Lift Station Preliminary Checklist 201203

Diunggah oleh

ZoebairHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lift Station Preliminary Checklist 201203

Diunggah oleh

ZoebairHak Cipta:

Format Tersedia

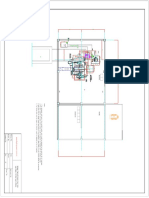

LIFT STATION DESIGN SUPPORT REVIEW CHECK LIST

Project/Lift Station: Consultant:

Guidelines Section Item No.

P.E.: Description Yes No N/A

A A1 A2 A3 A4 A4 A5 A5 A6 A7 A7 A8 A8 A8 A8 A8 A8 A8 A9 A9 A9 A10 A11 A12 A12 A13 A13 A14 A15 A15 A16 A17 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

A18 A17 & A18 A20 A21 A22 A23 B B1 B1 B2 B2 B3

32 33 34 35 36 37 38 39 40 41 42

General Requirements Cost analysis comparing a Gravity Main vs a Lift Station plus 30 year of operation & maintenance. Lift Station sized for ultimate built out. Pumps are submersible type. Engineering Report and Plans are Sealed by a Texas Professional Engineer. Proposed grades shown on drawings. Including driveway and site. Lift Station located over EARZ, EACZ or EATZ. Lift station submittal includes engineering report, plans and complete specs? Firm pumping capacity is greater than Peak Wet Weather Flow. Site provides ample room for maneuvering. Access road allows maintenance vehicles to arrive directly to wet well, generator, tower, on-site manhole and emergency by-pass without maneuvering need. Access Road located in a dedicated right-of-way or permanent easement. Minimum width of 16 feet, and pavement meets AASHTO HS 20-44 Standard. Include Plan, Section and Profile sheets, and drain pipes and details. Provided with soil erosion protection. Minimize turns and achieve the straightest possible alignment. If a straight access road is not provided, an adequate turn around is provided to allow a 55 foot, 18 wheeler tanker truck to freely turn around. Free of obstacles (vehicles, trash dumpsters, curves, posts, fences, landscapes, parking stalls, stripping, etc). 16-Foot double gate. And pole gates with wire fence if apply. Lift Station site is out of the Right-Of-Way. Is a turn around needed? Lift Station is protected from the 100-year flood event. A letter dated, signed and sealed by a Texas PE is included in the submittal. 8 foot chain link fence with 1 foot of barbed wire. Buyoancy calculations in engineering report. Top of concrete slabs are 4 to 6 inches above finished lift station pavement. Lift station site is completely paved with concrete or asphalt pavement. If asphalt pavement is used, must meet ASSHTO HS 20-44. Specifications of site pavement are included in the book of specifications. 3/4" minimum water service with hose bib and vacuum breaker, located within 10foot radius of wet well edge, and freeze proof type. Canopy included. 7' vertical clearance, 5' span to front and 3.5' span to back. Structural analysis for canopy foundation is included in engineering report. Calculations for H2S generation in wet well and force main for all phases. For exposed pipe, valves, and fittings outside the wet well receive after installation a 100% solids epoxy coating system with a top coat system of urethane (note must be included in drawings) Color Grey Pantone # 431U. For exposed pipe, valves, and fittings within the wet well receive after installation a 100% solids coal tar epoxy coating system (note must be included in drawings) Color Grey Pantone #431U. Approved manufacturers (Tnemec, Carboline, Sherwing-Williams, PPG, and M.A.B. Paints). Service pole located in a place that electric overhead cables do not cross over lift station site or near the SCADA tower. Lift station site is protected from storm runoff, and the grading allows storm water to drain away from the lift station site. Lift station is located at a sufficient distance from a developed area. Specifications require Contractor to submit lift station O&M Manuals to SAWS. Wet Well Design Minimum size is 6' Fiberglass Type (if Precast Type, must made arrangements with SAWS to discuss sections B5 to B8 for coatings, dimensions, etc.). Approved manufacturer is L.F. Manufacturing or Containment Solutions or approved equal. Wet well emergency storage calculations included in engineering report. (Emergency level start at the lead pump on level, and is done using ADF). Spill elevation is clearly shown in plans Detention time is less than 180 min for all phases

