PRESTRESSED

Diunggah oleh

nivi_09Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PRESTRESSED

Diunggah oleh

nivi_09Hak Cipta:

Format Tersedia

1) Explain the assumption made in the prestressed concrete sections and also the major steps to be followed in the

strain compatibility method. 2) Explain the various types of flexural failures encountered in pre stressed concrete members. 3) A prestressed concrete beam of effective span 16m is of rectangular section 400mm wide and 1200mm deep. The tendons consist of 3300mm2 of strands of characteristic strength 1700n/mm2 with an effective prestress at 910n/mm2. The strands are located 870mm from the top face of the beam. If fcu=60n/mm2, estimate the flexural strength of the section as per Indian code provisions for the following cases: 1) bonded tendons 2) unbounded tendons. 4) Explain with sketches the IS: 1343 code method of computing the moment of resistance of rectangular sections. 5) Design a non-cylinder pre-stressed concrete pipe of internal diameter 500mm to withstand a working pressure of 1n/mm2. High tensile wires of 2mm diameter stressed to 1200n/mm2 at transfer are available for use. Permissible maximum and minimum stresses in concrete at transfer and working loads are 13.5 and 0.8n/mm2 (compression) respectively. Loss ratio=0.8, Es=210n/mm2 calculate, i) the minimum thickness of concrete for the pipe ii) number of turns of wire per meter length of the pipe. iii) The test pressure required to produce a tensile stress of 0.7n.mm2 in the concrete when applied immediately after tensioning. iv)The winding stress in the steel. 6) A pre stressed concrete circular cylindrical water tank is required to store 2500 million liters of water. The permissible compressive stress in concrete at transfer should not exceed 13n/mm2 and the minimum compressive stress under working pressure should not be less than 1 n/mm2. The loss ratio is 0.75. High tensile wires of 7mm diameter with an initial stress of 1000 n/mm2 are available for winding round the tank. Fressynet cables of 12 wires of 8mm diameter which are stressed to 1200n/mm2 are available for vertical prestressing. The cube strength of concrete is 40n/mm2. Design the tank walls supported on elastomeric pads. Assume the co-efficient of friction as 0.5. 7) A composite beam 5m span is of T-section and consist of a precast pre stressed concrete rectangular beam, 100mm wide and 240mm deep. The cost insitu slab is 400mm wide and 60mm thick. The prestressed beam contains high tensile steel of area 180mm2 located 50mm from the soffit. The grade of concrete in the pre-stressed beam and cast in situ slab is M40 and M25 respectively. Fpu =1600n/mm2 and the ratio of effective to ultimate tensile stress in tendons is 0.5. design suitable reinforcements for resisting horizontal shear between the pre-stressed beam and cast in situ slab using the provision of i) British code ii) American code. 8) What are the advantages of pre stressed concrete bridges. 9) Explain the cantilever method of constructing pre-stressed concrete bridges with sketches. 10) Explain the various steps involved in the design of short span prestressed concrete solid slab decks for national highway to support I.R.C loads. 11) Explain with sketches the typical pre-tensioned and post-tensioned bridge decks commonly used in the construction of bridges. 12) A precast PSC beam of rectangular section has a breadth of 100mm and a depth of 200mm. the beam with an effective span of 5m is prestressed by tendons with their centroids coincides with bottom kern. The initial stress in the tendon is 150kn. The loss ratio=0.85. the beam is incorporated in a composite T-beam by casting a top flange of breadth 400mm and thickness 40mm. if the composite beam supports a live load of 8kn/m2, calculate the resultant stresses developed in the precast and insitu cast concrete assuming the pre tensioned beam as unpropped during the casting the slab. Eprecast psc=35kn/mm2 Einsitu con= 28kn/mm2.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- KarpagavalliDokumen2 halamanKarpagavallinivi_09Belum ada peringkat

- Research directions in UDDI for web servicesDokumen3 halamanResearch directions in UDDI for web servicesnivi_09Belum ada peringkat

