Ohns

Diunggah oleh

spsurya2013Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ohns

Diunggah oleh

spsurya2013Hak Cipta:

Format Tersedia

APPLICATION

RECOMMENDED QUALITIES EN-24, EN-19 EN-24 AISI T1, AISI T4 HCHC AISI D3 / HCHC AISI D2 AISI T1 / AISI T4 AISI M2/AISI T1/AISI T4 1% CARBON TOOL STEEL AISI T4, AISI M2 HC HC AISI D3 EN-31 AISI-T1 OHNS, HC HC OHNS, 1% CARBON STEEL HC HC MY EXTRA AISI T1, AISI M2 MY EXTRA HOT DIE AISI H11 MY EXTRA EN-47 HC HC AISI D3 HOT DIE STEEL MY EXTRA AISI T1

Axles & Axle Components Arbors Backing-out Tools

Beading Tools

Bits-Router

Bits/Tool Holder

Blacksmiths Tools

Boring Tools AISI T1, Brick Mould Liners Ball Races Broaches Bushes

Calipers Cams Caulking Tools Chasers-Screw Thread Chisels-Pheumatic Chisels-Hot Coal Cutters Collets Concrete Moulds Cores-Die Casting Concrete Breakers Counter-Bores (Countersinks)

Cropper Blades-Cold

Cold Extrusion Dies

Cold Forming Rolls

Cold Punches

Cutters

Die Bases (Impact Extrusion)

Dies-Blanking-Cold

Ceramic Moulding

Dies-Coining, Cold Extrusion

Dies-Extrusion-Hot

Diesel Oil injector Nozzles Drawing Plugs Drills Drills Plates Engraving Tools Extrusion Liners File Catting Chisels Gauges Gear Cutters Gripper Dies Guillotine Blades

HC HC AISI D3 HC HC AISI D3 / AISI D2 HC HC AISI D3 HC HC AISI D3 / HC HC AISI D2 AISI T1, AISI M2 HC HC AISI D3, HC HC AISI D2 HC HC AISI D3, HC HC AISI D2 HC HC AISI D3, HC HC AISI D2 HC HC AISI D3, HC HC AISI D2 HOT DIE STEEL AISI H24/AISI H11 AISI T1 HC HC AISI D3 AISI T1, AISI M2 OHNS AISI T1 EN24 AISI T1 OHNS, HC HC AISC D3 AISI T1 MY EXTRA, HC HC AISI D3 HC HC

Hacksaw Slotting Cutters Knives-Guillotine Lathe Tools Lines-Extrusion Layshafts Magneto Drive Coupling, Shaft and Wheels Mandrels-Tube Drawing Milling Cutters Parting Tools

Pins

Planer Tools Plug Gauges Pneumatic Tools Punches Pinion Shafts Pinions Reamers Ring Gauges Rivet Snaps / Sets Rolls-Cold Forming

Seaming Rolls

Shear Blades

Spinning Tools

Taps Thread Milling Cutters Thread Gauges Tool Bits

AISI D3 AISI T1 HC HC AISI D3 AISI T1, AISI T4 EN-24 EN-36 EN-24, EN-36 HC HC AISI D3 AISI T1, AISI T4 AISI T1, AISI T4 SILVER STEEL (SAE 52100) AISI T1, AISI M2 HC HC / OHNS MY EXTRA OHNS / HC HC EN-24 EN-24 AISI T1 OHNS MY EXTRA HC HC AISI D3 HC HC AISI D3, HC HC AISI D2 HC HC AISI D3 HC HC AISI D3, HC HC AISI D2 AISI T1 AISI T4 AISI T1, AISI T4 OHNS AISI T1, AISI M2

