IP0340 Buckle E

Diunggah oleh

oscarariagnaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

IP0340 Buckle E

Diunggah oleh

oscarariagnaHak Cipta:

Format Tersedia

A FLOATING STRUCTURE ACROSS OKANAGAN LAKE J. Buckle British Columbia Ministry of Transportation and Infrastructure Jon.Buckle@gov.bc.

ca ABSTRACT Highway 97 runs through the Okanagan region of British Columbia and crosses Okanagan Lake at Kelowna. By year 2000 an existing 3 lane floating bridge, opened in 1958, was in need of replacement due to severe traffic congestion and significant deterioration. Traffic volumes in excess of 50,000 vehicles/day were causing substantial delays crossing the only bridge across the 135 kilometre long lake. Delays were compounded by the requirement for the bridge to be temporarily closed to accommodate marine traffic.

Figure 1 - Old Okanagan Lake Bridge

The Province of British Columbia examined alternatives to address the issues of a highway crossing Okanagan Lake and established project objectives to address safety, traffic capacity, tolling, marine traffic, pedestrians and cyclists. The project ruled our rehabilitation and then focused on a new crossing of the kilometre wide lake. After examining cable stayed and tunnel options a combined floating and elevated structure was selected as the preferred solution to meet all project objectives. The bridge was delivered as a Public Private Partnership DBFO project with SNC Lavalin selected as the Concessionaire in June 2005 with a design/construction cost of $(Cdn)144.5 Million .The 5 lane bridge was completed in May 2008, 3 months ahead of schedule and on Budget.

1

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111121 1

1. INTRODUCTION Occasionally a transportation challenge presents itself that cannot be solved by conventional means. This paper presents one such project. The Province of British Columbia (B.C.) is Canadas most westerly Province. With a predominantly mountainous landscape, BC is also home to a number of lakes. In South Central BC, Highway 97S travels north-south through the Okanagan Valley. At Kelowna, a lakeside city of 130,000 residents, the Highway crosses the 135 km long Okanagan Lake. Originally the lake crossing was serviced with a vehicle ferry. In 1958, the province undertook the construction of a two lane floating bridge, the first of its kind in Canada. The bridge included a lift span to accommodate marine traffic. Growth in traffic resulted in the expansion to three lanes in 1983 with the centre lane designated as a reversible direction lane to accommodate peak flows. Over time, traffic volumes grew steadily, eventually reaching 50,000 vehicles/day, and causing substantial delays to commuter and commercial freight traffic travelling Highway 97S. These delays were further compounded by the operation of the lift span to service marine traffic. When activated for the passage of lake vessels under the bridge, the lift span caused the short term closure of the Highway and further congestion. Concurrent with the traffic growth was the progressive deterioration of some of the floating concrete pontoon sections, as well as the electrical-mechanical failure of the lift span. With increasing congestion, accelerated bridge deterioration plus the increased frequency of vehicle crashes, the Province determined that something drastic must be done to reverse these trends. 2. PROJECT OBJECTIVES In the late 1990s, the Province of British Columbia undertook an assessment of the alternatives to establish a sustainable, safe, reliable and fully functional highway crossing of Okanagan Lake capable of supporting all modes of transportation. The assessment focussed on the following factors: 2.1 Safety and reliability

The old bridge accommodated both directions of traffic with no separation. Vehicle collision frequency exceeded Provincial averages for similar conditions as did collision severity. Collisions typically closed the bridge entirely leading to extended severe congestion and delays. As the closure of the bridge meant a detour route around the lake taking more than two hours, improved availability and reliability of the bridge crossing was identified as a key project objective. 2.2 Traffic capacity

The rapid population growth in the Central Okanagan valley has led to Highway 97 in the vicinity of the lake crossing becoming the most congested section of Highway in the interior of the Province. Future projections had showed continuing traffic growth of about three percent annually. By the year 2000, volume exceeded capacity by 20%

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111131 1

leading to significant congestion delays particularly during the am and pm peak periods. It was determined that a sustainable solution would need to provide excess capacity of 50% that would be absorbed over time by the continued growth until the overall capacity constraints of the broader Highway corridor and system were reached. 2.1 Tolls

The Provincial government policy on tolls requires that a viable alternative route choice must be available to road users before the implementation of tolls can be considered. Due to the absence of a practical alternative lake crossing, the policy required that the bridge crossing remain a no-toll facility. 2.2 Accommodating marine traffic