- VocabularyDokumen1 halamanVocabularynivi_09Belum ada peringkat

- SubjectsDokumen1 halamanSubjectsnivi_09Belum ada peringkat

- Representing Events and Actions in Spatial Relations Over TimeDokumen1 halamanRepresenting Events and Actions in Spatial Relations Over Timenivi_09Belum ada peringkat

- System Arch 5Dokumen2 halamanSystem Arch 5nivi_09Belum ada peringkat

- ReferencesDokumen3 halamanReferencesnivi_09Belum ada peringkat

- Annual CorrelationDokumen1 halamanAnnual Correlationnivi_09Belum ada peringkat

- Anaconda Cheat SheetDokumen1 halamanAnaconda Cheat SheetBrianBelum ada peringkat

- AuthorsDokumen1 halamanAuthorsnivi_09Belum ada peringkat

- Ease Based STKRR: Predicted YES NO Actual YES 4 0 TP FN NO 1 133 FP TN 3 10 1 207Dokumen6 halamanEase Based STKRR: Predicted YES NO Actual YES 4 0 TP FN NO 1 133 FP TN 3 10 1 207nivi_09Belum ada peringkat

- How To Create Master SlideDokumen1 halamanHow To Create Master Slidenivi_09Belum ada peringkat

- Forward BackwardDokumen2 halamanForward Backwardnivi_09Belum ada peringkat

- ToolsDokumen1 halamanToolsnivi_09Belum ada peringkat

- UDDI FRAMEWORKS AND METHODOLOGIES FOR WEB SERVICE DISCOVERYDokumen3 halamanUDDI FRAMEWORKS AND METHODOLOGIES FOR WEB SERVICE DISCOVERYnivi_09Belum ada peringkat

- ReferencesDokumen8 halamanReferencesnivi_09Belum ada peringkat

- ContentsDokumen1 halamanContentsnivi_09Belum ada peringkat

- Universal Description Discovery and Integration (UDDI) : A ReviewDokumen34 halamanUniversal Description Discovery and Integration (UDDI) : A Reviewnivi_09Belum ada peringkat

- BooksDokumen1 halamanBooksnivi_09Belum ada peringkat

- Interaction Diagram - A. Sequence DiagramDokumen1 halamanInteraction Diagram - A. Sequence Diagramnivi_09Belum ada peringkat

- Survey EDITDokumen38 halamanSurvey EDITnivi_09Belum ada peringkat

- Allocation MethodsDokumen12 halamanAllocation Methodsnivi_09Belum ada peringkat

- M.Tech CSEDokumen11 halamanM.Tech CSEnivi_09Belum ada peringkat

- Interaction Diagram - A. Sequence DiagramDokumen1 halamanInteraction Diagram - A. Sequence Diagramnivi_09Belum ada peringkat

- Fig 8.1 Sequence DiagramDokumen1 halamanFig 8.1 Sequence Diagramnivi_09Belum ada peringkat

- Fig 8Dokumen1 halamanFig 8nivi_09Belum ada peringkat

- Gmail SystemDokumen2 halamanGmail Systemnivi_09Belum ada peringkat

- SlokasDokumen1 halamanSlokasnivi_09Belum ada peringkat

- Fig 8.1 Sequence DiagramDokumen1 halamanFig 8.1 Sequence Diagramnivi_09Belum ada peringkat

- BooksDokumen2 halamanBooksnivi_09Belum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- US Canada Europe automotive electronics EMC standards regulationsDokumen2 halamanUS Canada Europe automotive electronics EMC standards regulationschrosuBelum ada peringkat

- CJ Blossom Park Lab of the Year Award Winner 2018Dokumen3 halamanCJ Blossom Park Lab of the Year Award Winner 2018petiepanBelum ada peringkat

- Applied ChemistryDokumen5 halamanApplied Chemistryabdul hameed khanBelum ada peringkat

- Cable Type BS5308Dokumen2 halamanCable Type BS5308Jitendra MahidaBelum ada peringkat

- PackML Charter v3 0 Rev2Dokumen2 halamanPackML Charter v3 0 Rev2FranzKafkaBelum ada peringkat

- Oil-Free Centrifugal Chiller SpecificationDokumen11 halamanOil-Free Centrifugal Chiller SpecificationMohd RizalBelum ada peringkat

