CHP Assignment 2013-14 - Rabah

Diunggah oleh

Chirag JainJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CHP Assignment 2013-14 - Rabah

Diunggah oleh

Chirag JainHak Cipta:

Format Tersedia

PROCESS SYSTEMS ENGINEERING GROUP

SCHOOL OF ENGINEERING

ENERGY SYSTEMS AND THERMAL PROCESSES CARBON CAPTURE AND TRANSPORT ADVANCED MECHANICAL ENGINEERING MSc Course

ASSIGNMENT

Lecture Course: Lecturer(s): Assignment title: Date issued: Submission date: PSE 16: Power Generation Systems Dr Rabah Boukhanouf Combined Heat and Power 1 November 2013 29th November 2013 Full-time students 16th December 2013 Part-time students

This work should be handed to Mrs Kirsty Cain or Ms Mel Lucas, with an electronic copy submitted to Turnitin software via Blackboard, no later than 4.00 pm on the above submission date. You will be issued with a receipt for your work that will show the date and time the work was handed in. Any work that is not issued with a receipt will not be marked. You are reminded that in the absence of exceptional circumstances, overdue work will be penalised. In accordance with the policy of the Board of Faculty of Engineering and Aerospace, marks will be deducted at a rate of 5% per working day for each day that the work is overdue (for part time students the penalty is 5% per working week or part thereof). Your work should: be prepared in accordance with the Format for Assignments Presentation document (assignments not complying with the requirements will be returned with the penalty rule, for overdue work, applied); be stapled once in the top left corner (not bound in any other fashion) as a copy will be made and retained for purposes of Quality Assurance; and have form PSE16: POWER GENERATION SYSTEMS as the last page. All information in the assignment should be fully referenced and a complete list of the references cited should be provided.

PROCESS SYSTEMS ENGINEERING GROUP

SCHOOL OF ENGINEERING ENERGY SYSTEMS AND THERMAL PROCESSES CARBON CAPTURE AND TRANSPORT ADVANCED MECHANICAL ENGINEERING MSc Course

For your own personal use NOT for publication

PSE 16: Power Generation Systems (CHP)

Rabah Boukhanouf 2013

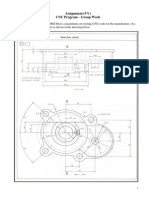

Combined Heat and Power Systems: Reducing energy consumption in a paper mill plant 1. BACKGROUND Process industries are large and complex plants that require huge quantities of energy for their operation. These industries usually have continuous processes offering extended operating hours and consistent energy load profiles independent of seasonal fluctuations. Paper mills in particular require energy for electricity to drive electric machines and steam to dry the paper. 2. LEARNING OBJECTIVES Understand the context of energy use in energy intensive industries Apply thermodynamic principles to evaluate energy requirements Evaluate economic and environmental impact of energy consumption in industrial processes (Carbon emissions) Identify and size appropriate energy system to provide heat and power (cogeneration) Learn to present the work in the form of a report with correct citation. 3. PROCESS DESCRIPTION In the proposed paper mill plant, the electrical energy and process steam are provided by the electricity utility and an oil-fired steam boiler respectively. The boiler generates steam at a temperature of 300oC and absolute pressure of 30 bar at efficiency of 75%. The paper manufacturing processes require superheated steam supply at absolute pressure of 10 bar for an average of 18 hours/day. Figure 1 shows the existing arrangement for supplying steam using a Pressure Reducing Valve (PRV).

Figure 1

The condensate from the plant processes is discharged at 40oC (i.e., no provision for condensate return to the boiler) and the make up water is supplied to the boiler at a temperature of 20oC. The monthly average electrical power and process steam demand of the plant is as shown in Table 1.