The old bridge lift span required activating to allow sailboats or larger commercial and pleasure vessels to pass under the bridge. Each lift meant the closure of the highway for at least 3 to 5 minutes. This constraint was seen to be increasingly unwelcome by the highway users as traffic and congestion delays expanded. The Province determined that a fundamental project objective was to eliminate vehicle-marine conflicts by requiring a fixed navigable marine channel capable of accommodating an 18 metre vertical clearance at high water be incorporated into the future crossing. 2.3 Cyclists and pedestrians

Although the old bridge had two narrow sidewalks, they were insufficient in width to accommodate safe two way cyclist and pedestrian movements. In addition, there was no separation between the walkways and the vehicle lanes other than a curb. As it is the Provinces policy to take measures to encourage transportation alternatives to passenger cars, it was agreed that the project would provide improved cycling and pedestrian facilities that would be safe and sufficiently wide to accommodate two way movements. 2.4 Communities and Environment

Okanagan lake is a clean water source that provides drinking water to over 200,000 people. Environmental sustainability and enhancement was identified early on as a vital objective, including the goal to meet and exceed regulatory requirements for biodiversity, water quality and waste management. The lake crossing also connects two urban areas and a first nations community. As most bridge users are residents of these communities it was established that a key objective would be to partner with each community, to develop a strong spirit of cooperation to foster mutual benefits, and for the First Nations, to provide further specific employment, business opportunities and recognition initiatives in keeping with Provincial policy. 3. DESIGN OPTIONS The lake crossing, at its narrowest point, is about 1000 metres across. Lake depths vary from a shallow 5 metre deep shelf on the western shore to depths of 60 metres for the eastern and central portions. However, the most challenging aspect of the site is

!"#$%&'()*+,&-./0)1111111111111111111111111111111111111111111111111111111111111111111111#1 1

the makeup of the lake bottom material where very soft lucustrian silts predominate to a depth of up to 20 metres creating a very unstable environment for structural foundations. 3.1 Cable stayed

A cable stayed design would have typically been considered an appropriate means to span the kilometre wide and up to 60 metre deep crossing. However, the deep lake sediments presented a major constraint to establishing affordable bridge tower foundations. Towers would need to be widely spaced near the shores of the lake creating a greater main span and a higher consequent cost. 3.2 Floating pontoon structure

The old bridge was a floating structure so there was no question that this proven, though high cost solution could be employed. The challenge was to construct a floating bridge that could also accommodate a navigable channel with an 18 metre vertical clearance to allow all marine traffic to pass unimpeded under the bridge. 3.3 Causeway and piers

The western third of the crossing was shallow and could certainly be supported by either a causeway fill or a series of pile supported pier foundations. The difficulty was that the deep eastern and central sections of the bridge site could not practically support a fixed foundation structure due to the depths and very unstable lake bottom silts. 3.4 Tunnel

A lake bottom tunnel was considered as an initial option but quickly discounted due to the deep soft silt lake bottom. The novel concept of a partially floating submerged tunnel was also conceptually examined but found to be unfeasible and without any known demonstrated application elsewhere. 3.5 The selected design

Through the process of elimination and the integration of options the selected design incorporated a light causeway fill on the western shore, adjoining a fixed 300 metre long elevated section accommodating the navigation channel supported by five deep pile supported piers, and finally a 700 metre long concrete pontoon floating section to span the deep center and eastern portions of the crossing. The design life of the new bridge was set at 75 years, meaning this duration before major structural rehabilitation would be required

!"#$%&'()*+,&-./0)1111111111111111111111111111111111111111111111111111111111111111111111$1 1

Figure 2 - Profile of the selected design

4. DELIVERY OPTIONS The bridge was originally intended to be procured through a design bid build process and so the Province commissioned the selected option to proceed to design. However, before completion of the design, the Province initiated a business evaluation of alternative forms of project delivery in keeping with a new policy to undertake alternate forms of delivery assessment, including P3, for infrastructure projects over $20 million. As a result of the qualitative and financial evaluation, a business case was developed to invite proposals for a Design Build Finance Operate (DBFO) model for a new bridge crossing of Okanagan Lake. Some of the key reasons for selecting the DBFO option and proposed features of this model included: Incentives for the private partner to manage the project efficiently, such as no payments until the bridge opened, in order to encourage early completion. Flexibility to facilitate innovation in design and construction. Assignment of risk to the partner best able to manage it. For example the Province retained land, legislative, archaeological and some environmental approval risk, while the private partner assumed all design, construction, operation and maintenance risk. Performance based payments over the life of the operating phase (27 years) based on traffic safety record, lane availability, traffic volumes, and bridge user satisfaction measures. Inclusion of long term operations and maintenance to encourage consideration of life cycle costs.

