TCS Q 113 01 R0

Diunggah oleh

Tori SmallDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TCS Q 113 01 R0

Diunggah oleh

Tori SmallHak Cipta:

Format Tersedia

PAGE NO.

2 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

TABLE OF CONTENTS

1.0 SCOPE

2.0 CONFLICTS AND DEVIATIONS

3.0 REFERENCE STANDARDS

3.1 Company Standards

3.2 Industry Standards

3.3 ASTM Specifications and Test Methods

3.4 AASHTO Standards and Test Methods

4.0 GENERAL REQUIREMENTS

4.1 On-Site Requirements

4.2 Material Requirements

4.3 Safety Requirements

5.0 DESIGN REQUIREMENTS

5.1 Specific Requirements

5.2 Operational Requirements

5.3 Miscellaneous/Minor Works

6.0 EARTHWORKS

6.1 Clearing and Preliminary Works

6.2 Sub-grade

6.3 Sub-base and Base Course Materials

6.4 Construction

7.0 PRIME AND TACK COAT REQUIREMENTS

7.1 Prime Coat

7.2 Tack Coat

7.3 Precautions and Maintenance of Bituminous Coating

PAGE NO. 3 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

8.0 ASPHALT CONCRETE AND PAVING

8.1 Materials

8.2 Asphalt Concrete Mix Design

8.3 Equipment

8.4 Preparation of Asphalt Concrete

8.5 Placement of Asphalt Concrete Mixture

8.6 Tolerances

8.7 Quality Control

8.8 Miscellaneous Works

9.0 FINAL CLEANUP

10.0 APPENDIX

PAGE NO. 4 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

1.0 SCOPE

This Standard covers the minimum mandatory requirements for the construction of Asphalt

concrete pavement for the Saudi Electricity COMPANY works and includes, but not limited

to, sub-grade preparation, installation of sub-base, base course and asphalt concrete paving,

sampling, testing and inspection of materials, and equipment.

2.0 CONFLICTS AND DEVIATIONS

2.1 Any conflicts between this Standard and other applicable Saudi Electricity

COMPANY (SEC) Standards, Industry Standards, Codes, and forms shall be

resolved in writing by the COMPANY Representative.

2.2 Any request to deviate from this Standard shall be directed to the Manager,

Transmission Standards and Specifications Department.

3.0 REFERENCE STANDARDS

The latest revisions of the following Codes and Standards shall be applicable for the

equipment/material covered in this TCS. In case of conflict, the vendor/ manufacturer may

propose equipment/material conforming to one group of Industry Codes and Standards

quoted hereunder without jeopardizing the requirements of this TCS.

3.1 COMPANY Standards

3.1.1 TCS-Q-113.02 Construction Standard for Earthworks

3.1.2 No. 6.483 Special Manual for Industrial Security (Construction Safety

Manual)

3.2 Industry Standards

3.2.1 AASHTO Guide for Design of Pavement Structures.

American Association of State Highway and Transportation Officials, 1993

3.2.2 The Asphalt Institute, Manual Series

1. MS-1 Thickness Design -Asphalt Pavements for Highways and Streets

2. MS-2 Mix design methods for asphalt concrete and other hot mix types

3. MS-8 Asphalt Paving Manual

4. MS-16 Asphalt in paving Maintenance

5. MS-17 Asphalt overlays for Highways and Street Rehabilitation

PAGE NO. 5 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

3.2.3 Ministry of Communication (MOC):-General Specification for Road and

Bridge Construction

3.2.4 General Specifications For Building Construction in Kingdom of Saudi

Arabia- Latest Edition

3.3 ASTM Specifications and Test Methods

3.3.1 Soil Materials

1. ASTM D 1556 Test Method for Density and Unit Weight of Soil in

place by the Sand Cone Method

2. ASTM D 1557 Test Method for Laboratory Compaction Characteristic

of soil using modified effort 56000 ft-lbs/ft

3

(2700 kN-

m/m

3

)

3. ASTM D 1883 Test Method for CBR (California Bearing Ratio) of

laboratory-compacted soils

4. ASTM D 2419 Test Method for Sand Equivalent Value of Soils and

Fine Aggregate

5. ASTM D 2922 Test Method for Density of Soil and Soil Aggregate in

place by the Nuclear Method (Shallow Depth)

6. ASTM D 4253 Test Method for Maximum Index Density and Unit

Weight of Soil using a Vibratory Table

7. ASTM D 4254 Test Method for Minimum Index Density and Unit

Weight of Soils and Calculation of Relative Density

8. ASTM D 4318 Test Method for liquid limit, Plastic limit, and

Plasticity Index of Soil.

3.3.2 Aggregate Materials

1. ASTM C 88 Test Method for Soundness of Aggregates by Use of

Sodium Sulfate or Magnesium Sulfate

2. ASTM C 117 Test Method for Materials finer than 75-m (No. 200)

Sieve in Mineral Aggregates by washing

3. ASTM C 131 Test Method for Resistance to Degradation of Small

Size Coarse Aggregate by Abrasion and Impact in the

Los Angles Machine

PAGE NO. 6 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

4. ASTM C 136 Method for Sieve Analysis of Fine and Coarse

Aggregates

5. ASTM D 692 Specification for Coarse Aggregate for Bituminous

Paving Mixtures

6. ASTM D 1073 Specification for Fine Aggregate for Bituminous

Paving Mixtures

7. ASTM D 4791 Test Method for flat particles, elongated particles, or

flat particles and elongated particles in coarse

Aggregate

3.4. AASHTO Standards and Test Methods

3.4.1. Bituminous Materials

1. AASHTO M-20 Specification for Penetration-Graded Asphalt Cement

(for use in Pavement Construction)

2. AASHTO M-81 Specification for Cut-back Asphalt (Rapid-Curing Type)

3. AASHTO M-82 Specification for Cut-back Asphalt (Medium-Curing

Type)

4. AASHTO M-156 Specification for Mixing Plants for Hot Mixed, Hot

laid Bituminous paving mixtures

5. AASHTO M-320 Standard Specification for Performance Grade Asphalt

Binder.

3.4.2. Test Procedures

1. AASHTO T-37 Specification for Mineral Filler for Bituminous Paving

Mixtures

2. AASHTO T-49 Test Method for Penetration of Bituminous Materials

3. AASHTO T-99 The Moisture Density Relations of Soils Using a 5.5

lb. Rammer and 12-Inch Drop

4. AASHTO T-180 The moisture-Density Relations of Soils Using a 10-lb.

Rammer and 18-inch Drop

5. AASHTO T-209 Test Method for Theoretical Maximum Specific

Gravity and Density of Bituminous Paving Mixtures

6. AASHTO T-275 Test Method for Bulk Specific Gravity and Density of

Non absorptive Compacted Bituminous Mixtures

PAGE NO. 7 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

4.0 GENERAL REQUIREMENTS

4.1 On-Site Requirements

4.1.1 All works performed and all materials furnished shall be in conformity with

the lines, grades, cross-sections, dimensions, and material requirements,

including tolerances, shown on the SEC approved plans/ drawings or

indicated in the SEC specifications.

4.1.2 All existing underground utilities which may be exposed/ uncovered or

otherwise be affected by the excavation work shall be properly protected, by

shoring, bracing, and supporting, etc., as needed.

4.1.3 Care shall be taken to protect aerial, surface or underground utilities around

the site.

4.1.4 Adequate dewatering equipment to remove and dispose all surface and ground

water entering the excavations and other parts of the work, shall be provided

at site and maintained properly.

4.1.5 Sub-grades or bottom of excavation for structures shall be firm, dense and

thoroughly compacted as specified under Construction Requirements. It shall

be free from mud and muck, and sufficiently stable to remain firm and intact

under the feet of the workmen.

4.2 Material Requirements

4.2.1 All materials shall meet or exceed the appropriate AASHTO, ASTM, or other

Standards and specifications as required by the SEC approved plans/ drawings

or as indicated in the SEC specifications, but in no case shall be less than the

requirements of this Standard.

