Chapt 05 PLC

Diunggah oleh

vk2you009Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chapt 05 PLC

Diunggah oleh

vk2you009Hak Cipta:

Format Tersedia

A PROGRAMMABLE LOGIC CONTROLLER (PLC) is an industrial computer control system that continuously monitors the state of input devices

and makes decisions based upon a custom program, to control the state of devices connected as outputs. Almost any production line, machine function or process can be automated using a PLC. The speed and accuracy of the operation can be greatly enhanced using this type of control system. But the biggest benefit in using a PLC is the ability to change and replicate the operation or process while collecting and communicating vital information. A PLC consists of following main parts

PLC Operations consist of four steps 1. Input Scan: Scans the state of the Inputs 2. Program Scan: Executes the program logic 3. Output Scan: Energize/de-energize the outputs 4. Housekeeping Advantages PLCs have been gaining popularity on the factory floor and will probably remain predominant for some time to come. Most of this is because of the advantages they offer. Cost effective for controlling complex systems. Flexible and can be reapplied to control other systems quickly and easily. Computational abilities allow more sophisticated control. Trouble shooting aids make programming easier and reduce downtime. Reliable components make these likely to operate for years before failure. Better accuracy Reduced critical wiring Reduced operator dependency Simple operation

ARCHITECTURE OF PLC

The basic building blocks of PLC are as follows Power supply unit This provides power to all the subunits such as CPU, Memory, I/O processing Unit, Display and keyboard etc. Central Processing Unit (CPU) CPU is a heart of PLC as it is responsible for organising all the controller activities. CPU decides the sequence of different operations to be executed, by using the instructions written in memory. These instructions are loaded there by means of the keyboard. In addition to this it can perform some other functions such as counting, comparing, timing etc. Memory Memory is either RAM or ROM type. ROM is read only memory which contains the program for system operation or control. This program is called as monitor program. RAM is the random access memory which can be used by the user to read and write his instructions. I/O Processing Unit I/O means input or output interface. The input interface accepts the signals from various machines or signals from different points of the same machine. These signals are then converted into binary signals so that CPU can act upon them. Output interface will convert the PLC signals into the signals compatible to the machines to be driven. These signals are used to control various machines.

Figure 1.1 Block Diagram of PLC

Applications of PLCs

1) 2) 3) 4) To control individually various processes. To supervise various processes or single processes. In control of any time varying parameter. It is being used as major problem solving tool in many industrial applications.

Anda mungkin juga menyukai

- CMOS Design and Digital Logic ConceptsDokumen3 halamanCMOS Design and Digital Logic Conceptsvk2you009100% (1)

- VHDL Oral QuestionsDokumen1 halamanVHDL Oral Questionsvk2you009Belum ada peringkat

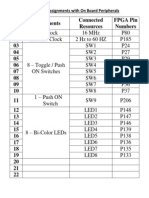

- Xilinx 2s50 Pins AssgnDokumen4 halamanXilinx 2s50 Pins Assgnvk2you009Belum ada peringkat

- Stability Routh CriteriaDokumen8 halamanStability Routh Criteriavk2you009Belum ada peringkat

- TV AND VIDEO ENGINEERING (404189Dokumen1 halamanTV AND VIDEO ENGINEERING (404189vk2you009Belum ada peringkat

- Ref BooksDokumen1 halamanRef Booksvk2you009Belum ada peringkat

- CFPDokumen1 halamanCFPvk2you009Belum ada peringkat

- PID algorithm industrial process controlDokumen1 halamanPID algorithm industrial process controlvk2you009Belum ada peringkat

- T.E. (E&TC) (Semester - I) Examination, 2011 Control Systems (2008 Pattern) (New)Dokumen2 halamanT.E. (E&TC) (Semester - I) Examination, 2011 Control Systems (2008 Pattern) (New)vk2you009Belum ada peringkat

- TelescopeDokumen4 halamanTelescopevk2you009Belum ada peringkat

- Pid ControlDokumen13 halamanPid ControlKhalil AhmadBelum ada peringkat

- Calculations Estimation Parameter: Block Diagram of A Self Tuning RegulatorDokumen10 halamanCalculations Estimation Parameter: Block Diagram of A Self Tuning Regulatorvk2you009Belum ada peringkat

- QP01Dokumen6 halamanQP01vk2you009Belum ada peringkat

- PID ControllersDokumen5 halamanPID ControllersJyoti Prakash PrustyBelum ada peringkat

- Imp Adaptive ControlDokumen13 halamanImp Adaptive Controlvk2you009Belum ada peringkat

- Your City Just Got Smaller, With Uninor's Unbelievable Local PacksDokumen1 halamanYour City Just Got Smaller, With Uninor's Unbelievable Local Packsvk2you009Belum ada peringkat

- Raw To RGBDokumen58 halamanRaw To RGBvk2you009Belum ada peringkat

- Altera - Datasheet 1Dokumen38 halamanAltera - Datasheet 1vk2you009Belum ada peringkat

- DTE CODE: 6632 MCA: Contact: - 8275449259 / 7709447690 / 9975157884Dokumen1 halamanDTE CODE: 6632 MCA: Contact: - 8275449259 / 7709447690 / 9975157884vk2you009Belum ada peringkat

- Navsahyadri Education Society'S Group of InstitutionsDokumen1 halamanNavsahyadri Education Society'S Group of Institutionsvk2you009Belum ada peringkat

- Solid State Devices and Circuits: Signals, Systems and ApplicationsDokumen26 halamanSolid State Devices and Circuits: Signals, Systems and ApplicationssanjuzadokarBelum ada peringkat

