine. The breaking point is observed. Step 6: Reporting. Based on the lab report, sizes of the core etc. an equivalent cube strength is calculated for the concrete applying necessary correction factors. The density, core strength and equivalent cube strength are reported. Influencing factors: Core diameter and length (h / d ratio) Proper capping and hydration of the cores as per IS code. Old/new/Mixed (jacketed) concrete. Understanding results: The result is normalized for comparison with compressive test results of a standard cube. This is done so that the cube results can be compared with the core results. Standard correction factors as per IS code are used for this purpose. This value may not be the same as the core strength. We report results as per IS code. IS code does not take into account the core cutting effect. When accounted for, the results can be higher than those reported. Discussion on this can be taken up with consultants as a separate assignment. Visual observations of the aggregate, failure pattern and probable causes of failure and suitalble remedies can be discussed separately and are not a part of the scope of conducting the test and reporting results. 6. PILE INTEGRITY TEST Pile integrity test is used to assess the continuity of piles. With this test, necking or bulging and uniformity of quality of concrete is checked.Piles that are doubtful for integrity are taken up for Dynamic load testing along with some piles which are ok. Typical defects identified by this test are shown below. Code: Method of Testing : There are Indian Standards for the pile integrity test & the most commonly used worldwide is Pile Integrity Test as per ASTM D 5882 00, Standard Test Method for Low Strain Integrity Testing of Piles. Relevant clause from the said ASTM standard is reproduced below: Clause no. 5.2.3 : Placement of Transducers The motion sensor should be placed at or near the pile head using a suitable, or temporary, bonding material (that is wax, vaseline etc.) so that it is assured that it correctly measures the axial pile motion. The motion sensor is placed generally near the center of pile. Additional locations should be considered for piles with diameters

greater than 500 mm. The low strain impact should be applied to the pile head within a distance of 300 mm from the motion sensor. Objective: To check the pile for continuity for the continuity of the shaft of the pile

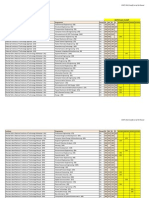

Background: In the sonic test, the top of the pile is hit with a plastic hammer and the reflected waves are recorded by a suitable computerized equipment. From the resulting signal, or reflectogram, one can determine both length and continuity of the pile. Although a powerful tool, the sonic method also has limitations, such as: the test produces no information regarding the pile capacity, and gives only limited information about the concrete quality. The sonic system, can only discover material impedance changes. It cannot tell anything whether these impedance changes are due to poor concrete or due to reduced cross section. Even then this test is a fast & economical tool for determining discontinuities in the pile shaft. If pile records are available, then the results can be fine tuned for greater & more reliable information. Limitations of the test: The accuracy of the length determination depends on the assumed wave velocity. This factor, which depends on the grade and age of the concrete, varies from pile to pile and may cause an error of the order of 10 percent. Site preparation Guide: For the test to be effective, the top of the pile should consist of clean concrete and free of debris, laitance and bentonite. Testing a pile with a head which was not properly prepared may yield misleading results. Table 2: Sample Report Sheet (Pile Integrity Test)

7. PILE DYNAMIC TEST Pile dynamic test is used to assess the load bearing capacity of the pile. This test uses a hammer of a couple of tons to drop on the pile. Displacements are measured using a high tech instrument. This data is processed to arrive at the pile dynamic load bearing capacity as per IS-2911(part-1 section-1). This test is easy to conduct and requires very few site arrangements. Code: Background: Modified Hileys formula is given in IS 2911, part 1, section 1. To obtain a reliable capacity prediction from dynamic pile testing, some very basic guidelines must be followed. Advantages: As a supplement to or replacement for static tests, dynamic testing takes far less time to perform and thus reduces the costs. Methodology The methodology of test is based on a large weight giving a dynamic impact to the elastic body. It equates the energy of hammer blow to work done in overcoming the resistance of the founding strata to the penetration of the ordinary cast-in-situ piles as well as grouted micro piles. Allowance is made for losses of energy due to the elastic compression of the pile, subsoil as well as losses caused by the impact of the pile. The modified Hileys