Table 1 Energy demand of the plant Month Jan Feb Mar Apr May June July Aug Sep Oct Nov Dec Steam demand (t/h) 29 35 26 24 22.50 20 20 17.50 20.50 22.50 35 27.50 Electricity demand (MW) 3.08 3.30 3.83 4.05 4.43 4.69 5.10 5.29 4.20 5.35 3.15 2.93

Additional Data Heavy Oil tariff: 250/tonne (including CCL) Boiler annual maintenance cost: 30,000 Purchased electricity tariff: 0.085/kWh (including CCL) Exported (surplus) electricity tariff: 25/MWh Oil fuel combustion emission factor: 0.32 kgCO2/kWh Grid electricity generation mix emission factor: 0.52 kgCO2/kWh Heavy oil gross calorific value: 39.60 MJ/kg

4. OBJECTIVE You are the energy manager of the plant and you have been mandated by the companys management board to consider introducing energy efficiency measures to reduce energy consumption and CO2 emission. Hence you initiated a feasibility study to assess alternative options for the provision of heat and power in a cost effective way. From provided plant information and operating data, two proposals were retained for further analysis. Proposal 1: Energy efficiency improvement measures Implementation of simple energy efficiency improvements with minimum capital investment would require upgrading paper drying equipment and allow the following:

i)

Decreasing the boiler steam pressure to 15 bar(a) and lower superheated steam temperature to 200C ii) Recycling 50% of the condensate iii) Cost of implementing the changes is estimated at 167,000

Proposal 2: CHP scheme implementation A steam turbine generator set could be another alternative for reducing energy consumption using existing equipments arrangement. The estimated capital and installation cost is 2.5m and an annual maintenance cost of 85,000. The isentropic efficiency of the turbine is 0.8 and the efficiency of the electric generator is 0.95. Explore the use of a backpressure steam turbine to provide heat and power for the paper mill plant. 5. ASSIGNMENT REQUIREMENTS Use the following suggested assignment report structure as a guide only in preparing the report. i. Introduction Explore briefly the need to improve energy efficiency in energy intensive industries and explain how CHP schemes could help to reduce energy consumption and pollutants emissions (2 pages max.). ii. Site baseline energy consumption Determine annual energy consumption, energy cost and the environmental impact (i.e., CO2 emission equivalent) of the site. iii. Implementation of energy efficient technologies Compare proposal 1 and 2 and make a case for the best option that would help the companys management board to make an informed decision to adopt an energy efficiency strategy. For each proposal, where appropriate, identify the technology, use diagrams and sketches, spreadsheets, steam tables, and show the main steps taken to justify your findings and calculations in assessing the economic and environmental merit (you can use computer software for the analysis but make sure to show in details any mathematical equations used for the calculation). iv. Discussion and conclusion Discuss and compare your findings before and after the implementation of energy efficient measures and outline the feasibility of each proposal. v. Critical Reflection Reflect on future trends of CHP technologies in the industrial sector (1/2 page max.). vi. References Cite all references used in the report.

PROCESS SYSTEMS ENGINEERING GROUP

SCHOOL OF ENGINEERING

ENERGY SYSTEMS AND THERMAL PROCESSES CARBON CAPTURE AND TRANSPORT ADVANCED MECHANICAL ENGINEERING MSc Course

PSE16: POWER GENERATION SYSTEMS

Lecture Course: Lecturer(s): Assignment title: Students Name: Maximum mark 50 Mark allocated PSE 16: Power Generation Systems Dr Rabah Boukhanouf Combined Heat and Power Systems

Task Technical analysis

Comments

General understanding

30

Critical reflection

10

Presentation and reporting 10 Additional comments

Overall mark

Signature and date

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Building Energy AuditingDokumen236 halamanBuilding Energy AuditingEngr AliBelum ada peringkat

- IGBC Green Factory Building Rating SystemDokumen82 halamanIGBC Green Factory Building Rating SystemRavish PatidarBelum ada peringkat

- Rehau Windows and Doors System Brochure SeaDokumen28 halamanRehau Windows and Doors System Brochure SeaAnonymous EgjDnOBelum ada peringkat

- BP Energy Outlook 2023Dokumen66 halamanBP Energy Outlook 2023Danna Lizeth Rueda ParedesBelum ada peringkat

- Zero Energy BuildingsDokumen44 halamanZero Energy BuildingsDivya Mantri0% (1)

- Green ConstructionDokumen19 halamanGreen ConstructionJohn ChristopherBelum ada peringkat

- Blue Book 2014Dokumen112 halamanBlue Book 2014Charles Fernandes100% (1)

- RIBA 05 Low Carbon Design ToolsDokumen16 halamanRIBA 05 Low Carbon Design ToolsMerant De VeraBelum ada peringkat

