Materials Engineering Exam Question

Diunggah oleh

aneece786Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Materials Engineering Exam Question

Diunggah oleh

aneece786Hak Cipta:

Format Tersedia

This question paper consists of 4 printed pages, each of which is identified by the Code Number PEME108001

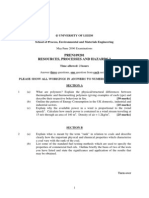

UNIVERSITY OF LEEDS School of Process, Environmental and Materials Engineering January 2010 Examinations

PEME108001 PROCESS AND PRODUCTION ENGINEERING

Time allowed: 3 hours Answer five questions, one question from each Section PLEASE SHOW ALL WORKINGS IN ANSWERS TO NUMERICAL QUESTIONS. SECTION A Resources 1 With the aid of diagrams and/or flowsheets, discuss TWO of the following: (a) (b) (c) primary ore comminution techniques froth flotation processes for recovering minerals electro-winning of metals from leach liquors.

[10 marks each]

Review the global production, commercial extraction and industrial utilisation of TWO of the following commodities: (a) salt (b) copper (c) lead [10 marks each]

SECTION B Materials Processing 3 Answer TWO of the following: (a) What are the general features of the casting technique for the production of shaped components? How can this technique be used for the production of hollow components? What factors limit the ability of a casting liquid to fill the mould? Discuss how suitable casting liquids may be obtained in metals, liquids and polymers, using sketch graphs, where appropriate, to illustrate your answer. [10 marks] Continued over

PEME108001

(b)

What are the general features of the forming technique for the production of shaped components? What is the most important material property requirement for this processing technique? List the classes of materials which generally possess this. The flow stress, and its variation with strain, strain rate and temperature, is important in forming why is this? Sketch graphs to illustrate this for a typical metal or alloy and explain this behaviour in terms of the processes occurring at a microstructural level within the material. [10 marks] Draw a flow sheet showing the stages in the production of a shaped component from powder. Describe briefly, and with the aid of diagrams, the press and sinter route, giving an example of one metal and one ceramic product typically processed by this route. Why might a powder route be preferred to a casting or forming route for the production of a metallic component? [10 marks] Why might a fabrication route be chosen over near-net-shape forming in the production of a component? Give examples of two products which illustrate this. What distinguishes between soldering, brazing and welding as joining techniques? Rank these in terms of the joint strength which results and explain this on the basis of the microstructures which result. [10 marks]

(c)

(d)

For EACH of FOUR of the articles listed below, draw a flowsheet to represent ONE possible route for the production of the article from the indicated material in its primary form. Take care to include all necessary stages and justify your choice of processing route. [Note that you should not use the same principal processing route more than once.] On your flowsheet, indicate the major energy inputs to the process and the major sources of waste. (a) (b) (c) (d) (e) (f) A steel crankshaft for an internal combustion engine; The nylon case of a notebook computer; A porcelain statuette; The stainless steel case of a watch; A gold dental crown; A bronze self-lubricating bearing. SECTION C Chemical Processes

[5 marks each part]

Many chemical products are manufactured using batch processing methods. (a) Highlight the main factors that influence the choice between using batch when compared to continuous processing methods and give two examples of common chemical products manufactured using batch processes. [4 marks] Continued over 2

PEME108001

(b)

A stirred tank reactor is commonly used in the batch synthesis and manufacture of a wide range of industrial materials. Outline and discuss the main issues that a process engineer needs to consider when developing a chemical process from small-scale laboratory work through to practical manufacture at a scale-size of (say) 5,000 litres. [4 marks] Explain, using an example such as the well-known Haber process used in the manufacture of ammonia, how processing conditions, drawing upon a consideration of process kinetics and equilibrium, can be optimised to design a viable commercial process. Where appropriate, state all relevant equations. [4 marks] Overview the three main potential processing routes for the commercial manufacture of aspirin and describe the rationale behind the selection of the actual process that is used for the practical manufacture of this product. [8 marks]

(c)

(d)