B3 B4 B4 B5 B6 B7 B8 B9 B14 B15 B16 B17 B18 C

43 44 45 46 47 48 49 50 51 52 53 54 55

C2

56

C2 C2 C2 C2 C3 C4 C5 C5 C5 C5 C6 C7 C8 to C10 D D1 D1

57 58 59 60 61 62 63 64 65 66 67 68 69

70 71

D3 D4 D5 D5 D5 D5 D6 D7 E E1

72 73 74 75 76 77 78 79 80

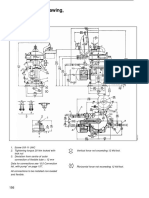

Odor control (if required) consist of drum scrubber Purafil. It operates at 99.5% gas removal. Wet well floor is sloped toward pump intake per standard drawings. If peak wet weather flow is greater than 2083 gpm, a anti-vortex baffler is installed within wet well. If design shows a monolithic or precast wet well, the design shows the thicknesses of wet well and slabs, and they meet the minimum requirements (12" bottom, 10" wall and 10" top). If concrete wet well is part of the design, it is internally coated with 100% pure calcium aluminate premix lining system. Approved manufacturer is Sewpercoat. 18" of subgrade level at the bottom of the wet well structure and 6" of flexible base for support. 98% compaction. Includes the TxDot Test note in the plans. 3000 psi reinforced concrete is installed around the wet well to 1/3 the depth of the wet well measured from the bottom. The remaining 2/3 is flowable fill. 316 stainless screen on goose neck vent. Minimum pipe size is 4", and is made of Stainless Steel 316. Installed as shown in standard drawings. Adequate access for hoisting equipment or crane. All chains, cables, guide rails, fasteners, brackets, bolts, nuts, washers, etc... inside the wet well are 316 stainless steel. The distance between the inflow invert and the bottom of the wet well is brtween 5 and 7 feet. Wet well specifications are included in the spec book. Wet well testing method and procedure is included in the specs. Pumping Equipment Lift station includes the correct number of pumps based on peak wet weather flow. . Duplex for 500 gpm PWWF or less. 3-inch sphere pass . Triplex for 501 to 1200 gpm PWWF. 3-inch sphere pass . Quadruplex for 1201 to 3000 gpm PWWF. 3-inch sphere pass . Quintuplex for 3001 gpm or more PWWF. 4-inch sphere pass Pump is centrifugal, non-clog, or semi-choper type (or grinder type as it may apply), with a adequate sphere pass according to table above. Minimum suction/discharge size is 4". Are the pumps required to have a 2-pole motor due to the low flow-high head. The firm pumping capacity is discharged with the required number of pumps. Was a self priming pump approved? If so, it meets all requirements and specifications are included in the project specs. Motors are inverter duty type suitable for VFD and soft starter use, and is capable of working continuously while totally immersed, partially immersed or dry. Motor is not overloaded along the pump curve. Motor is 5HP minimum. Pump curves and system curves included in report. Plans include all pump data. Pump duty point for 1 and 2 pumps lies within 75-115% of BEP flow. Cycle times meet the following minimum requriement: Less than 30HP PWWF: 10 min (3Fill, 7Empty) ADF: 13 min (10Fill, 3Empty) 30 to 75HP PWWF: 17 min (6Fill, 11Empty) ADF: 22 min (17Fill, 5Empty) Over 75HP PWWF: 25 min (8Fill, 17Empty) ADF: 32 min (22Fill, 7Empty) Submersible level installed per standard drawings. Pump is submersible (or other type previously agreed by SAWS), and meet the specifications required by SAWS lift station guidelines, or as approved by O&M Engineering. Detailed specifications for the pumps are included in the project. Station Piping Design Pumps are separated and immersed according to manufacturer recommendation. Pipe reducers installed at discharge base of submersibles and suction ports or non submersible pumps are eccentic type. Reducers installed at header are concentric type. If dry vaullts are approved, they are provided with means to drain back into wet well by either swamp pumps or gravity. If gravity drains are used, they are provided with means to block gases from escaping from wet well into dry vault. If swamp pump are used, calculations are provided in engineering report. Wet well piping is properly supported as indicated in Standard Drawings. Lift station piping is Ductile Iron Pipe Type. Piping is 100% flanged. Piping penetrations through concrete slabs or walls are sealed with link-seal. If self prining pumps are approved, the suction velocity is between 3 and 3.5 ft/s. Force main bends toward underground through 45 elbows instead of 90. Centerline of discharge piping at header is 3 feet above concrete slab. Station Valves Gate valves are either one of Clow F-6102, Mueller A-2360, Kennedy 4561/4701, or American Flow Control - Series 2500.

E2 E4 E4 E4 E5 E5 E5 E5 F F1 F2 F3 F4 F5 F6 F7 F7 F7 F8 F9

81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

F9 F10 F10 F11 F12 F12 F13 F14 F15 F15 G G1 G1 G1 G1 G1 G1 G2 G3 G4 G5 G5 G5 G6

100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122

Check Valves are either one of Clow Style 106LW, Mueller #2600-6-01, Kennedy IBBM Swing Check Valve, or American "50" Line with weight and lever. Air release valve installed on header? Air release valves are sewage rated, 2-inch minimum, provided with flush ports and mounted on isolation valve. Standard detail is provided in plans and valve specs are included in design. Air bleed pipe is 1-inch Sch. 40 PVC and located in a place that will not cause tripping hazard. Bleed pipe does not allow accummulation of liquid. Surge relief valves are selected according to firm pumping capacity. Engineering report shows the selection method. Surge relief valve is provided with isolation gate valve at inlet port. Mounted per SAWS standards. Detail is included in plans and blanks filled. Surge relief valve open setting is indicated in plans and opens at 5 psi above normal operating pressure at header under firm pumping capacity conditions. Surge relief pipe is routed back to either wet well or on-site manhole. Force Main Minimum bury depth is 4 feet. Detector tape is provided, and it is labeled "Pressurized Wastewater" 1.5-inch font Plan and profile is provided. Isolation gate valve is provided just before the force main turns toward underground, and is the last valve. Air release valve is provided in all high points of force main. Installed in a dry vault as indicated in SAWS standard drawings. Force main ties to discharge manhole via drop manhole type. Minimum force main size is 4-inch. Force main flow velocity is between 3.0 and 3.5 ft/s (with one pump running only). 4.8 ft/s max with two pumps running and 6.0 ft/s with three pumps running. Is this the case where discharge flow velocity is between 2.0 and 3.0 ft/s? Force main is HDPE either IPS or DIPS type. Plans show clearly the type. Force main specs are clearly depicted in the book of specifications. Double barrel force mains is provided if: lift station is over EARZ, EACZ (EATZ determined by SAWS), or for PWWF of 1200 gpm or greater, or force main lengths of 5000 feet or longer. If double barrel force main is required, it splits at the end of the common header with a wye above ground, and each force main is provided with isolation gate valve. Full redundancy is provided. Force main pressure rating exceeds the maximum surge pressure by 1.333 times. Force main minimum pressure rating is 150 psi. Force main average flush time is less than 180 minutes. Air release valves installed at header and high points along force main? Also ARV installed in force main are provided with dry vault per Standard Drawings? NAD83 State Plane coordinates of all air release vavles along force main are included in plans. Specifications require force main testing? Maintain rated pressure plus 50 psi for a minimum of 4 hours. Specifications require leak testing? Leak test does not exceed 10 gallons per inch diameter per mile of pipe per day. Isolation plug valves installed at least every 2000 feet? NAD83 State Plane coordinates of all plug vavles along force main are included in plans. Electrical Equipment Electrical service is 480/277 V, 3, 4 wire, and minimum service size is 200 A. General purpose transformer is 10 kVA minimum. All electrical enclosures are NEMA 4X, type 304 stainless steel white enameled. Panels are double door and lockable with padlock. 120 V loads are on left side and 480 V loads are on right side within pump control panel. Specs meet the wiring color code. Power conductors are stranded copper 75C rated for wet and dry locations. Wiring for motor controls are 14 AWG, and for SCADA is 16 AWG gauge. All mounting hardware is 304 stainless steel, and all the conduits connected to the wet well are properly sealed. Main electrical disconnect switch shall be Square D, Class 3110, 600-Volt, heavy duty, service rated, model H36_DS. Enclosuere is NEMA 4X, stainless steel 304. Main protection is either class J time delay fuses or circuit breaker, and are sized according to the load. Surge arrestor is provided, and is installed in a separated NEMA 4X, SS304 enclosure mounted on Service Pole mounting rack. Electrical equipment complies with NEC requirements for Class 1, Groups C and D, Division 1 Locations.