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111141 1

The procurement process from the Request for Expressions of Interest (RFEIO) through to the signing of a Concession Agreement took 20 months. The evaluation of the proposals was split into two processes. First a technical (pass-fail) evaluation was undertaken to ensure the proposals met all the essential Provincial requirements. Then a financial and commercial assessment was made to determine the best value for money. The successful proponent (Concessionaire) for the project was SNC Lavalin. The value of the design-build capital cost of the bridge was $144.5 million ($CAD) and the estimated total net present value of the 27 year stream of payments to the Concessionaire was $170 million including all capital and operating costs. 5. PROJECT IMPLEMENTATION The construction of the bridge and its approaches was expected to take three years. The key components of the construction were: 5.1 Graving dock (dry dock) Floating pontoons Fixed bridge and approach roadways Pontoon installation and anchoring Bridge fit-out The Graving Dock

The critical path for the project was focussed on the fabrication of the floating pontoons. Each pontoon was 25 metres wide and typically 90 metres in length and weighing approximately 7000 tonnes. To construct these very large, floating, heavily reinforced concrete boxes a special purpose dry dock, known as a graving dock, was required (see figure 3). A suitable site was located seven kilometres up the lake from the bridge and excavation commenced. Before the excavation had gone far, bones were unearthed and the project had to be shut down for two months while a full archaeological investigation was undertaken in co-operation with the neighbouring First Nations. The graving dock, measuring 100 metres long by 30 metres wide by 5 metres deep was constructed with steel sheet pile walls, a heated and cooled concrete floor and a 13,000 litre/minute dewatering pump system.

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111151 1

Figure 3 Constructing the Graving Dock 5.2 The Pontoons

The construction of the pontoons commenced with the building of a prototype to test the constructability of the design. In particular was the challenge of consolidating the concrete within the tall thin walled forms heavily laced with reinforcing steel and post tensioning conduits. A further challenge was the need to be able to place and support formwork to build over one hundred encased cells in each pontoon, and then to remove the formwork (see figure 4). Yet another challenge was the requirement to create 36 fully watertight cell compartments per pontoon with no leakage or dampness below the waterline.

Figure 4 Fabricating the pontoons

The first pontoon took five months to construct. The contractor soon realized that with such production rates continuing, the completion date would be substantially overshot. An initiative was launched to develop efficiencies in construction methods, materials handling, the training and distribution of workers and the use of new products.

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111161 1

Productivity steadily improved as the new methods were implemented including installing more overhead cranes, round the clock shifts, crew production incentives and innovative new construction methods. The last four pontoons were each completed in about sixty days representing a 250% productivity improvement. Upon completion of each pontoon, the graving dock was flooded, the gates to the lake were opened, and the new pontoon was floated out onto the lake and secured, awaiting its turn to be towed to the bridge site. 5.3 The Fixed Bridge and Approach Roadway

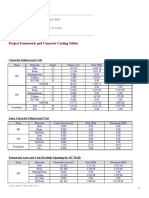

At the bridge site, causeway fills were constructed at the east and west approaches. The soft lake bed sediments led to settlements in excess of one metre as a result of the preload. To minimize the weight of the fill, Styrofoam blocks were used to construct very light weight embankments weighing only 24 kilograms per cubic metre, and represented only about one percent of the weight of an equivalent conventional granular fill. The fixed portion of the bridge was supported by five concrete piers, with each pier founded on twelve steel pipe piles each driven up to 60 metres in depth, as friction piles, into the soft lake bottom.

Figure 5 - The fixed elevated span and the navigation channel In order to provide an 18 metre high vertical clearance navigation channel under the bridge, pairs of concrete columns were constructed at each pier to support the elevated structure. (see figure 5) Horizontal members consisted of six welded steel girders each with a span of 50 metres. One of the unique features of this bridge was the special purpose expansion joints that were designed to accommodate multiple degrees of movement including longitudinal expansion and contraction, the rise and fall of the lake level and torsional rotation of the floating pontoons. The composite rubber and steel joints incorporate a stiff accordion diaphragm integrated with a sliding steel deck plate.