Biochemical processes are important in the manufacture of many everyday chemical products as well as in consideration of factors related to product safety. (a) (b) Give two examples of everyday materials prepared or processed using biochemical processing techniques. [2 marks] Review the biochemical manufacture of citric acid from the aspergillus niger fungus, highlighting an example of a typical processing set-up, the culture conditions typically adopted and the criteria that need to be followed to prevent the formation of oxalic acid as a by-product. [8 marks] Explain why biochemical reactors usually have to be sterilised prior to their use (say) for a fermentation reaction. [2 marks] An outbreak of botulism that took place in Lancashire in 1976 was found to be associated with the manufacture of a walnut flavoured yogurt. Highlight what happened, why it happened and what we have learned from this incident. [8 marks] SECTION D Energy and Fuels

(c) (d)

(a)

(i) (ii)

Outline the properties of gaseous fuels that are significant in combustion. [5 marks] Methane (CH4) has a gross calorific value of 890 MJ/kmol. Calculate the net calorific value (MJ/kmol) given that the latent heat of H2O = 2442 kJ/kg. [5 marks]

(b)

Explain the significance of the proximate analysis and ultimate analysis of a solid fuel. Show clearly, with examples, how the important physical and chemical properties which characterise a coal vary from low to high rank coals. [10 marks] Turn over 3

PEME108001

Answer TWO of the following. Illustrate your answers with diagrams or graphs as appropriate. (a) (b) (c) Discuss the significance and pattern of carbon dioxide pollutant emissions from energy sources. [10 marks] Outline the pattern of energy consumption in the UK industrial and domestic sectors. [10 marks] Explain why atomisation is a fundamental requirement in the combustion of a heavy fuel oil and outline the techniques that are used to achieve atomisation in industrial oil burners. Why is it often necessary to heat the oil prior to atomisation? [10 marks] (i) (ii) Explain the basic principles of nuclear power generation. [5 marks]

(d)

Estimate the area of solar photo-cells required to generate 2.0 kWh per day of electricity if the incident solar flux is 140W/m2, the electrical conversion efficiency of the photo-cells is 11% and the solar flux is available for 10 hours per day. [5 marks] SECTION E Fire and Safety

(a)

By reference to the combustion (fire) triangle, list and elaborate on the requirements for a fire or an explosion to occur. Look around you are the components of the triangle present in the examination room? Explain why you may or may not be concerned about the possibility of an imminent fire or explosion in the room. [7marks] What are polymers? Explain the physical/structural differences between thermoplastic and thermosetting polymers (giving examples of each type) and describe their respective behaviour in fire. [7 marks] Explain the techniques of venting and suppression for mitigating the effects of explosions in process equipment. [6 marks[ On a diagram showing the mass-burning rate against time for a typical compartment fire, mark clearly the phases of fire development. Briefly describe the characteristics of each phase and discuss some of the influencing parameters (and their effects) by comparison to an open fire. [9 marks] Explain the difference between fuel controlled and ventilation controlled burning regimes. With the aid of a diagram, explain how the temperature in a compartment may change with the ventilation. [4 marks] Calculate the maximum mass-burning rate in a compartment with a door (1x2 m2) and a window (1x1 m2). State any assumptions that you make. [7 marks] END 4

(b)

(c)

10

(a)

(b)

(c)

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Evidence From Thomas Croft Euthanasia and Assisted Suicide A Legal and Ethical DilemmaDokumen14 halamanEvidence From Thomas Croft Euthanasia and Assisted Suicide A Legal and Ethical Dilemmaaneece786Belum ada peringkat

- Polar MoleculeDokumen2 halamanPolar Moleculeaneece786Belum ada peringkat

- Reichert Cone Concentrator SystemDokumen9 halamanReichert Cone Concentrator Systemaneece786Belum ada peringkat

- Acetylsalicylic AcidDokumen3 halamanAcetylsalicylic Acidaneece786Belum ada peringkat

- TurbuhalerDokumen11 halamanTurbuhaleraneece7860% (1)

- Entropy, Gibbs EnergyDokumen4 halamanEntropy, Gibbs Energyaneece786Belum ada peringkat

- PREN109201 Resources, Processes and Hazards 2Dokumen3 halamanPREN109201 Resources, Processes and Hazards 2aneece786Belum ada peringkat

- Sulphonation and LABS Formulation Using SO3-AIR MethodDokumen3 halamanSulphonation and LABS Formulation Using SO3-AIR Methodaneece786Belum ada peringkat