formula given in the code I.S. 2911 part 1 section 1 is used in estimating the ultimate driving resistance in tonnes. From that with a factor of safety as outlined in the code the safe load on pile can be worked out. The instantaneous displacements including rebounds of the pile are precisely recorded in an automatic data acquisition system. This is done for several cycles & then using formulae as in I.S. 2911, the safe load capacity of the pile is calculated. An optical instrument is used for position sensitive measurement by non-contact continuous measurement with the instrument placed away from the vibrations due to impact load. The system is based on combined light emitting diode transmitters & a position sensitive detector. The transmitter & receiver are installed so that the light beam forms a reference line from the transmitter, receiver to the prism group reflector. The reflected light can be received & recorded 100 times per second. Using the energy transmitted to the pile & accounting for temporary compression of the pile, ground & dolly occurring during the impact loading the ultimate driving resistance is calculated. Modified Hileys Formula R = Whn / (s + c / 2) Where R = Ultimate driving resistance in tonnes W = Mass of Ram in tonnes h = Height of free fall in cm considered at 80% for winch operated drop n = Efficiency of the blow representing ratio of energy after impact to striking energy of ram s = Average final set per blow in cm c = Average sum of temporary elastic compression Applying the factor of safety, the safe load for the pile is then calculated. Some of the significant advantages of this method are: 1. Non-contact 2. Transparent 3. Accurate 4. Easy to Understand 5. Logical 6. Quick 7. No need to cut projecting reinforcement from pile head 8. No need to cast concrete on pile head 9. Greater capacity utilization in design Standard Setup Diagram 1.Non-contact 2. Transparent 3. Accurate 4. Easy to Understand 5. Logical 6. Quick 7. No need to cut projecting reinforcement from pile head 8. No need to cast concrete on pile head 9. Greater capacity utilization in design

Dynamic Testing Procedure Notes: 1.To the cured pile, to avoid splitting of head due to impact, a steel cap with timber cushioning between steel & pile head is provided. 2. The instrument and laptop computers is set up at a distance away from the vibrations due to impact. 3. The test considers average/best of 4 blows. It is a known fact that during the first blow, the settlement is larger. The results are co-related with other parameters before arriving at a final conclusion.

Dynamic Pile Test Methodology:

Information required before testing from the customer site: 1.Pile records (total length, socketing length etc.), soil profile in the area, pile drawings, plans etc. 2.Mix design (if used) details of grade of concrete. Facilities required at the client site to conduct the test: 1.Clear approachable test locations with unobstructed view of one meter length of cleaned pile top. 2.Steel Plate & Wooden Cushion. 3.Loading facilities like piling winch along with chisel of known weight with operators installed at the location.

Sample Dynamic testing Report:

Anda mungkin juga menyukai

- Strategy 13 Presentation - Social Emotional LearningDokumen29 halamanStrategy 13 Presentation - Social Emotional Learningapi-588940234Belum ada peringkat

- Complimentary JournalDokumen58 halamanComplimentary JournalMcKey ZoeBelum ada peringkat

- CE ProblemDokumen5 halamanCE ProblemJho FBelum ada peringkat

- How 50 Million People Are Changing the WorldDokumen5 halamanHow 50 Million People Are Changing the WorldCTRCTR0% (1)

- 03 Concrete WorksDokumen49 halaman03 Concrete WorksVivek GosaviBelum ada peringkat

- Non Destructive Test On ConcreteDokumen6 halamanNon Destructive Test On ConcreteOpany JuliusBelum ada peringkat

- Disappearance of Madeleine McCannDokumen36 halamanDisappearance of Madeleine McCannCopernicBelum ada peringkat

- 3-Non Destructive Testing of ConcreteDokumen31 halaman3-Non Destructive Testing of ConcreteAhtisham KhanBelum ada peringkat

- Sri Infro Rebound Hammer ReportDokumen14 halamanSri Infro Rebound Hammer ReportChandan MondalBelum ada peringkat

- Assess Concrete Structures with NDT TechniquesDokumen37 halamanAssess Concrete Structures with NDT Techniquesramya_an2411Belum ada peringkat