Tube Drawing Plugs Weighing Machine Pivots

HCHC AISI D3 OHNS

Ohns

Oil Hardened Non-shrinking Steel

Material composition

oil hardened non shrinking stell carbon0.91.3%cromium 0.5%tungsten 0.4-0.8%its an alloy steel mainly used for forming dies,its hardened upto 50to 55 hrc

hardness of the ohns is 60-70 hrc

The hardness of En8 (having quite high C 0.40%) will be dependent upon the supply condition - Annealed, Hardened, HT etc and may vary between say about 150 BHN to 40 HRC

Chemical composition

Oil Hardened Non-shrinking Steel / Oil Hardened Nickel Steel (Same Say) C: 0.95, Mn: 1.15, Cr :0.5, W:0.5, V:0.2

Example: iron; 0,90-1,10 % carbon; 0,90-1,60 % manganese; 0,40-0,60 % chromium, 0,40-0,60 % wolfram.

Industries

We offer a dimensionally accurate range of OHNS Round & Flat Steel, which is customized as per the specifications of our clients. These are used for manufacturing bars, tubes pipes and various other steel products and are in compliance with leading industry standards. We are one of the leading suppliers of a wide range of Ferrous & Non Ferrous Metal. These are offered in various grades and are demanded for high ductile strength as well as excellent corrosion resistance. Company : Ramdev Steel, Pune J-300, MIDC Bhosari, Pune, Maharashtra - 411 026, India City : Pune State : Maharashtra Phone : +(91)-(20)-27128899/27126533/27122997 Website : http://www.indiamart.com/ramdevsteel/

Contact Name : Ramdev Steel, Pune

Web Page : http://www.indiamart.com/ramdevsteel/

PUNCHES AND DIES

Legend Punches and Dies are Manufactured under ultra-modern technology (CNC & SPM*) for machining and engraving of masters and punches. They are suitable for D, B, BB, DB Tooling & Multi Tip Punches and Dies. Its Mirrored finished design offers Uniformity across all punches and dies giving interchange ability between every punch or die within the same set. Also they are manufactured under equipment and gauges of international standards to give high dimensional accuracy. Dies and Punches Specifications : Suitable for D, B,BB and DB Tooling. Dies and Punches for Hole- Polo Type Tablet & Bolus / Slug Tablet. Multi Tip Punches and Dies. Nickel plated & Plasma coated Dies and Punches can be provided as per customer requirement. Punches & Dies are Made of OHNS Oil Hardened Non-shrinking Steel/ HCHC High carbon High chromium steel/ SS440C.

Salient features : Manufactured under ultra-modern technology (CNC & SPM*) for machining and engraving of masters and punches. Uniformity across all punches and dies giving interchangeability between every punch or die within the same set. Manufactured under equipment and gauges of international standards to give high dimensional accuracy. Punch height measurement using highly accurate programmable height gauge. Computerised heat treatment.

Optimum clearance prevents product loss from lower punches. Standard : Dies and Punches as per Euro Standard/ TSM / IPT *Special Purpose **Special Die and Punch inspection and polishing Kits available on request. Standard Machine

Oil-hardening types[edit]

Grade Composition Notes

O1

0.90% C, 1.01.4% Mn, 0.50% Cr, It is a very good cold work steel and also makes very good 0.50% Ni, 0.50% W knives. It can be hardened to about 57-61 HRC.

Anda mungkin juga menyukai

- Newnes Workshop Engineer's Pocket BookDari EverandNewnes Workshop Engineer's Pocket BookPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDari EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionBelum ada peringkat

- Continuity TestingDokumen107 halamanContinuity TestingJohn Benedict MauricioBelum ada peringkat

- Analysis of Thermal Cycle during Multipass Arc WeldingDokumen6 halamanAnalysis of Thermal Cycle during Multipass Arc WeldingchirpynikBelum ada peringkat

- Fluid Properties: Dr. Akepati S. Reddy Thapar University Patiala (PUNJAB) - 147 004 IndiaDokumen29 halamanFluid Properties: Dr. Akepati S. Reddy Thapar University Patiala (PUNJAB) - 147 004 IndiaDr. Akepati Sivarami ReddyBelum ada peringkat