4.2.2 No material, regardless of its source, shall be incorporated in the Work until

representative samples taken and tested and have been reviewed and approved

by the COMPANY Representative.

4.2.3 Field and laboratory tests required to determine compliance with the

requirements of this Standard before and during the work shall be done by an

Independent Agency approved by the COMPANY.

PAGE NO. 8 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

4.3 Safety Requirements

4.3.1 All the required safety provisions of Construction Safety Manual shall be

strictly followed.

4.3.2 Excavation by the use of explosives shall be with prior written approval from

the COMPANY.

4.3.3 The stability of adjacent structures or facilities including public safety shall

not be impaired or endangered by excavation work.

PAGE NO. 9 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

5.0 DESIGN REQUIREMENTS

Design shall be as per AASHTO Guidelines for Design of Pavement Structure, along with

the requirements and guideline as given in the following sections.

The thickness of Asphalt Concrete Pavement shall be dependent upon operational

requirement as determined by COMPANY Design Engineer. The design shall be submitted

to the COMPANY for checking and approval. The parameters for the calculation of the

thickness of pavement shall be as given in the following sections.

5.1 Specific Requirements:

5.1.1 The traffic analysis period shall be twenty (20) years.

5.1.2 Axle loads shall be based on a load meter survey, truck and equipment

manufacturer's technical data or the maximum axle loads allowed by the

Ministry of Communications, Kingdom of Saudi Arabia. See Table I for

maximum legal Saudi Arabia truck loads.

Table I: Wheel Loads

Maximum Legal Saudi Arabia Truck Loads (per MOC)

Steerable axle

6000 kg

Single axle

13,000 kg

Tandem axle

20,000 kg

5.1.3 A Terminal Serviceability Index of 2.5 shall be used for all COMPANY

designated access (pavement) roads and 2.0 for parking and storage lots.

PAGE NO. 10 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

5.1.4 The Structural Layer Coefficient for each pavement component shall be per

Table II below:

Table II Structural Layer Coefficients

PAVEMENT COMPONENT Coefficient per cm.

Hot mix Asphalt (High

Stability)

0.16

Base Course

0.06

Sub-base Course

0.04

5.1.5 Traffic Equivalence Factor shall be based on a structural number (SN) of 5.

5.1.6 The equivalent 18000 lb. (EAL) loads shall be determined from Table III if a

traffic count cannot be made.

Table III: EAL Loads

EQUIVALENT PAVEMENT

CATEGORIES

TRAFFIC AND LOAD 18000 lb

(EAL) Loads

Access Roadways Sedans to Truck up to 20

Tons/Axle

1X 10

5

Designated Roadways inside

S/S yards

Sedans to Truck up to 20

Tons/Axle

IX 10

5

Undesignated areas inside S/S

yards

Sedans to Truck up to 20

Tons/Axle

I X 10

4

Parking and Storage Lots

Sedans and small trucks

I X 10

5

Parking and Storage Lots

Heavy Traffic (Truck Material

Yard)

I X 10

6

Plant Areas

Occasional Heavy Loads

I X 10

6

PAGE NO. 11 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

5.2 Operational Requirements

If the designed pavement thicknesses as per Section 5.1 are lesser than the values per

Table-IV, then, the values as shown in the Table IV shall be adopted.

Table IV Thickness of Pavement Components

Minimum Thickness of

Base Course (mm)

(1)

Minimum Thickness of Combined

Binder and Wearing Courses (mm)

(2)

PAVEMENT CATEGORIES

CLASS A & B CLASS A CLASS B & C

Access Roadways

150

80

100

Designated Roadways inside

Substation

150

80

100

Undesignated pavement inside

Substation

150

65

80

Parking & Storage lots for

Sedans and small trucks

150

80

100

Substations with provision for

Mobile units

300

-

100

Parking and Storage Lots for

Heavy Traffic (Material Yard)

230

120

140

Power Plants Areas

Occasional Heavy Loads

230

120

140

Note: (1). Base Course Classes A & B as per TCS-Q-113.02

(2). Asphalt Binder Course Classes A & B and Wearing Course Classes

A, B & C as per Table VI

5.3 Miscellaneous/Minor/Reinstatement Works

If the area to be asphalted is small, such as for utility trenches, and non-traffic areas,

the minimum base course and pavement thickness shall be as shown in Table IV

with grading limits shown in Table VI.

For all these works, the finish shall be better or at least same as before the start of

work. Also, protection and treinstatement shall be done for all markings, affected

structures and shoulders to the satisfaction of COMPANY and MOC Representative.

PAGE NO. 12 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

6.0 EARTHWORKS

6.1 Clearing and Preliminary Works

6.1.1 Clearing site and rough grading shall be per relevant clauses of TCS-Q-

113.02. Scarification shall be done if required as per COMPANY

Representative instructions.

6.1.2 Protection of bench marks, existing structures, roads, sidewalks, pavings and

kerbs shall be done against damage from vehicular traffic or personnel at the

existing utilities during cleaning / compaction of sub-grade.

6.1.3 Designated temporary roads, walkways and detours, for vehicles, pedestrians

and working personnel shall be maintained properly.

6.2 Sub-grade

6.2.1 The rough grading for sub-grade shall be completed prior to construction of

the surfacing. The sub-base/ base course material shal not be placed on loose,

soft and undesirable materials under any circumstances. All soft and yielding

spots shall be removed till hard and sound strata are available.

When the top soil consists of loose, soft (sand or clay) or otherwise

undesirable materials and if there is any inter bedded soil layer of loose, soft

(sand or clay), where disclosed underlying the firm/dense layer of soil, then

such material shall be completely removed until firm soils are encountered

and replaced with select fill material per TCS-Q-113.02.

The following soil parameter values shall be considered as soft/loose and

hence undesirable:

Table V: Parameters for Unsuitable Soils

Granular Soils

Standard penetration

resistance (SPT) N values

Less than 10

Standard penetration

resistance (SPT) N values

Less than 4 Cohesive

Soils

The unconfined

compression strength, (Cu)

Less than 1.0 kg/cm

2

Other portions of the sub-grade, which will not compact easily, when rolled

or tamped, shall be removed, and all loose rock or boulders, embedded rocks,

abandoned concrete etc., found in the excavation shall be removed or broken

off to a depth of not less than 150 mm below the surface of the sub-grade.

PAGE NO. 13 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

6.2.2 All holes, ruts, soft places, and other defects shall be corrected. Irregularities

or depressions that develop during the compaction should be corrected to the

specified grade by loosening the material at these places and adding,

removing, or replacing the material.

Where sub-grade is soil, levelling shall be achieved by using select fill

materials. In case of rock, the levelling shall be done by concrete of same

strength as the rock or 5500 psi, as directed by the COMPANY

Representative. The soft and loose spots shall be removed and filled woth

selet fill material/concrete as applicable.

Compaction is then done until the surface is smooth, and uniform. In no case,

shall the sub-base or base course be placed on soft or unstable material, or

over areas that are not properly drained. If the sub-grade is dusty or muddy,

operations shall be delayed until it is in a condition satisfactory to the

COMPANY Representative.

The compaction requirements for sub-grade shall be as follows:

a. For Substations, the entire sub-grade in the yard shall be compacted to

95% of the maximum density.

b. Unpaved and other vacant areas in Substations shall be compacted to

90% of the maximum density.

6.2.3 The sub-grade shall be formed so that after compaction it will conform to the

alignment, grade, and cross-section shown on the drawings, and as required

by the COMPANY Representative.

6.2.4 Where rolling of the sub-grade is required, any areas which are inaccessible

to a roller shall be compacted either by a mechanical or hand tamper meeting

the approval of the COMPANY Representative.

6.2.5 Equipment of such weight, used in such a way, as to cause a rut in the

finished sub-grade of 50 mm or more in depth, shall be removed from the

WORK, or the rutting otherwise prevented.

6.2.6 The sub-grade shall be kept drained during placing and compaction of the

sub-base, base course, binder and/or surface course. If berms of earth are

deposited along the area upon which the succeeding course is being placed,

provision shall be made for surface drainage by cutting lateral ditches

through the berm of earth.