- Crosshole Sonic Logging : ASTM D6760 - ACI 228.2RDokumen2 halamanCrosshole Sonic Logging : ASTM D6760 - ACI 228.2RrohitBelum ada peringkat

- NDT Structural SteelDokumen35 halamanNDT Structural Steeltinz_3100% (2)

- Shmidt Hammer Method StatementDokumen7 halamanShmidt Hammer Method StatementMurugesan ElaiyappanBelum ada peringkat

- Rebound Hammer TestDokumen12 halamanRebound Hammer Testmahmood hunar100% (4)

- Compressive Strength Test On Concrete CoreDokumen4 halamanCompressive Strength Test On Concrete CoreSyed Mohd MehdiBelum ada peringkat

- Rebound Hammer Test Method StatementDokumen2 halamanRebound Hammer Test Method StatementBassam AbdulwahabBelum ada peringkat

- Rebound Hammer TestDokumen14 halamanRebound Hammer TestChalakAhmed100% (6)

- Pile Integrity TestDokumen7 halamanPile Integrity TestFazren KamarudinBelum ada peringkat

- Lab Tests in ConstructionDokumen17 halamanLab Tests in Constructionsridhar k.l50% (4)

- Non-Destructive Test of Concrete and Masonry: Khwopa Engineering CollegeDokumen11 halamanNon-Destructive Test of Concrete and Masonry: Khwopa Engineering CollegeJeewanBelum ada peringkat

- Book3 79 111000 0000100120 DAH MPL RPT 000005 - ADokumen101 halamanBook3 79 111000 0000100120 DAH MPL RPT 000005 - ANassif Abi AbdallahBelum ada peringkat

- Modesto Mabunga Vs PP (GR 142039)Dokumen3 halamanModesto Mabunga Vs PP (GR 142039)Ericha Joy GonadanBelum ada peringkat

- Self-Compacting Concrete SeminarDokumen16 halamanSelf-Compacting Concrete SeminarAnubhab GhoshBelum ada peringkat

- Foundation Testing Data Sheet 1 Pile Integrity Testing - TDR MethodDokumen5 halamanFoundation Testing Data Sheet 1 Pile Integrity Testing - TDR MethodNishit PatelBelum ada peringkat

- Concrete Cube Durability Test Report SubmittalDokumen13 halamanConcrete Cube Durability Test Report SubmittalNawar ZainoBelum ada peringkat

- CSL Testing MethodDokumen4 halamanCSL Testing MethodGaneshalingam RamprasannaBelum ada peringkat

- Non Destructive Concrete TestingDokumen11 halamanNon Destructive Concrete TestingVivek GosaviBelum ada peringkat

- Concrete TestingDokumen34 halamanConcrete TestingKamarajanBelum ada peringkat

- Non-Destructive Testing Methods of Concrete StrengthDokumen26 halamanNon-Destructive Testing Methods of Concrete StrengthRaviKanthSrivastavBelum ada peringkat

- Non Destructive Testing of ConcreteDokumen7 halamanNon Destructive Testing of ConcreteSurya PaudelBelum ada peringkat

- New Japa Retreat NotebookDokumen48 halamanNew Japa Retreat NotebookRob ElingsBelum ada peringkat

- Ultrasonic Pulse VelocityDokumen3 halamanUltrasonic Pulse VelocitySougata DasBelum ada peringkat

- Bridge Monitoring SystemsDokumen43 halamanBridge Monitoring SystemsHoang NguyenBelum ada peringkat

- Rebound Hammer Test and Non Destructive Testing of ConcreteDari EverandRebound Hammer Test and Non Destructive Testing of ConcreteBelum ada peringkat

- Primary 2 (Grade 2) - GEP Practice: Contest Problems With Full SolutionsDokumen24 halamanPrimary 2 (Grade 2) - GEP Practice: Contest Problems With Full Solutionswenxinyu1002100% (1)

- Structural Inspection Report - SHENTON HOUSE - Cooling Tower With Method of Statement-Re1Dokumen48 halamanStructural Inspection Report - SHENTON HOUSE - Cooling Tower With Method of Statement-Re1Anonymous qi1Z7ZVlCBelum ada peringkat