- PIpingDokumen32 halamanPIpingbalumagesh1979100% (1)

- Technical Data Handbook of TK CorporationDokumen172 halamanTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoBelum ada peringkat

- Brubaker Tap Catalog 2016Dokumen116 halamanBrubaker Tap Catalog 2016Mauricio A. Tamayo RamirezBelum ada peringkat

- Thumb Rules For Designing A Column Layout - Civil Engineering - Civil Engineering ProjectsDokumen6 halamanThumb Rules For Designing A Column Layout - Civil Engineering - Civil Engineering ProjectsThulasi Raman Kowsigan0% (1)

- Drilling Bits SalamDokumen93 halamanDrilling Bits Salamkmelloistaken100% (3)

- Michigan Drill CatalogDokumen516 halamanMichigan Drill CatalogMDC-ITBelum ada peringkat

- ASTM Heavy Hex Bolt SpecificationsDokumen7 halamanASTM Heavy Hex Bolt Specificationspattanaik_munaBelum ada peringkat

- Piping Material Specification 2010014 00 l0 Gs 001Dokumen215 halamanPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDari EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonBelum ada peringkat

- En 10028 2 P265GH - Boiler Plate Steel - ProductsDokumen2 halamanEn 10028 2 P265GH - Boiler Plate Steel - ProductsShankey JAlanBelum ada peringkat

- PantechSteel CatalogueDokumen36 halamanPantechSteel Cataloguejok1974Belum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 316 Buttweld Pipe Fittings Manufacturer in IndiaDokumen4 halamanQuality Oriented and ISO Approved Stainless Steel 316 Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- 15 Rotating Toolholders WNT2013Dokumen177 halaman15 Rotating Toolholders WNT2013Natrajj SivakumarBelum ada peringkat

- Point-Fixed Glass Wall Fitting Typical Product Catalog160PDokumen155 halamanPoint-Fixed Glass Wall Fitting Typical Product Catalog160PNajib Kiwan100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDokumen5 halamanQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Tool & DieDokumen15 halamanTool & DieAabidah AbiyahBelum ada peringkat

- Components of Circulating Fluidized Bed BoilersDokumen20 halamanComponents of Circulating Fluidized Bed BoilersTyrelle Joseph ManitiBelum ada peringkat

- Understanding Elevated Copper Levels in Used Oil SamplesDokumen3 halamanUnderstanding Elevated Copper Levels in Used Oil SamplesYuszra SabillaBelum ada peringkat

- 17-07-23-Catalog of STEEL WORLDDokumen4 halaman17-07-23-Catalog of STEEL WORLDRajan BhardwajBelum ada peringkat

- Hitesh Metal (India) Introduction & Profile 1.2.18 PDFDokumen5 halamanHitesh Metal (India) Introduction & Profile 1.2.18 PDFHMI MumbaiBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 310h Buttweld Pipe Fittings Manufacturer in IndiaDokumen5 halamanQuality Oriented and ISO Approved Stainless Steel 310h Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- 321H Buttweld FittingsDokumen5 halaman321H Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Catalogue - Tanish Steel (Stainless Steel Bars Manufacturers)Dokumen13 halamanCatalogue - Tanish Steel (Stainless Steel Bars Manufacturers)Tanish SteelBelum ada peringkat

- Inosindt Seamless Tubes 22Dokumen40 halamanInosindt Seamless Tubes 22Pimen AjjahBelum ada peringkat

- 13 BushingsDokumen25 halaman13 BushingsRolffoTelloBelum ada peringkat

- Accessories For Pipes: FlangesDokumen7 halamanAccessories For Pipes: FlangesJbr IrvingBelum ada peringkat

