Cable Quality LIRA SIEMENS Brochure

Diunggah oleh

Engr Irfan AkhtarHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cable Quality LIRA SIEMENS Brochure

Diunggah oleh

Engr Irfan AkhtarHak Cipta:

Format Tersedia

Cable Quality Assurance Services with LIRA Technology

General approach Fault-free operations require highest quality and respectively quality control during manufacturing and installation. The highest cable-specific requirements on quality measurements are set by ISO 13628-5, design and operation of Subsea Umbilicals. Measurements are required for the following steps: At cable manufacturer: - Component acceptance test - Condition control At umbilical manufacturer: - Post-umbilical manufacture - Condition control - Umbilical Final Acceptance Test, FAT At loadout to installation vessel: - Pre-loadout test - Post-loadout test Transport and installation: - Integrity monitoring during lay Post-installation: - Condition control Trenching and Rockdumping: - Pre- and post-condition control Preconnection (Connection is typically performed some time after installation): - Condition control Post-connection: - Condition control During Operation: - Monitoring - Regular condition control Our Cable Quality Assurance Services performed with LIRA (Line Resonance Analysis) Technology will ensure highest quality from the first moment, as LIRA can detect all deteriorations and their severity which might have been induced during manufacturing and installation. Of course, all measured data will be stored like a fingerprint for future use e.g. for introduction of condition-based maintenance, CBM, based on regular assessments.

New cables on vessel, Source: Norsk Hydro

Your benefits at a glance With LIRA Cable Quality Assurance Services the operator can minimize the pending deteriorations caused by manufacturing and installation. LIRA offers location with the best accuracy compared with alternative technologies. By that, LIRA can reduce significantly the risk for post-connection fault recovery. Cable reports provide a database for future condition-based maintenance strategies. LIRA is a wear-free location methodology with only 5 V white noise. LIRA has no limitations in cable length.

The benefits apply to Transmission and Distribution grids On- and Offshore wind parks Process Industry Oil and Gas Industry - Topside and submarine cables (incl. Umbilical) Power Plants - I&C and Power cables Cable manufacturers - Reference measurements - Quality control

Monitoring, Diagnostics and Cable Services

High-quality cable properly installed

The LIRA-Technology LIRA is a system for diagnosis and condition based monitoring of installed electric cables. LIRA can measure cable length ranges from a less than 50 meters to several hundred kilometers, depending by the cable design and electric attenuation. The LIRA technology is a non-destructive test method, and will not damage any part of your cable or any equipment connected to the cable. The LIRA technology is based on the transmission line theory, through the estimation and analysis of the complex line impedance as a function of the applied signal frequency. LIRA can monitor the global, progressive degradation of the cable insulation, cable stealth and cable conductor caused either by to harsh environment conditions, or mechanical stresses LIRA is especially sensitive to small changes in the insulation material, which allows an early indication of challenged areas, detecting and localizing single and multiple faults and their severity. LIRA measurements are recorded and can be played back and analyzed off-site. Reports in MS-Excel format are automatically generated. The recorded measurements can be stored as reference infor mation (fingerprints) for later comparison with repeated measurements. .

The identification of new damage to the cable can thus be monitored and recorded. The system consists of "off the shelf" hardware plus connection devices and proprietary software performing the failure analysis, degradation analysis and cable simulations. LIRA can help to distinguish between different root causes as it is possible to deliver a full condition status and possible fault type and location with better accuracy then other methods. Features Best-in-class cable monitoring and diagnostic system. Sensitive to small degradation and defects. Accurate hot-spot and deviation locations. Non intrusive and non destructive. Applicable on multi-segment systems with different cable types. Pre-study/simulation of cable data and defects. LIRA performs a power spectrum analysis of impedance phase and amplitude an advanced detection method of abnormal conditions. Fast and simple connection to test object. Only one access point needed for measuring.

LIRA provides possibility to zoom in on blind zone at the near end termination. This feature enables detailed, high resolution measurements in the cable end close to the connection point. For all voltage levels from control cable to high voltage cables. Main data and applications Measuring range - From less than 50m to several 100km Frequency rage - 0 to 100MHz Voltage Level - 5Vpp, white noise Operating Mode - Acquire data - Simulate cable data and defects - Playback data for post analysis Accuracy - Better than 0,5% of cable length Cable types - I&C cables - Low & medium voltage - High voltage AC/DC - Single and multiple conductors - Conductor material Cu/Al Insulation types - PE, XLPE, PVC, PILC, EPR - Hypalon, Lipalon and more

Published by and copyright 2012: Siemens AG Infrastructure & Cities Sector Smart Grid Division Services Humboldstrasse 59 90459 Nuremberg, Germany www.siemens.com/infrastructure-cities

For more information, please contact our Customer Support Center. Phone: +49 (180) 5 24 8437* +49 (180) 5 CITIES* Fax: +49 180 524 24 71 (*Charges depending on provider) E-mail: support.ic@siemens.com

Smart Grid Division Order No. AS_FF_en_CableQualityLIRA_1202 Printed in Germany Printed on elementary chlorine-free bleached paper. LIRA Registered trademark, Pantent pending, owned by Wirescan AS.