- Pile Intigrity TestDokumen7 halamanPile Intigrity TestimranBelum ada peringkat

- Test 1 - Ultrasonic Pulse Velocity TestDokumen6 halamanTest 1 - Ultrasonic Pulse Velocity TestzeanBelum ada peringkat

- Method Statement For Sonic Logging Test-naga3-Rev.01-Dc230321Dokumen24 halamanMethod Statement For Sonic Logging Test-naga3-Rev.01-Dc230321Shafiq ZakariahBelum ada peringkat

- PHILHIS Executive Summary - EditedDokumen7 halamanPHILHIS Executive Summary - EditedMaxy Bariacto100% (1)

- Low Strain Pile Integrity TestingDokumen6 halamanLow Strain Pile Integrity TestingWaqas SadiqBelum ada peringkat

- What Are Universities ForDokumen19 halamanWhat Are Universities ForBikash Ranjan MishraBelum ada peringkat

- A Presentation On NDTDokumen23 halamanA Presentation On NDTBipin ShresthaBelum ada peringkat

- Concrete Quality Non-Destructive TestsDokumen5 halamanConcrete Quality Non-Destructive TestsNadhirah LnfBelum ada peringkat

- Ultrasonic Pulse Velocity Method for Testing Concrete QualityDokumen2 halamanUltrasonic Pulse Velocity Method for Testing Concrete QualitySzeJinTan100% (1)

- Non-Destructive Testing of ConcreteDokumen29 halamanNon-Destructive Testing of ConcreteNagha RamasamyBelum ada peringkat

- Sonic Logging Test Report BP_MC140Dokumen7 halamanSonic Logging Test Report BP_MC140Tuntun TatBelum ada peringkat

- Material Testing LaboratoryDokumen13 halamanMaterial Testing Laboratorydantan187100% (1)

- By P. Chetan Phani (06010417) Deep Gandhi (06010419) Hemant Kumar Bhaskar (06010421)Dokumen36 halamanBy P. Chetan Phani (06010417) Deep Gandhi (06010419) Hemant Kumar Bhaskar (06010421)Anonymous ouZFaSBRBelum ada peringkat

- Measure Concrete Quality with Pulse Velocity TestingDokumen4 halamanMeasure Concrete Quality with Pulse Velocity TestingKamal PakdamanBelum ada peringkat

- Cover Block Method StaDokumen1 halamanCover Block Method StaRavi kumarBelum ada peringkat

- Cover Meter Research PaperDokumen7 halamanCover Meter Research PaperMrinal AgarwalBelum ada peringkat

- Advanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiDokumen8 halamanAdvanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiVishvajit PatilBelum ada peringkat

- Co35Non-Destructive Testing of Hardened Concrete 35Dokumen4 halamanCo35Non-Destructive Testing of Hardened Concrete 35Moncef Thabet100% (1)

- NDTDokumen34 halamanNDTMohamed Ahmed RezkBelum ada peringkat

- Rebound hammer test for concrete compressive strengthDokumen2 halamanRebound hammer test for concrete compressive strengthrexdindigulBelum ada peringkat

- Methodology of UPVDokumen3 halamanMethodology of UPVAnonymous eKt1FCDBelum ada peringkat

- Method Statement Sonic Integrity TestingDokumen25 halamanMethod Statement Sonic Integrity Testingvenkateswara rao PothinaBelum ada peringkat

- Method ST6 - DCP - MANUAL PDFDokumen7 halamanMethod ST6 - DCP - MANUAL PDFsage.electconBelum ada peringkat

- Diaphragm WallDokumen14 halamanDiaphragm WallDwight AndersonBelum ada peringkat

- Ultrasonic Pulse Velocity Test - WikipediaDokumen14 halamanUltrasonic Pulse Velocity Test - WikipediaShiva KumarBelum ada peringkat

- Silt Test - Fine AggregateDokumen2 halamanSilt Test - Fine Aggregatestephenhcc1Belum ada peringkat