G6 G6 G7 G8 G9 G9 G9 G10 G10 G10 G10 G11 G11 G11 G11 G11 G11 G11 G11 G11 G12 G13 G14 G15 G15 G16 G16 G17 G17 G19 G20 G20 G21 G21 G21 G21 G21 G21 G21 G22 G22 G23 G23 G23 G23 G23 G24 G25 H

123 Power cables are installed per standard drawings. 124 High level float switch is provided, and is non-mercury type. 120 V duplex GFCI receptacles and light switches are installed in "in-use" weather 125 proof boxes. Electrical panels concrete pad is 4" minimum (6" max), and is protected from 126 potential flooding. Mounting rack is constructed of PVC-coated steel, epoxy coated steel or 304 type 127 stainless steel strut. 1-1/2" minimum, mounted on a 4" galvanized steel pipe. Manufacturer is either UNISTRUT, Kindorf or B-Line. 128 Material for strut channel is stainless steel 304. end caps are included in design. Service pole is within the fence, is independent from the rack and is located in a 129 place where service drop does not cross over lift station site. If generator is not required, the service rack includes Crouse-Hinds connectors, cam130 lok E1016 or E1017 Series (depending on load), male type. 5 connectors, phases, ground and neutral. Next to manual transfer switch. Manual transfer switch is equal to Square D, class 3140, 600 V, double throw, non131 fused safety switch, NEMA 4X, Model 8234_DS. 132 Transfer switch is sized to handle the entire load of the lift station. 133 Plans show detail for porgeble generator quick connectors per Standard Drawings 134 If the generator is provided, the transfer switch is automatic. Generator electric load calculations, including motor starting kVA and voltage dip are 135 included in the design. Voltage dip does not exceed 15%. 136 Generator calculations are done in kVA units. 137 4-foot clearance all around generator, service rack, tower and service pole. 138 Generator is provided with residential rated sound attenuation package. 139 Containment structure is included in the design. 140 Generators over EARZ and EACZ are fueled by natural gas (if available). 141 Generators not over EARZ and EACZ are fueled by diesel. 142 Diesel tank has double wall and is sized to run generator at 100% load for 10 hr. 143 Remote control is provided in the control diagram for future remote start. 144 All lightning and switches installed in dry vaults are explosion proof. All underground electrical conduits are Rigid Nonmetallic Conduit (PVC), and are 145 buried 18" to 24". 146 All exposed conduits bare Rigid Aluminum Type. 147 All conduit is buried or embeded in concrete slabs. Plans show this note clearly. 148 General illumination is provided, 1 foot-candle (average) 149 Task lights are installed under the canopy. Selector switches allow lift station to operate automatically while other pump(s) are 150 off or removed. Self priming pumps (if approved by SAWS) are provided with a non-fused 151 disconnect switch with auxiliary contact. 152 All electrical conduits and components are sized for ultimate built. 153 Pump control allows to alternate all pumps. Pump control panel has two doors, and all 480V loads are located on right side and 154 120V loads are located in left side of panel. Soft starters installed for 50+ HP motors, 5000+ feet long Force Mains, 5+ ft/s flow 155 velocity and/or 60+ feet Static Head. Soft Starters operation is 20 sec Start ramp and 20 sec Stop ramp minimum. Specs included in Specifications. 156 Soft Starters are rated for a minimum of 50 C operating temperature. 157 Soft starters are provided with by-pass contactor. 158 Soft Starters have programmable accelerating and decelerating ramp features. 159 Soft Starter enclosure is climate controlled. 2200 BTU @ 95 F, 120V motor. 160 A 2 feet clearance is maintained around the A/C unit to allow maintenance. 161 Louvers are used instead of A/C unit. (If approved by SAWS) A junction box used for motor power cables, motor signal cables, high level float 162 switch and submersible level transmitter is installed outside the wet well as indicated in standard drawings. 163 Conduit sealing material remains soft all time. 164 Ground resistance does not exceed 5 Ohms. 165 Design includes moizturizing ports at service pole, tower and generator. Moisturizing ports consist of 1-inch Sch. 80 PVC pipe, installed 1 inch away from 166 grounding rods. 167 PVC pipe has a threaded cap at the top. 168 A 6-inch diameter DI cap is installed to protect the moisturizing port. 169 All electric and signal conductors fill the conduits by no more than 40%. Laminated wiring schematics for pump control and SCADA panels are required in 170 the specifications. Also delivery of hard copies of wiring schematics to be delivered to the Owner is required in the specifications. Station Controls, Instrumentation and Monitoring

H1 H1 H1 H1 H1 H1 H2 H2 H2 H2 H3 H3 H4 H5 H5 H5 H5 H6 H6 I I1 I1 I1 I1 I2 I2 I2 I2 I3 I4 I5 I6 I7 I8 I8 I8 I9 I9 I9 I10 I10 I11 I12 J J2 J2 J2

171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204

Primary level monitoring and pump control is Siemens Milltronics HydroRanger 200, Greyline instruments or Drexelbrook. Submersible level transmitter is provided, and is provided with a 10-lb weight. Submersible level transmitter is installed per SAWS standard drawings. Submersible level transmitter is powered by a 24V dc, 15W din rail mounted power supply. Power supply is installed within pump control panel. Power supply is independednt, and is separated from the SCADA system. Pressure transmitter is 0-150 psi range, and specifications requires the transmitter to be calibrated to read operating and surge pressures. Pressure transmitter is powered vy a 24 V dc power supply installed within the SCADA panel. Pressure transmitter is installed per SAWS standard drawings. Pressure transmitter includes an LCD display and measures the pressure in psig. Pressure level transmitter and high level float switch are installed in the wet well as indicated in SAWS standard drawings. All motor cables, high level float switch and submersible level transmitter cabling is connected at a single junction box next to the wet well as indicated in SAWS standard drawings. Pumps alternate properly Duplex, Triplex, Quadruplex or Quintuplex. Pressure gauges are rated for corrosive service. Pressure gauges meet the follwing specs: 4.5" dial, grade 1A, ASME 40B.100, +/1% full scale accuracy, liquid filled, type 316 stainless steel bourdon tube, glass safety lens, full blowout protection, weatherproof, hermetic seal and with a 1/4-inch NPT. Pressure gauge is installed per SAWS standard drawinigs. Pressure gauge is 3 times greater than the operating pressure of the pump. Elapsed time meters are provided in pump control panel. They are non-resetable. Overload relays are reset by a metal extension with a plastic cap that allow to reset the overload relays with the panel inner door closed. Supervisory Control And Data Acquisition (SCADA) A radio path study is included in the lift station engineering report. Radio path report include computer and physical test results. NAD83 State coordinates are included in the radio path study report and plans. The radio path study report shows a clear and quality signal communication with SAWS lilft station radio network. Is the lift station able to communicate directly to Hildebrand Tank? Is the lift station able to communicate directly to any SAWS existing repeater? Is the lift station able to communicate directly to any SAWS existing facility? If a radio repeater needs to be built in such SAWS existing facility are the upgrades included in the plans? If the lift station cannot communicate to any existing SAWS facililty, the design includes a repeater station design that complies with SAWS standard drawings and guidelines. SCADA system monitors all points established by SAWS guidelines and standard drawings. Isolation relays are included in the SCADA design and are located within the SCADA panel. Radio is located in SCADA panel, and is capable for two way communication. SCADA Panel includes a temperature transmitter, which is provided with RTD sensor and transmitter. SCADA panel is 48" high x 36" wide x 16" deep.