6.2.7 The finished sub-grade shall be maintained in a smooth and compacted

condition until the sub-base, base course, binder and/or surface course is

placed.

PAGE NO. 14 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

Where existing sub-grade materials are of poor quality, with California

Bearing Ratioo (CBR) value less than 5 after 4-day soaking., sub-grade

modification shall be accomplished to improve the CBR to a minimum value

of 15. Prior approval of the COMPANY shall be obtained for any

modification.

In case CBR test values are not available, test shall be conducted from the top

0.5 m of soil.

Sub-grade modification shall be done by one or more of the following

methods:

a. Addition of aggregate such as crushed stone or coarse screenings

b. Replacement of the sub-grade soil with sub-base material with

minimum CBR of 15 and shall be minimum thickness of 200 mm.

c. Chemical stabilization/treatment with lime or cement

d. Asphalt stabilization

e. Use of geotextiles and/or geogrids

The minimum compacted thickness of the improved layer shall be 200 mm.

CBR tests shall be conducted after the modification to verify the minimum

requirements.

6.2.8 Developing of Sabkhah area shall be in accordance with the applicable

Sections of TCS-Q-113.02.

6.2.9 At locations where grounding grid is to be installed below the asphalt level,

following requirements shall be satisfied:

a. The backfill materials shall have a maximum thermal resistivity less

than 1.2 K-m/W.

b. The Thermal Resistivity of the backfill materials shall be lesser than

that of the existing soil.

6.3 Sub-base and Base Course Materials

Minimum thickness of combined binder and wearing courses depends upon the type

of sub-base. Hence, sub-base / base course materials shall be well-graded of the class

or classes shown on the approved drawings or specifications. In addition, the

following requirements are to be satisfied;

PAGE NO. 15 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

6.3.1 All materials shall be free from organic matter, shale or other deleterious

matter and shall be of such quality that it will bind readily to form a firm

stable base for placement of flexible pavement.

6.3.2 Gradation and physical properties for base and sub-base materials shall

conform to the requirements of TCS-Q-113.02.

6.3.3. Class C materials shall not be used for base course for COMPANY Utilities.

6.3.4. Class C and Class D materials for Sub-base shall be as per TCS-Q-113.02.

6.4 Construction

6.4.1 General Requirements

Prior to placement of the sub-base or the next layer of fill, the sub-grade or

sub-base shall be inspected and approved by the COMPANY Representative

for conformity to lines, grades, and typical sections shown on the approved

construction drawings.

6.4.2 CBR values for each class of fill materials shall be as per TCS-Q-113.02.

6.4.3 Placing / Spreading

Base or sub-base materials shall be spread on the approved sub-grade in

layers not exceeding 150 mm in compacted thickness. Spreading shall be

done by means of approved mechanical spreader, distributing the materials to

the required loose thickness. Where the required base or sub-base thickness is

greater than 150 mm, the materials shall be placed in layers of equal

thickness. In no case shall a layer be less than 75 mm thick. Under no

circumstances shall any soil materials be dumped in a pile on the sub-grade.

When base or sub-base course is constructed more than one layer, the

previously compacted layer shall be cleaned of loose and foreign matter.

The materials shall be handled so as to avoid segregation. Segregated

materials shall be remixed until uniformity is attained. Suitable precautions

shall be taken to prevent rutting of the sub-base or sub-grade during the

spreading of fill materials. No hauling or placement of materials will be

permitted when in the judgment of the COMPANY Representative, the

weather or road conditions are such that the hauling operations will cause

cutting or rutting of the sub-base or sub-grade or cause contamination of the

fill materials. The water content of the fill material shall be maintained at the

optimum moisture content ( 2%) as determined by ASTM D 1557 or

AASHTO T-180, as obtained from soil investigation reports.

PAGE NO. 16 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

6.4.4 Compaction

a. The sub-base or base materials shall be compacted, keeping the

moisture content between ( 2%) of optimum moisture content, with

equipment capable of obtaining the desired density to the full depth of

the respective layer.

The rolling shall continue until the sub-base or base are compacted to

not less than 95% of the maximum laboratory density as determined

by ASTM D 1557 or AASHTO T-180 Method for soils containing

more than 15% materials passing the 75 micron (# 200) sieve or

compacted to 85% of relative density as determined by ASTM D

4253 and ASTM D 4254 for free draining soils containing less than

15% non-plastic materials passing the 75 Microns (#200) sieve unless

otherwise specified as per other approved methods.

b. Base and sub-base materials shall be compacted by means of

approved compaction equipment, progressing gradually from the

outside towards the center with each succeeding pass uniformly

overlapping the previous pass. Rolling shall continue until the entire

thickness of each layer is thoroughly and uniformly compacted to the

specified density. Rolling shall be accompanied by sufficient blading

in a manner approved by the COMPANY Representative, to insure a

smooth surface free from ruts or ridges and having the proper section

line and grade.

c. All areas inaccessible to normal compaction equipment shall be

compacted by means of mechanical tampers until satisfactory

compaction is obtained.

d. Each layer of base/sub-base material must be completely compacted,

tested and approved by the COMPANY Representative prior to

delivery of materials for a succeeding layer. Frequency of testing

shall be in accordance with TCS-Q-113.02.

6.4.5 Finishing

The surface of the compacted materials shall be finished by blading or with

automated equipment especially designed for this purpose and rolled with a

steel-wheeled roller. In no case shall thin layers of fine materials be added to

the top layer of the base course in order to meet the required elevation. The

surface of the completed base course shall not show any deviation in excess

of 4 mm when tested with a 4 meter straightedge. The completed thickness of

the base shall be within 5 mm of the thickness indicated, and the average

thickness shall not be less than the design thickness.

PAGE NO. 17 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

7.0 PRIME AND TACK COAT REQUIREMENTS

Asphalt work including primer application and placing of asphalt concrete mixtures shall be

done only when the atmospheric temperature is 4C or above and when the weather is not

foggy or rainy and when the existing surface is free from moisture.

7.1 Prime Coat

7.1.1 Materials

The prime coat shall be of medium-curing type cutback asphalt consisting of

asphaltic base fluxed with suitable petroleum distillates. The product shall be

free of water, show no separation prior to use, shall not foam when heated to

application temperature and shall conform to the requirements of Grade MC-

70 or MC-250 of ASTM D 2027.

Emulsified asphalt MS-1 or SS-1 conforming to ASTM D 977 may also be

used after getting approval from the COMPANY.

7.1.2 Surface Preparation

The surface shall be cleaned of all loose dirt and other objectionable

materials by means of approved mechanical sweepers or blowers and or hand

brooms prior to the application of the prime coat.

7.1.3 Application

Prime coat shall be applied uniformly to the base course using a pressure

distributor at a rate between 1.0 to 1.75 liters per square meter. Excess

application of primer shall be blotted by using clean and natural sand. The

application temperature shall be within the ranges of 50C to 80C for MC-

70 between 65C to 105C for MC-250. The primer shall be applied to a

width of at least 300 mm greater on each side of the specified width of the

finished surface. Surfaces in contact with the asphalt are to be primed up to

the asphalt thickness. The surfaces of manholes, catch basins, etc., which

need to remain free of asphalt, shall be protected with oil to prevent asphalt

adhesion.

Prime coat shall be applied only when the surface to be treated is dry and

when the weather is not foggy or rainy.

7.1.4 Curing

The prime coat shall be cured until the penetration into underlying surface

has been approved by the COMPANY Representative. It shall be fully set

and cured for not less than 24 hours before placing an asphalt concrete

mixture on the base.

PAGE NO. 18 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

7.2 Tack Coat

7.2.1 Materials

Tack coat shall be of rapid-curing type cutback asphalt consisting of asphalt

base fluxed with suitable petroleum distillates. The product shall be free of

water, show no separation prior to use, shall not foam when heated to

application temperature and shall conform to the requirements of Grade RC-

800 of ASTM D 2028.

