Pipe Thickness Calculation PDF

Diunggah oleh

Heny Martha67%(3)67% menganggap dokumen ini bermanfaat (3 suara)

2K tayangan1 halamanPIPE THICKNESS CALCULATIONS As per ASME B 31. - 1996 Edition, 1998 Addenda. Minimum thickness of pipe is equal to Nominal thickness x 0.875 Required thickness : Para. 304.1. Mm thk. Selected, thus OK pipe selected schedule Maximum Allowable Working Pressure (Hot and Corroded) Sd E (tmin-c) P(H+C) = = barg 53 (D / 2) -

Deskripsi Asli:

Judul Asli

Pipe Thickness Calculation.pdf

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniPIPE THICKNESS CALCULATIONS As per ASME B 31. - 1996 Edition, 1998 Addenda. Minimum thickness of pipe is equal to Nominal thickness x 0.875 Required thickness : Para. 304.1. Mm thk. Selected, thus OK pipe selected schedule Maximum Allowable Working Pressure (Hot and Corroded) Sd E (tmin-c) P(H+C) = = barg 53 (D / 2) -

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

67%(3)67% menganggap dokumen ini bermanfaat (3 suara)

2K tayangan1 halamanPipe Thickness Calculation PDF

Diunggah oleh

Heny MarthaPIPE THICKNESS CALCULATIONS As per ASME B 31. - 1996 Edition, 1998 Addenda. Minimum thickness of pipe is equal to Nominal thickness x 0.875 Required thickness : Para. 304.1. Mm thk. Selected, thus OK pipe selected schedule Maximum Allowable Working Pressure (Hot and Corroded) Sd E (tmin-c) P(H+C) = = barg 53 (D / 2) -

Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

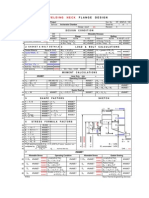

PIPE THICKNESS CALCULATIONS

As per ASME B 31.3 - 1996 Edition, 1998 Addenda.

Design Data : Design Pressure Nominal Pipe Size Nominal wall thickness Material Spec. Corrosion Allowance Coefficient (Table 304.1.1)

Note :

P tn c y

: : : : : :

46 barg 200 NPS 8.179 mm A 106 Gr.B 3.00 mm 0.4 ( t < D/6 )

Design Temp. Outside Diameter Minimum wall thickness Stress Value @ Stress Value @ Quality Factor 93 38

o o

T D tmin C C Sd St E

: : : : : :

93 C 219.075 mm 7.156 mm *) 1,379 bar 1,379 bar 1

*) Minimum thickness of pipe is equal to Nominal thickness x 0.875

Required thickness :

Para. 304.1.2

t =

P*D 2*(Sd*E + y*P)

+c

6.60

mm

< thk. selected, thus OK

Pipe selected schedule

40

Maximum Allowable Pressure (New & Cold) St*E*tmin P(N+C) = 92.51 = (D/2) - y*tmin

barg

Maximum Allowable Working Pressure (Hot & Corroded) Sd*E*(tmin-c) P(H+C) = = barg 53 (D/2) - y*(tmin-c) Maximum Allowable Non Shock W.P. of Flange Material Grade At 93

o

A 105

(Group 1.1) 47 barg Limited by : 69.81 barg Flange

C Design Temperature for

300 lb, ANSI Rating = Pmax = = 47 barg, barg

Maximum Allowable Working Pressure Hydrotest Pressure

Para. 345.4.2

1.5 x Pmax x St / Sd

Anda mungkin juga menyukai

- Design Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal PressureDokumen10 halamanDesign Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal Pressurefaisman100% (1)

- Wall THK Calculation Asme b31.4Dokumen5 halamanWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Design Calculations For Pressure ShellDokumen33 halamanDesign Calculations For Pressure ShellGeorge GeorgianBelum ada peringkat

- Pipe thickness calculations as per ASME B31.3Dokumen1 halamanPipe thickness calculations as per ASME B31.3alvinchuanBelum ada peringkat

- Pipe Bend Againts Coating 3LPE AnalisisDokumen25 halamanPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Wall THK Calculation Asme b31.4Dokumen7 halamanWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- SampleCalculationspipingB3132008 PDFDokumen13 halamanSampleCalculationspipingB3132008 PDFsosatlantiqueBelum ada peringkat

- ASME 31 - 8mDokumen1 halamanASME 31 - 8mMarcoAlbaBelum ada peringkat

- Thickness Calculation For PipeDokumen7 halamanThickness Calculation For PipeNAYEEM100% (5)

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDokumen7 halamanPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiBelum ada peringkat

- Branch Reinforcement Pad Requirement CalculationDokumen2 halamanBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Reinforcement CheckDokumen2 halamanReinforcement Checkviv0102Belum ada peringkat