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111171 1

Figure 6 Towing the pontoons to the bridge site Other special materials included maintenance free weathering steel to fabricate the bridge girders and silica fume concrete to cast the deck, aiding in durability and resistance to de-icing salts.

5.4

Pontoon Installation

Each of the nine pontoons was towed in sequence to the bridge site (see figure 6). The installation first required making lateral connections with twelve anchors on each side of the bridge. These large seventy-five tonne anchors and their corresponding cables were then each hydraulically tensioned to their particular design load to ensure the floating bridge remained in alignment under all wind, wave and ice conditions. Each pontoon was then connected with its adjoining pontoons through 144 separate post tensioned wire tendon joints. These connections were designed to be extremely strong, in effect creating one 700 metre long rigid pontoon. Once the floating structure was in its final position, a continuous concrete deck overlay was cast to establish the final running surface.

Figure 7 Constructing the floating elevated section

!"#$%&'()*+,&-./0)111111111111111111111111111111111111111111111111111111111111111111111181 1

5.5

Final Bridge Fit-out

The fit-out of the bridge included the construction of the sidewalk for pedestrians and cyclists, the installation of median barrier, parapets, overhead lighting, signage, and lane markings. Fourteen video cameras were installed in conjunction with integrated systems allowing the counting of vehicles (a performance measure) as well as facilitating rapid response to vehicle crashes, stalls and road conditions. 6. RESULTS The five lane William R Bennett Bridge was opened to traffic in May 2008, 108 days ahead of the contract substantial completion date. Two adjoining projects on Highway 97 either side of the new bridge provided additional lanes, eliminated intersections and made other safety improvements to ensure a less constrained flow of traffic to the bridge. The bridge met the quality requirements specified by the Province with the exception of two areas. The first involved the failure of the grout used to support the expansion joints and the subsequent failure of the joints themselves. The Concessionaire had to replace the expansion joints to resolve this problem. The second quality issue was the extensive full depth cracking of the cast concrete deck for the fixed bridge. This problem is being addressed by an extensive and ongoing program of epoxy crack sealing. Both quality issues were the full responsibility of the Concessionaire who has had to spend a significant cost undertaking these extensive repairs and replacements through an ongoing program of night work partial lane closures.

Figure 8 Closing the gap for the new bridge

!"#$%&'()*+,&-./0)11111111111111111111111111111111111111111111111111111111111111111111112%1 1

The operational performance of the bridge has been excellent to date with an extremely good safety record, good lane availability performance and positive stakeholder satisfaction ratings. Traffic growth since the opening of the bridge has continued at a slow but steady rate. 7. SUCCESS FACTORS 7.1 Risk Assignment

The private partner assumed the design, construction and operations risk of the bridge while the public sector retained the land, legislative and adjoining corridor improvements integration risk. This worked well as each party was in a position to best manage the risks assigned to them. Some risks, for example environmental matters were shared. Such shared risks had to be carefully defined to delineate the respective responsibilities and avoid disputes. 7.2 Performance based incentives

The payment structure was strongly geared to the Concessionaires performance. The Concessionaire did not receive any payments until substantial completion, which placed a strong schedule incentive to finish as early as possible. The monthly payments to the Concessionaire are partially tied to the performance measures of lane availability, traffic volume, safety and public satisfaction. These incentives proved to be helpful in providing motivation to meet and exceed the objectives established by the Province. 7.3 Life-Cycle costs

In principle, design choices and material specifications that are focussed on sustainable and maintainable outcomes usually lead to lower life-cycle costs. While these choices must be optimized with overall design and construction costs, most decisions on the bridge design were closely linked to life-cycle costs. Two poorly performing areas, expansion joints and deck cracking resulted in the Concessionaire having to spend considerable expense to address them, but in general the consideration of life-cycle costs has led to a very successful end product. 7.4 Inter Governmental Co-operation

The bridge, paid for by the Province of British Columbia spans Okanagan Lake and in so doing joins the City of Kelowna and the Westbank First Nation. For the bridge to function effectively, work was required within the two adjoining communities to upgrade the corridor. Through formal agreements, and the spirit of a three way partnership the three projects have been able to tie seamlessly together to achieve a broad, corridor wide, successfully integrated transportation system. 7.5 Contractor Innovation