Emulsified asphalt RS-1 conforming to ASTM D 977 or CRS-1 conforming

to ASTM D 2397 may also be used after getting approval from the

COMPANY.

7.2.2 Application

Tack Coat shall be applied on top of the binder course and damaged surfaces

that are being overlaid by means of bitumen distributor from 0.5 to 1.0 liters

per square meter or as directed by COMPANY Representative. This shall be

uniformly applied over the entire surface of the area to be covered. The

temperature shall be between 95C to 120C.

Tack coat shall not be placed during rainy weather, sand storm or stormy

weather, or when the moisture on the surface to be paved would prevent

proper bond. If application of the surface course is delayed by more than

three days, dirt or sand and other impurities have contaminated the tack coat,

then a new tack coat shall be applied thinly after the original one has been

swept clean.

7.3 Precautions and Maintenance of Bituminous Coating

7.3.1 Protection of adjacent structures

When primers are being applied, the surfaces of all structures, guard rails,

curbs and gutters, and other roadway appurtenances shall be protected in a

manner approved by the COMPANY Representative, to prevent them from

being splattered with primer or marred by equipment operation.

7.3.2 Maintenance of Bituminous Coating

Prime and tack coats shall be maintained intact until they are covered by the

succeeding course. Any area where prime coat or previous course has been

damaged by traffic or by equipment or personnel shall be cleaned of all loose

materials, the defective surfaces are to be repaired to the satisfaction of

COMPANY Representative and the prime coat or tack coat shall be re-

applied. In case of rain after the application of the primer, the surface shall be

scraped and allowed to dry to the condition prior to the application before re-

applying the primer.

PAGE NO. 19 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

8.0 ASPHALT CONCRETE AND PAVING

8.1 Materials

8.1.1 Asphalt Cement shall be homogenous, Performance Grade 60-70, 85-100 or

150-200, free of water, shall not foam when heated to 177C, and conforming

to the requirements of ASTM D 946.

8.1.2 Mineral aggregates shall consist of coarse aggregates, fine aggregates, and

filler material all complying with the following requirements:

a. When tested according to ASTM C 117 and ASTM C 136, the

combined mineral aggregates shall conform to the gradation, shown

on Table VI below.

Table VI: Gradation for Combined Aggregates

Sieve Size

Asphalt Binder

Course

Asphalt Wearing Course

mm/micron(US) Class A Class B Class A Class B Class C

38.0

100

-

-

-

25

100

80-100

-

-

-

19.0

80-100

70-90

100

100

12.5

------

------

80-95

80-100

100

9.5

60-80

55-75

------

------

80-100

4.75 (No. 4)

45-65

44-62

48-62

50-70

55-75

2.0 (No. 10)

30-50

33-48

32-45

32-47

32-47

425 micron (No. 40)

15-32

16-27

16-26

16-26

16-26

212 micron (No. 80)

-

-

8-18

10-18

10-18

75 micron (No. 200)

3-10

3-10

4-8

4-10

4-10

The job mix formula grading may be varied within the specified limits on

the basis of Marshall tests to obtain optimum stability, percent air voids,

and voids in mineral aggregates of the compacted bituminous paving

mixture.

PAGE NO. 20 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

b. The combined mineral aggregates for asphalt binder course

and asphalt wearing course shall consist of crushed rock or

crushed gravel. These shall be clean, hard, tough, durable and

sound and shall be of uniform quality, free from soft and

friable materials and shall conform to the physical

requirements as per Table VII.

c. Mineral filler shall be finely ground particles of limestone,

hydrated lime or other mineral dust approved by the

COMPANY, free of clay, silt, or other organic or deleterious

materials, passing 600 microns, with a maximum retention of

20% on 75 micron (# 200).

Table VII: Physical Requirements

Tests Specified

ASTM

Requirement

Sand Equivalent

D2419

45 minimum

Binder course

3 Maximum

Plasticity Index

Wearing course

D4318

6 Maximum

Binder course

50% Maximum Loss by Abrasion

Wearing course

C131

40% Maximum

Fine aggregates

12% Maximum Loss by Sodium

Sulphate test.

Coarse aggregates

C88

15% Maximum

Fine aggregates

18% maximum Loss by Magnesium

Sulfate Soundness Test

Coarse aggregates

C88

20% maximum

Thin and elongated pieces, by weight (larger

than 25 mm, thickness less than 1/5 length)

D 4791

5% maximum

Moisture Content

0.25%

Maximum

Soft and friable materials

Nil

PAGE NO. 21 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

8.2 Asphalt Concrete Mix Design

8.2.1 Mix Design Methods

Asphalt concrete mix shall be designed by satisfying any one of the following

methods.

8.2.1.1 Marshall Test Method

This method is used in this document as guideline for the mix design.

8.2.1.2 SHRP (Superpave) System

This method of design has been explained in Appendix. The

parameters to be obtained and other details are also included.

8.2.1.3 HVEEM Test Method

This method can be adopted for design of asphalt pavement for the

SEC system upon approval by the COMPANY Design Engineer.

8.2.2 The asphalt concrete mix design shall be submitted for review and approval

by the COMPANY at least thirty (30) days prior to start production of plant

mix. The design shall be a combination of mineral aggregates and asphalt

cement in such proportion as to produce a mixture conforming to the

composition limits by weight per Table VIII.

Table VIII

Mineral Aggregate

Percent

Total Mineral

93-96

Asphalt cement

4-7

PAGE NO. 22 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

When tested according to the Marshall Method, the Asphalt Concrete mixture

shall conform to the requirements of Table IX:

Table IX

Binder Course Wearing Course

Flow (mm)

2.4-5.0

2.0-4.0

Stability (kg)

820 min.

820 min.

Loss of Marshall stability by

submerging (ASTM D1559). (see note)

25% max.

20% max.

Voids in total mix (%)

3.0-7.0

3.0-5.0

Voids filled with Bitumen (%)

60-75

70-80

Class A- 13 % Class A- 14 %

ClassB - 12 % Class B- 15 %

Voids in mineral aggregate (VMA)

ASTM D2041

(Minimum)

Class C -16 %

Note: Loss of Marshall Stability is measured by submerging specimens in water at

60C for 24 hours as compared to stability measured after submersion in

water at 60C for 20 minutes. (ASTM D 1559)

A compaction effort of 75 blows per ASTM D 1559 shall be used for the mix

design of all asphalt mixtures for SEC works.

8.2.3 After receiving the COMPANY approved asphalt mix design, the

proportioning of the individual aggregates, mineral filler and asphalt cement

shall be done so as to produce a final mix that, when compared to the asphalt

mix design, shall be within the tolerance limits of Table X.

Table X Mix Design Tolerances

Materials

Tolerance

Aggregate sieve size 4.76 mm (No.4) and larger

5.0

Aggregate sieve size 2.0 mm (No.10) and retained

on sieve size 75 microns (No.200)

5.0

Aggregate sieve size 75 microns (No.200) and

smaller

1.5

Asphalt content

0.3

PAGE NO. 23 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

The Asphalt concrete mix shall be tested periodically for conformity to the

approved asphalt mix design. If, during production, the grading of the

aggregates alters, the mixture shall be redesigned and the plant to be

readjusted.

8.3 Equipment

8.3.1 All the construction and asphalt batching plant equipment shall conform to

the requirements of Ministry of Communication (MOC), General

Specification for Road and Bridge Construction.

8.3.2 In addition to the above requirements, trucks used for hauling Asphalt

Concrete Mixture shall have tight, clean, smooth metal beds which have been

thinly coated with a minimum amount of paraffin oil, lime solution (1:3 with

water), or other approved material to prevent the mixture from adhering to

the beds. Each vehicle shall be equipped with a canvass, tarpaulin cover, or

other suitable material of such size to protect the mixture from the weather.

No petroleum derivatives shall be used to coat the truck beds.

8.3.3 Rolling equipment shall be self-propelled. The wheels on the rollers shall be

equipped with adjustable scrapers and the rollers shall have water tanks and

sprinkling apparatus which shall be used to keep the wheels wet and prevent

the surface material from sticking.