All rights reserved. Trademarks mentioned in this document are the property of Siemens AG, its affiliates, or their respective owners. Subject to change without prior notice. The information in this document contains general descriptions of the technical options available, which may not apply in all cases. The required technical options should therefore be specified in the contract.

www.siemens.com/infrastructure-cities

Anda mungkin juga menyukai

- Substation Construction ManualDokumen63 halamanSubstation Construction ManualAnicet VincentBelum ada peringkat

- PD Surveys BrochureDokumen2 halamanPD Surveys BrochureEngr Irfan AkhtarBelum ada peringkat

- Resume Noman Rasool.Dokumen3 halamanResume Noman Rasool.Engr Irfan AkhtarBelum ada peringkat

- ITB Short Form Construction Contract Section IV 13 Elec. D.repDokumen5 halamanITB Short Form Construction Contract Section IV 13 Elec. D.repdairiseaBelum ada peringkat

- Concrete Work PDFDokumen13 halamanConcrete Work PDFIsmaulIkhsanMpBelum ada peringkat

- PD Surveys BrochureDokumen2 halamanPD Surveys BrochureEngr Irfan AkhtarBelum ada peringkat

- Power Quality Audit FinalDokumen3 halamanPower Quality Audit FinalEngr Irfan AkhtarBelum ada peringkat

- Governance For The Eurozone - Integration or DisintegrationDokumen264 halamanGovernance For The Eurozone - Integration or DisintegrationManuel SantillanBelum ada peringkat

- Siemens ISCMDokumen5 halamanSiemens ISCMEngr Irfan AkhtarBelum ada peringkat

- Tap Changer Condition Assessment Using DRM: Prescon Engineering PVT LimitedDokumen1 halamanTap Changer Condition Assessment Using DRM: Prescon Engineering PVT LimitedEngr Irfan AkhtarBelum ada peringkat

- Diverter Switch LTC OperationDokumen11 halamanDiverter Switch LTC OperationEngr Irfan AkhtarBelum ada peringkat

- TanD Res InfoDokumen6 halamanTanD Res InfojjcanoolivaresBelum ada peringkat

- Prescon Advantage PDFDokumen1 halamanPrescon Advantage PDFEngr Irfan AkhtarBelum ada peringkat

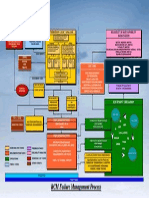

- RCM Failure Management Process: Reliability & Maintainability Data Analysis RCM Decision Logic / Analysis FmecaDokumen1 halamanRCM Failure Management Process: Reliability & Maintainability Data Analysis RCM Decision Logic / Analysis FmecaEngr Irfan Akhtar100% (1)

- 04 C 4Dokumen22 halaman04 C 4Jose Luis RattiaBelum ada peringkat

- Tdei Emi-Pd Rev1Dokumen16 halamanTdei Emi-Pd Rev1Engr Irfan AkhtarBelum ada peringkat

- Services and Solutions e 1Dokumen0 halamanServices and Solutions e 1Engr Irfan AkhtarBelum ada peringkat

- Tap Changer Condition Assessment Using DRM: Prescon Engineering PVT LimitedDokumen1 halamanTap Changer Condition Assessment Using DRM: Prescon Engineering PVT LimitedEngr Irfan AkhtarBelum ada peringkat

- Problems With Newer Generators 3Dokumen72 halamanProblems With Newer Generators 3Engr Irfan AkhtarBelum ada peringkat

- Tdei Emi-Pd Rev1Dokumen16 halamanTdei Emi-Pd Rev1Engr Irfan AkhtarBelum ada peringkat

- Tdei Emi-Pd Rev1Dokumen16 halamanTdei Emi-Pd Rev1Engr Irfan AkhtarBelum ada peringkat

- TM4 Profil Corporatif - OB110511Dokumen8 halamanTM4 Profil Corporatif - OB110511Engr Irfan AkhtarBelum ada peringkat

- RMO200A: Micro OhmmeterDokumen3 halamanRMO200A: Micro OhmmeterEngr Irfan AkhtarBelum ada peringkat

- SF6 Properties and Use in MV and HV SwitchgearDokumen26 halamanSF6 Properties and Use in MV and HV SwitchgearPradeep_Vashist100% (1)

- UET AlumniDokumen8 halamanUET AlumniEngr Irfan AkhtarBelum ada peringkat

- 04 C 4Dokumen22 halaman04 C 4Jose Luis RattiaBelum ada peringkat

- A Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesDokumen12 halamanA Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesAnonymous OCDJg17Z100% (1)