- TOR Implementation of Building CodeDokumen5 halamanTOR Implementation of Building CodeNepali KanchooBelum ada peringkat

- NDT SOP-1 Rebound HammerDokumen1 halamanNDT SOP-1 Rebound HammerRaviraj Thorat100% (1)

- CBR TestDokumen4 halamanCBR TestAtish Kumar100% (1)

- 9686-CPP-NCR - 0017 - Uncontrolled BackfillingDokumen3 halaman9686-CPP-NCR - 0017 - Uncontrolled BackfillingANIL PLAMOOTTIL100% (1)

- NDTDokumen35 halamanNDTningshaBelum ada peringkat

- M. Tech SynopsisDokumen8 halamanM. Tech SynopsisemtiazBelum ada peringkat

- Short Summary On The TestsDokumen4 halamanShort Summary On The TestsJaguar EngineeringBelum ada peringkat

- Need For Non-Destructive Testing (NDT) of Reinforced Concrete & Various ND Tests Aryan EngineersDokumen3 halamanNeed For Non-Destructive Testing (NDT) of Reinforced Concrete & Various ND Tests Aryan EngineersRajwinder Singh BansalBelum ada peringkat

- Non Destructive Testing of Structures: From Sri Vasavi Institute of Engineering & TechnologyDokumen27 halamanNon Destructive Testing of Structures: From Sri Vasavi Institute of Engineering & TechnologyMohamedSajeerMBelum ada peringkat

- Destructive Testing and Non Destructive TestingDokumen71 halamanDestructive Testing and Non Destructive TestingJay PatelBelum ada peringkat

- Condition Assessment of Concrete With NDT - CaseDokumen5 halamanCondition Assessment of Concrete With NDT - CaseInternational Journal of Research in Engineering and TechnologyBelum ada peringkat

- Tailor MadeDokumen1 halamanTailor MadeVivek GosaviBelum ada peringkat

- 6 ExamplesDokumen77 halaman6 ExamplesVivek GosaviBelum ada peringkat

- Torsion BeamDokumen15 halamanTorsion BeamVivek GosaviBelum ada peringkat

- Able of Contents: Section A: Installation GuideDokumen28 halamanAble of Contents: Section A: Installation GuideHawraz MuhammedBelum ada peringkat

- Vendor Registration FormDokumen2 halamanVendor Registration FormVivek GosaviBelum ada peringkat

- Vierendeel GirdersDokumen29 halamanVierendeel GirdersSaadallah Oueida100% (2)

- Tailor MadeDokumen1 halamanTailor MadeVivek GosaviBelum ada peringkat

- AnethatsDokumen1 halamanAnethatsVivek GosaviBelum ada peringkat

- Vendor Registration FormDokumen2 halamanVendor Registration FormVivek GosaviBelum ada peringkat

- Gate Ce 2004Dokumen10 halamanGate Ce 2004mitulkingBelum ada peringkat

- 4.52 ME Civil StructruralDokumen40 halaman4.52 ME Civil StructruralAshish DumbreBelum ada peringkat

- Reaction of Matr1Dokumen17 halamanReaction of Matr1Vivek GosaviBelum ada peringkat

- GATE 2013 BrochureDokumen93 halamanGATE 2013 BrochureSurbhi KumariBelum ada peringkat

- 16 PDFDokumen12 halaman16 PDFVivek GosaviBelum ada peringkat

- CCMT2012 Cutoff List-Round2Dokumen15 halamanCCMT2012 Cutoff List-Round2Shivam MangalBelum ada peringkat

- M.Tech in Ocean EngineeringDokumen5 halamanM.Tech in Ocean EngineeringVivek GosaviBelum ada peringkat

- CCMT2012 Cutoff List-Round3Dokumen13 halamanCCMT2012 Cutoff List-Round3Chockalingam ChidambaramBelum ada peringkat

- Round 4Dokumen12 halamanRound 4Vivek GosaviBelum ada peringkat

- How To InstallDokumen1 halamanHow To InstallVivek GosaviBelum ada peringkat

- Round 4Dokumen12 halamanRound 4Vivek GosaviBelum ada peringkat

- E TN SWD Ubc97 003Dokumen4 halamanE TN SWD Ubc97 003Vivek GosaviBelum ada peringkat