Weights of two-axle tandem steel rollers, three-axle tandem steel rollers,

three-wheel steel rollers and self propelled pneumatic tired rollers shall be as

specified in MOC General Specification for Road and Bridge Construction.

The total weight of the pneumatic tired roller shall be varied to prevent

displacement of the asphalt concrete mixture.

8.4 Preparation of Asphalt Concrete

8.4.1 Asphalt cement shall be heated within a temperature range of 135C to

163C at the time of mixing. All materials reheated more than 42C above

the maximum shall be considered overheated and shall be rejected until the

materials can be re-sampled and tested. The reacceptance or rejection shall be

made on the same requirements as established for the original materials.

Asphalt cement received from the refinery at temperatures in excess of

163C, but not exceeding 191C, may be used.

Note: If polymers are used, these may require higher mixing temperatures.

Mixing temperature range should be determined to be the temperature at

which the asphalt binder has viscosity of 0.170 0.020 pa-s while

compaction temperature range should be determined to be the temperature at

which the asphalt binder has viscosity of 0.280 0.030 pa-s. The limits can

be determined from temperature-viscosity plot as developed by Rotational

Viscometer.

PAGE NO. 24 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

8.4.2 Each aggregate ingredient shall be heated and dried at such temperatures that

the temperature recorded in the hot fines bin after screening shall not exceed

163C. If the aggregates contain sufficient moisture to cause foaming in the

mixture, or if their temperature is in excess of 163C, they shall be removed

from the bins and returned to their respective stockpiles.

Immediately after heating, the aggregates shall be screened into at least three

(3) sizes and conveyed into separate bins ready for batching and mixing with

asphalt cement. When the aggregates furnished are of such size and grading

that separating into three (3) bins is impractical, the number of required

separations may be reduced to two (2) with the approval of the Engineer. The

efficiency of the screening operations shall be sufficient to produce, at plant

operating capacity, gradations in each of the sizes of heated and dried

aggregates, which are reasonably uniform and result in the production of a

mixture complying with the limits specified for the asphalt concrete mixture.

8.4.3 Dried aggregates as specified for asphalt concrete pavement construction and

prepared as prescribed above shall be combined in the plant in the

proportionate amounts as approved. Asphalt cement shall be introduced into

the mixture in the proportionate amount all according to the COMPANY

approved asphalt concrete mix design.

The temperature of the asphalt, except for temporary fluctuations, shall not

be lower than 14C below the temperature of the aggregate at the time the

two materials enter the mixer or pug mill.

During drying operations of aggregates for batch and continuous mixing

plants to produce central plant hot-mixtures, the moisture content of mineral

aggregates shall not exceed 0.25 percent.

8.5 Placement of Asphalt Concrete Mixture

8.5.1 Placing/Spreading

a. The Asphalt Concrete Mixture shall be placed without delay on

completion of 24 hours after priming the base course.

b. All asphalt concrete mixtures shall be delivered to the site covered

with tarpaulin prior to loading on the pavers at a temperature between

139

0

C to 163

0

C. Mixtures delivered at other than these temperatures

shall be rejected. No placement of asphalt concrete shall be permitted

if the atmospheric temperature is below 4

o

C, when the weather is

foggy or rainy, and when the existing surface is not free from

moisture.

If polymers are used which may require higher mixing temperatures,

(see note in clause 7.4.1), mixing and laying temperature range should

be determined and used.

PAGE NO. 25 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

c. The Asphalt Concrete Mixture shall be spread and finished true to

line and grade by automatically controlled bituminous paver. The

maximum lift for any layer shall be 75 mm. Asphalt Concrete

mixtures may be spread and finished by hand methods only where

machine methods are impractical as determined by the COMPANY

Representative.

d. Asphalt concrete binder course shall be spread in a placement

thickness so that after rolling, the nominal thickness after compaction

will not exceed 75 mm or less than 50 mm per layer.

e. The automatically controlled paver shall spread the Asphalt Concrete

mixture without tearing the surface and shall strike a finish that is

smooth, true to cross section, uniform density and texture and free

from hollows, transverse corrugations and other irregularities. The

joints made during the work shall be vertical, straight, clean, and free

of broken or loose materials. All vertical joints are shall be primed to

ensure proper bond.

f. The paver shall be operated at a speed which will give the best result

and which coordinates satisfactorily with the rate of delivery of the

mixture to the paver so as to provide a uniform rate of placement

without intermittent stoppages.

g. Asphalt concrete wearing course shall be made flush with rain gutters,

if any, adjacent to the pavement.

8.5.2 Compaction of Mixtures

a. After spreading and strike-off of asphalt mixture and as soon as

possible, mixture shall be thoroughly and uniformly compacted.

b. Rollers shall be of the steel/pneumatic tire type, shall be of good

condition capable of reversing without backlash, and shall be operated

at speeds slow enough to prevent displacement of the mixture. The

number and weight of rollers shall be sufficient to compact the

mixture to the required density while it is still in a workable

condition. Use of equipment, which results in excessive crushing of

the aggregates shall not be permitted.

c. Compaction shall be carried out in three passes sequence operations.

Each pass of roller shall overlap the previous pass to ensure smooth

surface free of roller marks. Rollers shall be operated by competent

and experienced operators and shall be kept in operation

continuously, if necessary, so that all parts of the pavement will

receive substantially equal compaction within the time desired.

PAGE NO. 26 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

d. The initial or breakdown rolling shall be done by means of a tandem

power steel roller or three (3) wheeled power steel roller followed by

rolling with a pneumatic-tired roller. Final compacting and finish

rolling shall be done by means of pneumatic tired roller. The wheels

of the rollers shall be kept properly moistened with water to prevent

adhesion of the mixture to the rollers. Excessive water shall not be

permitted. For other equipment, see section 8.3.

e. Hand tamping or plate compactor may be used where the area is

inaccessible to the rolling equipment.

f. The surface of the compacted asphalt pavement shall be true to lines,

grades and elevations indicated and shall be free from any

depressions. The paving machine shall be fitted with an automatic

screed control operating from an independent grade line or with a

long ski (traveling reference) for leveling the courses. The binder

course shall be laid with utmost accuracy so that there are fewer

chances of deformations in the wearing course.

g. The compacted density of asphalt concrete pavement shall be equal or

greater than 96% of the Marshall Density of each day's production.

8.6 Tolerances

8.6.1 Weighing Scales

The accuracy of the weighing devices for mineral aggregates and bituminous

materials shall be within 1.0% of the actual weight being measured per

ASTM D 995.

8.6.2 Thickness of Asphalt Concrete

The total thickness of the asphalt concrete pavement shall be measured in a

separate operation for each course. Measurement of any core sample shall not

be deficient by 5 mm or 7% of the designed thickness whichever is less.

Core samples shall be taken from the binder course prior to placement of the

wearing course. Core sampling for the wearing course shall be taken as near

as possible to the location where the core sample for binder course was taken.

The placement thickness of the wearing course shall be adjusted when the

average thickness of the binder course is deficient by more than 5 mm.

If the total thickness of asphalt is found deficient, additional cores at intervals

of not more than 25 meters apart for parking/storage lots and at every 100

linear meters for roadways taken parallel to the centerline in each direction to

determine the average thickness of the pavement. Deficiency in average

thickness exceeding the specified tolerance shall be corrected without

additional compensation from the COMPANY.

PAGE NO. 27 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

Correction shall be done by total removal of deficient materials and replacing

them with new materials. The deficient thickness area shall be removed by

saw cutting to the full depth of wearing and binder courses, forming parallel

and perpendicular lines to the architectural features where practical. Same

procedure will be done for all the areas to be repaired.

Application of additional thin layers of fine materials to the top of wearing

course shall be permitted in order to achieve the required thickness or

specified tolerances.