SCADA Panel is climate controlled and insulated as specified in Standard Drawings. 205 Are louvers being installed instead of the A/C unit? Tower is capable to rise unguided up to 45 feet and be able to withstand wind gusts 206 of 90 MPH. 207 Tower is located in a place where maintenance vehicles arrive directly. 208 Tower is at least 40 feet away from overhead lines. 209 SCADA is provided with a two hour uninterruptible power supply. 210 Uninterruptible power supply is used exclusively for SCADA loads. A transient voltage surge suppressor is installed within the SCADA panel? 211 Specifications are included in the design. 212 Tower ground resistance does not exceed 5 ohms. Emergency Provisions Wet well emergency storage is calculated using Average Daily Flow, and from Lead 213 Pump On to SSO Level? 214 Wet well emergency storage time excludes the collection system? 215 Is the lift station located over EARZ or EACZ?

J2 J2 J2 J3 J3 J4 J4 J4 J6 J7 J7 J7 J8 J8 K K1 K2 K3 K3 K3 K4 K5 K5 K5 K6 K6 K6 K6 K7 K7 K7 K8 K8 K8 K8 K8 K9 L L1 L1 L1 L1 L1 L1 L1 L2 L2A L2B1a L2B1b L2B2a L2B2c L2bd L2C1 L2C6 L2C7

216 217 218 219 220 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255 256 257 258 259 260 261 262 263 264 265 266 267 268

Lift Station is designed to provide 60 minutes emergency storage (wet well only) plus a standby generator and automatic transfer switch. Standby generator and ATS are sized to handle 100% lift station load? Force main is double barrel, and firm pumping capacity can be discharged through a single force main to provide full redundancy. Lift station is located over EATZ? If located over EATZ, will design comply with EARZ requirements? Is lift station located outside EARZ, EACZ and EATZ? Lift station is designed to provide 120 minutes emergency storage (wet well only) without generator, plus a manual transfer switch with cam-lok quick connectors. Lift Station is designed to provide 60 minutes emergency storage (wet well only) plus a standby generator and automatic transfer switch. Audiovisual alarm is included in the design and is activated only by wet well high level events through both level controller and high level float switch. Design includes emergency by-pass connector at header piping, and is sized according to header piping (4, 6 or 8 inch). Emergency by-pass is provided with gate valve and check valve. Emergency by-pass is installed as indicated in Standard Drawings. If design includes soft starters, a by-pass starter is included in the design to fully bypass the soft starter and maintain lift station service during soft starter failure. Each pump is provided with a selector switch that allows to operate through either soft starter or full voltage by-pass starter. Safety Requirements Lift station site free of overhead lines? All conduits are buried and/or embeded in concrete slabs. Engineering report includes an arc flash analysis. Arc flash hazard rating is category 2 or less. Specifications require proper labeling of panels. Plans show label details. Bollards are included in the design to protect equipment. Bollard details included in Aluminum removable handrails are included in the design and specs. Portable handrails are designed to slide into sleeves on wet well slab? Drawings include portable handrail mounting details. Dry vaults are provided with explosion proof blowers and lights. Access to dry vaults are designed to allow personnel to enter and land on flat floor within the vault away from equipment, piping, accessories, etc. Dry vault provides proper clearances for maintenance personnel safety. If laders are used, they are made of aluminum and comply with OHSA regulations. Lift station design includes an emergency eyewash and shower. Eyewash and shower is freeze proof. Eyewash and shower is located within 10 feet of wet well. Wet well access hatch is made of aluminum, and is lockable, flush with wet well top slab and has anti-slip top surface. Detail included in drawings. Minimum hatch dimensions are 3 by 4 feet, or larger to provide ample clearance for pump removal. Access hatch is provided with an aluminum safety grate. Safety grate is flushed with wet well top slab surface, and gaps are no larger than 5inch wide. Access hatch detail is included in the plans. Wet well is free of ladders. Submittal Requirements Includes a detailed cost estimate with updated prices. Is it a phased development? Engineering Report shows flows for initial and final phase. Wet well design calculation. Includes system curves and pump curves. Includes an Energy Analysis comparing different pumps, impellers, and pipe sizes. Overall layout map submitted & master plan (if apply). The engineering report have all the following information: Project name, date, developer/owner's name, and engineering firm. Type, location and size of development. Lots or buildings to be served. Location and type of gravity system the force main will discharge into. Stated in the report is: Whether the entire development will be serviced by the proposed phase or if several phases will be involved. State the number of lots will encompass initially and finally if future phases are to be constructed. Incoming flows (ADF, PWWF, MDWF) for all development phases. Total head calculation with pipe material factors. Net positive suction head (if apply).

L2C8 L2C9 L2C10 L2C11 L2C12 L2D1 L2D2 L2D3 L2D4

269 270 271 272 273 274 275 276 277

Total suction lift (if apply). Wet well storage requirements. Wet well buyoancy calculations. Water hammer calculations. Force main flush time. Average detention time based on Average Daily Flow (ADF) for all phases. Maximum detention time based in Minimum Dry Weather Flow for all phases. Total cycle times. Size, type and length of the force main.