- PREN109201 Resources, Processes and Hazards 2: School of Process, Environmental and Materials EngineeringDokumen2 halamanPREN109201 Resources, Processes and Hazards 2: School of Process, Environmental and Materials Engineeringaneece786Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Plumbing Breakup M 01Dokumen29 halamanPlumbing Breakup M 01Nicholas SmithBelum ada peringkat

- Hydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and EthanolDokumen11 halamanHydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and Ethanolkelly betancurBelum ada peringkat

- 8 Categories of Lipids: FunctionsDokumen3 halaman8 Categories of Lipids: FunctionsCaryl Alvarado SilangBelum ada peringkat

- Careerride Com Electrical Engineering Interview Questions AsDokumen21 halamanCareerride Com Electrical Engineering Interview Questions AsAbhayRajSinghBelum ada peringkat

- Tackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavDokumen9 halamanTackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavMalcolm PintoBelum ada peringkat

- Flores V PinedaDokumen10 halamanFlores V Pinedacha chaBelum ada peringkat

- 9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityDokumen3 halaman9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityAchraf BouraBelum ada peringkat

- Unit-7 (EVS)Dokumen32 halamanUnit-7 (EVS)g6614134Belum ada peringkat

- Remote Control Unit Manual BookDokumen21 halamanRemote Control Unit Manual BookIgor Ungur100% (1)

- Unknown Facts About Physicians Email List - AverickMediaDokumen13 halamanUnknown Facts About Physicians Email List - AverickMediaJames AndersonBelum ada peringkat

- G.R. No. 178741Dokumen1 halamanG.R. No. 178741Jefferson BagadiongBelum ada peringkat

- An Energy Saving Guide For Plastic Injection Molding MachinesDokumen16 halamanAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoBelum ada peringkat

- 99 AutomaticDokumen6 halaman99 AutomaticDustin BrownBelum ada peringkat

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDokumen2 halamanComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINABelum ada peringkat

- Havehas Affirm Neg Interrogwith Aliens - 19229Dokumen3 halamanHavehas Affirm Neg Interrogwith Aliens - 19229Ana Victoria Cuevas BeltránBelum ada peringkat

- Thai Guava Production PDF by VNRDokumen29 halamanThai Guava Production PDF by VNRDatta100% (2)

- NTJN, Full Conference Program - FINALDokumen60 halamanNTJN, Full Conference Program - FINALtjprogramsBelum ada peringkat

- Composite Restorations: Dr. Dina NouriDokumen38 halamanComposite Restorations: Dr. Dina NouriCatherine LoyolaBelum ada peringkat

- Chapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Dokumen44 halamanChapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Tommy RamazzottoBelum ada peringkat

- Sol. Mock Test CBSE BiologyDokumen3 halamanSol. Mock Test CBSE BiologysbarathiBelum ada peringkat

- Rajivgandhi University of Health Sciences Bangalore, KarnatakaDokumen19 halamanRajivgandhi University of Health Sciences Bangalore, KarnatakaHUSSAINA BANOBelum ada peringkat

- Hodgkin LymphomaDokumen44 halamanHodgkin LymphomaisnineBelum ada peringkat

- Catalogue CV. Traka Abadi UniversalDokumen15 halamanCatalogue CV. Traka Abadi UniversalHackers StevenBelum ada peringkat

- Aakanksha ProjectDokumen32 halamanAakanksha ProjectAakash murarkaBelum ada peringkat

- Metallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoDokumen1 halamanMetallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoEmigdio MartinezBelum ada peringkat

- BV DSG eDokumen18 halamanBV DSG eIulianIonutRaduBelum ada peringkat

- 2021 Life Skills ATP Grade 5Dokumen10 halaman2021 Life Skills ATP Grade 5Koketso SekwenyaneBelum ada peringkat

- Recommended Standards For Newborn ICU DesignDokumen39 halamanRecommended Standards For Newborn ICU DesignAlbert SekarBelum ada peringkat

- f2607-#### f2607 20191203 111644Dokumen2 halamanf2607-#### f2607 20191203 111644คุณชายธวัชชัย เจริญสุขBelum ada peringkat

- Dissertation Topics Forensic BiologyDokumen7 halamanDissertation Topics Forensic BiologyHelpMeWriteMyPaperPortSaintLucie100% (1)