Exercise 02 13

Diunggah oleh

brulaxHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Exercise 02 13

Diunggah oleh

brulaxHak Cipta:

Format Tersedia

11034 Advanced Building Information Modeling (BIM)

Exercise 02

Learning objectives

Revit Families: Creating a Host-based Family, a conceptual and a detailed, modular Window

Earlier we have created a simple family, a Standalone family. Now we will deal with host-based. Host-based families have components that require hosts. An example is a window family hosted by a wall family. The window family template contains a generic wall (system family) and an opening (Opening Cut) and two dimensions defining the opening vertically as parameters: Default Sill Height and the Height for the opening. One parameter defines the Width of the opening. These parameters are type parameters, but are adjustable after the window is part of the project. In this opening you create more or less detailed window families. In BIM design we have a concept, Information Level, expressing a proposals degree of concretisation, from an early stage to a fully detailed project. In this task, we work with two of 6 levels of information: Level 1 (exercise A) and level 4 (exercise B). A reference to cuneco materials about Information levels: http://cuneco.dk/informationsniveauer#3

Tutorial:

Creating a Window Family The tutorial is taken from the Autodesk website. You can download it from the URL address: http://revit.downloads.autodesk.com/download/RAC2009/Families_Guide/E NU/Family_Guide/PDF/ArchitectureFamiliesMetENU.pdf Part 1: creating a simple window family. Page 241 to 258. Here you only create a custom window family on the definition of a fixed rectangular window. You do not create the grille or mullions. You use a sweep operation to create the window frame, and extrusion for the sash and glazing. Part 2: You create and assign materials to the windows components, glass and pine finish. Page 271 to 274, Assigning Materials to the window components.

Exercise 02A

Making a window family on a conceptual level, Information Level 1. It is a very simple representation of a window: an opening covered with a piece of glass. There are no details as frame, sash, joint etc. The procedure is simple. You make a New / Family. You choose a window family template. Here is the opening created with parameters. You make e piece of glass (Extrusion) aligned to the surfaces in the openings and then lock the constraints. Finally you define the material for the piece of glass. Make several types with different modular dimensions (900, 1200, 1500 mm.). A CCS Classification Code We want to give the window family a classification code after the Danish cuneco system CCS. The classification code is a parameter and you have two types: 1) a shared parameter (it has its own file and can be shared between different families and project plus you can see it in a schedule) and 2) a simple parameter included in the family file. In this exercise we use the simple one. The procedure is as follow:

DTU Byg E13/fv

In the family file you choose Modify > Properties > Family Types > and in the Parameters field you choose Add In the Parameter Properties window you choose Family parameter. In the Parameter Data field you choose Type and under Name write: CCSclassificationCode, Discipline: Common, Type of Parameter: Text and Group parameter under: Identity Data. Now you have your parameter in your family file. Now we will give a value (CCS code for window). Cuneco have made a tool to get the classification tool (it is only in a beta version). You can get it from the website: http://cunecoclassification.dk/. Here you can search for vindue (window) (unfortunately only in Danish for the moment). Vindue is a komponent (component) and you write the value in the value column. Exercise 02B Component specifications: Making your own Window Family: A Single Window after Danish Standards with fixed parameters. Detailed as Information Level 4. A Danish windows manufacturer wants a Revit Window Family containing all the types of his single rectangular windows. He wants it in height detailing, so it can be used in digital 3D projects by the consultants in the Detailed Design phase. Height detailing means, that a joint (Danish: joint) and the real dimensions of the window are included in the window specification. It is a single rectangular Window. The Width and the Height of the window are Type parameters. The Sill Height is an Instance parameter. The Window Family want to be constructed with some dimensions fixed and some dimensions parametric. In the following specifications the parameters is emphasized with a bold font, and de default values is in normal font.

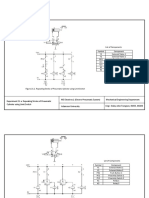

Frame

The dimension of the frame profile is partly parametric. In the drawing you can se the dimensions and parameters: The Frame Width is parametric (Type). The Frame Height is parametric (default 50 mm). The insertion Sash Length is parametric (default 50 mm). The Sash Stop plane (Danish: anslaget) is fixed 20 mm.

Sash

For the profile of the sash: the Sash Width and the Sash Height is the same (the type parameter: Sash Length).

Glass Window insertion

The glazing is located 25 mm from the sash exterior plane. The glass dimension is 12 mm or you define it as a parameter: Glass Thickness. When you insert the window in a project you can specify an offset from the external plane of the wall. This parameter is called Window Insertion, and is an instance parameter. It is a detailed window construction, so we want the joint contained in the construction. In the other hand we want to make window types of a modular kind: 600, 900, 1200 mm etc. That means that we subtract half a joint inside the window and inside the wall around the border of the window. An example: We insert a window with a modular width at 900 mm. The concrete window have the width 888 mm and the opening have the width 912 mm. To do so it can be beneficial to make a bigger opening in the wall for the window: the modular width plus 2 x a joint. See later how to make a bigger opening.

Joint

Materials

You assign materials to the window elements. We want two different materials at the frame and at the sash and we want the glass transparent with a green colour. If you make the joint solid we want it light gray. We want hatch in the materials when you make a cut view.