- Irfan Akhtar - Brief IntroDokumen1 halamanIrfan Akhtar - Brief IntroEngr Irfan AkhtarBelum ada peringkat

- UET AlumniDokumen8 halamanUET AlumniEngr Irfan AkhtarBelum ada peringkat

- Earth Clamp Tester 6416 6417 Technical PresentationDokumen22 halamanEarth Clamp Tester 6416 6417 Technical PresentationEngr Irfan AkhtarBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Selux Installation Manual PDFDokumen75 halamanSelux Installation Manual PDFIgorr75% (8)

- Expansions Meet Health Care Needs: Economists Question Trump Plan FiguresDokumen10 halamanExpansions Meet Health Care Needs: Economists Question Trump Plan FiguresThe Daily Tar HeelBelum ada peringkat

- Musk Founded Space Exploration Technologies Corporation, or Spacex, in 2002 With TheDokumen4 halamanMusk Founded Space Exploration Technologies Corporation, or Spacex, in 2002 With TheLauren Harris0% (1)

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementDokumen52 halamanCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- Cyrille MATH INVESTIGATION Part2Dokumen18 halamanCyrille MATH INVESTIGATION Part2Jessie jorgeBelum ada peringkat

- Evolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldDokumen20 halamanEvolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldJhon Alex ValenciaBelum ada peringkat

- Check List For Design Program of A Parish ChurchDokumen11 halamanCheck List For Design Program of A Parish ChurchQuinn HarloweBelum ada peringkat

- Practical CS ProcessingDokumen483 halamanPractical CS ProcessinganAMUstudent100% (2)

- Certain Application of Photovo PDFDokumen235 halamanCertain Application of Photovo PDFaun_nustBelum ada peringkat

- Statement of Cash Flows AnswerDokumen3 halamanStatement of Cash Flows Answeranber mohammadBelum ada peringkat

- Business English ExerciseDokumen11 halamanBusiness English ExerciseAdeline KwanBelum ada peringkat

- SS EN 1991-1-1-2008 (2017) - PreviewDokumen16 halamanSS EN 1991-1-1-2008 (2017) - PreviewNg SHun JieBelum ada peringkat

- 7 ApportionmentDokumen46 halaman7 Apportionmentsass sofBelum ada peringkat

- SmoothWall Express 2.0 Quick-Start GuideDokumen6 halamanSmoothWall Express 2.0 Quick-Start Guideinfobits100% (1)

- JHS Integrated Science Preamble, Jan 2012 - FinalDokumen15 halamanJHS Integrated Science Preamble, Jan 2012 - Finalfrank adamsBelum ada peringkat

- Nursing EnglishDokumen139 halamanNursing EnglishSara Williams100% (3)

- College Invitation Letter - Managedia 2023Dokumen2 halamanCollege Invitation Letter - Managedia 2023Sandeep DeyBelum ada peringkat

- THE Ketofeed Diet Book v2Dokumen43 halamanTHE Ketofeed Diet Book v2jacosta12100% (1)

- Ken Holt 06 The Secret of Hangman's InnDokumen216 halamanKen Holt 06 The Secret of Hangman's InnPastPresentFuture100% (2)

- Introduction To Regional PlanningDokumen27 halamanIntroduction To Regional Planningadeeba siddiquiBelum ada peringkat

- Hazop Close Out ReportDokumen6 halamanHazop Close Out ReportKailash PandeyBelum ada peringkat

- Pu3-Mo A1 MoversDokumen40 halamanPu3-Mo A1 MoversMiss María José SalasBelum ada peringkat

- Procedures Involved in The Ansys ACP17.2Dokumen10 halamanProcedures Involved in The Ansys ACP17.2Vijayanandh RBelum ada peringkat

- U04 Fxs of Humeral ShaftDokumen88 halamanU04 Fxs of Humeral Shaftadrian_mogosBelum ada peringkat

- 30xa 100t PDFDokumen162 halaman30xa 100t PDFleung ka kitBelum ada peringkat

- IPT .Quarter 2 (Grade 7-Mathematics, English &TLE)Dokumen2 halamanIPT .Quarter 2 (Grade 7-Mathematics, English &TLE)ARRIANE JOY TOLEDOBelum ada peringkat

- CalculusDokumen101 halamanCalculuskusnoBelum ada peringkat

- Reviewer For Bookkeeping NCIIIDokumen18 halamanReviewer For Bookkeeping NCIIIAngelica Faye95% (20)

- Intermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageDokumen11 halamanIntermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageRickCy Perucho PccbsitBelum ada peringkat

- Bubble Deck SlabDokumen29 halamanBubble Deck SlabJhimy Rusbel Gutierrez YanapaBelum ada peringkat