8.6.3 Surface Tolerance

The asphalt concrete surface shall be tested either by the straightedge test

method or by the water flooding test method as directed by COMPANY

Representative at his option:

a. Roadways

i. The variation of the asphalt surface from the testing edge of

the four {4) meter straightedge between any two (2) contacts

with the surface shall at no point exceed 4.0 mm when placed

on or parallel to the centerline of the roadway or 3.0 mm when

placed perpendicular to the centerline of the roadway.

ii. For water flooding test, the finished asphalt concrete surface

shall not have evidence of water ponding greater than 5.0 mm.

b. Large Areas

Surface tolerances for large areas, such as substation yards, storage

yards, parking areas, etc., are specified below;

i. The variation of the asphalt surface from the testing edge of

the four (4) meter straightedge between any two (2) contacts

with the surface shall at no point exceed 4.0 mm when placed

in any direction.

ii. Water flooding of the asphalt concrete surface shall be done to

check proper drainage and water ponding and the following

conditions shall be adhered to:

(a) The finished surface shall not show any water ponding.

(b) The finished surface shall not have any depression.

All humps and depressions exceeding the specified tolerances

shall be corrected by removing the defective work and

replacing it with new material as directed by the COMPANY

Representative conforming to Asphalt Manual MS-16.

PAGE NO. 28 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

8.7 Quality Control

8.7.1 A Quality Control Program shall be prepared and submitted for review and

approval by the COMPANY which shall include, but not limited to, material

and equipment checks, construction, inspection and testing of finished

asphalt concrete pavement.

8.7.2. The asphalt concrete batching plant shall also maintain a Quality Control

Program which includes the following material tests and frequencies:

a. Materials

Test Frequency

Penetration of Asphalt Cement

1/week or 1/lot

Gradation of Fine, Coarse

Aggregates & Filler materials

1/week or 1/lot

Specific Gravity of Aggregates

l/week

Resistance to Abrasion (LA)

l/month

Sulfate and Magnesium soundness

l/month

Sand equivalent

l/month

Plasticity Index

l/month

b. Uncompacted Asphalt Concrete

Samples for extraction, gradation and Marshall Properties shall be

taken daily at the following rates of production

0 to 500 tons 1 per 100 tons

500 to 800 tons 1 per 150 tons

800 and above tons 1 per 200 tons

c. Compacted Asphalt Concrete

Cores for density and thickness shall be taken daily from previous

day's work at the following rates of placement

Less than 4000 m

2

1 per 400 m

2

4,000 to 20,000 m

2

1 per 900 m

2

20,000 and above m

2

1 per 1200 m

2

For minor Asphalt Works, the sampling for Marshall Properties and

Cores shall be taken as directed by the COMPANY Representative.

PAGE NO. 29 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

8.7.3 The independent laboratory must provide upon request, valid calibration

certificates of all testing equipment and the results of all Quality Control

(QC) tests on materials and asphalt concrete mixtures to the COMPANY.

Validity period for Calibration Certificates shall be 4 (four) months and the

calibration shall be done by COMPANY approved laboratory.

COMPANY Representative shall be given full access to the testing

laboratory facilities, the asphalt concrete batch plant, and the job site for his

inspection. All testing and production records shall be made available upon

request.

8.7.4 Protect the newly compacted section of asphalt concrete from traffic by

providing barricades or approved suitable method until it has hardened

properly.

8.8 Miscellaneous Works

Suitable and appropriate methods as directed by the COMPANY Representative

from Asphalt Institute Manuals MS-16 and MS-17 shall be adopted for the following

works:

Preventive maintenance, including Drainage maintenance, Fog Seal

Routine Maintenance like crack sealing, Pot Holes and Patching, etc.

Major Maintenance, including Surface Treatment, Distortions, Slurry Seals, Surface

recycling, etc.,

9.0 FINAL CLEANUP

Upon completion of the work and before final acceptance, the project site including adjacent

properties defaced, damaged or occupied by the equipment and personnel in connection with

the work shall be cleaned of all rubbish, excess materials, false work, temporary structures

and equipment and the damages repaired to the satisfaction of the COMPANY

Representative. The project site and all parts of the work shall be left in a neat and

presentable condition.

10.0 APPENDIX

Superpave (SHRP) Method of design has been explained in th Appendix.

PAGE NO. 30 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

SUPERPAVE (SHRP) METHOD OF PAVEMENT DESIGN.

1.0 SELECTION OF DESIGN LEVEL

Superpave analysis and design method being more complex than those in current use, the

extent of its use depends on the traffic level or functional classification of the pavement for

which it is being used. Consequently, three levels of superpave mixture design and analysis

are being used. Their extent of use and testing requirements are:

Table-I

Traffic, ESALs

Design level

Testing requirements*

10

6

Mix Design

Volumetric design

10

6

< ESALs 10

7

Intermediate mix design

Volumetric design+

Performance prediction tests

ESALs>10

7

Complex mix analysis

Volumetric design+ Enhanced

performance prediction tests

* In all cases, moisture susceptibility must be evaluated using AASHTO T-283.

For SEC facilities, referring to Table III in TCS-Q-001, the design level is to be limited to

option # 1 in the above table, corresponding to the traffic Level of up to ESALs 1X10

6

.

2.0 TERMS AND DEFINITIONS

TERMS SYMBOL DEFINITIONS

2.1 Air Voids P

a

or V

a

Total Volume of small air pockets between coated

aggregates particles expressed as Percentage of the bulk

volume of the compacted paving mixture

2.2

Voids in

Mineral

Aggregates

VMA

The volume of inter granular void space between the

aggregate particles of a compacted paving mixture that

includes the air voids and effective asphalt content

expressed as Percentage of the total volume of the

compacted paving mixture

2.3

Effective

Asphalt

content

Pbe

The total asphalt content of the paving mixture less the

portion of asphalt binder that is absorbed by the aggregate

particles expressed as Percentage of the total weight of the

compacted paving mixture

2.4 Voids filled

with Asphalt

Pfa or

VFA

The portion of the VMA that contains asphalt binder

expressed as Percentage of the total volume of mix or

VMA

PAGE NO. 31 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

TERMS SYMBOL DEFINITIONS

2.5 Aggregate

Bulk specific

gravity

G

sb

The ratio of the mass in air of a unit volume of aggregate,

including permeable and impermeable voids, to the mass of

an equal volume of water, both at the same temperature

2.6 Aggregate

effective

specific

gravity

G

se

The ratio of the mass in air of a unit volume of aggregate,

excluding voids permeable to asphalt, to the mass of an

equal volume of water, both at the same temperature

2.7 Asphalt

binder

specific

gravity

G

b

The ratio of the mass in air of a given volume of asphalt

binder, to the mass of an equal volume of water, both at the

same temperature

2.8 Mixture Bulk

specific

gravity

G

mb

The ratio of the mass in air of a given volume of compacted

HMA to the mass of an equal volume of water, both at the

same temperature

2.9

Theoretical

maximum

specific

gravity of the

mix

G

mm

The ratio of the mass of a given volume of HMA with no

air voids to the mass of an equal volume of water, both at

the same temperature

2.10 Volume of

absorbed

asphalt

V

ba

The volume of the asphalt binder that has been absorbed

into the pores of the aggregate

PAGE NO. 32 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

3.0 VOLUMETRIC MIX DESIGN

For design of the asphalt concrete mix, the following steps to be adopted:

3.1 Selection of aggregates

3.2 Selection of binders

3.3 Selection of a design aggregate structure (Trial Blend Analysis)

3.4 Selection of Design Asphalt Binder Content

3.5 Moisture Sensitivity

3.6 Performance Based tests

3.1 Selection of Aggregates

3.1.1 Properties of Aggregates

Table-II gives the tests and the requirements for the aggregates for use in

Superpave for SEC facilities.