Comments:

Reviewed by: Date Received: Date Complete:

LIFT STATION ASSESSMENT CHECK LIST

Lift Station: Location:

Guideline Section

Map No. Description General Requirements Cost analysis comparing a Gravity Main vs a Lift Station plus 30 year of operation & maintenance. Lift Station sized for ultimate built out. Engineering Report and Plans are Sealed by a Texas Professional Engineer. Does the lift station have insufficient pumping capacity issues? Access Road Access Road located in a dedicated right-of-way or permanent easement. Minimum width of 16 feet, and all weather conditions road. Include Plan and Profile sheets, and drain pipes, details and engineering calculations. Provided with soil erosion protection. Minimize turns and achieve the straightest possible alignment. Is it a phase development? Is it a temporary access road? Free of obstacles (vehicles, trash dumpsters, curves, posts, fences, landscapes, parking stalls, stripping, etc). 8-Foot gates. Is a turn around needed? (due to heavily traveled areas). Lift Station is protected from the 100-year flood event. 6 foot fence with 1 foot of barbed wire. Minimum hatch dimensions are 3' x 4' (36" x 48"). Hatch is provided with a safety grate made of aluminum or non corrosive fiberglass reiforced material to provide fall protection. Buoyancy calculations in engineering report. All the Lift Station site is completely paved. 3/4" minimum water service with hose bib and bacuum breaker, located near the wet well, and freeze proof type. Freeze proof type eyewash station, and are located near the wet well. Is enough space to install the canopy? Calculations for H2S generation in wet well and force main. For exposed pipe, valves, and fittings outside the wet well receive after installation a 100% solids epoxy coating system with a top coat system of urethane (note must be included in drawings) Color Grey Pantone # 431U. For exposed pipe, valves, and fittings within the wet well receive after installation a 100% solids coal tar epoxy coating system (note must be included in drawings) Color Grey Pantone #431U. Approved manufacturers (Tnemec, Carboline, Sherwing-Williams, PPG, and M.A.B. Paints). Wet Well Design Minimum size is 6' Fiberglass Type (if Precast Type, must made arrangements with SAWS to disscuss sections B5 to B8 for coatings, dimensions, etc.). Approved manufacturer is L.F. Manufacturing or Containment Solutions or approved equal. Does the wet well have enough emergency storage capacity? Detention time is less than 180 min for all phases Odor control (if required) consist of drum scrubber Purafil. It operates at 99.5% gas removal. Yes No

Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

A A1 A2 A4 A6 A8 A8 A8 A8 A8 A8 A8 A8 A8 A9 A9 A10 A11 A12 A12 A13 A14 A15 A16 A17 A18 A19

A20

27 28

B B1 B1 B2 B3 B3

29 30 31 32 33

B9 B10 B11 B16 B17 B18 C C1 C1 C1 C2 C3 C4 C6 D D1 D2 D5 D6 D8 E E1 E2 F F1 F2 F3 F4 F5 F8 F9 G G1 G1 G1 G2 G3 G3 G3 G4 G5 G6

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

18" of subgrade level at the bottom of the wet well structure and 6" of flexible base for support. Gravel subgrade filler around the wet well is 1/3 the depth of the wet well measured from the bottom. 316 stainless screen on goose neck vent. Minimum size is 4". Manual lighting/ventilation switch is installed to override the automatic control. Adecuate access for hoisting equipment or crane. All chanis, cables, guide bars, fasteners, brackets, bolts, nuts, washers, anchor bolts etc... inside the wet well are 316 stainless steel. Pumping Equipment Alternating duplex station as minimum. Pump is centrifugal, non-clog, 3" throughlet, and performing well. Minimum suction/discharge size is 4". Minimum pump power is 5 HP, 460 V, 3. Minimum total cycle time is 6 minutes. Level control device is fully accessible without entering the wet well, and is unaffected by the pumps, pipes, etc Minimum hydraulic efficiency is 65%. Station Piping Pipe reducer is eccentric type. Surge relief valve is provided, and is provided with an isolation ball/gate valve of blonze or stainless steel 316. Properly mounted. Piping is supported by concrete or metal manufactured supports on the pad, and is 3 feet high. All piping is Ductile Iron, and all is flanged. Pressure gauges provided for each pump discharge, and are provided with an isolation ball valve. Minimum 4" dial, 5% accuracy, liquid filled. Station Valves Gate valves are either one of Clow F-6100, Mueller A-2370, Kennedy 4561/4701, or American Flow Control - Series 2500. Check Valves are either one of Clow F5345, Mueller #2600-6-01, Kennedy IBBM Swing Check Valve, or American "50" Line with weight and lever. Force Main Minimum bury depth is 3 feet. Tracer wire is provided. Plan and profile is provided. Mechanical restraints along the force main. Gate valve is provided at the end of the header, is provided with an isolation ball valve, and is the last valve. The velocity is between 3 and 6 feet per second. Material is HDPE or PVC. Electrical Electrical service is 480/277 V, 3, 4 wire, and minimum service size is 200 A. General purpose transformer is 10 kVA. All electrical enclosures are NEMA 4X, NEMA 3R type 316 stainless steel. All mounting hardware is 316 stainless steel, and all the conduits connected to the wet well are properly sealed. Main electrical disconnect is equal to Square D, class 3110, 600 V, heavy duty, service rated safety switch, model H36_DS. Main protection is either class J time delay fuses or circuit breaker, and are sized according to the load. Surge arrestor is provided, and is installed in a separated enclosure attached to the back of the main enclosure. High level float switch is provided. 120 V duplex GFI receptacle in a weather proof box is provided. Electrical panels conctere pad is 4" minimum (6" max), and is protected from potential flooding.

52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70

G7 G7 G8 G8 G8 G8 G9 G11 G12 G14 G14 G17 G18 G19 H H1 H2 H2 H3 H3 H6 H6 I I2 I2 J J2 J2A J2B1a J2B1b J2B2a J2B2c J2bd J2C1 J2C6 J2C7 J2C8 J2C9 J2C10 J2D1 J2D2 J2D3 J2D4 K