There are approximately ten large floating bridges world wide. To undertake a technically very challenging task of this sort, a combination of innovative thinking and proven design and construction approaches is required. The William R Bennett Bridge brought together new and modern composite materials, industrial engineering

!"#$%&'()*+,&-./0)1111111111111111111111111111111111111111111111111111111111111111111111221 1

innovations in fabrication and production, novel recruitment training and retention strategies for workers and the financing, management and oversight of a world class engineering firm. Thanks largely to this combination of innovative approaches, the project was completed within budget, ahead of schedule and resulted in the delivery of an urgently needed bridge that is now addressing the traffic, safety and service needs of this primary British Columbia transportation corridor.

!"#$%&'()*+,&-./0)1111111111111111111111111111111111111111111111111111111111111111111111231 1

Anda mungkin juga menyukai

- 2014 Bridge LeesonDokumen13 halaman2014 Bridge LeesonShubhangi SinghBelum ada peringkat

- 2014 Bridge LeesonDokumen13 halaman2014 Bridge LeesonMarvin AbugaoBelum ada peringkat

- Design and Construction Planning of The Macleay River and Floodplain Bridge (Australia's Longest Bridge)Dokumen13 halamanDesign and Construction Planning of The Macleay River and Floodplain Bridge (Australia's Longest Bridge)RogelBinayugBelum ada peringkat

- Key Issues:: 5-Water QualityDokumen12 halamanKey Issues:: 5-Water QualitySushil DhunganaBelum ada peringkat

- Design of Very Long Bridge - Neil TincknellDokumen13 halamanDesign of Very Long Bridge - Neil TincknellMaitrabarun KarjeeBelum ada peringkat

- HW 1 Isd 520 PDFDokumen4 halamanHW 1 Isd 520 PDFChiragBelum ada peringkat

- Improving The Performance of Shallow Draft Tugs in Northern Canada, MULDER, 2006 Mulder - Improving - The - performance.2006.TRANSDokumen16 halamanImproving The Performance of Shallow Draft Tugs in Northern Canada, MULDER, 2006 Mulder - Improving - The - performance.2006.TRANSapidkhhBelum ada peringkat

- Bridge Approach Treatment Works On The Cooper Nook To Herons Creek Section of The Pacific Highway UpgradeDokumen10 halamanBridge Approach Treatment Works On The Cooper Nook To Herons Creek Section of The Pacific Highway UpgradeHoang Tien TrungBelum ada peringkat

- Tipaimukh DamDokumen63 halamanTipaimukh Damvirous08Belum ada peringkat

- Manukau Memorial Gardens, Auckland, Arch Bridge: John Mcneil, Aaron Bougher, Ian SloaneDokumen12 halamanManukau Memorial Gardens, Auckland, Arch Bridge: John Mcneil, Aaron Bougher, Ian SloaneBALRAJBelum ada peringkat

- Silver Lake DamDokumen8 halamanSilver Lake DamRiko Riswandha Fahmi PrasetyoBelum ada peringkat

- Hendon Park Footbridge and The Waterview Shared Path Bridges Connecting CommunitiesDokumen10 halamanHendon Park Footbridge and The Waterview Shared Path Bridges Connecting CommunitieskingdbmBelum ada peringkat

- 12.12.13 Rail TrailDokumen3 halaman12.12.13 Rail TrailWatershed PostBelum ada peringkat

- Ark River Reconstruction ClimaxDokumen33 halamanArk River Reconstruction ClimaxHeiidy Shessira Cadenas VilcaBelum ada peringkat

- Prestressed Concrete Design SRDR5523: Manuel S. Enverga University FoundationDokumen7 halamanPrestressed Concrete Design SRDR5523: Manuel S. Enverga University FoundationAllyson DulfoBelum ada peringkat

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. Paper No. 1150Dari EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. Paper No. 1150Belum ada peringkat

- Matecconf - Iccrrr2018 - 06003 ASHTON ARCH BRIDGEDokumen6 halamanMatecconf - Iccrrr2018 - 06003 ASHTON ARCH BRIDGENicholas FeatherstonBelum ada peringkat

- BridgeDokumen30 halamanBridgeNurul NadhirahBelum ada peringkat

- Local Arch Bridges in The PhilippinesDokumen2 halamanLocal Arch Bridges in The PhilippinesAlfie Angelo ReyesBelum ada peringkat