CCS Classification

We want the Code for the CCS classification implemented in the family file as a parameter. Use the same procedure as in exercise 02A. Template You select the Family Template: Metric Window.rft Modelling the geometry: You start making all the reference planes. Remember reference planes for the joint. You make dimensions and you add parameters. After that you make the solids by sweep operations or other operations. Remember to lock the vertex to the reference plane. Making a new opening You make a new opening in the wall by Void Extrusion. In order to use the void as a new opening, you need to delete the standard rectangular opening cut. Also, the void needs to be cut from the wall geometry. Go to a 3D view. Select the left vertical edge of the default opening and press Delete. The opening in the wall is deleted. On the Tools toolbar click Cut Geometry. Select the void, and then select the wall geometry. The void is cut from the wall. Making Family Types: Make 6 Types based on: Width modular: 600, 900, and 1200 (Module unit: 3M = 300 mm). Height modular: 600, 800, 1000, and 1200 (Module unit: 2M = 200 mm).

Procedure for the exercise

Create a parameter: CCSclassificationCode and give it a value. Implement the types in a project Use the Family Types in a concrete project. On the campus net you can find a Revit project: VM Building from exercise 01. Upload your Family to the project and use your Family Types to exchange some of the windows. Output from the exercise On the campusnet/Assignments you upload the files from your exercises: .rfa files from exercise 02A and 02B. A plot in PDF of the exterior of the VM Building including the new windows in a 3D view. Make a render image.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Akeeba Backup Guide PDFDokumen185 halamanAkeeba Backup Guide PDFJhon ArteagaBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Communication in AfricaDokumen5 halamanCommunication in AfricaJaque TornneBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- 194 Sample ChapterDokumen27 halaman194 Sample ChapterVikas TiwariBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Djdusty VideolistDokumen302 halamanDjdusty VideolistgonduBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Acronyms Used in Offshore ConstructionDokumen32 halamanAcronyms Used in Offshore ConstructionDaniel De Assis ItaborahyBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- New Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)Dokumen3 halamanNew Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)TASHKEELBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Declarative KnowledgeDokumen2 halamanDeclarative KnowledgeEliiAfrBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- User's Manual Installation Guide for Wind DisplayDokumen21 halamanUser's Manual Installation Guide for Wind DisplayVM ServicesBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Slabs Are Plate Elements Forming Floors andDokumen5 halamanSlabs Are Plate Elements Forming Floors andyasas89Belum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Meteor Burst Communications. Request For Expertise, Russian Fed, Ukraine, Etc DCSTDokumen3 halamanMeteor Burst Communications. Request For Expertise, Russian Fed, Ukraine, Etc DCSTSkybridge Spectrum FoundationBelum ada peringkat

- Instruction and Maintenance Manual: Silenced Screw Rotary Compressor UnitsDokumen34 halamanInstruction and Maintenance Manual: Silenced Screw Rotary Compressor UnitsJohnny Diaz VargasBelum ada peringkat

- Padlock Sharper Image FingerprintDokumen1 halamanPadlock Sharper Image FingerprintHenryW.CampbellJr.Belum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- IQ3-95SP-BC dimensional data sheetDokumen2 halamanIQ3-95SP-BC dimensional data sheetren kaiBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Installation Guide: For Packetfence Version 8.3.0Dokumen270 halamanInstallation Guide: For Packetfence Version 8.3.0Ferjani TarekBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- AKA DP Close Bus Ring SolutionsDokumen2 halamanAKA DP Close Bus Ring Solutionssun qiBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 1100cc Engine Parts CatalogueDokumen39 halaman1100cc Engine Parts CatalogueSimon placenciaBelum ada peringkat

- CONSTRUCTION OF INTERNAL ROADS & INFRASTRUCTURE WORKS FOR SECTOR EAST 25, PHASE 2, ABU DHABI - DELAY EVENT IMPACT CALCULATIONSDokumen10 halamanCONSTRUCTION OF INTERNAL ROADS & INFRASTRUCTURE WORKS FOR SECTOR EAST 25, PHASE 2, ABU DHABI - DELAY EVENT IMPACT CALCULATIONS143Belum ada peringkat

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDokumen3 halamanBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Product Oriented Performance Based OrientedDokumen43 halamanProduct Oriented Performance Based OrientedAlmira A. Mira-ato100% (1)

- List of ComponentsDokumen2 halamanList of ComponentsRainwin TamayoBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- EY Global Commercial Banking Survey 2014Dokumen28 halamanEY Global Commercial Banking Survey 2014Share WimbyBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Reaction Paper The Flight From ConversationDokumen4 halamanReaction Paper The Flight From ConversationJoe NasalitaBelum ada peringkat

- Waterfall Model - The Original Software Development Process ModelDokumen3 halamanWaterfall Model - The Original Software Development Process ModelmushfiqBelum ada peringkat

- Precast Concrete Septic Tank 5000dsDokumen1 halamanPrecast Concrete Septic Tank 5000dsMarco Vega TaipeBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Ax2012 Enus Sam 04 PDFDokumen26 halamanAx2012 Enus Sam 04 PDFErnesto J DuranBelum ada peringkat

- Dse7110 Mkii Dse7120 Mkii Operator ManualDokumen100 halamanDse7110 Mkii Dse7120 Mkii Operator Manualseanfsmyth100% (1)

- Open-Ended CG Experiments Spark CreativityDokumen9 halamanOpen-Ended CG Experiments Spark CreativityArjun ShettyBelum ada peringkat

- Equifax Aftermath NotesDokumen2 halamanEquifax Aftermath Notesnope123nopeBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Casing & Compressor of Air ConditionerDokumen22 halamanCasing & Compressor of Air ConditionerAbdullah Zakirin Abdul 'AzamBelum ada peringkat

- Range and Angle Tracking Techniques for Moving Target EstimationDokumen34 halamanRange and Angle Tracking Techniques for Moving Target Estimationmykingboody2156Belum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)