71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91

92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108

Mounting rack is constructed of PVC-coated steel, epoxy coated steel or 316 type stainless steel strut. 1-1/2" minimum, mounted on a 4" galvanized steel pipe. Manufacturer is either UNISTRUT, Kindorf or B-Line. Service pole is within the fence, and is independent from the rack. Generator connectors are Crouse-Hinds, cam-lok E1016 or E1017 Series, male type. 5 connectors, phases, ground and neutral. Next to the transfer switch. Manual transfer switch is equal to Square D, class 3140, 600 V, double throw,non-fused safety switch, NEMA 4X, Model 8234_DS. Transfer switch is sized to handle the entire load of the lift station. Generator is fueled by natural gas, and is provided with noise control. Remote control is provided in the control diagram. Rigid PVC coated steel is used in all 90 turn down from lift station slab. All underground electrical conduits are PVC, and are buried 18" to 24". General illumination is provided, 1 foot-candle (average) Task lights are installed under the canopy. All electrical components are sized for ultimate built. Soft starter is installed for 50 HP motors or greater. Flood plain is provided. Station Controls, Instrumentation and Monitoring Primary level monitoring and pump control is Siemens Milltronics HydroRanger 200, Greyline instruments or Drexelbrook. SCADA system is provided. Alarm signals are: Pump ON, Pump Fail, Motor High Temp, Phase Failure, Power Outage, Generator/Utility Power, Force main Pressure, Wet Well Level, Low Water Alarm, High Water Alarm. Level transducer is located alone in a NEMA 4X stainless steel enclosure on top of the wet well. The high level float switch is located in conjunction with the motor splices on top of the wet well in a NEMA 4X 316 stainless stee. Box. 120 V elapsed time meter is provided. Overload reset button is located on the dead front panel. Emergency Provisions Emergency bypass connection is provided at the header, is flanged, sized according to the pump size, is isolated with a gate valve, and has a "quickdisconnect" male fitting with dust cap. Emergency bypass is provided with a check valve. Submittal Requirments The engineering report have all the following information: Project name, date, developer,/owner's name, and engineering firm. Type, location and size of development. Lots or buildings to be served. Location and type of gravity sistem the force main will discharge into. Stated in the report is: Wether the entire development will be serviced by the proposed phase or if several phases will be involved. State the number of lots will encompass initially and filally if future phases are to be constructed. Incoming flows (ADF, PWWF, MDWF). Total head calculation with C values of 140 & 100. Net positive suction head (if apply). Required Wet Well storage volume. Buyoancy calculations. Water hammer calculations. Average detention time based on Average Daily Flow (ADF) for all phases.

Maximum detention time based in Minimum Dry Weather Flow for all phases. 109 Total cycle times. 110 Size, type and length of the force main. Preferences

K1 K2 K3 K4 K5 K6 K7 K8 K9 K10 K11 K12 K13 K14 K15 K16 K17 K18

111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128

Overal layout map submitted. Proposed grades shown on drawings. Proposed elevations of the driveway are shown. Top of the concrete slab is 4" min / 6" max over the finish grade. All the electrical components are within the fence. Control panels are dead front type. Generator have clear access to the connection pannel. Flood plain and required calculations to guarantee that the lift station is out of the 100 year flood event are provided, and are dated, signed and sealed by a Texas Professional Engineer. The site is protected from storm runoffs. Electrical control diagram is shown. Electrical one line diagram is shown. The distance between the inflow invert and the bottom of the wet well is 5' minimum. If a straight access road is not provided, an adecuated turn around is provided to allow a 18 wheeler tanker truck to freely turn around. The access road allows to the maintenance vehicles to arrive directly to the wet well without the need of maneuvering within the site. Wet Well depth is less than 20 feet. Level transducer is located in a maner that nothing will block the ultrasonic beam. Located and sent the LS site in the MAPSCO book, and sent it to Alberto Baiza, Darly Flaggs, Tony Alvarez, David Dera, Gary Collins, Jorge Monserrate & Phil McDonald. Send 4 sets of drawings to Eddie Gonzales for Approval

Additional Comments:

Reviewed by: Date Received: Date Complete:

Nelson Barrera

Check List Last Update: 9/13/2007

Anda mungkin juga menyukai

- WIP - Water Treatment PlantDokumen74 halamanWIP - Water Treatment PlantCapitol Steel ConstructionBelum ada peringkat

- Weight Factors For Electrical Construction WorkDokumen4 halamanWeight Factors For Electrical Construction WorkS.m.sajjad Haider NaqviBelum ada peringkat

- DM Auto Irrigation Systems SpecificationsDokumen71 halamanDM Auto Irrigation Systems SpecificationsbargothiBelum ada peringkat

- Lift Station - Design ProjectDokumen30 halamanLift Station - Design ProjectChristian DoriaBelum ada peringkat

- Out Going LettersDokumen461 halamanOut Going LettersHemn Rafiq TofiqBelum ada peringkat

- Sarthi Skybay - D - Plumbing Internal, Duct, Terrace BOQDokumen171 halamanSarthi Skybay - D - Plumbing Internal, Duct, Terrace BOQamolBelum ada peringkat

- WS CalculationDokumen29 halamanWS CalculationMac ShaikBelum ada peringkat

- Drawing List MEP SERVICES - Detailed Desi: Ajara Hospital - Warangal Ajara HospitalDokumen6 halamanDrawing List MEP SERVICES - Detailed Desi: Ajara Hospital - Warangal Ajara HospitalSanjay SahulBelum ada peringkat

- Mannings Formula SpreadsheetDokumen18 halamanMannings Formula SpreadsheetparthivBelum ada peringkat

- Plumbing Calculation PDFDokumen17 halamanPlumbing Calculation PDFHosamMohamedBelum ada peringkat

- UZGTL ITB Index20121120Dokumen69 halamanUZGTL ITB Index20121120Hyun Jin Yoo0% (1)

- Electrical Thumb Rules (Part 7)Dokumen5 halamanElectrical Thumb Rules (Part 7)AriesFranandaPanjaitanBelum ada peringkat

- Booster PDSDokumen3 halamanBooster PDSsunii19847908Belum ada peringkat

- Pump Station Design For Storm Water Retention Ponds PDFDokumen3 halamanPump Station Design For Storm Water Retention Ponds PDFAnonymous CX51waI100% (1)

- Material Submittal Log Sheet - MechanicalDokumen2 halamanMaterial Submittal Log Sheet - MechanicalElla CelineBelum ada peringkat

- 230313-MEP Client RequirementDokumen19 halaman230313-MEP Client RequirementSelcen yeniçeriBelum ada peringkat

- 2x12MW-Electrical Load CalculationDokumen5 halaman2x12MW-Electrical Load CalculationManoranjan Kumar ChoudharyBelum ada peringkat

- Stormwater ToolDokumen22 halamanStormwater Toolmnt6176Belum ada peringkat

- Villa MEP BOQDokumen3 halamanVilla MEP BOQIsuru Deshan WijewardanaBelum ada peringkat

- Pre-Bid QueriesDokumen89 halamanPre-Bid QueriesprasadBelum ada peringkat

- List of Punch Point SiteDokumen4 halamanList of Punch Point SiteDiwakar MishraBelum ada peringkat

- Team Meeting Minutes Template 12Dokumen1 halamanTeam Meeting Minutes Template 12jblumbeBelum ada peringkat

- SEQ SPS Electrical Drawings 910 Series Queensland Urban UtilitiesDokumen27 halamanSEQ SPS Electrical Drawings 910 Series Queensland Urban UtilitieskulukundunguBelum ada peringkat