- Cramond Bridge Feasibility Study Final ReportDokumen39 halamanCramond Bridge Feasibility Study Final ReportShreerang R. KambleBelum ada peringkat

- Unique New Bridge Designs For Four Highway Interchanges in BCDokumen17 halamanUnique New Bridge Designs For Four Highway Interchanges in BCShaileshRastogiBelum ada peringkat

- Constructon A DamDokumen14 halamanConstructon A DamYusf RwandzyBelum ada peringkat

- Floodplain Culvert FactsheetDokumen2 halamanFloodplain Culvert FactsheetSebastian RojasBelum ada peringkat

- Townsville Recreational Boating Park Staging: June 2013Dokumen2 halamanTownsville Recreational Boating Park Staging: June 2013userismetigerBelum ada peringkat

- Lyttelton Road TunnelDokumen28 halamanLyttelton Road TunnelrudnikaleksandarBelum ada peringkat

- STL - Richard Strange - Ahwatukee Lakes Drainage Considerations - Final PDFDokumen52 halamanSTL - Richard Strange - Ahwatukee Lakes Drainage Considerations - Final PDFapi-267867666Belum ada peringkat

- LLCMM Emp 2006 07 PartcDokumen61 halamanLLCMM Emp 2006 07 PartcFajardo GmzBelum ada peringkat

- Hydrology AssignmentDokumen9 halamanHydrology Assignmentafi khanBelum ada peringkat

- 5 Innovative Slurry Trench MethodsDokumen9 halaman5 Innovative Slurry Trench MethodsMalik BilalBelum ada peringkat

- AwardsDokumen5 halamanAwardsIndra Nath MishraBelum ada peringkat

- Bandra Worli Sea LinkDokumen6 halamanBandra Worli Sea LinkSabeesh Antony0% (1)

- Broadmeadow Estuary Bridge: Integration of Design and ConstructionDokumen27 halamanBroadmeadow Estuary Bridge: Integration of Design and ConstructionRavi GuptaBelum ada peringkat

- Herbert Hoover Dike - What'S The Big Dam Deal, A Case Study of Backward Erosion Piping and The Plan To Reair The DamDokumen13 halamanHerbert Hoover Dike - What'S The Big Dam Deal, A Case Study of Backward Erosion Piping and The Plan To Reair The DamMarcelo ProtzBelum ada peringkat

- Building The Bay BridgeDokumen3 halamanBuilding The Bay BridgeMayaBelum ada peringkat

- 1129 Cofferdam Ohio River Power PDFDokumen16 halaman1129 Cofferdam Ohio River Power PDFDiego Montaña P100% (1)

- Innovative Bridge Pier Solution To Reduce Risks Associated With Construction Adjacent To RailwayDokumen11 halamanInnovative Bridge Pier Solution To Reduce Risks Associated With Construction Adjacent To Railwayankit kumarBelum ada peringkat

- Singing BridgeDokumen2 halamanSinging BridgemgreenBelum ada peringkat

- High Head Small HydroDokumen17 halamanHigh Head Small HydroCortney JohnsonBelum ada peringkat

- DTLB Resolutions 2016-19 Re Lake RDDokumen5 halamanDTLB Resolutions 2016-19 Re Lake RDGeorge WoodBelum ada peringkat

- Indian Railways Bridge Manual (Edition 1998)Dokumen24 halamanIndian Railways Bridge Manual (Edition 1998)p.k.guptaBelum ada peringkat

- Canal Maintenance & OperationDokumen22 halamanCanal Maintenance & OperationDevendra Sharma100% (2)

- Value To The Nation: Inland Waterway NavigationDokumen4 halamanValue To The Nation: Inland Waterway Navigationesgee3518Belum ada peringkat

- Packed Train Seconds From Disaster in Bridge CollapseDokumen5 halamanPacked Train Seconds From Disaster in Bridge CollapseCarmen RadulescuBelum ada peringkat

- Ocqueoc River Watershed HISTORY, MichDokumen4 halamanOcqueoc River Watershed HISTORY, MichC. M. LyonBelum ada peringkat

- A Report On Case Study of Three Gorges DamDokumen12 halamanA Report On Case Study of Three Gorges DamRohan ShindeBelum ada peringkat