- 304H Buttweld FittingsDokumen4 halaman304H Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- 316ti Buttweld FittingsDokumen5 halaman316ti Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Carmex Catalogue WebDokumen203 halamanCarmex Catalogue WebPaisaje SilenciosoBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 310s Buttweld Pipe Fittings Manufacturer in IndiaDokumen4 halamanQuality Oriented and ISO Approved Stainless Steel 310s Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Seamless Tubes: Stainless Steel - Nickel Alloys - TitaniumDokumen40 halamanSeamless Tubes: Stainless Steel - Nickel Alloys - TitaniumwidiantoekoBelum ada peringkat

- En 8Dokumen3 halamanEn 8ajaykrishnaaBelum ada peringkat

- A&B Product Brochure PDFDokumen25 halamanA&B Product Brochure PDFLuisBelum ada peringkat

- High Speed Steel PDFDokumen1 halamanHigh Speed Steel PDFYogesh PatelBelum ada peringkat

- UNS R30006 Steel GradesDokumen3 halamanUNS R30006 Steel GradesRatnakar PatilBelum ada peringkat

- Apex Shears - Metal Cutting Circular SawsDokumen2 halamanApex Shears - Metal Cutting Circular SawsRahul MandeliaBelum ada peringkat

- 13 Solid Carbide Milling CuttersDokumen309 halaman13 Solid Carbide Milling CuttersManu GimenezBelum ada peringkat

- Steel Bar Product BroucherDokumen16 halamanSteel Bar Product BroucherCREATIVE PIPING SOLUTIONS PVT. LTD.Belum ada peringkat

- Report On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Dokumen21 halamanReport On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Maroof Alam100% (2)

- CNOOD Product CatalogueDokumen42 halamanCNOOD Product CatalogueLeonardo SilvaBelum ada peringkat

- Tungsten Carbide Rotary Burrs GuideDokumen19 halamanTungsten Carbide Rotary Burrs GuideSun SunBelum ada peringkat

- Materialqualitaeten EDokumen2 halamanMaterialqualitaeten EjvilamaiorBelum ada peringkat

- Brubaker Tap Catalog 2016-1Dokumen116 halamanBrubaker Tap Catalog 2016-1api-456828121Belum ada peringkat

- SAE L6, Steel Grades, Tool SteelDokumen1 halamanSAE L6, Steel Grades, Tool SteelMayur12345dt0% (1)

- Catalog of Steel Handbook Printed 1691239428Dokumen8 halamanCatalog of Steel Handbook Printed 1691239428fahid masoodBelum ada peringkat

- Tapping Feed and Speed Viking Drill and ToolDokumen1 halamanTapping Feed and Speed Viking Drill and ToolDaniele TropepeBelum ada peringkat

- Apex Steel - Suppliers of Ferrous & Non-Ferrous MetalsDokumen3 halamanApex Steel - Suppliers of Ferrous & Non-Ferrous MetalsRamboBelum ada peringkat

- D-Series Catalogue PDFDokumen64 halamanD-Series Catalogue PDFandresboy123Belum ada peringkat

- EquipmentDokumen58 halamanEquipmentPartsGopher.com100% (1)

- AISI 51b60Dokumen2 halamanAISI 51b60PABLO DIAZ ENRIQUEZBelum ada peringkat

- EN9 Carbon Steel Bright Bar - EN9 Forging - EN9 Round - Saaj SteelDokumen3 halamanEN9 Carbon Steel Bright Bar - EN9 Forging - EN9 Round - Saaj SteelNaiduBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 321 Buttweld Pipe Fittings Manufacturer in IndiaDokumen5 halamanQuality Oriented and ISO Approved Stainless Steel 321 Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Dr. Suvandan Saraswat: Machine Design I (NME-501)Dokumen47 halamanDr. Suvandan Saraswat: Machine Design I (NME-501)Suvandan SaraswatBelum ada peringkat

- Normative ReferencesDokumen3 halamanNormative ReferencesProfCarlos GamaBelum ada peringkat

- Pferd - Limas Rotativas Cat. 202Dokumen64 halamanPferd - Limas Rotativas Cat. 202MinatelBelum ada peringkat