- Adopting PDCA (Plan-Do-Check-Act) Cycle For Energy OptimizationDokumen17 halamanAdopting PDCA (Plan-Do-Check-Act) Cycle For Energy OptimizationMuhammad NaeemBelum ada peringkat

- The future of fleet operations is here: How a connected ECDIS unlocks digital benefitsDokumen22 halamanThe future of fleet operations is here: How a connected ECDIS unlocks digital benefitsECDIS i100% (1)

- LHC Project Report 215Dokumen5 halamanLHC Project Report 215scribddisantoBelum ada peringkat

- Risk Analysis of The ITER Cryogenic SystemDokumen9 halamanRisk Analysis of The ITER Cryogenic SystemChirag JainBelum ada peringkat

- An Experimental Study of Cold Helium Dispersion in AirDokumen9 halamanAn Experimental Study of Cold Helium Dispersion in AirChirag JainBelum ada peringkat

- "Helium Discharge and Dispersion in The LHC AccelerationDokumen5 halaman"Helium Discharge and Dispersion in The LHC AccelerationChirag JainBelum ada peringkat

- Experimental Simulation of Helium Discharge Into The LHC TunnelDokumen5 halamanExperimental Simulation of Helium Discharge Into The LHC TunnelChirag JainBelum ada peringkat

- Courant Number DerivationDokumen3 halamanCourant Number DerivationChirag JainBelum ada peringkat

- Effects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesDokumen9 halamanEffects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesChirag JainBelum ada peringkat

- Preliminary Risk Analysis of The LHC Cryogenic SystemsDokumen9 halamanPreliminary Risk Analysis of The LHC Cryogenic SystemsChirag JainBelum ada peringkat

- Combined Thermo-Hydraulic Analysis of A Cryogenic JetDokumen9 halamanCombined Thermo-Hydraulic Analysis of A Cryogenic JetChirag JainBelum ada peringkat

- Thermo-Mechanical Analysis of Cold Helium Injection Into Medium Pressure Gas Storage TanksDokumen12 halamanThermo-Mechanical Analysis of Cold Helium Injection Into Medium Pressure Gas Storage TanksChirag JainBelum ada peringkat

- Thermo - Hydraulic Analysis of A Cryogenic Jet Application To Helium Recovery Following Resistive Transitions in The LHCDokumen16 halamanThermo - Hydraulic Analysis of A Cryogenic Jet Application To Helium Recovery Following Resistive Transitions in The LHCChirag JainBelum ada peringkat

- Blue DayDokumen2 halamanBlue DayChirag Jain100% (1)

- 3 - Tutorial Week 2 2014Dokumen6 halaman3 - Tutorial Week 2 2014Chirag JainBelum ada peringkat

- 1 - MEC3302 CMD Assignment 1 S1 2014 Version1Dokumen7 halaman1 - MEC3302 CMD Assignment 1 S1 2014 Version1Chirag JainBelum ada peringkat

- 1 Section-1Dokumen10 halaman1 Section-1Chirag JainBelum ada peringkat

- Network Security OverviewDokumen32 halamanNetwork Security OverviewChirag JainBelum ada peringkat

- 1 CNC Assignment FinalDokumen2 halaman1 CNC Assignment FinalChirag JainBelum ada peringkat

- 1 - Mec3203 A1 S1 2014Dokumen6 halaman1 - Mec3203 A1 S1 2014Chirag JainBelum ada peringkat

- Al 1Dokumen13 halamanAl 1Abhijith GajjagowniBelum ada peringkat

- 1 EssayDokumen1 halaman1 EssayChirag JainBelum ada peringkat

- BCirct 97Dokumen134 halamanBCirct 97Berlin MerrinBelum ada peringkat

- 1 Aerodynamics of Bobsleigh TemplateDokumen1 halaman1 Aerodynamics of Bobsleigh TemplateChirag JainBelum ada peringkat

- Objectives:: Aerodynamics of BobsleighDokumen1 halamanObjectives:: Aerodynamics of BobsleighChirag JainBelum ada peringkat

- Shigley's Mechanical Engineering Design 9th Edition ErrataDokumen8 halamanShigley's Mechanical Engineering Design 9th Edition Erratalordofhaladin100% (1)