- Three Gorges Dam, Dam On The Yangtze River (Chang Jiang) Just West of The City of Yichang in HubeiDokumen2 halamanThree Gorges Dam, Dam On The Yangtze River (Chang Jiang) Just West of The City of Yichang in HubeiДима ВасканBelum ada peringkat

- Design of Pier in CagbaleteDokumen11 halamanDesign of Pier in CagbaleteErlinda OlaBelum ada peringkat

- Deep Tunnels For Combined Sewer Overflow Storage and TransportDokumen17 halamanDeep Tunnels For Combined Sewer Overflow Storage and TransportpabulumzengBelum ada peringkat

- EnglezaDokumen8 halamanEnglezaDanu GolbanBelum ada peringkat

- Finding of No Significant Impact For The Lake Mead Intake No. 3 ProjectDokumen14 halamanFinding of No Significant Impact For The Lake Mead Intake No. 3 ProjectRefa RestiyaBelum ada peringkat

- The Hinton Beaver Boardwalk Back Story PDFDokumen3 halamanThe Hinton Beaver Boardwalk Back Story PDFAnonymous DFzWck7SDBelum ada peringkat

- Lake Pontchartrain CausewayDokumen4 halamanLake Pontchartrain CausewayVeronika Ronnie JBelum ada peringkat

- Blue Gradient Travel (Presentation (169) )Dokumen7 halamanBlue Gradient Travel (Presentation (169) )miscoidoina493Belum ada peringkat

- Fluvial Design Guide - Chapter 6.sflbDokumen14 halamanFluvial Design Guide - Chapter 6.sflbAnita Az ZahraBelum ada peringkat

- Bridges & Hydraulic StructuresDokumen24 halamanBridges & Hydraulic StructuresMikee Rody CalmaBelum ada peringkat

- 2011 Bridge TurnerDokumen15 halaman2011 Bridge TurnerShamaBelum ada peringkat

- IP0513 Rapaport EDokumen12 halamanIP0513 Rapaport EoscarariagnaBelum ada peringkat

- Study On Reduction of Vibration Control Devices For Akashi-Kaikyo BridgeDokumen15 halamanStudy On Reduction of Vibration Control Devices For Akashi-Kaikyo BridgeoscarariagnaBelum ada peringkat

- IP0363 Pouget EDokumen11 halamanIP0363 Pouget EoscarariagnaBelum ada peringkat

- IP70 Matsumoto EDokumen10 halamanIP70 Matsumoto EoscarariagnaBelum ada peringkat

- IP0011 Tolppanen EDokumen12 halamanIP0011 Tolppanen EoscarariagnaBelum ada peringkat

- IP0117 Szczyrba EDokumen16 halamanIP0117 Szczyrba EoscarariagnaBelum ada peringkat

- Measures For Improving The Long-Term Durability of A Prestressed Concrete Bridge Using High-Strength ConcreteDokumen9 halamanMeasures For Improving The Long-Term Durability of A Prestressed Concrete Bridge Using High-Strength ConcreteoscarariagnaBelum ada peringkat

- IP00479 DelValle EDokumen13 halamanIP00479 DelValle EoscarariagnaBelum ada peringkat

- Larenasg@Iingen - Unam.Mx Rgomezm@Iingen - Unam.Mx Adgarcias@Iingen - Unam.Mx Jess@Pumas - Ii.Unam - MXDokumen11 halamanLarenasg@Iingen - Unam.Mx Rgomezm@Iingen - Unam.Mx Adgarcias@Iingen - Unam.Mx Jess@Pumas - Ii.Unam - MXoscarariagnaBelum ada peringkat

- Soil Investigation and ExplorationDokumen11 halamanSoil Investigation and ExplorationRajesh KhadkaBelum ada peringkat

- Standard Specification: Tecnicas Reunidas, S.ADokumen9 halamanStandard Specification: Tecnicas Reunidas, S.AaquilesanchezBelum ada peringkat

- CE 318 Structure Analysis and Design Ii LabDokumen12 halamanCE 318 Structure Analysis and Design Ii LabMd. Murshedul Islam 173-47-091Belum ada peringkat

- DSR Thane 2015-16 PDFDokumen335 halamanDSR Thane 2015-16 PDFNishikantk87% (30)

- JSA NO 2-Piling WorkDokumen3 halamanJSA NO 2-Piling WorkKarthik GanesanBelum ada peringkat