- Peoples Steel Mills LTDDokumen19 halamanPeoples Steel Mills LTDalmasBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 316L Buttweld Pipe Fittings Manufacturer in IndiaDokumen7 halamanQuality Oriented and ISO Approved Stainless Steel 316L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- Special Steel Sheet: Cat - No.B1E-005-05Dokumen16 halamanSpecial Steel Sheet: Cat - No.B1E-005-05wahyuBelum ada peringkat

- Quality Oriented and ISO Approved Stainless Steel 410 Buttweld Pipe Fittings Manufacturer in IndiaDokumen5 halamanQuality Oriented and ISO Approved Stainless Steel 410 Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Belum ada peringkat

- DanCut Rev1 en PDokumen8 halamanDanCut Rev1 en PDaniel ConwayBelum ada peringkat

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderDari EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderBelum ada peringkat

- 1223Dokumen67 halaman1223spsurya2013Belum ada peringkat

- 1224Dokumen67 halaman1224spsurya2013Belum ada peringkat

- 1222Dokumen68 halaman1222spsurya2013Belum ada peringkat

- 1225Dokumen67 halaman1225spsurya2013Belum ada peringkat

- 1220Dokumen69 halaman1220spsurya2013Belum ada peringkat

- 1214Dokumen7 halaman1214spsurya2013Belum ada peringkat

- 1214Dokumen7 halaman1214spsurya2013Belum ada peringkat

- 1219Dokumen70 halaman1219spsurya2013Belum ada peringkat

- 1213Dokumen8 halaman1213spsurya2013Belum ada peringkat

- 1221Dokumen69 halaman1221spsurya2013Belum ada peringkat

- 1214Dokumen7 halaman1214spsurya2013Belum ada peringkat

- 1214Dokumen7 halaman1214spsurya2013Belum ada peringkat

- 1212Dokumen2 halaman1212spsurya2013Belum ada peringkat

- 002Dokumen1 halaman002spsurya2013Belum ada peringkat

- 15 NMGFMDokumen7 halaman15 NMGFMspsurya2013Belum ada peringkat

- 221Dokumen1 halaman221spsurya2013Belum ada peringkat

- 1EGEWDokumen7 halaman1EGEWspsurya2013Belum ada peringkat

- Jobs - Supply Planning Manhnjhj, Jager - Middle East Job - Shell - Nov 2015 - RigzoneDokumen3 halamanJobs - Supply Planning Manhnjhj, Jager - Middle East Job - Shell - Nov 2015 - Rigzonespsurya2013Belum ada peringkat

- 1012Dokumen1 halaman1012spsurya2013Belum ada peringkat

- 156Dokumen2 halaman156spsurya2013Belum ada peringkat

- 55Dokumen2 halaman55spsurya2013Belum ada peringkat

- 2 HrhyreyDokumen6 halaman2 Hrhyreyspsurya2013Belum ada peringkat

- DQWDokumen6 halamanDQWspsurya2013Belum ada peringkat

- 122Dokumen1 halaman122spsurya2013Belum ada peringkat

- 10Dokumen1 halaman10spsurya2013Belum ada peringkat

- Dharmaraj Sfasfsundaramoorthy OriginalDokumen4 halamanDharmaraj Sfasfsundaramoorthy Originalspsurya2013Belum ada peringkat

- Kfgvu Hsbfiuqwfhqwnbfjkq S Fns HFJQWBFQWHFLNQW Ofjwswm FopjqwDokumen1 halamanKfgvu Hsbfiuqwfhqwnbfjkq S Fns HFJQWBFQWHFLNQW Ofjwswm Fopjqwspsurya2013Belum ada peringkat

- 1 UreuDokumen7 halaman1 Ureuspsurya2013Belum ada peringkat

- 2Dokumen7 halaman2spsurya2013Belum ada peringkat

- 29Dokumen6 halaman29spsurya2013Belum ada peringkat

- 2GIG ZWave CT30e Thermostat Installation GuideDokumen19 halaman2GIG ZWave CT30e Thermostat Installation Guideyamimaker2002Belum ada peringkat