- Power Factor CalculatorDokumen2 halamanPower Factor Calculatorbee398Belum ada peringkat

- Steel PVC CPVC Pipes Dimensions Weight ChartDokumen5 halamanSteel PVC CPVC Pipes Dimensions Weight Chartdh24992499Belum ada peringkat

- Electrical LoadDokumen2 halamanElectrical LoadkrakatuaBelum ada peringkat

- Storm Water Calculation and Pipe SizingDokumen3 halamanStorm Water Calculation and Pipe SizingSaeed MBelum ada peringkat

- GOA - Casino - Revised BOQDokumen6 halamanGOA - Casino - Revised BOQShashikant GatkalBelum ada peringkat

- Estimate Barpali....Dokumen42 halamanEstimate Barpali....Sagarika SahooBelum ada peringkat

- Mep AssumptionsDokumen12 halamanMep Assumptionssachinsaklani23Belum ada peringkat

- 26 24 16.00 40-1 Submittal Review SheetDokumen6 halaman26 24 16.00 40-1 Submittal Review SheetLuisSalinasBelum ada peringkat

- Bermad - LisDokumen66 halamanBermad - LisRamesh Kumar100% (1)

- Fluid Mechanics - Pump-Pipeline System Analysis & Design Solved Problem No.3Dokumen6 halamanFluid Mechanics - Pump-Pipeline System Analysis & Design Solved Problem No.3Mohamed Salah YassinBelum ada peringkat

- Complete Submittal-Zoya PDFDokumen163 halamanComplete Submittal-Zoya PDFXiPHeR100Belum ada peringkat

- Design Coordination Checklist Electrical Verfeb282020Dokumen4 halamanDesign Coordination Checklist Electrical Verfeb282020xe cuôc NguyễnBelum ada peringkat

- Boq For Abb Flow MeterDokumen166 halamanBoq For Abb Flow MeterDeepak RajanBelum ada peringkat

- List Building BOQ Checklist Update (11032019)Dokumen18 halamanList Building BOQ Checklist Update (11032019)MukidiBelum ada peringkat

- Seminar PPT - Storm Water & Sewerage Design-1 - 2915Dokumen12 halamanSeminar PPT - Storm Water & Sewerage Design-1 - 2915Abhijit Haval100% (1)

- Daily Progress Report: Manpower Contractor LabourDokumen1 halamanDaily Progress Report: Manpower Contractor LabourMohammed AyazBelum ada peringkat

- Project Name: Booster Pump CalculationsDokumen4 halamanProject Name: Booster Pump CalculationsSharon LambertBelum ada peringkat

- Biological Odour Control System Specification - R1Dokumen24 halamanBiological Odour Control System Specification - R1Hedi Ben MohamedBelum ada peringkat

- External Electrical - BOQDokumen41 halamanExternal Electrical - BOQroy_nhp100% (1)

- WWTF Improvements Project Design Report Technical Memorandum - INFLUENT PUMP STATIONDokumen60 halamanWWTF Improvements Project Design Report Technical Memorandum - INFLUENT PUMP STATIONveliger100Belum ada peringkat

- Estimate Load CalculationDokumen2 halamanEstimate Load Calculationmeeng2014Belum ada peringkat

- Booster Pump Head Calculation - AaDokumen5 halamanBooster Pump Head Calculation - AaAdnan AttishBelum ada peringkat

- Dubai Hills Villa - Phe Boq - 20210713Dokumen32 halamanDubai Hills Villa - Phe Boq - 20210713Mohammed AzharBelum ada peringkat

- Busbar RatingsDokumen1 halamanBusbar RatingsRa ArBelum ada peringkat

- Pumping Station Design Examples: Garr M. Jones Gary S. Dodson Theodore B. WhitonDokumen18 halamanPumping Station Design Examples: Garr M. Jones Gary S. Dodson Theodore B. WhitonlinBelum ada peringkat

- MAS Road Storm Water DesignDokumen1 halamanMAS Road Storm Water DesignWaseem SiddiqueBelum ada peringkat

- Total Demand Calculation Fixtures TypeDokumen5 halamanTotal Demand Calculation Fixtures Typenido77Belum ada peringkat

- Coordination With Other DepartmentDokumen3 halamanCoordination With Other Departmentdanishsaifi2007Belum ada peringkat

- Water Supply Booster PumpDokumen5 halamanWater Supply Booster PumpMahmoud MahmoudBelum ada peringkat

- MEP FP Inspection Checklist PDFDokumen6 halamanMEP FP Inspection Checklist PDFRichard RajkumarBelum ada peringkat

- Proj-003 - Siddhitex - ELECTRICAL BOQ - Revised03 - NMDokumen81 halamanProj-003 - Siddhitex - ELECTRICAL BOQ - Revised03 - NMSaurav ShuklaBelum ada peringkat

- CRS Qatar Energy Comments - VI-D-IEE-23-735-2240Dokumen12 halamanCRS Qatar Energy Comments - VI-D-IEE-23-735-2240planningBelum ada peringkat

- Technical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Dokumen11 halamanTechnical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Naushad WadiaBelum ada peringkat

- Technical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Dokumen11 halamanTechnical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Naushad WadiaBelum ada peringkat

- Technical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Dokumen23 halamanTechnical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Naushad WadiaBelum ada peringkat

- Steam 1Dokumen5 halamanSteam 1NaBelum ada peringkat

- Structures and Mechanisms ClassificationsDokumen1 halamanStructures and Mechanisms ClassificationsminakirolosBelum ada peringkat

- 90 Series (ET1590) InstructionsDokumen24 halaman90 Series (ET1590) InstructionsZoebairBelum ada peringkat

- TurbinesDokumen19 halamanTurbinesSamarakoon BandaBelum ada peringkat

- Appendix B - 20100903 - 145453Dokumen25 halamanAppendix B - 20100903 - 145453AkoKhalediBelum ada peringkat

- Spring-Supported Thrust BearingsDokumen4 halamanSpring-Supported Thrust BearingsZoebairBelum ada peringkat

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDokumen9 halamanInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairBelum ada peringkat

- Installation and Operating Procedures: Manual Grease InterceptorsDokumen8 halamanInstallation and Operating Procedures: Manual Grease InterceptorsZoebairBelum ada peringkat

- Quality Conference TTL KUDokumen6 halamanQuality Conference TTL KUZoebairBelum ada peringkat

- Type of ThreadDokumen13 halamanType of ThreadVils ArabadzhievaBelum ada peringkat