- Led VHDLDokumen1 halamanLed VHDLThành Tuấn NguyễnBelum ada peringkat

- ReferenceDokumen5 halamanReferencevk2you009Belum ada peringkat

- Muktagiri AddDokumen1 halamanMuktagiri Addvk2you009Belum ada peringkat

- Net 3G Network & PalnsDokumen2 halamanNet 3G Network & Palnsvk2you009Belum ada peringkat

- Lab Manual PageDokumen2 halamanLab Manual Pagevk2you009Belum ada peringkat

- Quatation Enquiry FormDokumen1 halamanQuatation Enquiry Formvk2you009Belum ada peringkat

- ElectronicsDokumen70 halamanElectronicsvk2you009Belum ada peringkat

- Exp10 BCDAdderDokumen4 halamanExp10 BCDAddervk2you009Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Tutorial DataGeosis Office EspañolmtdDokumen205 halamanTutorial DataGeosis Office Españolmtdramm70Belum ada peringkat

- Chap4 Student VersionDokumen39 halamanChap4 Student VersionAzrif MoskamBelum ada peringkat

- Spokane County Sheriff's Internal Communication PlanDokumen11 halamanSpokane County Sheriff's Internal Communication Planjmcgrath208100% (1)

- Chapter 1: Introduction: 1.1 The Construction ProjectDokumen10 halamanChapter 1: Introduction: 1.1 The Construction ProjectamidofeiriBelum ada peringkat

- High Surge Energy Non-Inductive Compact Size: U Series ResistorsDokumen2 halamanHigh Surge Energy Non-Inductive Compact Size: U Series ResistorsYouness Ben TibariBelum ada peringkat

- KPC Tech Catalog 2010Dokumen84 halamanKPC Tech Catalog 2010Mattia KrumenakerBelum ada peringkat

- Design of Water Cooled Electric Motors Using CFD and Thermography TechniquesDokumen6 halamanDesign of Water Cooled Electric Motors Using CFD and Thermography TechniquesNicolas JerezBelum ada peringkat

- FUTURE SHOCK by ALVIN TOFFLERDokumen5 halamanFUTURE SHOCK by ALVIN TOFFLERgeraldine100% (1)

- MF1547Front Linkage - Seat PDFDokumen18 halamanMF1547Front Linkage - Seat PDFAhmad Ali NursahidinBelum ada peringkat

- What is a Gear Motor? - An In-Depth GuideDokumen15 halamanWhat is a Gear Motor? - An In-Depth GuidePuneet KumarBelum ada peringkat

- Carrier LDU ManualDokumen123 halamanCarrier LDU Manualdafrie rimbaBelum ada peringkat

- System Software Module 3Dokumen109 halamanSystem Software Module 3arunlaldsBelum ada peringkat

- AT-8600 Series Switch: Hardware ReferenceDokumen30 halamanAT-8600 Series Switch: Hardware ReferenceSubbuBelum ada peringkat

- Pid Handbook 1002-02 PDFDokumen94 halamanPid Handbook 1002-02 PDFMUHAMMAD TAUFEEQBelum ada peringkat

- Monitoring Critical Applications at SeaDokumen3 halamanMonitoring Critical Applications at SeaMohamed AliBelum ada peringkat

- Câtlo ABB PDFDokumen288 halamanCâtlo ABB PDFquocthinh_09Belum ada peringkat

- Sadi Mohammad Naved: Duties/ResponsibilitiesDokumen3 halamanSadi Mohammad Naved: Duties/ResponsibilitiesNick SanchezBelum ada peringkat

- Ee8602 Protection and SwitchgearDokumen2 halamanEe8602 Protection and SwitchgeararwinBelum ada peringkat

- Jinal Black BookDokumen7 halamanJinal Black Bookhardik patel0% (1)

- PACK PAR BoilersDokumen31 halamanPACK PAR BoilersJosé MacedoBelum ada peringkat

- DNS Amplification Attacks ExplainedDokumen13 halamanDNS Amplification Attacks ExplainedhammBelum ada peringkat

- Tim'S Tinkerings: My Ikea Billy' Bookcase Hack For Under $500Dokumen1 halamanTim'S Tinkerings: My Ikea Billy' Bookcase Hack For Under $500Jolgra PokerBelum ada peringkat

- Usb Modem 2Dokumen4 halamanUsb Modem 2emadBelum ada peringkat

- 3530 Nellikuppam Clarifier SpecDokumen62 halaman3530 Nellikuppam Clarifier Specgopalakrishnannrm1202100% (1)

- DPD Catalog 05 PDFDokumen36 halamanDPD Catalog 05 PDFRuth D.Belum ada peringkat

- Cable Diagram: Technical Data SheetDokumen1 halamanCable Diagram: Technical Data SheetCharlie MendozaBelum ada peringkat

- Manajemen Berbasis Nilai, Studi Atas Penerapan Manajemen Berbasis NilaiDokumen20 halamanManajemen Berbasis Nilai, Studi Atas Penerapan Manajemen Berbasis NilaitsfBelum ada peringkat

- ZQYM Diesel Cummins Series Injector 2023.07Dokumen13 halamanZQYM Diesel Cummins Series Injector 2023.07harbh9355Belum ada peringkat

- Guide to Manual J Load Calculations in 40 CharactersDokumen27 halamanGuide to Manual J Load Calculations in 40 Characters123john123100% (3)

- Class B BiosolidsDokumen9 halamanClass B BiosolidsGissmoBelum ada peringkat