- Fluid MechanicsDokumen9 halamanFluid MechanicsShubham BagalBelum ada peringkat

- Nyu Neworleans Activity1 Stress Strain Worksheet As v2 JlyDokumen2 halamanNyu Neworleans Activity1 Stress Strain Worksheet As v2 JlyakhilBelum ada peringkat

- Corner Fitting Iso 1161 Type - Bottom Left (243000C-Bl)Dokumen4 halamanCorner Fitting Iso 1161 Type - Bottom Left (243000C-Bl)mabuhamdBelum ada peringkat

- Methods of Preparing Horizontal Construction Joints in Mass ConcreteDokumen82 halamanMethods of Preparing Horizontal Construction Joints in Mass ConcreterabeeabuahmadBelum ada peringkat

- Hummel PG GlandsDokumen7 halamanHummel PG GlandsBob JohnsonBelum ada peringkat

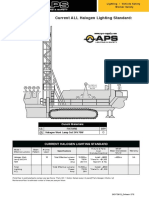

- Drilltech D75 LED Vs Halogen (26228)Dokumen2 halamanDrilltech D75 LED Vs Halogen (26228)Oscar Acevedo MirandaBelum ada peringkat

- 7th Sem Project Presentation Final Ppt-1Dokumen26 halaman7th Sem Project Presentation Final Ppt-1Bhaswat KashyapBelum ada peringkat

- 1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance ParametersDokumen8 halaman1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance Parametersعامر شیخBelum ada peringkat

- Mila Window HandlesDokumen17 halamanMila Window Handleswflorence1986Belum ada peringkat

- Fan HistoryDokumen6 halamanFan HistoryAsadBelum ada peringkat

- Light Commercial INVERTER Top Discharge CDU type Service ManualDokumen99 halamanLight Commercial INVERTER Top Discharge CDU type Service ManualAbel Recinos100% (1)

- A-1 - Perspective, Vicinity Map and Location MapDokumen1 halamanA-1 - Perspective, Vicinity Map and Location MapOJ MatiasBelum ada peringkat

- Greenheck DGXDokumen72 halamanGreenheck DGXBrad GBelum ada peringkat

- Lecture Notes Conductors, Insulators, and SemiconductorsDokumen2 halamanLecture Notes Conductors, Insulators, and Semiconductorsoduleke davidBelum ada peringkat

- Warranty and Service GuideDokumen4 halamanWarranty and Service GuideVanessaBelum ada peringkat

- Apgenco (Mechanical) 2017-QpDokumen16 halamanApgenco (Mechanical) 2017-QpSamresh GarnaikBelum ada peringkat

- ERHARD Butterfly Valves enDokumen32 halamanERHARD Butterfly Valves enMaryug HrBelum ada peringkat

- STM (2022)Dokumen49 halamanSTM (2022)Kaustav Jit BoraBelum ada peringkat

- East Halmahera Ferronickel Development Project (P3Fh Project)Dokumen2 halamanEast Halmahera Ferronickel Development Project (P3Fh Project)nailulfalah17Belum ada peringkat

- Course:: Heating Ventilation & Air-Conditioning (ME 326)Dokumen45 halamanCourse:: Heating Ventilation & Air-Conditioning (ME 326)Muhammad OsamaBelum ada peringkat

- Title 14 KT: Master Alloy For Casting of 375-585 (9-14 KT) Yellow GoldDokumen2 halamanTitle 14 KT: Master Alloy For Casting of 375-585 (9-14 KT) Yellow GoldTony BrutiglianoBelum ada peringkat

- Automatic Concrete Block Making Machine: DescriptionDokumen10 halamanAutomatic Concrete Block Making Machine: DescriptionTesfayeBelum ada peringkat