- Leeds Guidelines ConnecticutDokumen48 halamanLeeds Guidelines ConnecticutDuong Thai BinhBelum ada peringkat

- Method of Design - SLAB & BEAMDokumen19 halamanMethod of Design - SLAB & BEAMসামিউলইসলামBelum ada peringkat

- 02 - 202-203 DC ContactorDokumen2 halaman02 - 202-203 DC Contactorshailesh284Belum ada peringkat

- Finding the Right Inspection EngineerDokumen3 halamanFinding the Right Inspection Engineerkhwaja NomanuddinBelum ada peringkat

- Understanding Architectural Form: A Conceptual Framework: Saleem M. Dahabreh, PH.DDokumen14 halamanUnderstanding Architectural Form: A Conceptual Framework: Saleem M. Dahabreh, PH.DAlla ElfallahBelum ada peringkat

- Ansi Asabe S366.2 May2004 (Iso 5675-1992) (R2009)Dokumen3 halamanAnsi Asabe S366.2 May2004 (Iso 5675-1992) (R2009)StephanBelum ada peringkat

- Use of The AASHTO 1993 Guide MEPDG and Historical Performance Pavement Design CaelogDokumen29 halamanUse of The AASHTO 1993 Guide MEPDG and Historical Performance Pavement Design Caelogs_khan1997466Belum ada peringkat

- Our People - Doc (Updated)Dokumen15 halamanOur People - Doc (Updated)Mark Ceidrick LimBelum ada peringkat

- Assignment Ets ReportDokumen9 halamanAssignment Ets ReportsamtomBelum ada peringkat

- A Central University Established by An Act of ParliamentDokumen8 halamanA Central University Established by An Act of ParliamentPriyanka deyBelum ada peringkat

- Oil Field: Main CatalogueDokumen176 halamanOil Field: Main CatalogueM. Aguiar100% (1)

- Chapter 5 - Rigid Pavement - LatestDokumen50 halamanChapter 5 - Rigid Pavement - LatestThiva RajanBelum ada peringkat

- University of Engineering and Technology, Taxila Department of Mechanical EngineeringDokumen2 halamanUniversity of Engineering and Technology, Taxila Department of Mechanical EngineeringYasir KhalidBelum ada peringkat

- CCE Certification FlowchartDokumen1 halamanCCE Certification FlowchartonixexenBelum ada peringkat

- Engineering NotebookDokumen5 halamanEngineering NotebookChettamilsBelum ada peringkat

- As 62040.3-2002 Uninterruptible Power Systems (UPS) Method of Specifying The Performance and Test RequirementDokumen10 halamanAs 62040.3-2002 Uninterruptible Power Systems (UPS) Method of Specifying The Performance and Test RequirementSAI Global - APACBelum ada peringkat

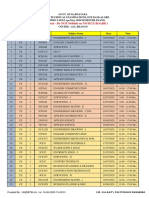

- School of Electrical Engineering and Computer Science Time TableDokumen5 halamanSchool of Electrical Engineering and Computer Science Time TableJunaidZafarBelum ada peringkat

- All Branch Time TableDokumen10 halamanAll Branch Time TableUday hpBelum ada peringkat

- Bulletin 2018 19Dokumen404 halamanBulletin 2018 19AppleBelum ada peringkat

- A Voltage Controlled Pin Diode Attenuator Using An Accurate Pin Diode ModelDokumen10 halamanA Voltage Controlled Pin Diode Attenuator Using An Accurate Pin Diode Modelagmnm1962Belum ada peringkat

- DISOGRIN DMRW Rod Wiper Features & BenefitsDokumen24 halamanDISOGRIN DMRW Rod Wiper Features & BenefitsRicardo RivasBelum ada peringkat

- BCA 1B - Code of Practice On Buildability-2015 PDFDokumen75 halamanBCA 1B - Code of Practice On Buildability-2015 PDFdelciogarciaBelum ada peringkat

- Tensile Strength TestDokumen2 halamanTensile Strength TestJanice VaflorBelum ada peringkat

- Elements of Civil EngineeringDokumen62 halamanElements of Civil EngineeringShubhamBelum ada peringkat