- 4 CNC Machining Manual Only 2014Dokumen26 halaman4 CNC Machining Manual Only 2014Chirag JainBelum ada peringkat

- 1 - MEC3302 CMD Assignment 1 S1 2014 Version1Dokumen7 halaman1 - MEC3302 CMD Assignment 1 S1 2014 Version1Chirag JainBelum ada peringkat

- RN 2103213618 1 MT 204468-1-Beam-Equation - 1Dokumen1 halamanRN 2103213618 1 MT 204468-1-Beam-Equation - 1Chirag JainBelum ada peringkat

- T.E (Electronics)Dokumen3 halamanT.E (Electronics)Chirag JainBelum ada peringkat

- PS Ec50 52 202106 enDokumen3 halamanPS Ec50 52 202106 enAgus WinBelum ada peringkat

- A System Dynamics Model of CO2 Mitigation in China's Intercity Passenger TransportDokumen8 halamanA System Dynamics Model of CO2 Mitigation in China's Intercity Passenger TransportAnonymous v9zDTEcgsBelum ada peringkat

- Building - Permits - Sustainability - Sara J WilkinsonDokumen39 halamanBuilding - Permits - Sustainability - Sara J WilkinsonPerizinan Bangunan Unit PTSP SelatanBelum ada peringkat

- Renewable Energy in The Service of Mankind - Energy Efficiency Building Codes PDFDokumen8 halamanRenewable Energy in The Service of Mankind - Energy Efficiency Building Codes PDFsatpal20253788Belum ada peringkat

- Philips-1458632083-Gc9630 20 Pss PDFDokumen3 halamanPhilips-1458632083-Gc9630 20 Pss PDFKristijan ModrušanBelum ada peringkat

- A Risk-Responsive Framework For Green Retrofit Projects in Sri Lanka PDFDokumen15 halamanA Risk-Responsive Framework For Green Retrofit Projects in Sri Lanka PDFcebiBelum ada peringkat

- Oil Injected Compressors Oil-Free CompressorsDokumen44 halamanOil Injected Compressors Oil-Free CompressorsGözde KaraBelum ada peringkat

- 2019 Cold Chain IndiaDokumen32 halaman2019 Cold Chain IndiaKavitha Reddy GurrralaBelum ada peringkat

- CogenDokumen138 halamanCogenzubair1951100% (2)

- Design small scale solar houseDokumen7 halamanDesign small scale solar houseAlison Dayana RubioBelum ada peringkat

- BSR Energy Management HandbookDokumen51 halamanBSR Energy Management HandbookJack SoBelum ada peringkat

- Revamping of Crude Distillation UnitDokumen168 halamanRevamping of Crude Distillation UnitDriss EddeniaBelum ada peringkat

- Ge 2008 Ecomagination ReportDokumen36 halamanGe 2008 Ecomagination ReportTheBusinessInsiderBelum ada peringkat

- Modern Building Materials and Items and Their ImportanceDokumen5 halamanModern Building Materials and Items and Their ImportanceAcademic JournalBelum ada peringkat

- Maxilift BrochureDokumen16 halamanMaxilift BrochureShreeram SharmaBelum ada peringkat

- Valdes Direct Testimony and Exhibits in Potomac Edison Maryland Rate Case 2023Dokumen48 halamanValdes Direct Testimony and Exhibits in Potomac Edison Maryland Rate Case 2023Kirill BorichevskiyBelum ada peringkat

- Greenhouse Lighting System GreenhouseDokumen14 halamanGreenhouse Lighting System GreenhouseLuis AndresBelum ada peringkat

- Evaluation of Overall Thermal Transfer ValueDokumen15 halamanEvaluation of Overall Thermal Transfer ValueMochyBelum ada peringkat

- Media-ICT building blends architecture with valuesDokumen8 halamanMedia-ICT building blends architecture with valuesmichellesanchezb2001Belum ada peringkat

- D 4.1 Consolidated Question Banks 1.1-4.5Dokumen204 halamanD 4.1 Consolidated Question Banks 1.1-4.5Ritesh MokhadeBelum ada peringkat

- LED PresentationDokumen36 halamanLED PresentationYashwanth MnBelum ada peringkat