- Pile Capacity Based On Dynamic Methods & Wave EquationDokumen30 halamanPile Capacity Based On Dynamic Methods & Wave EquationvijaydandageBelum ada peringkat

- Minimizing Scour Around Bridge Pile Using Holes: Ain Shams Engineering JournalDokumen8 halamanMinimizing Scour Around Bridge Pile Using Holes: Ain Shams Engineering JournalUsman IftikharBelum ada peringkat

- ProjectDokumen4 halamanProjectNurmuliana Abdul WahabBelum ada peringkat

- LOD Spec 2021 Part II FINAL 2021 12 28Dokumen593 halamanLOD Spec 2021 Part II FINAL 2021 12 28James K. Atencio IllescasBelum ada peringkat

- Spud CanDokumen16 halamanSpud CanDyah Arintha DewiBelum ada peringkat

- Downloadmela Com ST7006 Design of BridgesDokumen14 halamanDownloadmela Com ST7006 Design of BridgesSuman.SBelum ada peringkat

- Jntuk M Tech r16 Se SyllabusDokumen26 halamanJntuk M Tech r16 Se SyllabusbhargavkakaniBelum ada peringkat

- Daily Construction Report: Commercial & Luxury ApartmentsDokumen3 halamanDaily Construction Report: Commercial & Luxury ApartmentsFaheem MushtaqBelum ada peringkat

- Section 7 GangwaysDokumen14 halamanSection 7 Gangwayssimonorr17Belum ada peringkat

- 2012 ANZ Lacey Kemp SundaramDokumen7 halaman2012 ANZ Lacey Kemp SundaramVetriselvan ArumugamBelum ada peringkat

- (A. Anagnostopoulos, M. Pachakis, Ch. Tsatsanifos) (B-Ok - CC)Dokumen1.950 halaman(A. Anagnostopoulos, M. Pachakis, Ch. Tsatsanifos) (B-Ok - CC)Emil Oltean100% (1)

- Geotechnical Engineering-2: Unit-Iv Pile FoundationDokumen27 halamanGeotechnical Engineering-2: Unit-Iv Pile FoundationAble KuriakoseBelum ada peringkat

- ITP & Ceklis Bored PileDokumen5 halamanITP & Ceklis Bored Pilefari_civil06Belum ada peringkat

- Ash Handling PlantDokumen6 halamanAsh Handling Plantapumoni123Belum ada peringkat

- Method Statement of Pile Driving AnalyzerDokumen8 halamanMethod Statement of Pile Driving AnalyzerAnik DasBelum ada peringkat

- MS - Hydraulic Jack-In Pile (Cylonix) - 240Dokumen2 halamanMS - Hydraulic Jack-In Pile (Cylonix) - 240aniesbaek100% (1)

- OSHPD 1 - TIO Program 2013 CBCDokumen11 halamanOSHPD 1 - TIO Program 2013 CBCViet NguyenBelum ada peringkat

- Ground Improvement - A Green Technology For Housing Infrastructure and Utilities Developments in Malaysia (1) - 1Dokumen20 halamanGround Improvement - A Green Technology For Housing Infrastructure and Utilities Developments in Malaysia (1) - 1Abhishek ShatagopachariBelum ada peringkat

- (150 X 150 R.C. SQ. PILE) Pilecap Data Column Data: Shear Check SatisfactoryDokumen19 halaman(150 X 150 R.C. SQ. PILE) Pilecap Data Column Data: Shear Check SatisfactoryJacky TiongBelum ada peringkat

- Foundation Design To Eurocode 7, A.Bond (Geocentrix)Dokumen0 halamanFoundation Design To Eurocode 7, A.Bond (Geocentrix)Davor KirinBelum ada peringkat

- BA42 Intergral Bridges PDFDokumen27 halamanBA42 Intergral Bridges PDFBridgy mcbridgeBelum ada peringkat

- New Design Methods For Large Diameter Piles Under Lateral Loading For Offshore Wind ApplicationsDokumen7 halamanNew Design Methods For Large Diameter Piles Under Lateral Loading For Offshore Wind ApplicationsH. MathomBelum ada peringkat

- Inspection Guidelines ManualDokumen319 halamanInspection Guidelines ManualCK-LAO TEE100% (1)

- Building On LandfillDokumen19 halamanBuilding On LandfillAlbi AlboBelum ada peringkat

- Turner (1990)Dokumen22 halamanTurner (1990)Simon YUBelum ada peringkat