- ENZX TechDokumen30 halamanENZX TechZoebairBelum ada peringkat

- Ratle Enm Reply Tecnical Prebid Points 080212Dokumen42 halamanRatle Enm Reply Tecnical Prebid Points 080212ZoebairBelum ada peringkat

- Construction Specification 71-Water Control Gates: Instructions For UseDokumen2 halamanConstruction Specification 71-Water Control Gates: Instructions For UseZoebairBelum ada peringkat

- 1 12 (End)Dokumen17 halaman1 12 (End)ZoebairBelum ada peringkat

- 1 Technical Data Sheets TurbineDokumen7 halaman1 Technical Data Sheets TurbineZoebairBelum ada peringkat

- 1 - Layout of H-FrancisDokumen1 halaman1 - Layout of H-FrancisZoebairBelum ada peringkat

- Calculate The Number of Extinguishers Needed in A BuildingDokumen3 halamanCalculate The Number of Extinguishers Needed in A BuildingZoebairBelum ada peringkat

- CA6NMDokumen2 halamanCA6NMjoene3Belum ada peringkat

- Indigenous ManufacturersDokumen6 halamanIndigenous ManufacturersZoebairBelum ada peringkat

- Solutions EngDokumen6 halamanSolutions EngZoebairBelum ada peringkat

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Dokumen1 halaman8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairBelum ada peringkat

- Load AcceptanceDokumen2 halamanLoad AcceptanceZoebairBelum ada peringkat

- PJPR0 V 200 Ucturing 0 Data 0 SheetDokumen3 halamanPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairBelum ada peringkat

- Scada SystemDokumen1 halamanScada SystemZoebairBelum ada peringkat

- Datasheet TurbineDokumen2 halamanDatasheet TurbineZoebairBelum ada peringkat

- PJPR0 V 200 Ucturing 0 Data 0 SheetDokumen3 halamanPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairBelum ada peringkat

- Hy 25 ValvesDokumen3 halamanHy 25 ValvesZoebairBelum ada peringkat

- Hy 25 ValvesDokumen3 halamanHy 25 ValvesZoebairBelum ada peringkat

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDokumen7 halamanCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairBelum ada peringkat

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDokumen2 halaman3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewBelum ada peringkat

- 3 Tables Friction Loss AquacultureDokumen10 halaman3 Tables Friction Loss AquacultureZoebairBelum ada peringkat

- Wafflemat Design WhitepaperDokumen13 halamanWafflemat Design WhitepaperantiacidoBelum ada peringkat

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDokumen18 halamanDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajBelum ada peringkat

- Notes PDFDokumen252 halamanNotes PDFclose022Belum ada peringkat

- Compound CylinderDokumen11 halamanCompound CylinderLiliana Ara GubanBelum ada peringkat

- Iso 3036 PDFDokumen3 halamanIso 3036 PDFPalani.MBelum ada peringkat

- Module 2Dokumen43 halamanModule 2Manchimsetty Sri NidhiBelum ada peringkat

- SCHEME - G Third Semester 2223434Dokumen39 halamanSCHEME - G Third Semester 2223434AnjithBelum ada peringkat

- Signum-Technical-Guide LO SAMPLING GUIDEDokumen30 halamanSignum-Technical-Guide LO SAMPLING GUIDEshirishkv100% (1)

- 9792 PHYSICS: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersDokumen14 halaman9792 PHYSICS: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersbobBelum ada peringkat

- Operation and Maintenance of Power PlantDokumen31 halamanOperation and Maintenance of Power PlantAnkur Pathak100% (1)

- TSSA-DLB-2020-Feb-09-2021-Biogas ProjectDokumen9 halamanTSSA-DLB-2020-Feb-09-2021-Biogas ProjectNazrul IslamBelum ada peringkat

- Fundamentals of Fluid Mechanics Chapter 12 TurbinesDokumen44 halamanFundamentals of Fluid Mechanics Chapter 12 Turbinesalisnowkiss6570Belum ada peringkat

- Refresher No.4 (Pipe)Dokumen5 halamanRefresher No.4 (Pipe)chyno.kang08Belum ada peringkat

- Different Types of Moment FramesDokumen2 halamanDifferent Types of Moment FramesRazell RuizBelum ada peringkat

- Tutorial Vapor and Combined Power CyclesDokumen3 halamanTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- 1D Monoatomic Chain 3-5Dokumen33 halaman1D Monoatomic Chain 3-5M IrfanBelum ada peringkat

- Mitutoyo - Formtracer Avant FTA - H4 C3000-D (MM)Dokumen2 halamanMitutoyo - Formtracer Avant FTA - H4 C3000-D (MM)nyanaungBelum ada peringkat

- Thermodynamics 2 - Chapter 5 Part1Dokumen29 halamanThermodynamics 2 - Chapter 5 Part1Amir SallehBelum ada peringkat

- Boiler Starting Operating ProcedureDokumen2 halamanBoiler Starting Operating ProcedureRoopeshBelum ada peringkat

- N A GockcenDokumen12 halamanN A GockcendolkeenBelum ada peringkat

- Data Sheet - Rev 01Dokumen158 halamanData Sheet - Rev 01Martin DanzeBelum ada peringkat

- Deformation and Fracture Mechanics SolutionDokumen28 halamanDeformation and Fracture Mechanics SolutionSam Iguana100% (4)

- IGCSE 13 Forces&MovementDokumen26 halamanIGCSE 13 Forces&MovementHakim Abbas Ali PhalasiyaBelum ada peringkat

- Fluidic Muscle1Dokumen39 halamanFluidic Muscle1alexanderfortis8628Belum ada peringkat

- Easa Ar100 2006 PDFDokumen33 halamanEasa Ar100 2006 PDFChecho Buenaventura100% (1)

- Replacement Parts BUSHDokumen33 halamanReplacement Parts BUSHIsaac Rodríguez BetancourtBelum ada peringkat

- Optimized Skid Design For Compressor PackagesDokumen9 halamanOptimized Skid Design For Compressor Packagesmario_gBelum ada peringkat

- Copeland PDFDokumen1 halamanCopeland PDFEdwin GallegosBelum ada peringkat

- PHYSICS LAB REPORT NO.6 (Compound Pendulum)Dokumen7 halamanPHYSICS LAB REPORT NO.6 (Compound Pendulum)Rajput JanjuaBelum ada peringkat

- Cooling System MechanicallDokumen23 halamanCooling System MechanicallStuart FerreiraBelum ada peringkat