PAGE NO. 33 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

Table-II

All tests are for ESALs 0.3-1x10

6

Tests

ASTM

AASHTO

Requirements

Remarks

Coarse Aggregate

angularity*

75% top 100 mm

50% lower than

100 mm

(At least one

crushed faces)

Fine Aggregate angularity*

40%

Flat and elongated pieces,

by weight (larger than 25

mm, thickness less than 1/5

length)

D 4791 10% max

Sand Equivalent

D 2419

T 176

45% min

Los Angeles Abrasion

Limits

T 96

45% max

For Wearing &

binder Courses

Specific Gravity for Coarse

Aggregates

C 127

Depends on

local material

Specific Gravity for Fine

Aggregates

C128

Depends on

local material

Deleterious Materials

T 112

Nil

For Wearing &

binder Courses

12% max Fine

aggregates

Loss by Sodium Sulphate

test.

C88

T 104

15% max Coarse

Aggregates

18% max Fine

aggregates

Loss by Magnesium Sulfate

Soundness Test

C88

T 104

20% max

Coarse

Aggregates

Moisture Content

0.25% Max.

* For Surface Course depth <100 mm and Base Course depth >100 mm.

3.1.2 Gradation And Restricted Zone

a. The control points for the Superpave mixtures gradation are as

follows:

PAGE NO. 34 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

Table-III

Percentage Passing For Mixture Types Sieve Size

(mm)

SP375 SP250 SP190 SP125 SP95

50 100

37.5 90-100

25.0 90-100 100

19.0 90-100 100

12.5 90 90-100 100

9.5 90-100

2.36 15-41 19-45 23-49 28-58 32-67

0.075 0-6 1-7 2-8 2-10 2-10

b. Restricted Zones

The combined aggregate gradation shall pass between control points

and should not pass through the restricted zone as shown in the table

IV and as plotted on a 0.45 power chart. Mixtures passing through this

zone will be considered only if the mixture satisfies all other

requirements.

Table-IV

Percent passing limits for Restricted Zone Sieve Size

(mm)

SP375 SP250 SP190 SP125 SP95

4.75 34.7 39.5

2.36 23.3-27.3 26.8-30.8 34.6 39.1 47.2

1.18 15.5-21.5 18.1-24.1 22.3-28.3 25.6-31.6 31.6-37.6

0.600 11.7-15.7 13.6-17.6 16.7-20.7 19.1-23.1 23.5-27.5

0.300 10 11.4 13.7 15.5 18.7

3.2 Selection of Binders

Asphalt binder shall be selected based on AASHTO MP-1 specification

Performance-Graded Asphalt Binder to meet Performance Grade (PG) of at least

76-10. The selected Binder should meet the testing requirements shown in table V.

The contractor should present testing certificate from an acceptable testing agency to

certify that the selected asphalt meets the requirements of Table V. Polymer additive

may be required to meet the PG 76-10 requirements.

PAGE NO. 35 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

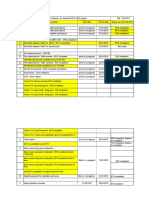

Table V: Performance-Graded Asphalt Binder Specification

PAGE NO. 36 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

3.3 Selection of a Design Aggregate Structure (Trial Blend Analysis)

3.3.1 Selection of Trial Blend

For the selection of the trial blend, at least three sets of aggregate blends

consisting of varying stockpile percentages of each aggregate size are taken.

The sieve analysis is conducted for each of the blends. A plot of percentage

passing and sieve size raised to power 0.45 is done. It is recommended that

the plot passes below the restricted zone and must be within the control

points.

3.3.2 Estimation of Aggregate Blend Properties

The aggregate blend properties shall be calculated mathematically from

calculated values as follows with the limits as shown in Table II.

3.3.3 Evaluation of trial blends

Two specimens are made with each of the blends using Superpave Gyratory

Compactor and volumetric properties are determined. The trial asphalt binder

content is determined for each trial blend by estimating the effective specific

gravity of the blend using the formula below:

a. Bulk specific gravity

G

se

= G

sb

+ Y (G

sa

-G

sb

)

Where, Y= 0.7 to 0.8 depending on the absorption of the aggregate

The Bulk specific gravity of the combined aggregate (G

sb

)

G

sb

= (P

1

+ P

2

+P

3

)

P

1

P

2

P

3

G

1

G

2

G

3

Where Pi =Percent by mass of each component aggregate in blend

Note: (P

1

+ P

2

+P

3

) = 100

G

i

= G

sb

of each component aggregate in blend

b. Volume of asphalt binder (V

ba

)

Calculate the volume of asphalt binder (V

ba

) absorbed into the

aggregates by using the following equation:

+ +

PAGE NO. 37 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

V

ba

= P

s

x (1-V

a

) x 1 1

P

b

Ps G

sb

G

sc

G

b

G

se

Where, V

ba

= volume of absorbed binder, cm

3

/cm

3

of mix

P

s

= Percent of aggregates

V

a

= volume of air voids

G

b

= specific gravity of binder

P

b

= Percent of binder

c. Volume of effective binder (V

be

)

Calculate the Volume of effective binder (V

be

) for the blend using the

following formula:

(V

be

) = 0.081 0.02931 x {In(S

n

)} cm

3

/cm

3

of mix

where S

n

= The nominal maximum sieve size of the aggregate

blend (in inches)

d. Initial trial asphalt binder (P

bi

)

Calculate the initial trial asphalt binder (P

bi

) using the following

formula:

P

bi

= G

b

x (V

be

+ V

ba

) x 100

G

b

x (V

be

+ V

ba

)

W

s

Where P

bi

= Percent (by weight of mix) of binder

W

s

= weight of aggregate (grams)

Where W

s

= P

s

x (1 V

a

)

P

b

+ P

s

G

b

G

se

e. Maximum theoretical specific gravity of the mixture

Two specimens are prepared for the determination of Maximum

theoretical specific gravity of the mixture. Two other samples are

made for each trial blend using Superpave Gyratory Compactor

(SGC). AASHTO T-209 gives the minimum size of sample required

for various mixtures.

+

-

PAGE NO. 38 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

The number of gyrations for initial compaction, design compaction

and maximum compaction shall be determined from Table VI

following AASHTO MP-2 specification.

Densification is done for the sample specimens and SGC data

obtained. Plots are drawn for %G

mm

versus the logarithm of the

number of gyrations.

Also, the percent of air voids and voids in the mineral aggregates

(VMA) are determined from these tables, using the following

equations:

% Air Voids = 100 - % G

mm

@ N

design

% VMA = 100- (%G

mm

@N

design

x G

mm

xP

s

)

G

sb

Keeping 4% air voids at N

design

, the asphalt binder is estimated for

each trial blend using the empirical formula as given below:

P

b,estimated

= P

bi

0.4x (4- V

a

))

Where, P

b,estimated

= Estimated percent binder

P

bi

= Initial (trial) percent binder

V

a

= percent air voids at N

design

From all the three trial blends, the effective asphalt binder is

determined as follows:

P

be,estimated

= - (P

s

x G

b

) x ( G

se

-G

sb

) + P

b,estimated

G

se

x G

sb

Calculation of dust proportion is as follows:

DP = P

0.075

P

be,estimated

The values of dust proportion shall be between 0.6 to 1.2.

The trial blend satisfying the criteria shown in Table VI (AASHTO

MP-2) shall be selected as the design aggregate structure.

PAGE NO. 39 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

Table VI: Superpave Volumetric Mixture Design Requirements

(1) Design ESALs are anticipated project traffic level expected on the design lane over a

20 years period. Regardless of the actual design life of the roadway, determine the

design ESALs for 20 years and choose appropriate Ndesign level.

(2) For 9.5 mm nominal maximum size mixtures the specified VFA range shall be 73%

to 76% for design traffic levels > 3 million ESALs.

(3) For 25.0 mm nominal maximum size mixtures the specified lower limit of the VFA

shall be 66% for design traffic levels <3 million ESALs.

(4) For 37.5 mm nominal maximum size mixtures the specified lower limit of the VFA

shall be 63% for all design traffic levels

3.4 Selection of Design Asphalt Binder Content

Once the design aggregate structure is selected, specimens are compacted at varying

asphalt binder contents. The mixture properties are then evaluated to determine

design asphalt binder content.