- Calculation of PipeReinforcement ASMEB31.1Dokumen3 halamanCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Branch Reinforcement Calculation: Pipe Material Design Temperature Design Pressure Allowable StressDokumen32 halamanBranch Reinforcement Calculation: Pipe Material Design Temperature Design Pressure Allowable Stressnitin_bir100% (3)

- ASME B31 8 Riser CalcDokumen12 halamanASME B31 8 Riser CalcEmmanuel LawrenceBelum ada peringkat

- Flange CalculationsDokumen5 halamanFlange CalculationsswapnavattemBelum ada peringkat

- PTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingDokumen4 halamanPTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washingalvinchuan100% (1)

- Wall Thickness and MITERDokumen1 halamanWall Thickness and MITERnirgaBelum ada peringkat

- Calculation For Reinforced PadDokumen4 halamanCalculation For Reinforced Padjsridhar_34750% (2)

- Pipe Insulation THK CalculationDokumen6 halamanPipe Insulation THK Calculationnitin_bir100% (2)

- Size:: Weight STD XS S160 0 0 0Dokumen17 halamanSize:: Weight STD XS S160 0 0 0Vimin Prakash100% (2)

- FLANGEDokumen1 halamanFLANGEscrbdgharavi50% (2)

- Asme B31.8Dokumen14 halamanAsme B31.8omar equihua100% (1)

- Area Reinforcement CalculatorDokumen5 halamanArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Pipe cap thickness and coupling rating calculationsDokumen2 halamanPipe cap thickness and coupling rating calculationsmasaminathanBelum ada peringkat

- Wall Thickness Calculation of 36in Gas PipelineDokumen1 halamanWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDokumen8 halamanAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Steam tracing simulation determines Process Fluid TemperatureDokumen74 halamanSteam tracing simulation determines Process Fluid TemperaturecybermineBelum ada peringkat

- 302 - Nozzle Design Tool Ver E4.01Dokumen2 halaman302 - Nozzle Design Tool Ver E4.01Honey TiwariBelum ada peringkat

- Pipe Thickness Calculation As Per ASME B31.3Dokumen3 halamanPipe Thickness Calculation As Per ASME B31.3vipulBelum ada peringkat

- Pipe Wall Thickness Calculation According ASME B31 3Dokumen93 halamanPipe Wall Thickness Calculation According ASME B31 3linhcdt3100% (1)

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDokumen12 halaman8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11Belum ada peringkat

- ASME B31.3 - 2008 PipeCalculationDokumen6 halamanASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDokumen6 halamanCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingBelum ada peringkat

- Blind flange design calculationDokumen4 halamanBlind flange design calculationmukesh100% (2)

- Pd5500 Flange CalculationDokumen6 halamanPd5500 Flange CalculationMakrand SakpalBelum ada peringkat

- Imperial Piping Weight Load Calculation WorkbookDokumen13 halamanImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Pipe Stress Amp SupportDokumen24 halamanPipe Stress Amp SupportShilpa GanganBelum ada peringkat

- INTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESDokumen89 halamanINTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESCastro Quinteros WinstonBelum ada peringkat

- Pipeline Calculations - ASAB Gas Lift LinesDokumen11 halamanPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqBelum ada peringkat

- AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSDokumen33 halamanAS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSaike_5Belum ada peringkat

- Area replacement calculation for CC1 E-1A LNG Vaporizer branchDokumen2 halamanArea replacement calculation for CC1 E-1A LNG Vaporizer branchJahsbuck100% (1)

- ASME B31.3 wall thickness calcDokumen11 halamanASME B31.3 wall thickness calcAnonymous wIPMQ5rhBelum ada peringkat

- Internal CoilDokumen2 halamanInternal CoilwhngomjBelum ada peringkat

- Wall Thickness Calculation for Piping SystemsDokumen47 halamanWall Thickness Calculation for Piping Systemsthinhvipro100% (1)

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Dokumen30 halamanDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012Belum ada peringkat

- Asme Viii Shell & Se HeadDokumen5 halamanAsme Viii Shell & Se HeadSnr George RaczBelum ada peringkat

- AST Heating Coil Design Calculation Rev 0Dokumen3 halamanAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Pipeextp-Asme Ug 28Dokumen1 halamanPipeextp-Asme Ug 28alvinchuanBelum ada peringkat

- Calculation of Pipe Reinforcement ASME B31 3Dokumen3 halamanCalculation of Pipe Reinforcement ASME B31 3Brant AkkanBelum ada peringkat

- Calculation of Pipe Reinforcement ASME B31.3Dokumen9 halamanCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Calculation of Pipe Reinforcement ASME B31 3Dokumen4 halamanCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- 31barg CalculationDokumen10 halaman31barg Calculationshani5573Belum ada peringkat