- E TN CFD Eurocode2 1992 007Dokumen1 halamanE TN CFD Eurocode2 1992 007Vivek GosaviBelum ada peringkat

- E TN SFD Aisc Lrfd93 012Dokumen3 halamanE TN SFD Aisc Lrfd93 012Vivek GosaviBelum ada peringkat

- E TN CFD BS 8110 97 005Dokumen1 halamanE TN CFD BS 8110 97 005Vivek GosaviBelum ada peringkat

- E TN SWD Ubc97 005Dokumen5 halamanE TN SWD Ubc97 005Vivek GosaviBelum ada peringkat

- E TN SFD BS5950 90 005Dokumen4 halamanE TN SFD BS5950 90 005Vivek GosaviBelum ada peringkat

- Welcome To ETABSDokumen52 halamanWelcome To ETABSjhakepascuaBelum ada peringkat

- Ifatsea Atsep Brochure 2019 PDFDokumen4 halamanIfatsea Atsep Brochure 2019 PDFCondor GuatonBelum ada peringkat

- 6470b0e5f337ed00180c05a4 - ## - Atomic Structure - DPP-01 (Of Lec-03) - Arjuna NEET 2024Dokumen3 halaman6470b0e5f337ed00180c05a4 - ## - Atomic Structure - DPP-01 (Of Lec-03) - Arjuna NEET 2024Lalit SinghBelum ada peringkat

- Electronics Foundations - Basic CircuitsDokumen20 halamanElectronics Foundations - Basic Circuitsccorp0089Belum ada peringkat

- YSUUSYs NiCd Battery RepairDokumen6 halamanYSUUSYs NiCd Battery Repairrwesseldyk50% (2)

- Direction: Read The Questions Carefully. Write The Letters of The Correct AnswerDokumen3 halamanDirection: Read The Questions Carefully. Write The Letters of The Correct AnswerRomyross JavierBelum ada peringkat

- Lab Report AcetaminophenDokumen5 halamanLab Report Acetaminophenapi-487596846Belum ada peringkat

- Kanavos Pharmaceutical Distribution Chain 2007 PDFDokumen121 halamanKanavos Pharmaceutical Distribution Chain 2007 PDFJoao N Da SilvaBelum ada peringkat

- Prodelin 1385Dokumen33 halamanProdelin 1385bebebrenda100% (1)

- Turabian Sample PaperDokumen9 halamanTurabian Sample Paperemme_lopez908133% (3)

- Project Report VajDokumen15 halamanProject Report VajTamil SelvanBelum ada peringkat

- Youre The Inspiration CRDDokumen3 halamanYoure The Inspiration CRDjonjammyBelum ada peringkat

- Rock Type Identification Flow Chart: Sedimentary SedimentaryDokumen8 halamanRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosBelum ada peringkat

- Handout CalmAlphaDokumen2 halamanHandout CalmAlphaDave SnowdenBelum ada peringkat

- Explanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradDokumen4 halamanExplanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradMountainofknowledgeBelum ada peringkat

- Digital MarketingDokumen70 halamanDigital MarketingTarun N. O'Brain Gahlot0% (2)

- Activities/Assessments 2:: Determine The Type of Sampling. (Ex. Simple Random Sampling, Purposive Sampling)Dokumen2 halamanActivities/Assessments 2:: Determine The Type of Sampling. (Ex. Simple Random Sampling, Purposive Sampling)John Philip Echevarria0% (2)

- Comparing Financial Performance of Conventional and Islamic BanksDokumen9 halamanComparing Financial Performance of Conventional and Islamic BanksIkbal HardiyantoBelum ada peringkat

- Test Fibrain RespuestasDokumen2 halamanTest Fibrain Respuestasth3moltresBelum ada peringkat

- Arts9 q4 Mod1 Theatricalforms v5Dokumen30 halamanArts9 q4 Mod1 Theatricalforms v5Harold RicafortBelum ada peringkat