A minimum of two specimens are compacted at each of the following asphalt

contents:

a. Estimated binder content

b. Estimated binder content 0.5% and

c. Estimated binder content + 1.0%

Four asphalt binder contents are a minimum in Superpave mixture design.

Voids in Mineral Aggregate

(VMA)

(Minimum Percent)

Required Density

(Percent of G

mm

)

Nominal Maximum Aggregate

Size (mm)

Design

ESALs

(1)

(Millions

)

N

initial

N

desi

gn

N

max

37.5 25.0 19.0 12.5 9.5

Voids Filled

with Asphalt

(VFA)

(Minimum

Percent)

Dust-

to-

Binder

Ratio

< 0.3

< 91.5 70-80

(3)

0.3 to <

3

< 90.5 65-75

(2)

3 to <10

10 to <

30

> 30

< 89.0

96.0

< 98.0

11

(4)

12.0

13.0

14.0

15.0

65-75

(2)

0.6-1.6

PAGE NO. 40 OF 40

TCSQ11301R0/SZA

TRANSMISSION CONSTRUCTION STANDARD

TCS-Q-113.01, Rev. 0

Date of Approval: April 10, 2006

Minimum of two specimens are also prepared for determination of maximum

theoretical Specific gravity at the estimated binder content. Specimens are prepared

and tested in the same manner as the specimens from the section. 3.3. above.

The test results are tabulated for each trial asphalt binder content. Densification

curves for each trial asphalt binder content shall be plotted, the average densification

curve taken from the two specimens for each asphalt content plotted on the same

plot.

Mixture properties are evaluated for the selected blend at the different asphalt binder

contents, by using the densification data at N

initial

, N

design

, and N

maximum

.

The volumetric properties are calculated at the design number of gyrations (N

design

)

for each trial asphalt binder content. From these data points, graphs of air voids,

VMA, and VFA versus asphalt binder content are generated.

The design asphalt binder content is established at 4.0% air voids. The design

asphalt binder content corresponding to 4.0% air voids at N

design

is adopted as the

design asphalt binder content. All other mixture properties are checked at the design

asphalt binder content to verify that they meet criteria.

3.5 Moisture Sensitivity

The final step in the Superpave mixture design process is to evaluate the moisture

sensitivity of the design mixture. This is accomplished by performing AASHTO T-

283 testing on the design aggregate blend at the design asphalt binder content.

Specimens are compacted to approximately 7% air voids. One subset of three

specimens are considered control specimens. The other subset of three specimens is

the conditioned subset. The conditioned subset is subjected to vacuum saturation

followed by an optional freeze cycle, followed by a 24 hour thaw cycle at 60

0

C. All

specimens are tested to determine their indirect tensile strengths. The moisture

sensitivity is determined as a ratio of the tensile strengths of the conditioned subset to

the tensile strengths of the control subset.

The minimum criterion for tensile strength ratio is 80%. The design blend, if it

exceeds the minimum requirement, is the Superpave mixture.

3.6 Performance Based tests:

The Performance Based tests for Superpave mix design are optional, as the traffic

level is 10

6

ESALs, where only volumetric mix design is considered sufficient.

Anda mungkin juga menyukai

- Cable Instl'n, Eng'g. Reqrmt's. TES P 104 05 R0Dokumen26 halamanCable Instl'n, Eng'g. Reqrmt's. TES P 104 05 R0Pageduesca Rouel50% (4)

- TESP12209R0 حدود الأمان Clearances1Dokumen39 halamanTESP12209R0 حدود الأمان Clearances1hafezasad50% (4)

- Ab 036677 001 PDFDokumen1 halamanAb 036677 001 PDFfawad ali50% (2)

- General Specification FR Roads and Bridges Construction - KSADokumen143 halamanGeneral Specification FR Roads and Bridges Construction - KSAJay Alvin Dagpin Denoyo78% (18)

- 70 TMSS 03 R0Dokumen38 halaman70 TMSS 03 R0Tori SmallBelum ada peringkat

- TCS Q 113.02 R0Dokumen46 halamanTCS Q 113.02 R0brooters Ramos67% (3)

- SAES-T-928 Telecommunications - OSP Buried CableDokumen18 halamanSAES-T-928 Telecommunications - OSP Buried CableAbdul Rahim ShaikhBelum ada peringkat

- Tes P 119 21 R0 PDFDokumen37 halamanTes P 119 21 R0 PDFMohammed ElmakBelum ada peringkat

- CHAPTER 1 Design Criteria - General Requirements Rev 0Dokumen26 halamanCHAPTER 1 Design Criteria - General Requirements Rev 0saminaali100% (3)

- TCS-Q-113.01 (Rev 01) -沥青混凝土路面Dokumen41 halamanTCS-Q-113.01 (Rev 01) -沥青混凝土路面heng liu100% (1)

- TCS Q 113.03 R.1Dokumen43 halamanTCS Q 113.03 R.1Azhar Ali100% (1)

- Tes P 119 18 R1Dokumen17 halamanTes P 119 18 R1Chandra SekeranBelum ada peringkat

- S-TR-CIVIL-CAB (Rev.0-2013)Dokumen28 halamanS-TR-CIVIL-CAB (Rev.0-2013)German Barota BorlagdanBelum ada peringkat

- Seeds Ii 00Dokumen44 halamanSeeds Ii 00Tori Small83% (6)

- Tes - P - 122.11Dokumen21 halamanTes - P - 122.11Enus Benjamin100% (1)

- 002-PDS-CON-011 Method Statement For TCF ConstructionDokumen18 halaman002-PDS-CON-011 Method Statement For TCF ConstructionMalik ZamanBelum ada peringkat

- WA-725-3 - Irrigation Manual (Volume III) Technical SpecificationsDokumen1.729 halamanWA-725-3 - Irrigation Manual (Volume III) Technical SpecificationsBindu Sagar Kolluri100% (2)

- Indices of Approved Transmission Standards and SpecificationsDokumen13 halamanIndices of Approved Transmission Standards and Specificationsbadhur zaman hajaBelum ada peringkat

- Tes H 107 01 R1 Painting PDFDokumen58 halamanTes H 107 01 R1 Painting PDFUtkucan KILIÇBelum ada peringkat

- Content: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDokumen2 halamanContent: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualmalika_00100% (2)

- Final Pts 12cc348Dokumen233 halamanFinal Pts 12cc348shantivan50% (2)

- 002-PDS-CON-005 Method Statement For Demoilition of Pipelines Asphalt, Concrete, Houses and FenceDokumen22 halaman002-PDS-CON-005 Method Statement For Demoilition of Pipelines Asphalt, Concrete, Houses and FenceMalik ZamanBelum ada peringkat

- Imam Hussain Sermon at MinaDokumen15 halamanImam Hussain Sermon at MinaTori SmallBelum ada peringkat

- Main Lab: FT-A-21226 29Y Female SelfDokumen1 halamanMain Lab: FT-A-21226 29Y Female SelfTori SmallBelum ada peringkat

- AFAR - 07 - New Version No AnswerDokumen7 halamanAFAR - 07 - New Version No AnswerjonasBelum ada peringkat

- Building For The Environment 1Dokumen3 halamanBuilding For The Environment 1api-133774200Belum ada peringkat

- Cast in Place Concrete TCS Q 113.03 R0Dokumen44 halamanCast in Place Concrete TCS Q 113.03 R0Pageduesca RouelBelum ada peringkat

- TCS Q 113.03 Rev 00Dokumen44 halamanTCS Q 113.03 Rev 00chand saigvBelum ada peringkat

- Transmission Construction Standard: Saudi ElectricitycompanyDokumen12 halamanTransmission Construction Standard: Saudi ElectricitycompanyTori Small0% (1)

- Coatings and Waterproofing: KhalafDokumen19 halamanCoatings and Waterproofing: KhalafmohamedBelum ada peringkat

- TES-P-122-11-R0 - Access Roads and Structure PadsDokumen21 halamanTES-P-122-11-R0 - Access Roads and Structure PadsPrabhi Thomas50% (2)