- Pipe Sizing and Wall Thickness Calculation SheetDokumen2 halamanPipe Sizing and Wall Thickness Calculation SheetWijayantoBelum ada peringkat

- Retiring Wall Thickness Calculation For PipeDokumen4 halamanRetiring Wall Thickness Calculation For PipeFares JawadBelum ada peringkat

- Hdpe Pipe Wall Thickness CalculationsDokumen1 halamanHdpe Pipe Wall Thickness CalculationsTsouki TsoukiBelum ada peringkat

- Section VIII CalDokumen19 halamanSection VIII CalPradeep Kothapalli100% (1)

- Section VIII CalDokumen21 halamanSection VIII CalRuben Samoel Barros RochaBelum ada peringkat

- Pipe Thickness CalculationDokumen4 halamanPipe Thickness CalculationHarryBelum ada peringkat

- ASME B31.3 Pipe Wall ThicknessDokumen2 halamanASME B31.3 Pipe Wall ThicknessAnonymous cyKuQKBelum ada peringkat

- Process Engineer Job Desc - 1Dokumen2 halamanProcess Engineer Job Desc - 1Heny MarthaBelum ada peringkat

- Application Engineer Job Desc - 1Dokumen1 halamanApplication Engineer Job Desc - 1Heny MarthaBelum ada peringkat

- PRH 04Dokumen6 halamanPRH 04Heny MarthaBelum ada peringkat

- 8100 Series Brochure PDFDokumen12 halaman8100 Series Brochure PDFHeny MarthaBelum ada peringkat

- Air Cooler 45 Case1 PDFDokumen2 halamanAir Cooler 45 Case1 PDFHeny MarthaBelum ada peringkat

- BSPT Thread ChartDokumen1 halamanBSPT Thread ChartAli FikarBelum ada peringkat

- Glycol Dehydrators - Rev 0Dokumen10 halamanGlycol Dehydrators - Rev 0Suleman TariqBelum ada peringkat

- Basic Operation and Function of Control ValvesDokumen65 halamanBasic Operation and Function of Control ValvesEdgar Huanca0% (1)

- JPT2003 09 Gas FocusDokumen7 halamanJPT2003 09 Gas FocusHeny MarthaBelum ada peringkat

- CO2 Capture Process TitleDokumen8 halamanCO2 Capture Process TitlesahilchemBelum ada peringkat

- AirTorqueBrochuremetric PDFDokumen26 halamanAirTorqueBrochuremetric PDFHeny MarthaBelum ada peringkat

- Catalogue AIR TORQUE N° 4thG.-R-BDokumen6 halamanCatalogue AIR TORQUE N° 4thG.-R-BnegrinBelum ada peringkat

- CNG Cylinders Type I: Material & ProductionDokumen16 halamanCNG Cylinders Type I: Material & Productionawrche020676100% (2)

- CBE 362L 1 Double PipeDokumen8 halamanCBE 362L 1 Double PipeDodOng GwapoBelum ada peringkat

- OneSteel Piping Systems Data ChartDokumen18 halamanOneSteel Piping Systems Data Chartpete0980100% (1)

- BSPT Thread ChartDokumen1 halamanBSPT Thread ChartAli FikarBelum ada peringkat

- ORNL Mark 7 Improvements r1Dokumen19 halamanORNL Mark 7 Improvements r1Heny MarthaBelum ada peringkat

- OneSteel Piping Systems Data ChartDokumen18 halamanOneSteel Piping Systems Data Chartpete0980100% (1)

- HMTDokumen11 halamanHMTHeny MarthaBelum ada peringkat

- HMTDokumen11 halamanHMTHeny MarthaBelum ada peringkat

- Heat Equation PDFDokumen4 halamanHeat Equation PDFnoxleekBelum ada peringkat

- Soq EnergyDokumen31 halamanSoq EnergyHeny MarthaBelum ada peringkat

- CoalescerDokumen16 halamanCoalescerHeny Martha100% (2)

- BKI guidelines for FPSO construction certificationDokumen99 halamanBKI guidelines for FPSO construction certificationArdhika HermigoBelum ada peringkat

- BTEX EmissionDokumen1 halamanBTEX EmissionHeny MarthaBelum ada peringkat

- How To Estimate Reid Vapor Pressure (RVP) of A BlendDokumen10 halamanHow To Estimate Reid Vapor Pressure (RVP) of A BlendRashedul IslamBelum ada peringkat

- Spec Heat Q ADokumen1 halamanSpec Heat Q ARony Putera NapitupuluBelum ada peringkat

- Stack CalculationDokumen1 halamanStack CalculationHeny MarthaBelum ada peringkat

- Refrigeration Basics and LNGDokumen43 halamanRefrigeration Basics and LNGEnrico GambiniBelum ada peringkat